Understanding the different elements that make up a sliding cover system can greatly enhance its functionality and maintenance. When delving into these mechanisms, it’s helpful to identify the key components and how they interact to provide seamless operation and durability.

Each component serves a specific role in ensuring smooth movement and reliable performance. Recognizing the purpose of each piece and how they connect within the overall setup allows for easier troubleshooting and replacement. Whether it’s adjusting the tension, ensuring proper alignment, or addressing wear and tear, knowing the arrangement of these elements is crucial.

By examining the structure and placement of various pieces, one

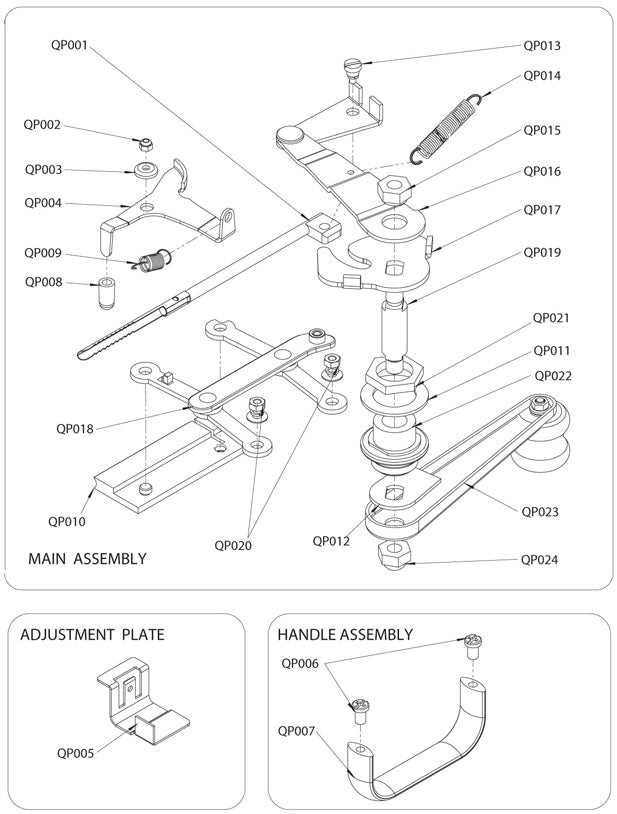

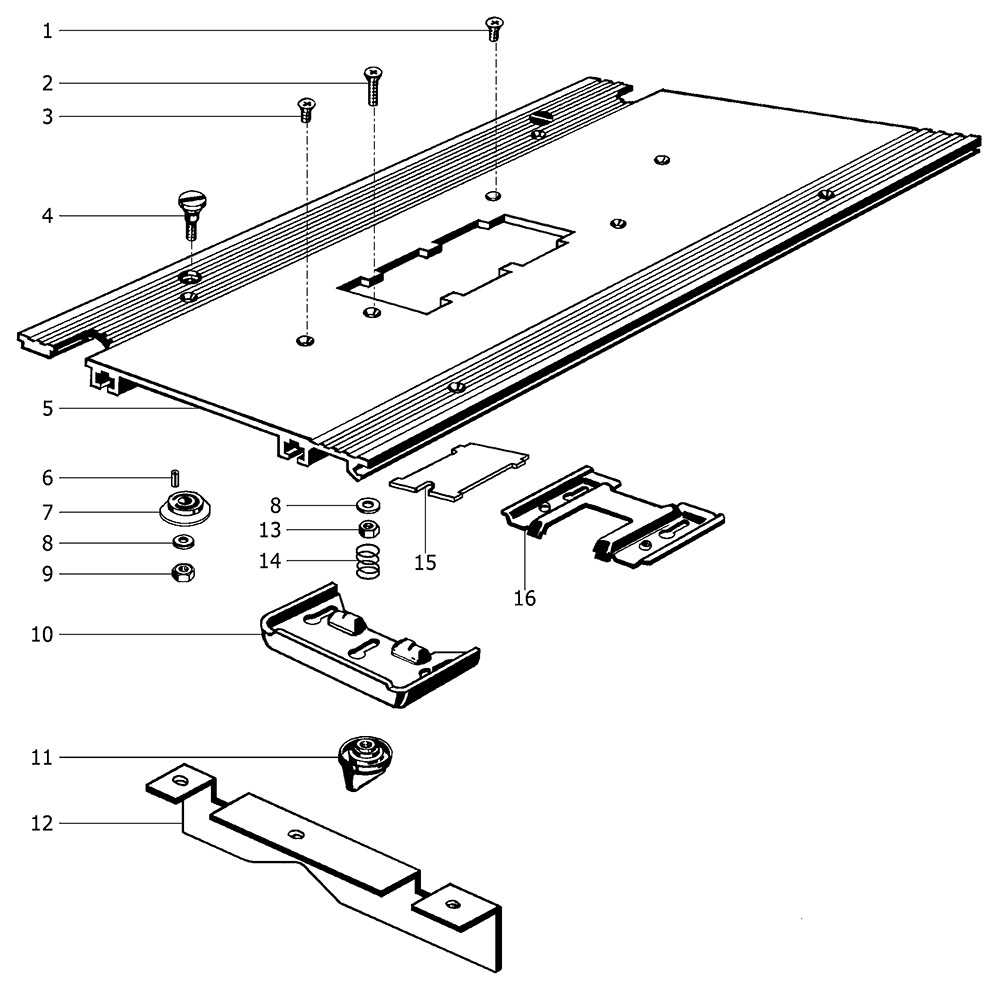

Roll n Lock Parts Diagram

The visual representation of this tonneau cover system provides a clear view of its various components, making it easier to understand how they work together. This guide offers insight into the essential elements that contribute to its functionality and durability, helping users identify and maintain different sections of the cover.

Main Components Overview

- Cover Assembly: The retractable section that spans the bed, designed for smooth sliding and secure storage.

- Track System: Mounted along the bed rails, these guides ensure seamless movement of the retractable section.

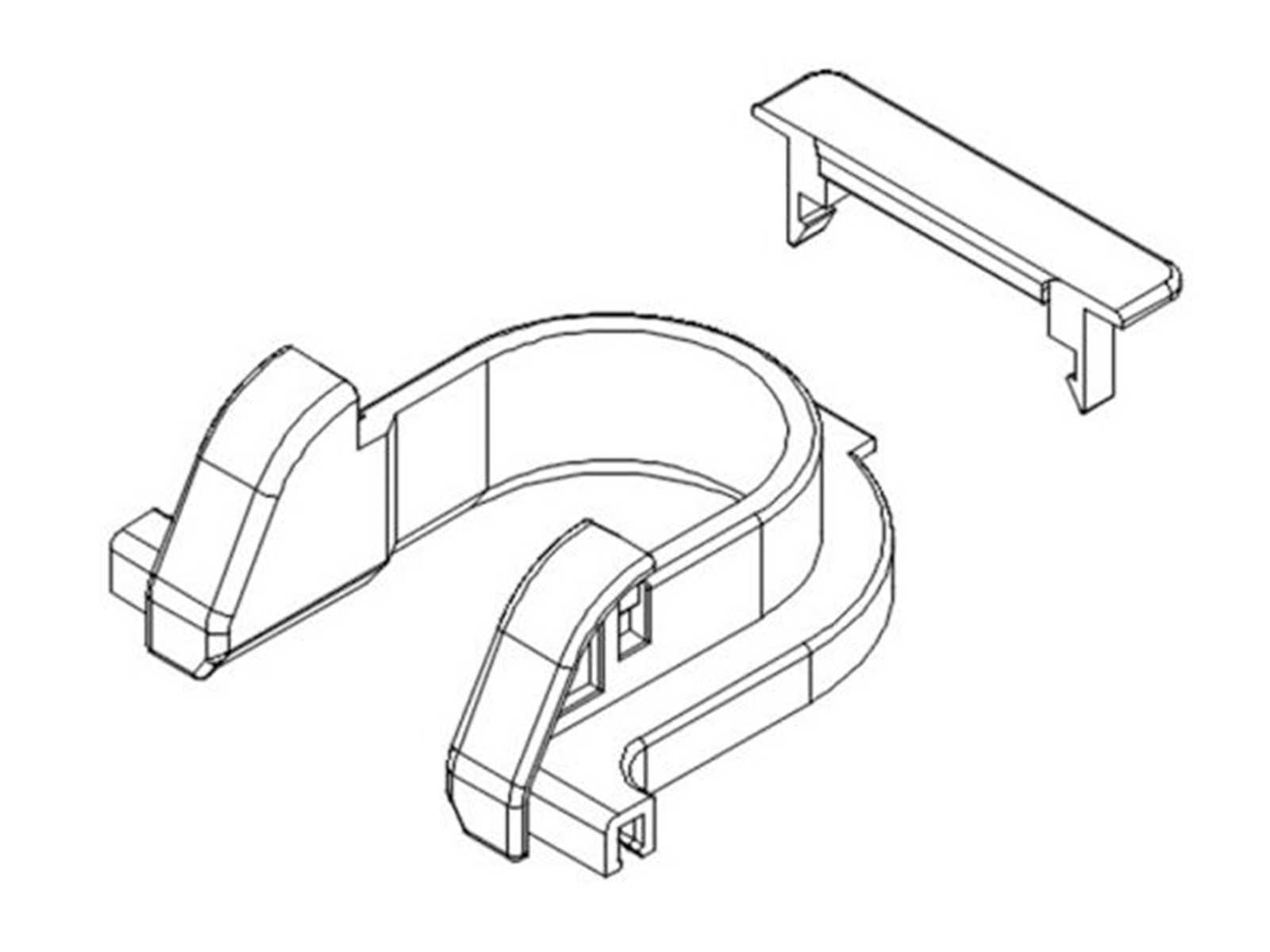

- Housing Unit: Positioned at the front, this compartment stores the cover when it is rolled up, keeping it protected from

Understanding the Roll n Lock System

The mechanism is designed to provide a convenient and secure solution for covering and protecting items stored in the truck bed. It offers a flexible structure that can be adjusted to fit various needs, allowing users to easily access their belongings while ensuring they remain safeguarded from weather conditions and potential theft.

Its design combines durability with ease of use, featuring materials that resist wear and tear over time. The system’s adaptability allows for partial or full coverage, depending on specific requirements, and it can be adjusted smoothly to achieve the desired level of protection.

Additionally, the setup promotes a streamlined appearance, maintaining the vehicle’s aesthetics while providing functionality. With its user-friendly operation, the cover can be opened or closed with minimal effort, making it suitable for everyday use as well as long journeys

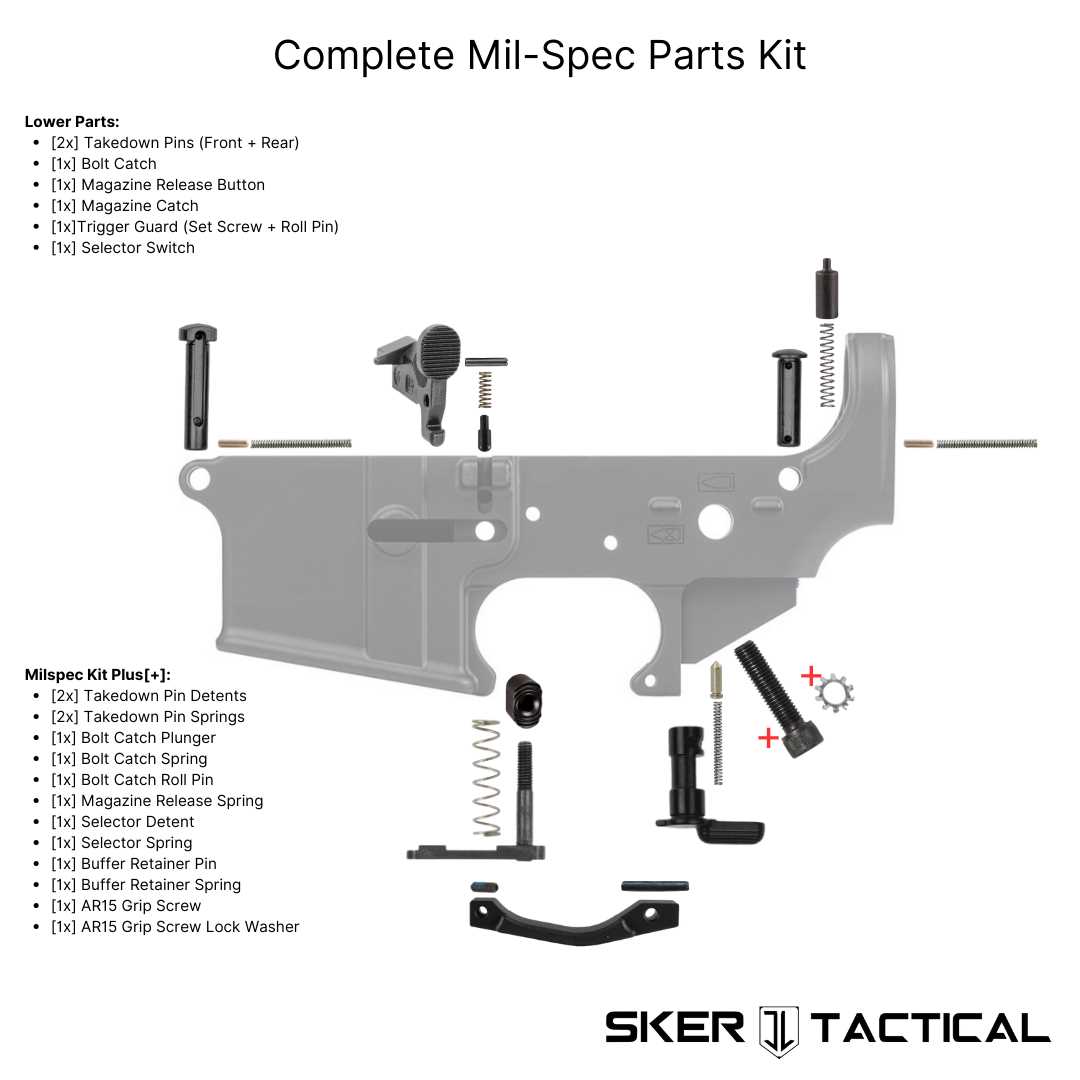

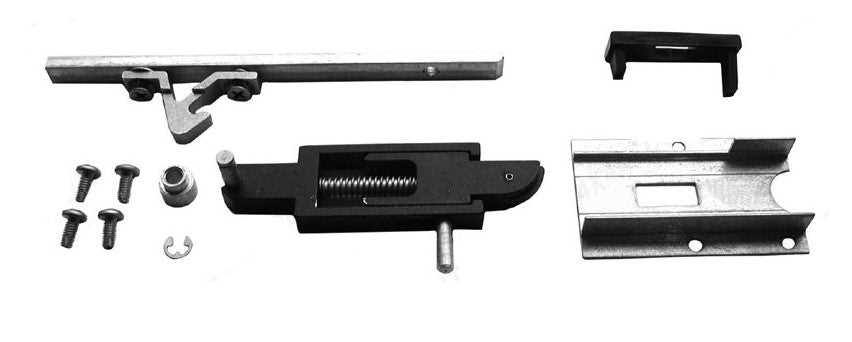

Key Components and Their Functions

The system is made up of various elements, each playing a crucial role in ensuring smooth operation and durability. Understanding these elements and their roles helps in maintaining optimal performance and addressing any issues that may arise. Below is a detailed look at some of the most important elements in the system.

Primary Structure

The main framework serves as the backbone, providing support and stability. It ensures that all other elements are securely held in place, allowing for consistent and efficient functionality. This structure is often reinforced to withstand external forces and resist wear over time.

Movement Mechanism

The movement mechanism facilitates the seamless sliding action. It includes components designed to reduce friction, ensuring a smooth and quiet operation. High-quality materials used in these elements help to extend

Identifying Common Replacement Parts

Understanding the various components that may need replacement over time is crucial for maintaining any equipment. Familiarity with these items helps ensure smooth operation and timely maintenance, enhancing the overall lifespan of the system.

Frequently Replaced Components

- Cover Materials: Regular exposure to elements can lead to wear and tear on protective coverings. Replacing the fabric or material can restore the protective function and appearance.

- Fasteners and Hinges: Frequent use can cause wear on connectors, making it necessary to update screws, bolts, or hinges to maintain secure attachment.

- Guiding Mechanisms

Maintenance Tips for Roll n Lock

Proper upkeep of your cover system ensures long-term reliability and smooth operation. Regular attention to cleanliness and lubrication can prevent common issues that arise over time, such as wear and resistance during use. By taking preventive measures, you can avoid the need for more extensive repairs in the future.

Start by keeping the tracks free from dirt and debris. A simple rinse with water is often enough to clear any buildup. Avoid using harsh chemicals that could damage the surface. Regularly check the cover’s condition for any signs of tears or abrasions, and address them promptly to prevent further deterioration.

Lubrication of the moving components is essential. Use a silicone-based spray to

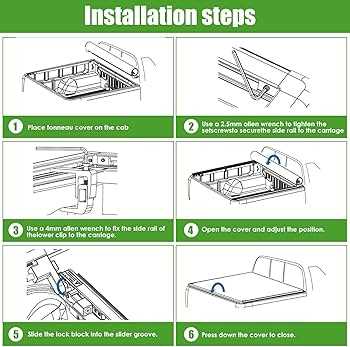

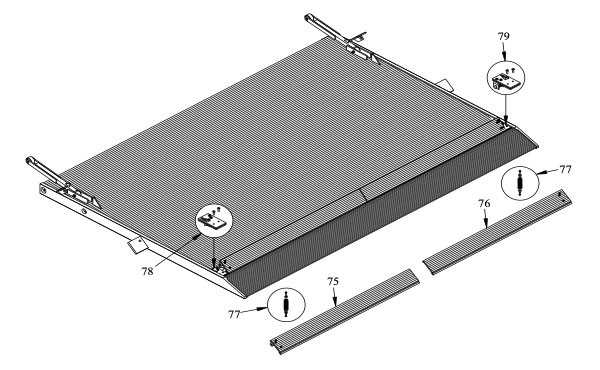

Exploring Installation Diagrams and Guides

Understanding installation schematics and instructions is crucial for anyone looking to enhance or modify their equipment. These visual aids serve as essential tools, guiding users through complex processes and ensuring that each component is correctly positioned. With the right illustrations, individuals can gain confidence in their ability to tackle installation tasks efficiently.

The Importance of Visual Aids

Visual representations simplify the assembly process by breaking down intricate tasks into manageable steps. They help users identify various components, understand their functions, and see how they fit together. Moreover, clear instructions minimize the likelihood of errors, promoting a smoother and more effective installation experience.

Utilizing Resources Effectively

When engaging with these resources, it is beneficial to take the time to familiarize oneself with each element shown. By paying close attention to the accompanying notes and guidelines, users can optimize their understanding and execution of the tasks at hand. Emphasizing attention to detail during the installation can lead to improved outcomes and prolonged performance.

How to Troubleshoot Common Issues

When encountering difficulties with your equipment, understanding the root causes can help streamline the resolution process. Various challenges may arise during operation, leading to inefficiencies or malfunctions. By systematically addressing these common problems, you can ensure optimal performance and longevity of your device.

Below is a table summarizing typical issues and their potential solutions:

Issue Possible Solution Unresponsive operation Check power connections and ensure the device is plugged in. Inconsistent performance Inspect for obstructions or debris that may affect functionality. Strange noises Examine moving components for wear or misalignment. Frequent errors Reset the system and verify all settings are correctly configured. By following these guidelines, you can effectively address and resolve issues, ensuring smooth operation of your equipment.

Choosing the Right Parts for Repair

When it comes to maintaining or fixing your equipment, selecting suitable components is crucial for ensuring optimal functionality and longevity. Understanding the different options available can greatly impact the performance of your system, leading to enhanced efficiency and reliability.

To make informed decisions, it’s important to consider various factors, such as compatibility, quality, and purpose of the components. Below is a table that outlines some key aspects to keep in mind while selecting the necessary items for your repair tasks.

Factor Description Compatibility Ensure the chosen components are compatible with your existing setup to avoid issues during installation. Quality Opt for high-quality materials that offer durability and performance, reducing the need for frequent replacements. Purpose Identify the specific function of each component to select those that best meet your operational needs. Cost Evaluate the cost-effectiveness of different options, balancing quality with budget constraints. By taking these factors into account, you can enhance the overall performance of your system and ensure a successful repair process.

Enhancing Performance with Upgraded Parts

Improving the functionality and efficiency of your equipment can be achieved by integrating advanced components. These enhancements can lead to better durability, increased responsiveness, and overall superior operation. By selecting high-quality replacements, users can experience a significant upgrade in performance, allowing their devices to perform at their best.

Here are some benefits of utilizing enhanced components:

- Increased Efficiency: Enhanced components often operate with improved precision, contributing to overall system efficiency.

- Improved Durability: Upgraded materials can withstand greater stress and wear, prolonging the lifespan of your equipment.

- Better Performance: High-performance replacements can lead to noticeable improvements in speed and effectiveness.

- Cost-Effectiveness: Investing in better components can reduce the need for frequent repairs and replacements, saving money in the long run.

Choosing the right upgrades can transform how your equipment performs, making it essential to consider quality and compatibility. Whether for personal use or professional applications, these advancements are vital for maximizing potential and achieving desired outcomes.