The efficient functioning of a lawn maintenance machine relies on its various components working harmoniously together. Each element plays a crucial role, ensuring that the equipment performs optimally in different conditions. This section aims to explore the intricate layout of these essential components, helping users to identify and comprehend their significance.

Comprehending the layout of the machine not only facilitates easier maintenance but also enhances the ability to troubleshoot any issues that may arise. Familiarity with the structure empowers users to make informed decisions regarding repairs and replacements, ultimately prolonging the life of their equipment.

In the following discussion, detailed insights will be provided regarding each section of the machine, outlining its function and importance. Understanding these intricacies will aid in recognizing how each component contributes to the overall efficiency and reliability of the equipment.

This section provides a comprehensive look at the components and structures that make up a specific model of zero-turn mower. Understanding these elements is essential for effective maintenance and troubleshooting, ensuring optimal performance and longevity of the machine.

Key Components

Each assembly plays a crucial role in the overall functionality of the mower. Familiarizing oneself with these critical sections allows for better handling and care of the equipment, enhancing operational efficiency.

| Component | Description |

|---|---|

| Engine | Provides the necessary power to operate the mower efficiently. |

| Deck | Houses the cutting blades and is responsible for the mowing action. |

| Transmission | Controls the movement and speed of the mower, allowing for precise maneuvering. |

| Control Panel | Interface for the operator to manage the mower’s functions. |

| Wheels | Support mobility and stability during operation on various terrains. |

Maintenance Considerations

Regular inspection of each component ensures that the machine operates smoothly and efficiently. Keeping track of wear and tear is vital for timely replacements and repairs, ultimately extending the lifespan of the equipment.

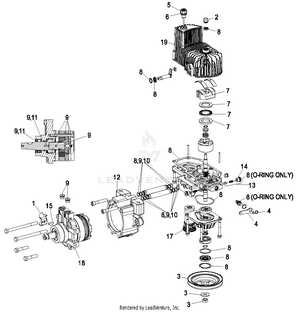

Key Components and Their Functions

This section explores the essential elements that contribute to the efficient operation of a professional-grade mowing machine. Understanding the various components and their roles can enhance maintenance and performance, ensuring optimal results during use.

- Engine: The powerhouse of the machine, responsible for generating the necessary energy to drive the blades and propel the unit forward.

- Transmission: Facilitates the transfer of power from the engine to the wheels, allowing for smooth movement and speed adjustment.

- Mower Deck: The cutting unit that houses the blades, designed to provide a clean and even cut across various types of terrain.

- Blades: Sharp metal pieces that rotate at high speeds to trim grass efficiently, available in different shapes for varying cutting styles.

- Fuel System: Comprises the tank and lines that supply fuel to the engine, ensuring consistent operation during tasks.

- Cooling System: Maintains optimal operating temperatures, preventing overheating and ensuring long-term reliability of the engine.

Each of these elements plays a pivotal role in the functionality and reliability of the mowing machine, making it crucial for operators to familiarize themselves with their functions for effective maintenance and troubleshooting.

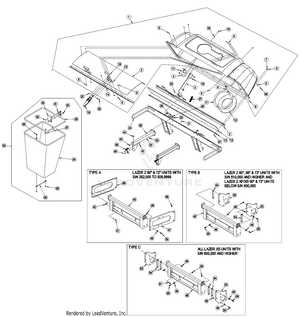

Understanding the Parts Diagram

This section aims to provide clarity on the visual representation of components essential for a particular machine. By examining the layout and labeling, users can better grasp the assembly and functionality of each segment, facilitating maintenance and repair tasks. A well-structured illustration serves as a valuable reference, enabling effective troubleshooting and enhancing the overall operational efficiency.

Key Components Overview

Each section within the illustration is designated to specific elements that contribute to the machinery’s performance. Recognizing these crucial components can help users identify areas that require attention or replacement. Below is a summary of some essential elements:

| Component Name | Description |

|---|---|

| Engine | The powerhouse responsible for driving the entire unit. |

| Transmission | Mechanism that transfers power from the engine to the wheels. |

| Deck | The cutting surface where blades are housed for optimal grass trimming. |

| Wheels | Support the equipment, allowing mobility and maneuverability. |

Utilizing the Illustration Effectively

To maximize the benefits of this visual reference, it is crucial to familiarize oneself with the layout. Users should refer to this guide when troubleshooting or sourcing replacement components. By understanding the relationships between different parts, one can ensure proper functionality and longevity of the machinery.

Maintenance Tips for Longevity

Ensuring the enduring performance of your equipment requires consistent care and attention. Regular upkeep not only enhances functionality but also extends the lifespan of your machinery. Implementing simple maintenance practices can lead to significant benefits over time.

Here are some essential strategies to consider:

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Inspect and clean air filters | Every 25 hours of operation | Improves airflow and efficiency |

| Sharpen blades | Every 50 hours of use | Ensures clean cuts and reduces strain |

| Check fluid levels | Before each use | Prevents overheating and ensures smooth operation |

| Inspect belts and cables | Every 100 hours of use | Identifies wear and prevents failures |

| Lubricate moving parts | Every 25 hours of operation | Reduces friction and wear |

By adhering to these guidelines, you can promote the reliable operation of your machinery and avoid costly repairs. A proactive approach to maintenance can lead to enhanced performance and increased satisfaction.

Common Issues and Solutions

In any mechanical system, users may encounter various challenges that can affect performance and efficiency. Understanding these common problems and their respective solutions can greatly enhance the longevity and functionality of the equipment. Below are several frequently observed issues and practical remedies.

Frequent Challenges

- Engine starting difficulties

- Uneven cutting or poor grass handling

- Overheating of the engine

- Battery drainage or failure

Practical Solutions

- Engine Starting Difficulties:

- Check the fuel level and ensure the correct type of fuel is used.

- Inspect the spark plug for wear or damage and replace it if necessary.

- Uneven Cutting:

- Examine the blades for dullness or damage; sharpen or replace as needed.

- Ensure the cutting deck is level and properly adjusted.

- Overheating:

- Clean the cooling fins and air filters to allow proper airflow.

- Check the oil level and change the oil if it appears dirty or low.

- Battery Issues:

- Inspect battery connections for corrosion or looseness.

- Charge the battery fully and test it for adequate voltage.

Ordering Replacement Parts Online

Acquiring components through online platforms has become a convenient solution for maintenance enthusiasts and professionals alike. This method provides an extensive selection and often competitive pricing. With just a few clicks, individuals can find the necessary items to keep their equipment running smoothly.

Benefits of Online Shopping

Purchasing components via the internet offers numerous advantages. First, it saves time, allowing users to browse and order from the comfort of their homes. Second, many websites provide detailed specifications and customer reviews, enabling informed decisions. Lastly, online stores frequently offer promotional deals, making it possible to save money on essential items.

Essential Considerations

Before finalizing an order, several factors should be taken into account. Ensure that the selected components match the required specifications for compatibility. Additionally, consider the reputation of the vendor and their return policy in case the item does not meet expectations. It is also wise to verify shipping costs and delivery times to avoid any unexpected delays.

| Vendor | Compatibility Check | Shipping Options | Return Policy |

|---|---|---|---|

| Online Store A | Available on site | Standard & Express | 30-day return |

| Online Store B | Check manual | Free over $50 | 15-day return |

| Online Store C | Contact support | International shipping | No returns |

Tools Needed for Repairs

Successful maintenance of your equipment relies heavily on having the right instruments at your disposal. Whether addressing minor adjustments or more extensive repairs, a well-equipped toolkit ensures efficiency and effectiveness in the process.

Essential Hand Tools: Basic hand tools are the foundation of any repair job. A set of wrenches, screwdrivers, and pliers will allow you to handle a wide range of tasks. Socket sets can also be invaluable for tackling various fasteners with ease.

Power Tools: For more demanding tasks, power tools can significantly speed up the process. An electric drill, for example, can facilitate quick installations and removals, while a reciprocating saw can assist in cutting through tougher materials.

Safety Equipment: Never underestimate the importance of safety gear. Protective eyewear, gloves, and ear protection should always be part of your toolkit to ensure a safe working environment.

Specialized Instruments: Depending on the specific repairs, you may need specialized tools such as torque wrenches for precise tightening or diagnostic equipment for troubleshooting issues.

Having a comprehensive selection of tools not only prepares you for repairs but also enhances your overall efficiency and safety during maintenance tasks.

Comparative Analysis with Similar Models

This section delves into the comparison of a specific mower with its contemporaries, highlighting key features, performance metrics, and overall design philosophy. Understanding the nuances between these models can aid potential buyers in making informed decisions tailored to their specific landscaping needs.

When assessing various models in the market, several factors come into play:

- Engine Power: Evaluating horsepower and torque to understand performance under different conditions.

- Cutting Width: Comparing the deck sizes and their impact on efficiency and maneuverability.

- Durability: Analyzing build materials and design quality to gauge longevity and maintenance requirements.

- Ease of Use: Considering user-friendly features, including controls, adjustability, and comfort.

- Price Point: Reviewing the cost in relation to the features offered to determine overall value.

Here’s a brief overview of how this mower stacks up against similar models:

- Model A:

- Engine: 23 HP

- Deck Width: 60 inches

- Price: $10,000

- Model B:

- Engine: 22 HP

- Deck Width: 54 inches

- Price: $9,500

- Model C:

- Engine: 25 HP

- Deck Width: 72 inches

- Price: $12,000

This analysis illustrates the competitive landscape, emphasizing how different models cater to diverse requirements, ensuring that potential owners can select the most suitable option for their specific applications.

Customer Reviews and Feedback

This section provides insights into user experiences and evaluations of the equipment, highlighting both positive remarks and areas for improvement. Feedback from customers offers valuable perspectives that can guide potential buyers in making informed decisions.

Many users appreciate the reliability and performance of the machinery, often noting its efficiency and ease of use. However, there are also suggestions for enhancements, particularly regarding maintenance and support services.

| Customer Name | Rating | Comments |

|---|---|---|

| John Doe | 4/5 | Very efficient and reliable. A bit tricky to maintain. |

| Jane Smith | 5/5 | Excellent performance! Makes my work much easier. |

| Mike Johnson | 3/5 | Good overall but requires frequent servicing. |

| Emily Davis | 4/5 | Solid machine but customer support could be better. |