In the realm of high-performance machinery, a thorough comprehension of its individual elements is essential for optimal functionality. Each segment plays a pivotal role, contributing to the overall efficiency and power output. Delving into the intricate arrangement and interconnections of these components reveals the artistry of engineering at its finest.

To grasp how these elements interact, one must explore their configurations and relationships. The complexity of these systems often requires a visual representation to facilitate understanding. By examining the layout and placement of each piece, enthusiasts and technicians alike can enhance their knowledge and skills.

Equipped with this information, one can appreciate the craftsmanship involved in creating such robust mechanisms. Recognizing how each element operates within the larger assembly empowers users to troubleshoot, maintain, and optimize performance effectively. This exploration not only enhances technical insight but also fosters a deeper appreciation for the ingenuity behind these powerful creations.

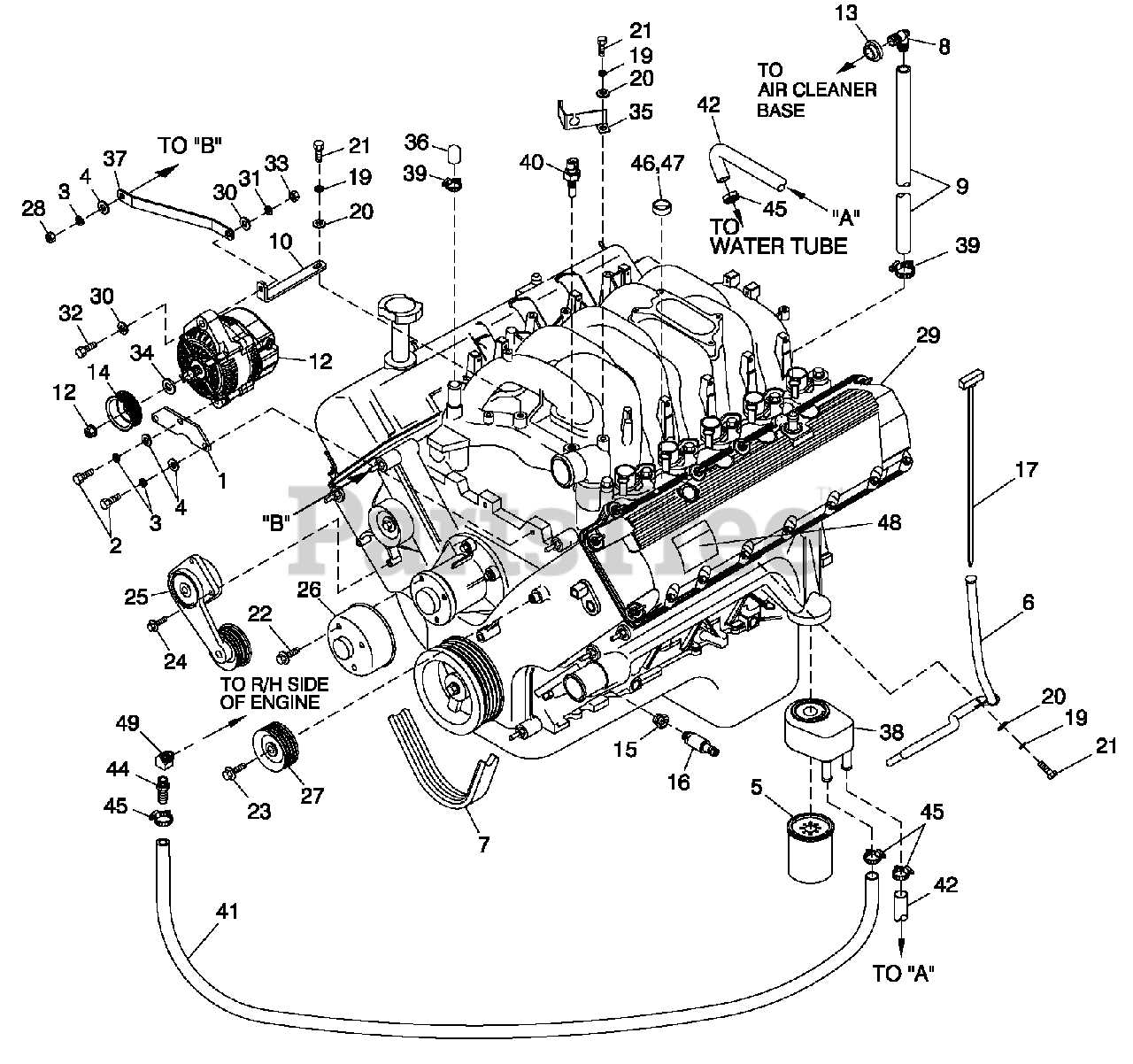

Understanding the 5.3 Engine Components

Grasping the intricacies of a high-performance machine requires an appreciation for its fundamental elements. Each component plays a vital role, working harmoniously to deliver optimal functionality and efficiency. In this section, we will explore the key constituents that contribute to the overall performance of this powerhouse.

The primary components can be categorized into several groups:

- Fuel System: Responsible for delivering the right mixture of fuel and air.

- Ignition System: Ensures that the air-fuel mixture ignites at the correct moment.

- Cooling System: Maintains an optimal temperature to prevent overheating.

- Lubrication System: Reduces friction between moving parts to enhance durability.

Each of these categories encompasses various individual elements:

- Fuel Injectors: Precisely spray fuel into the intake manifold.

- Ignition Coil: Transforms battery voltage into a higher voltage to create a spark.

- Radiator: Cools the engine coolant before it circulates again.

- Oil Pump: Circulates oil to lubricate moving parts.

Understanding these components allows for better maintenance and troubleshooting, ensuring long-lasting performance and reliability. Each part’s function is crucial, and awareness of how they interact enhances overall comprehension of the system’s operation.

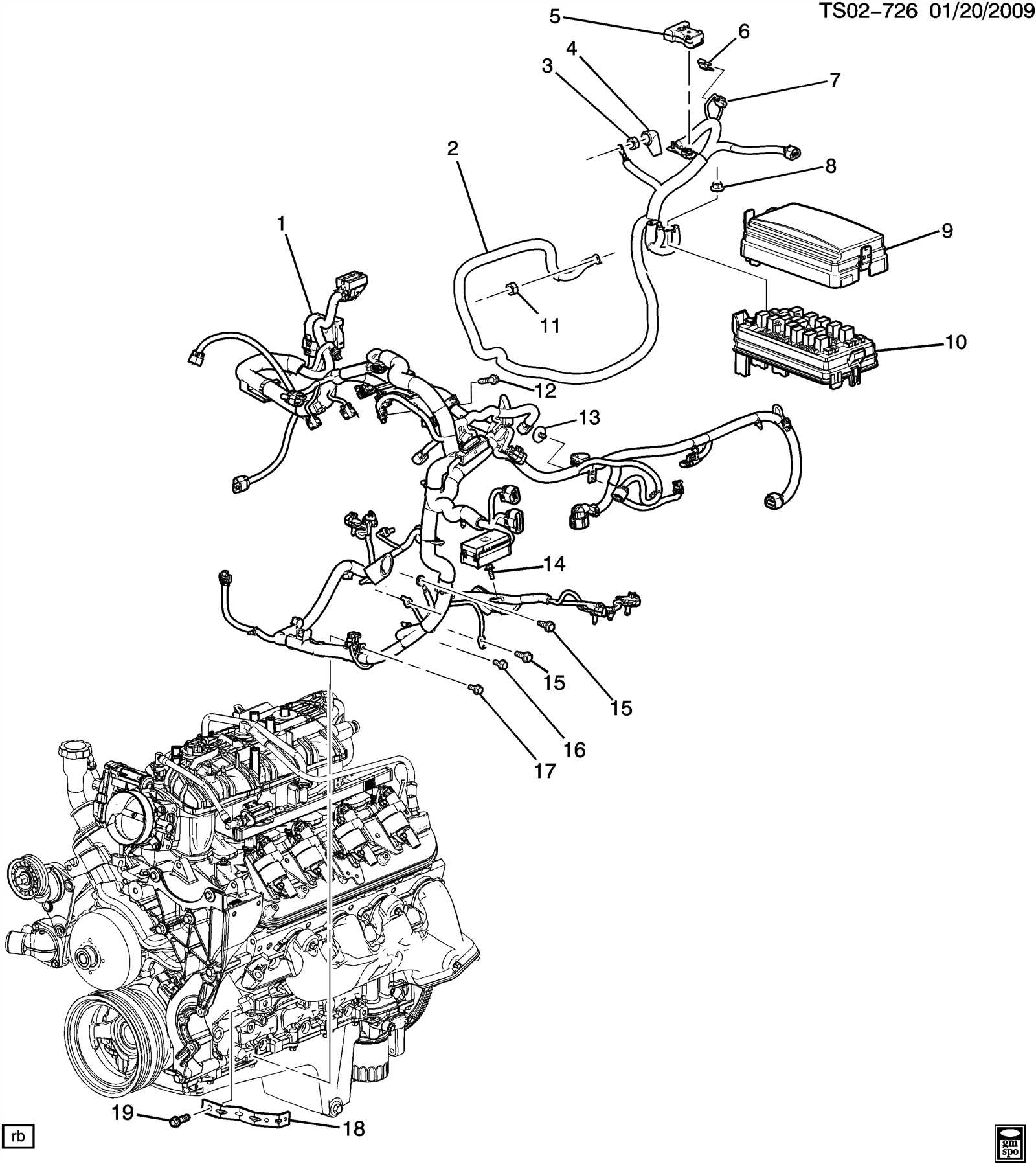

Visual Overview of Engine Parts

This section provides a comprehensive look at the various components that work together to create powerful motion. Understanding these elements is essential for anyone interested in automotive mechanics or simply wanting to enhance their knowledge of how vehicles function.

Key elements include:

- Crankshaft: Transforms linear motion into rotational force.

- Pistons: Move up and down within the cylinders, creating pressure and power.

- Cylinders: Houses the pistons and is integral to the combustion process.

- Valves: Control the intake of air and fuel, as well as the exhaust of gases.

- Camshaft: Regulates the timing of the valve movements.

Each component plays a vital role in ensuring smooth operation and efficiency. A detailed understanding allows for better maintenance and troubleshooting.

- Familiarize yourself with the layout and function of each item.

- Recognize how they interact during operation.

- Explore the significance of proper maintenance and potential upgrades.

By gaining insights into these fundamental elements, enthusiasts and professionals alike can appreciate the intricacies of automotive design and performance.

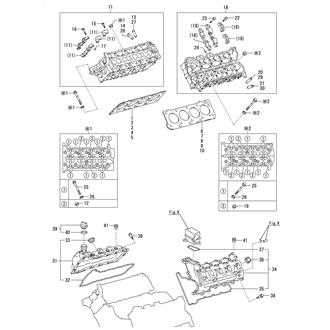

Functionality of the 5.3 Engine

This section explores the operational principles and components that contribute to the efficiency and performance of a particular power unit. Understanding these mechanisms provides insight into how this powerhouse delivers power and reliability in various applications.

The core of this unit’s design revolves around its ability to convert fuel into mechanical energy. This process is facilitated through a series of well-coordinated actions that involve air intake, combustion, and exhaust management. The combination of these functions ensures optimal performance under different driving conditions.

One key aspect is the incorporation of advanced technologies that enhance fuel efficiency and reduce emissions. Systems such as variable valve timing and electronic control modules play a crucial role in adapting the operation to varying loads and speeds, thus improving overall efficiency.

Furthermore, the durability of the internal mechanisms ensures that the unit can withstand the stresses associated with high-performance applications. High-quality materials and precision engineering contribute to longevity and reliability, making it suitable for both everyday use and demanding environments.

Overall, the integration of these features creates a harmonious balance between power output and operational efficiency, highlighting the sophistication of this mechanical system.

Common Issues with 5.3 Engines

Many vehicles equipped with this specific powertrain experience a variety of challenges that can affect performance and longevity. Understanding these common problems is crucial for proper maintenance and troubleshooting. Below are some of the frequently encountered issues.

Oil Consumption: One notable concern is excessive oil consumption, which may lead to decreased efficiency and increased emissions. Regular monitoring of oil levels is essential to mitigate this problem.

Cooling System Failures: Overheating can be attributed to failures in the cooling system, including water pump malfunctions or radiator leaks. This issue can result in significant damage if not addressed promptly.

Fuel Injector Problems: Clogged or malfunctioning fuel injectors can cause rough idling and decreased fuel efficiency. Routine cleaning and inspection are recommended to maintain optimal performance.

Timing Chain Issues: Some models may experience problems with the timing chain, which can lead to poor performance or even catastrophic failure if the chain slips or breaks.

Ignition System Failures: Faulty spark plugs or ignition coils can result in misfires, affecting acceleration and overall driving experience. Regular maintenance of the ignition system is vital for smooth operation.

Being aware of these prevalent issues allows owners to take proactive measures, ensuring reliability and performance for years to come.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your machinery requires regular attention and care. Implementing a consistent maintenance routine not only enhances efficiency but also extends the lifespan of critical components. Below are some essential strategies to keep your system running smoothly for years to come.

Regular Inspections

Conducting routine checks is vital for identifying potential issues before they escalate. Regular assessments can help catch wear and tear early, allowing for timely repairs. Focus on areas prone to degradation and ensure that all connections are secure.

Fluid Management

Maintaining proper fluid levels and quality is crucial for the seamless operation of your equipment. Regularly check and replace fluids as necessary to prevent overheating and friction-related damage.

| Fluid Type | Recommended Change Interval |

|---|---|

| Oil | Every 5,000 miles |

| Coolant | Every 30,000 miles |

| Transmission Fluid | Every 15,000 miles |

By following these guidelines, you can significantly enhance the reliability and performance of your machinery, ensuring it serves you well for a long time.

Upgrading Components for Performance

Enhancing the various elements of a mechanical unit can significantly boost its overall efficiency and responsiveness. By carefully selecting and replacing certain components, enthusiasts can unlock greater power and improved handling characteristics. This process involves a strategic approach, focusing on key areas that yield the most noticeable results.

Key Areas for Enhancement

When considering modifications, several crucial aspects should be prioritized to maximize performance gains:

| Component | Upgrade Options | Benefits |

|---|---|---|

| Intake System | Cold Air Intake | Increased airflow, improved throttle response |

| Exhaust System | High-Performance Muffler | Enhanced exhaust flow, deeper sound |

| Fuel Delivery | High-Flow Fuel Pump | Better fuel atomization, increased power potential |

| Ignition | Aftermarket Spark Plugs | Improved combustion efficiency, better fuel economy |

Considerations for Upgrades

Before embarking on the upgrade journey, it’s essential to consider the compatibility of new components with existing systems. Proper research and planning can prevent potential issues and ensure seamless integration. Additionally, consulting with professionals can provide valuable insights and recommendations tailored to specific objectives.

Parts Replacement: What to Consider

When it comes to swapping out components in your vehicle, several key factors must be taken into account to ensure optimal performance and longevity. Understanding the intricacies of what you are replacing can significantly influence the overall efficiency and functionality of your transportation system.

Quality vs. Cost

While it may be tempting to opt for the least expensive options available, it is crucial to weigh quality against cost. Investing in higher-quality replacements can save you money in the long run, as they are often more durable and reliable.

Compatibility and Specifications

Before making any replacements, ensure that the components you select are fully compatible with your vehicle’s specifications. Mismatched parts can lead to performance issues or even damage, making it essential to consult manuals or seek expert advice.

Exploring Aftermarket Options

Aftermarket solutions offer enthusiasts a chance to enhance performance and customize their vehicles. These alternatives can significantly impact efficiency, reliability, and aesthetics, providing a pathway to tailor a ride to individual preferences.

Benefits of Aftermarket Solutions

- Improved performance through upgraded components.

- Increased customization options for a unique look.

- Potential cost savings compared to original equipment.

- Access to specialized parts that may not be available through manufacturers.

Considerations When Choosing Aftermarket Products

- Research the reputation of manufacturers.

- Ensure compatibility with your specific model.

- Evaluate the warranty and support offered.

- Read reviews from other users for real-world insights.

Real-Life Applications of 5.3 Engines

This section explores the diverse ways in which a popular powertrain has been utilized across various sectors. From daily commuting to heavy-duty tasks, its versatility showcases its importance in modern machinery and transportation.

Automotive Industry

This power unit is widely found in trucks and SUVs, providing a balance of performance and efficiency. Its robust design supports towing capabilities, making it ideal for both personal and commercial use.

Agricultural Use

In farming, this type of propulsion is integrated into tractors and equipment, enhancing productivity. Its reliability ensures that essential tasks are carried out efficiently, contributing significantly to agricultural output.