The intricate design of specialized equipment often requires a comprehensive overview of its individual elements. This knowledge not only aids in effective usage but also enhances maintenance and repair processes. By examining a specific set of components, users can gain valuable insights into the functionality and efficiency of the machinery in question.

Familiarity with the layout and organization of these essential parts is crucial for both novice and experienced operators. Understanding how each component interacts within the larger system allows for informed decision-making when it comes to troubleshooting or upgrades. This exploration emphasizes the importance of knowing your equipment inside and out.

In this section, we will delve into a detailed visual representation of the key elements that make up this specialized tool. By dissecting each segment, we aim to empower users with the knowledge needed to optimize performance and ensure longevity. Join us as we navigate through the essential features that define this unique machinery.

Understanding Echo PAS 225 Parts

When delving into the intricate components of outdoor equipment, a comprehensive grasp of their individual elements is essential for optimal performance and maintenance. Each piece plays a crucial role in the overall functionality, influencing everything from power delivery to user experience. This segment aims to unravel the essential components, highlighting their significance and interconnections.

Key Components Overview

Among the various segments, the motor stands out as the heart of the machinery, generating the necessary force for operation. Coupled with this is the transmission system, which effectively transfers power, ensuring smooth functionality. Additionally, the cutting mechanism is designed to deliver precision, making it vital for tasks that require accuracy.

Maintenance and Care

Proper upkeep of these components not only prolongs the lifespan of the equipment but also enhances performance efficiency. Regular inspection and timely replacement of worn parts can prevent unexpected failures. Understanding the significance of each element allows users to make informed decisions regarding repairs and upgrades.

Overview of Echo PAS 225 Features

This section highlights the notable characteristics of a versatile gardening tool designed for efficiency and ease of use. Ideal for both casual gardeners and professionals, this equipment offers a range of functionalities that cater to diverse landscaping needs.

Power and Performance

The machine is equipped with a robust engine that ensures reliable performance, enabling users to tackle various tasks with minimal effort. Its lightweight design contributes to excellent maneuverability, making it easy to handle during extended use.

Versatility and Attachments

One of the standout attributes of this tool is its adaptability. It supports multiple attachments, allowing users to switch between different functions effortlessly. Whether trimming, edging, or cultivating, this device provides the necessary versatility for comprehensive yard maintenance.

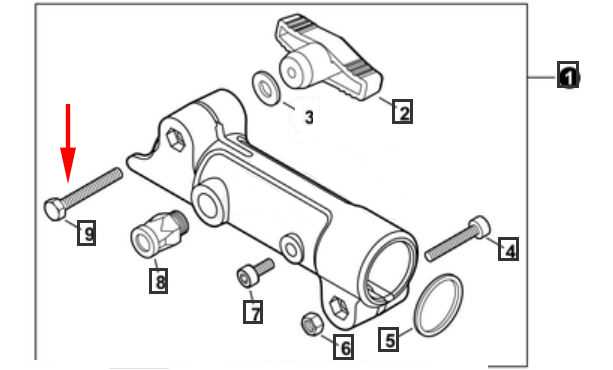

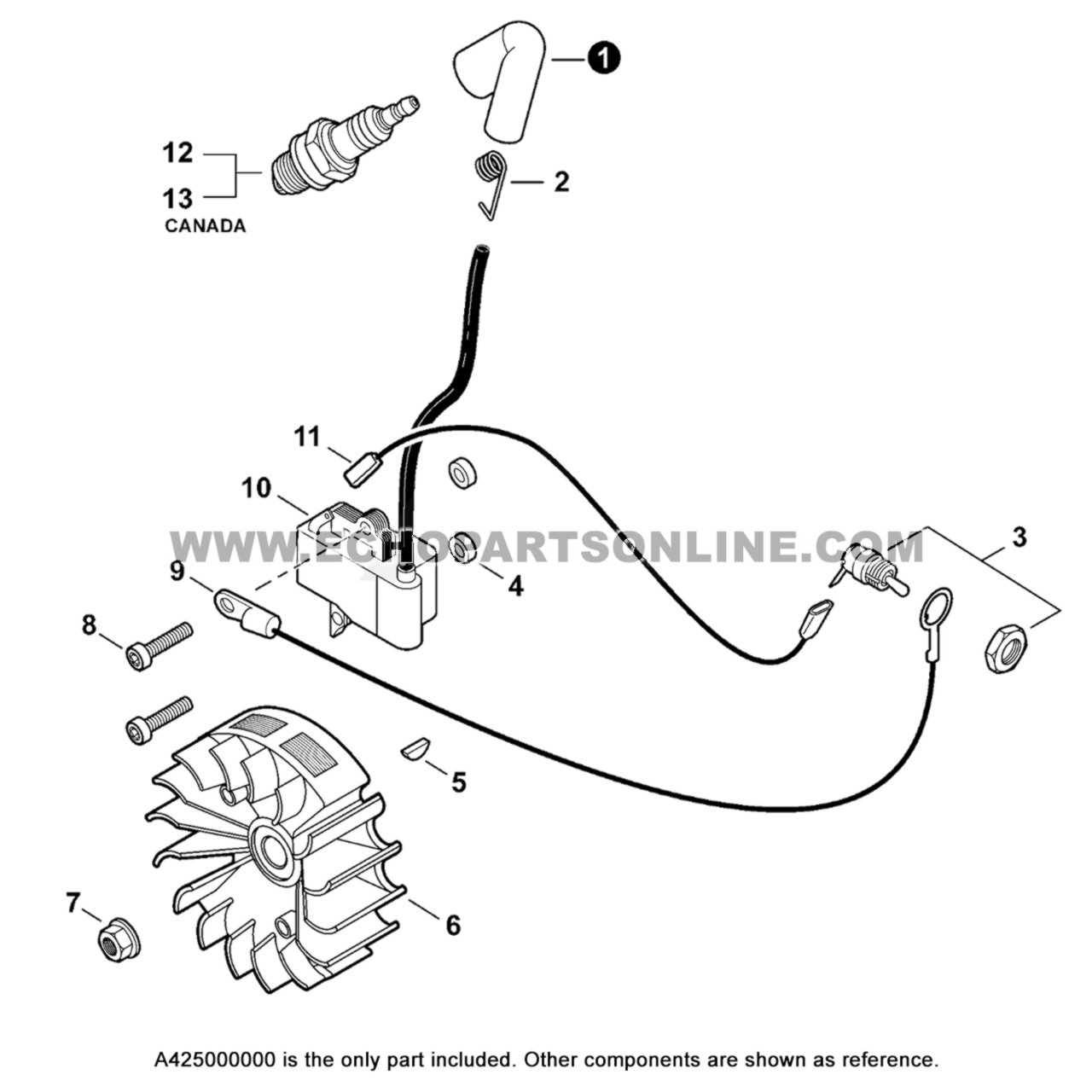

Importance of Parts Diagram

A visual representation of components is crucial in understanding the assembly and functionality of machinery. Such illustrations serve as a roadmap for users, enabling them to identify individual elements and comprehend their relationships within the system. This understanding enhances maintenance, troubleshooting, and repair processes, ultimately improving efficiency and longevity.

These visual guides also play a significant role in training new operators and technicians. By providing a clear overview of the equipment’s structure, they facilitate quicker learning and mastery of the device’s operation. Furthermore, they minimize the risk of errors during reassembly or replacement tasks.

| Benefits | Description |

|---|---|

| Enhanced Understanding | Facilitates grasping the complex relationships between different elements. |

| Improved Maintenance | Aids in identifying wear and tear, leading to timely interventions. |

| Streamlined Training | Accelerates the learning curve for new personnel. |

| Reduced Errors | Minimizes mistakes during assembly and repairs. |

Overall, a comprehensive visual guide is not just a helpful tool; it is an essential asset that supports operational excellence and fosters a deeper understanding of the equipment’s design and functionality.

Identifying Key Components

Understanding the fundamental elements of any machinery is essential for effective maintenance and troubleshooting. By recognizing these crucial parts, one can enhance operational efficiency and ensure longevity. This section delves into the primary components that contribute to the overall functionality of the equipment in question.

Essential Elements

Among the vital parts, the engine stands out as the powerhouse, driving the entire system. It is complemented by the fuel system, which ensures that the engine receives the necessary energy to function optimally. Additionally, the transmission plays a significant role in transferring power and controlling speed, making it indispensable for performance.

Supporting Components

Other supporting elements, such as the ignition system and air filtration unit, are equally important. The ignition system initiates the combustion process, while the air filtration unit maintains the quality of the air entering the engine, protecting it from contaminants. Together, these components create a harmonious interaction that enhances overall effectiveness and reliability.

Common Issues with Echo PAS 225

Users of this versatile tool often encounter a range of typical problems that can hinder its performance and usability. Understanding these common challenges can help in troubleshooting and ensuring optimal operation. From engine troubles to maintenance concerns, recognizing the signs early can prevent more serious issues down the line.

Frequent Engine Problems

One of the most prevalent issues faced by operators involves engine performance. Users may notice difficulties in starting or irregular idling. These symptoms can arise from various factors, including fuel quality and air filter conditions. Regular checks and maintenance can mitigate these problems effectively.

Maintenance and Wear

Over time, wear and tear can impact the efficiency of the machine. Components such as the cutting head and line can degrade, leading to subpar performance. Regular inspections and timely replacements are crucial to maintaining the functionality of the equipment.

| Issue | Symptoms | Potential Solutions |

|---|---|---|

| Starting difficulties | Engine won’t start or requires multiple attempts | Check fuel quality and spark plug condition |

| Irregular idling | Engine runs inconsistently or stalls | Inspect air filter and carburetor settings |

| Cutting performance | Inability to cut through thick grass | Replace worn cutting line and inspect head |

How to Read Parts Diagrams

Understanding technical illustrations is crucial for effective maintenance and repair. These visual guides provide a structured way to identify components and their relationships within a machine, facilitating quicker troubleshooting and assembly.

Begin by familiarizing yourself with the symbols and notations used in the illustration. Each element typically represents a specific component, often accompanied by a reference number that links it to a detailed list. This list will detail the part’s specifications and availability.

Next, follow the layout systematically. Start from one end and move across or down, ensuring you understand how each component fits within the overall system. Pay attention to any notes or legends that may highlight important information regarding assembly or disassembly.

Lastly, practice makes perfect. Regularly reviewing various technical illustrations will enhance your ability to quickly interpret these resources, making repairs and maintenance tasks more efficient.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for ensuring the extended lifespan and optimal performance of your equipment. By following a systematic maintenance routine, you can prevent potential issues and enhance efficiency over time.

Routine Checks

- Inspect components regularly for signs of wear and tear.

- Ensure all fasteners are tightened to prevent any loose parts during operation.

- Check fuel levels and replace as necessary to avoid performance dips.

Cleaning and Care

- Clean the exterior and interior of the device to remove dirt and debris.

- Use appropriate cleaning agents that won’t damage sensitive parts.

- Lubricate moving parts to reduce friction and wear.

By adhering to these guidelines, you can maximize the efficiency and longevity of your machinery, ensuring it remains in prime condition for years to come.

Where to Find Replacement Parts

Locating suitable components for your equipment is essential for maintaining optimal performance and longevity. Whether you are a professional or a hobbyist, having access to quality replacements ensures your tools remain in peak condition.

Authorized Dealers

One of the most reliable sources for obtaining high-quality components is through authorized distributors. They often carry a comprehensive selection of original components and can provide expert advice on compatibility and installation.

Online Retailers

The internet offers a vast marketplace for sourcing various replacements. Websites specializing in tool accessories often feature detailed descriptions and customer reviews, making it easier to find the right items for your needs. Always check for trustworthy sellers to ensure quality.

Resources for Further Information

This section aims to provide valuable references for those seeking to deepen their understanding of small engine maintenance and repair. Whether you’re a novice or an experienced technician, accessing reliable information is crucial for effective troubleshooting and service.

Online Resources

- Small Engines Resource Hub – A comprehensive website featuring guides, articles, and troubleshooting tips.

- YouTube Channel: Small Engine Repair – Video tutorials demonstrating various repair techniques and maintenance practices.

- Reddit Community – An active forum for discussing problems and sharing solutions with fellow enthusiasts.

Books and Manuals

- Small Engine Repair Manual – A detailed guide covering a wide range of topics related to engine upkeep.

- Maintenance and Repair of Small Engines – An excellent resource for both beginners and seasoned mechanics, featuring step-by-step instructions.

- Troubleshooting Small Engines – Focused on diagnosing issues effectively with practical tips and strategies.