Marine propulsion systems are essential for ensuring smooth and reliable navigation in various water conditions. These mechanisms require precise coordination between different elements to optimize performance and durability over time. Knowing the structure and configuration of key components helps in maintaining and enhancing the functionality of the system.

When it comes to watercraft propulsion, understanding the arrangement of individual elements plays a crucial role in routine maintenance and repair. Identifying the correct configurations and connections ensures that all components work efficiently together, preventing unnecessary wear and tear and extending the overall lifespan of the system.

Regular inspections and timely replacements of certain mechanical elements are important for maintaining optimal performance. Understanding the system’s detailed structure makes it easier to troubleshoot and replace worn or damaged parts, ensuring smooth and uninterrupted operation.

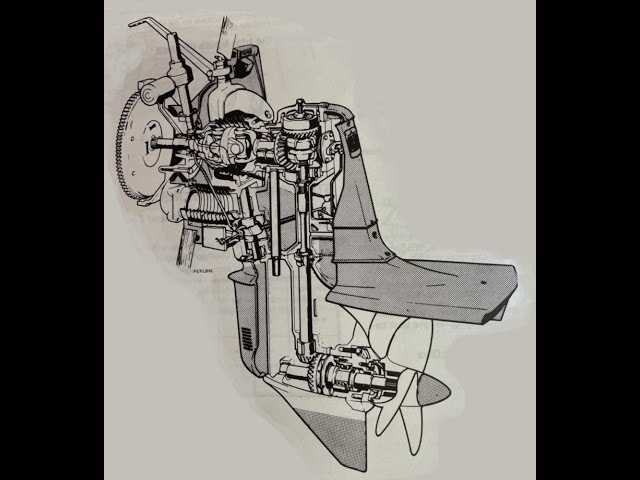

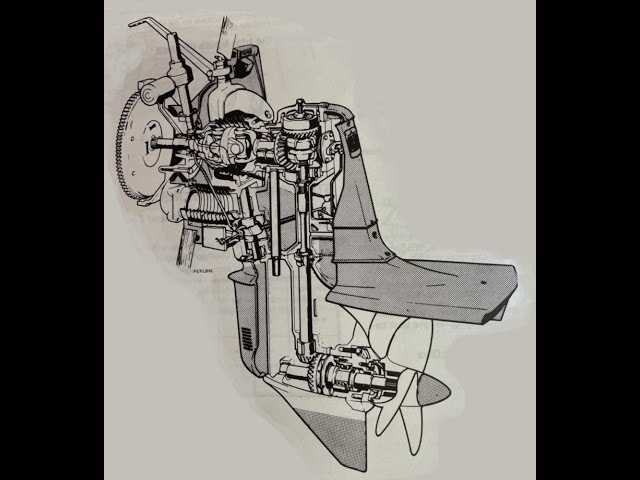

This section provides a comprehensive overview of the essential mechanisms involved in the propulsion system of certain marine vehicles. The focus will be on detailing the main segments that ensure smooth operation, from power transmission to steering functionalities, and understanding how these elements work together in harmony.

Main Structural Elements

- Drive casing for durability and protection

- Transmission assembly responsible for power transfer

- Propeller hub to optimize water flow

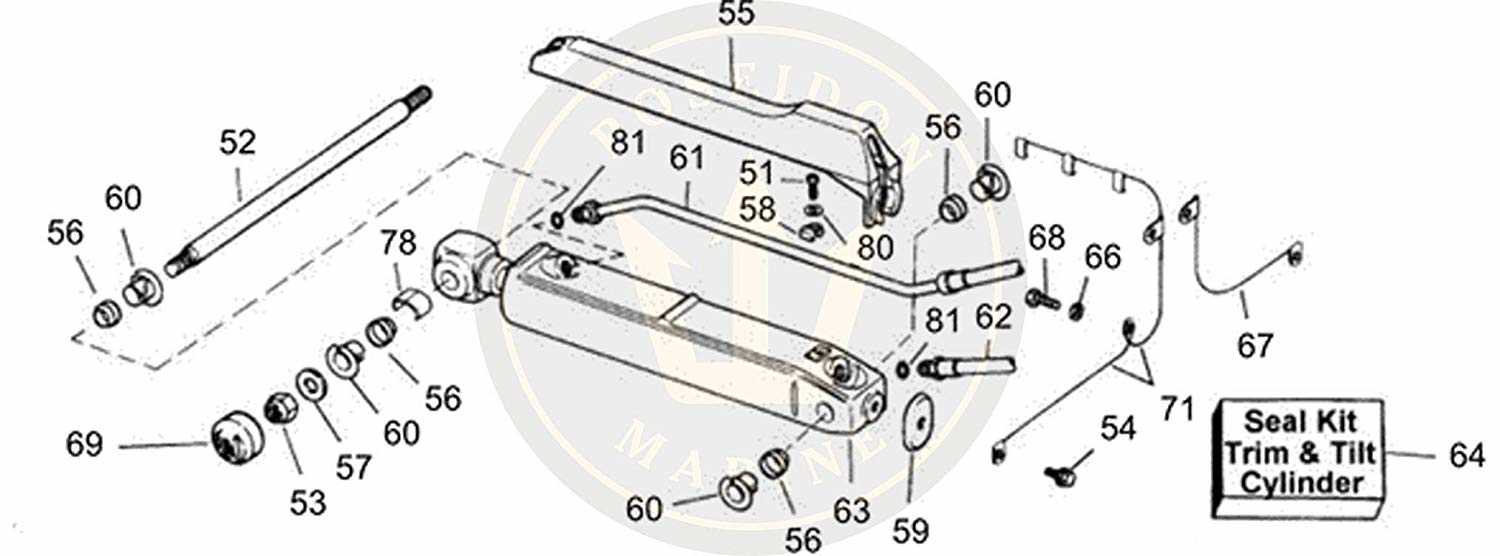

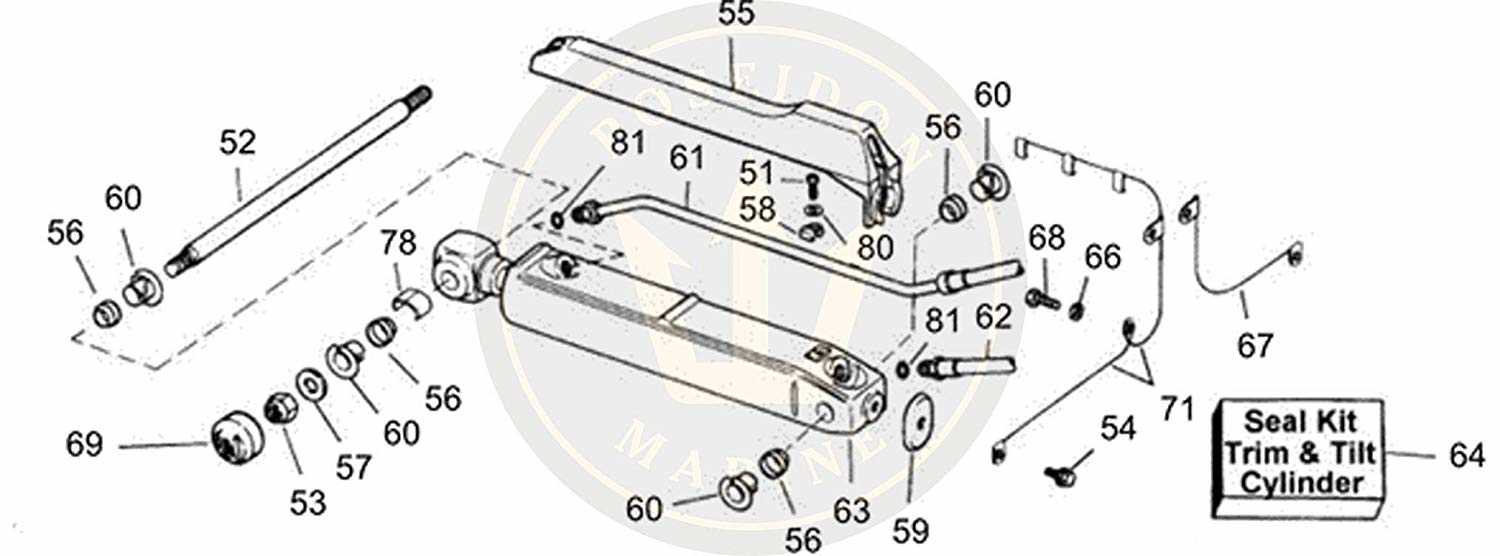

Auxiliary Components

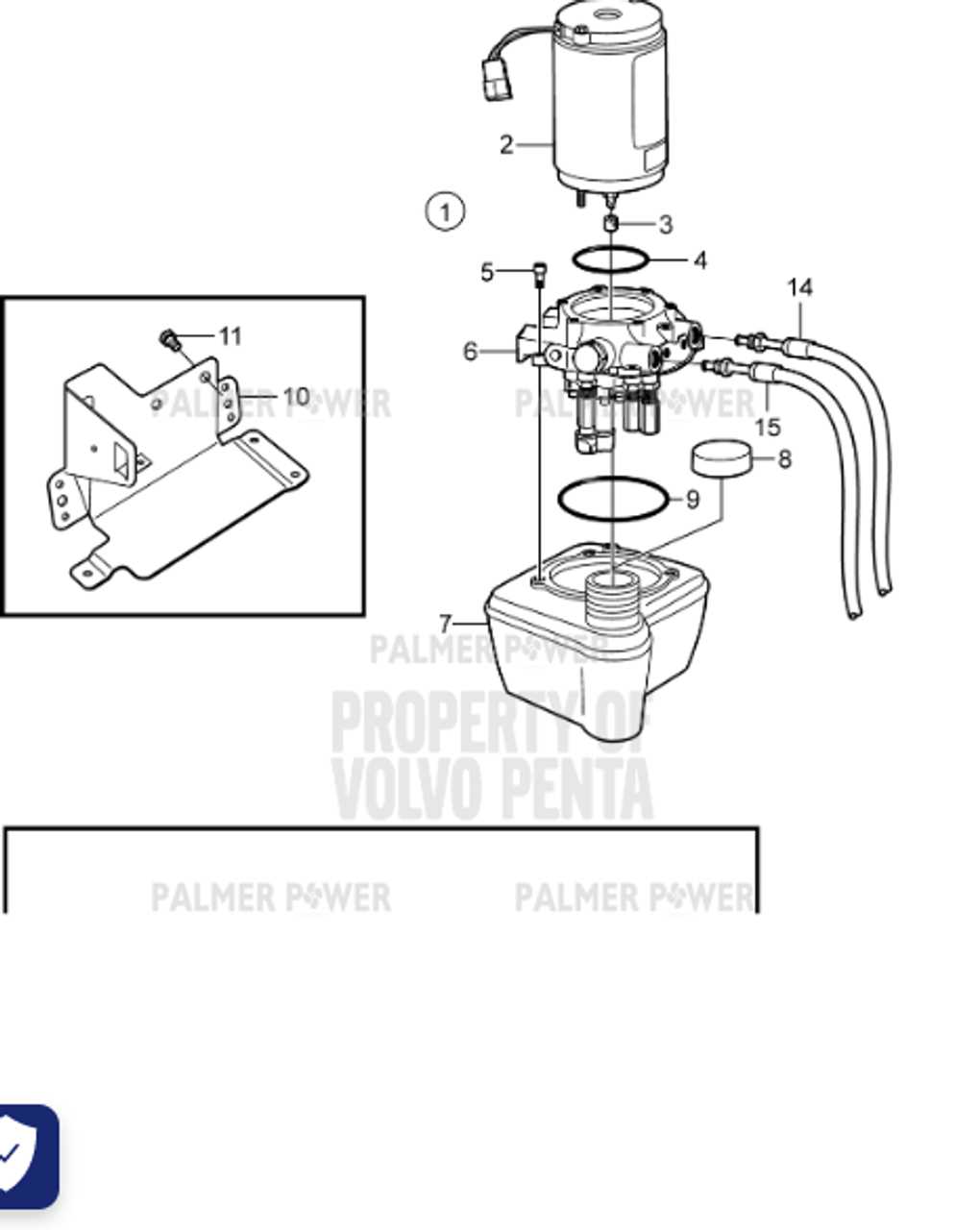

- Trim and tilt mechanism for position adjustment

- Steering control for navigation

- Cooling system for temperature regulation

Key Features of Marine Propulsion System

The marine propulsion system offers a reliable and efficient solution for various watercraft. Built for durability, it ensures smooth navigation even in challenging conditions. This section highlights some of the standout aspects that make this equipment a preferred choice for boaters seeking performance and ease of maintenance.

Durability and Longevity

Designed to withstand harsh marine environments, this system boasts corrosion-resistant materials, ensuring a longer lifespan. Its robust construction minimizes wear, making it ideal for those who demand long-term reliability from their boating equipment.

Efficient Power Transmission

Optimized for delivering consistent power, the unit enables smooth and efficient energy transfer to the propeller. This feature enhances overall vessel performance, allowing for better speed control and fuel efficiency.

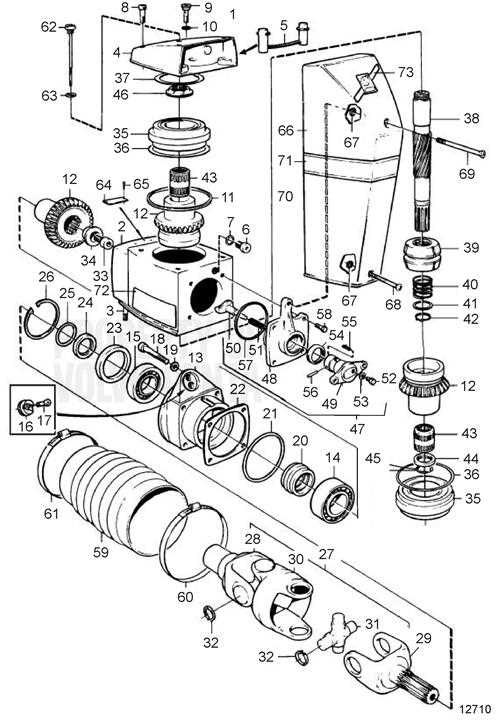

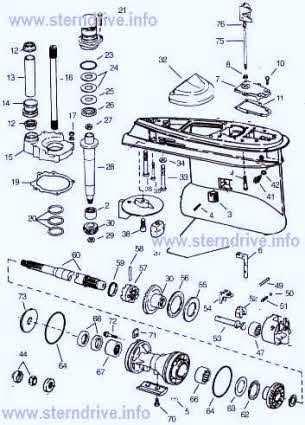

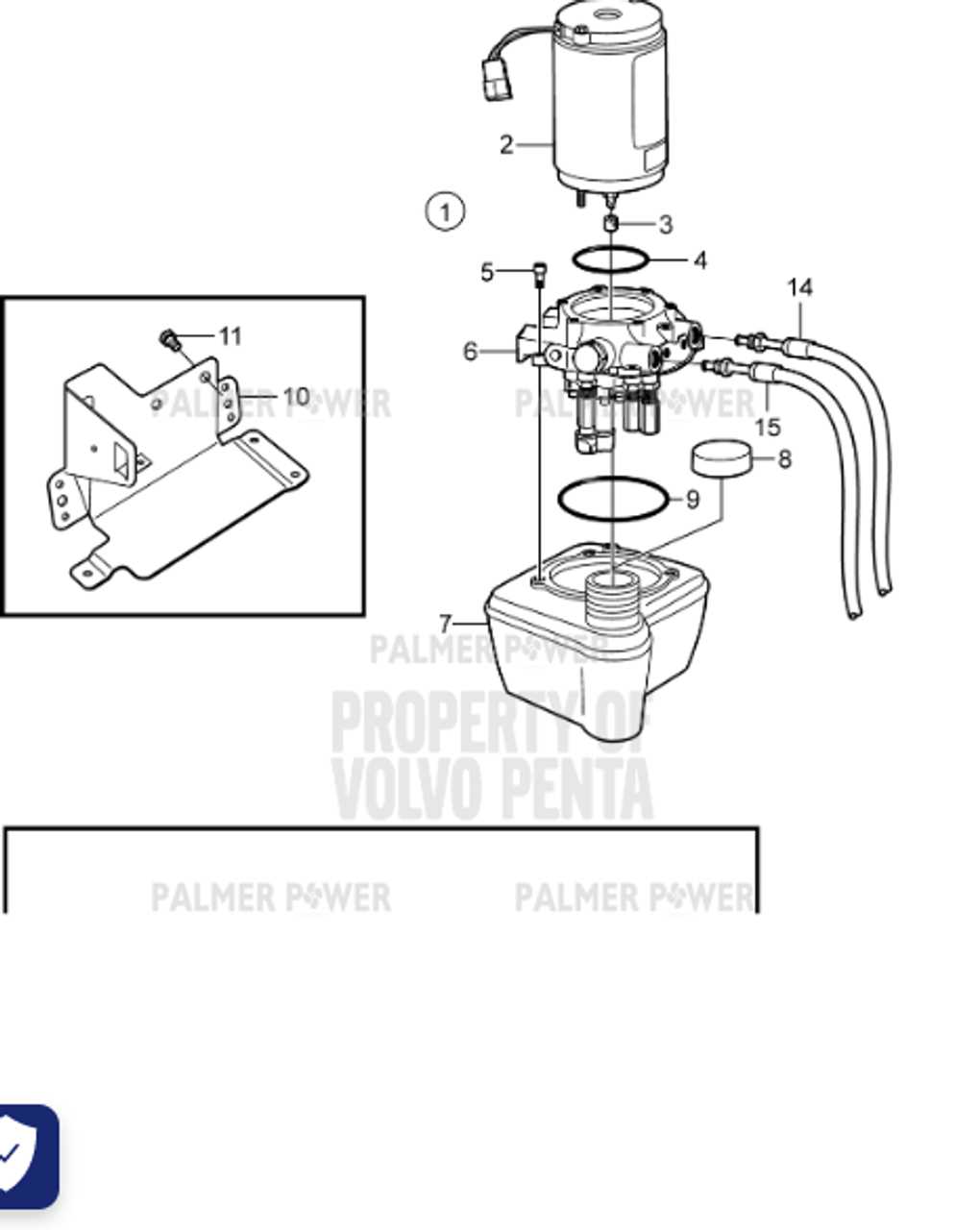

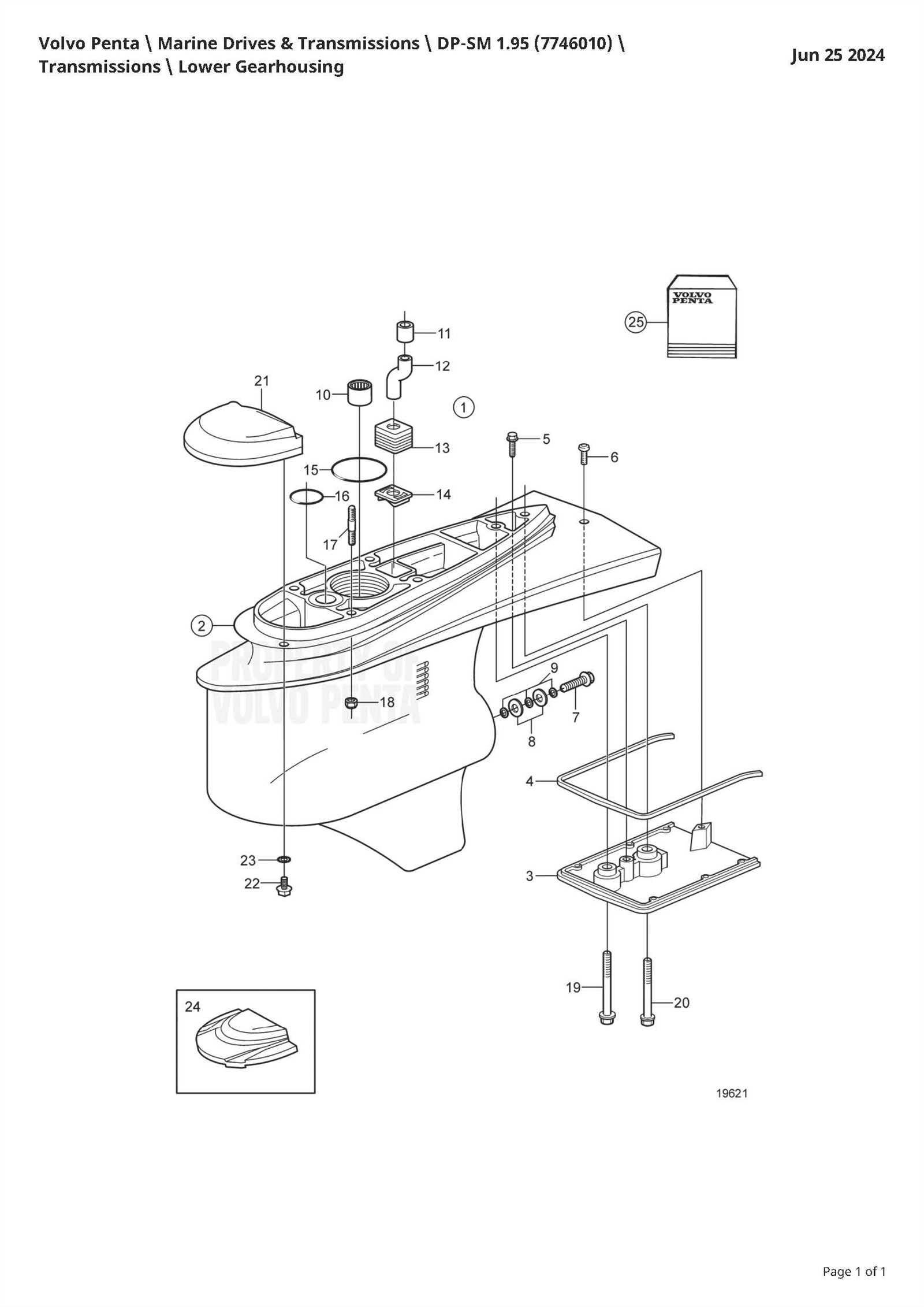

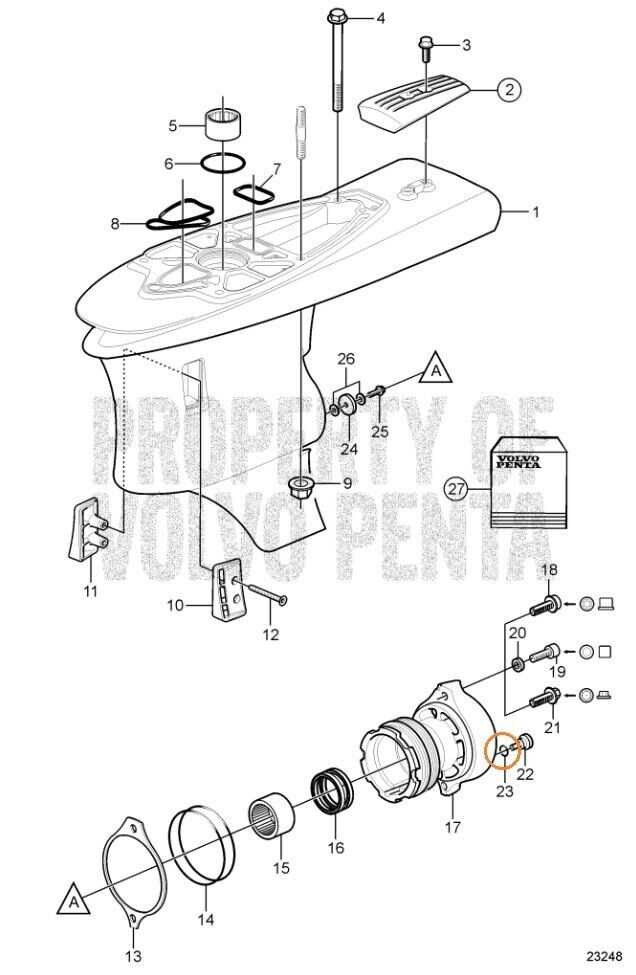

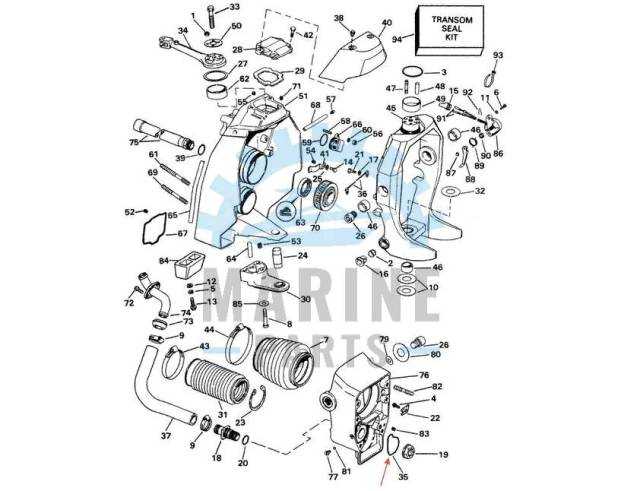

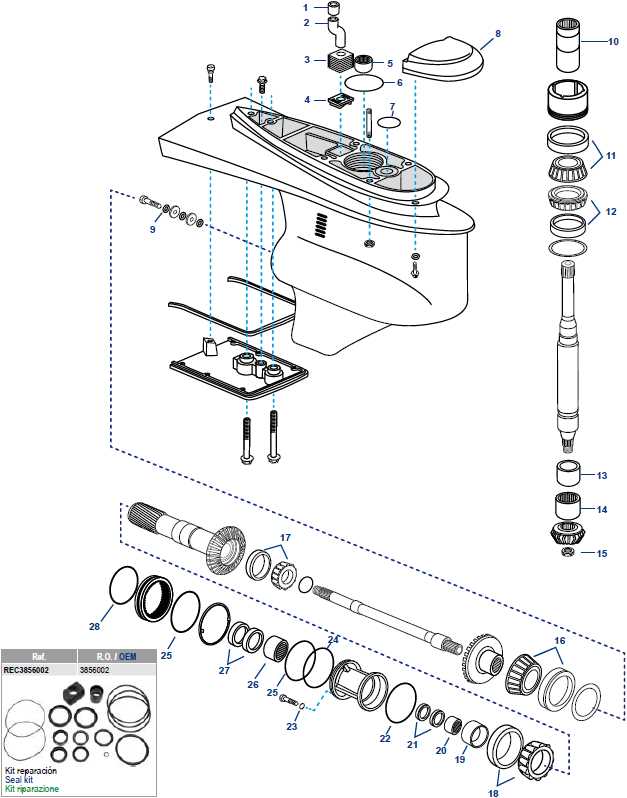

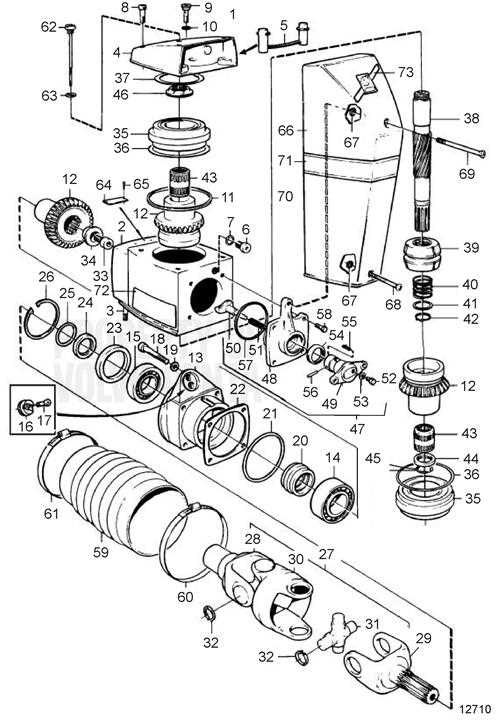

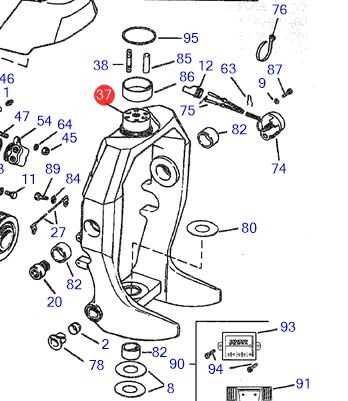

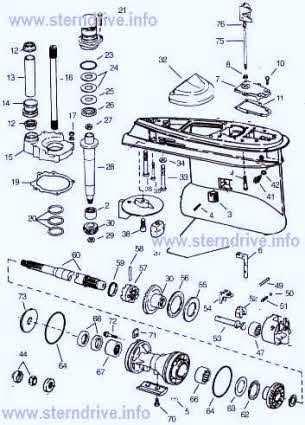

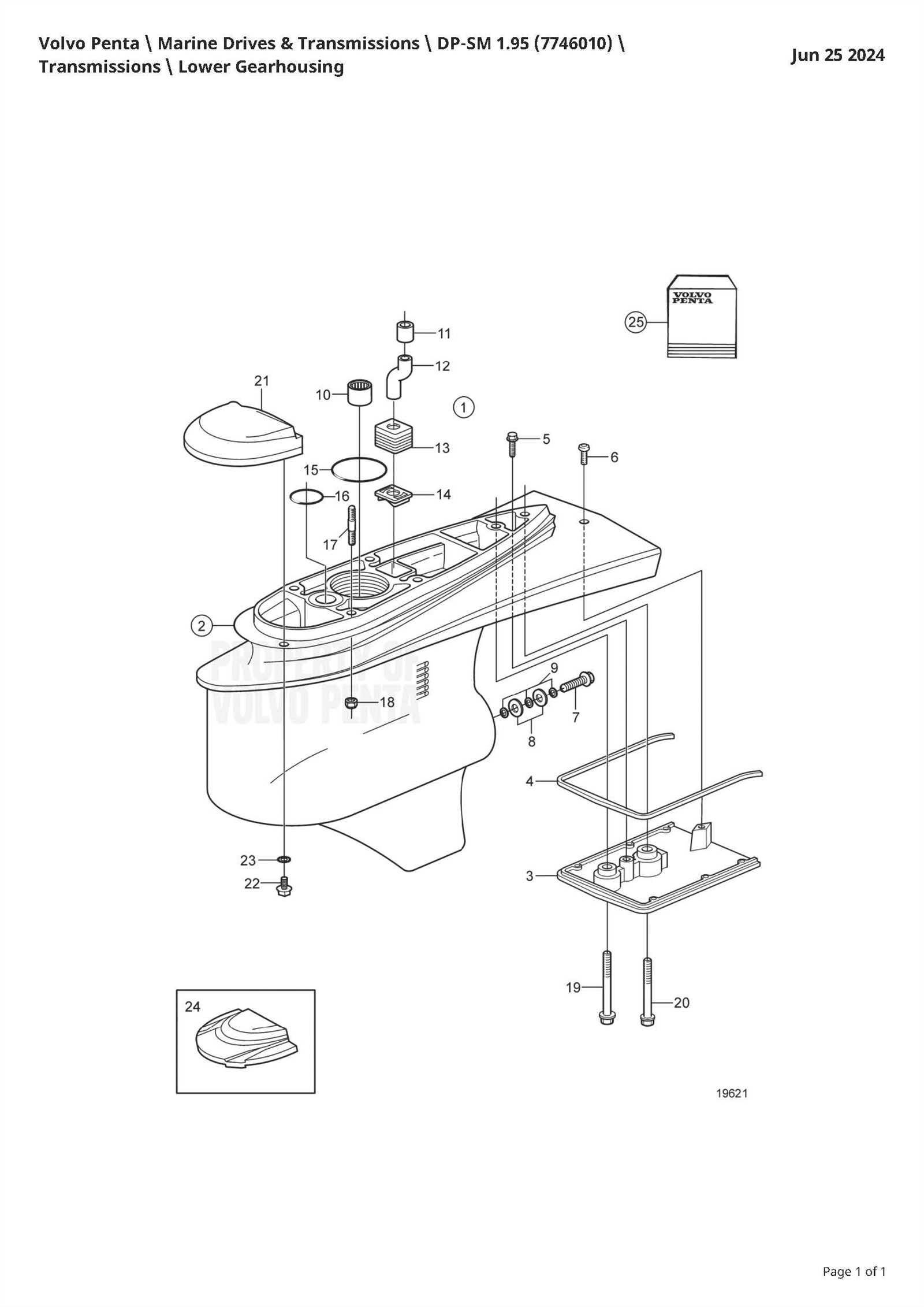

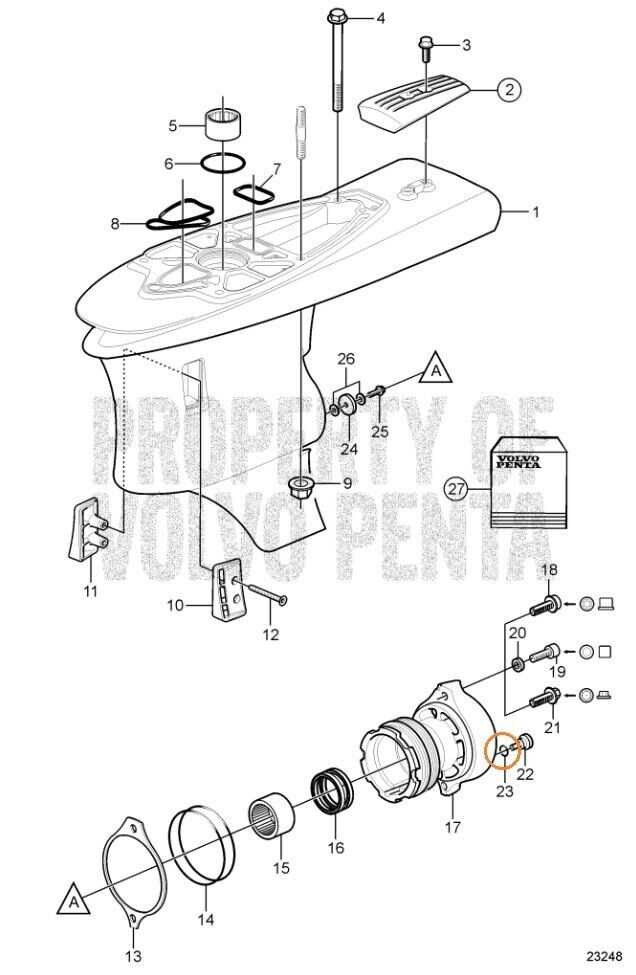

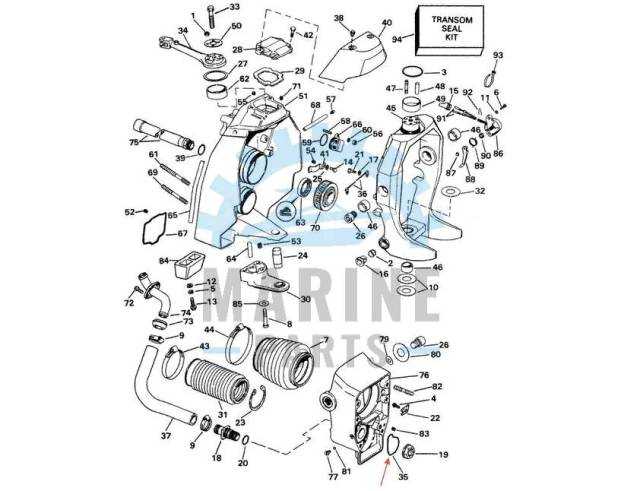

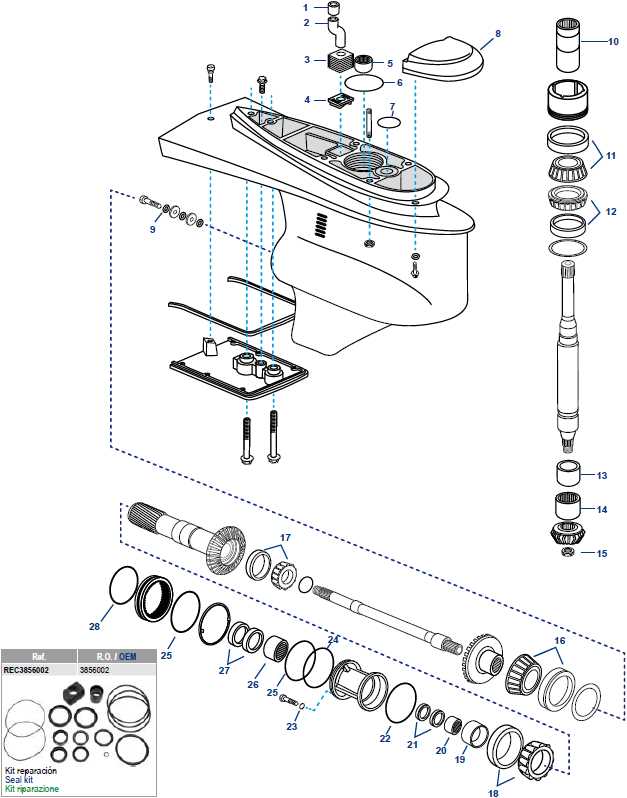

Understanding the Parts Diagram

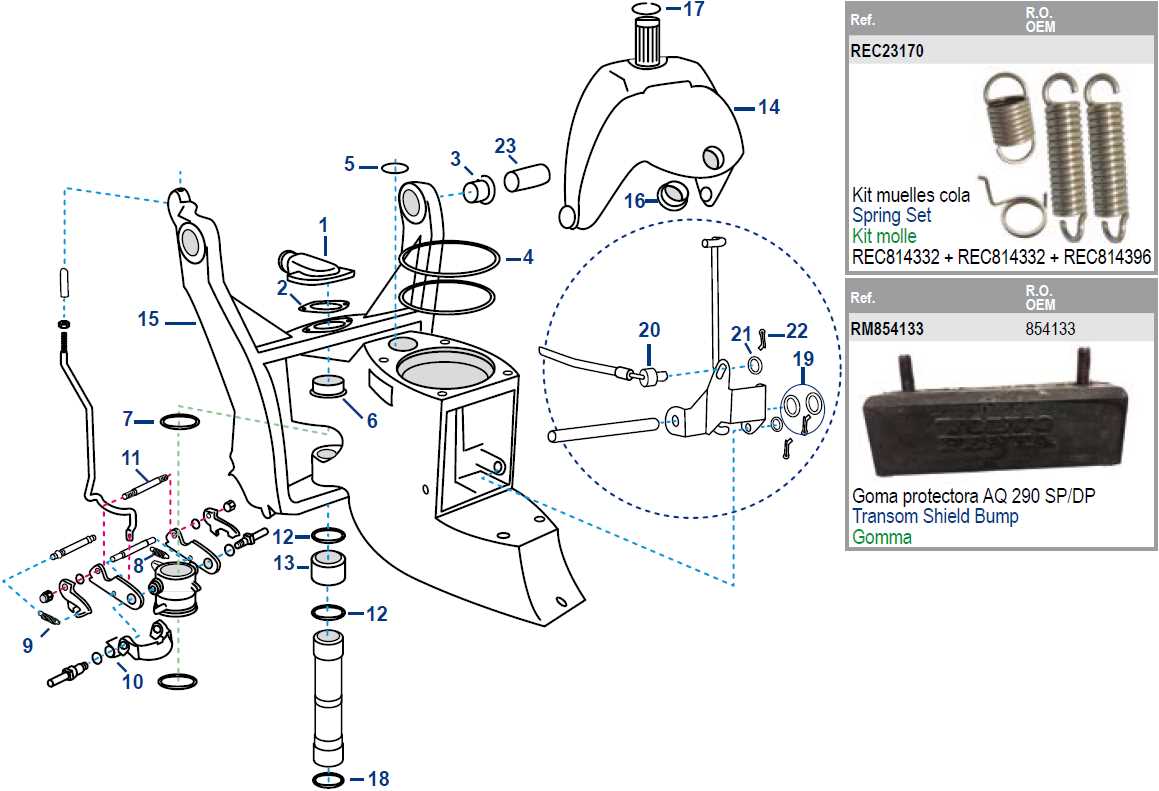

When examining the technical layout of a marine propulsion system, it’s essential to grasp how the individual components fit together. Each element plays a crucial role in ensuring the smooth operation of the entire setup, and understanding their relationships is key to proper maintenance and troubleshooting.

- Mechanical structure: This includes all major physical elements that form the base of the propulsion system, providing support and ensuring stability during operation.

- Drive mechanism: The propulsion unit relies on specific mechanical parts to transfer power effectively from the engine to the propeller, ensuring efficient movement through the water.

- Sealing elements: These components protect the internal systems from water intrusion, preserving the integrity and longevity of the propulsion mechanism.

- Control systems: Devices that regulate the performance and direction of the unit, ensuring precise maneuvering and responsive control during operation.

Familiarizing yourself with this schematic is essential for identifying issues, performing repairs, and ensuring long-term reliability.

Maintenance Tips for SX-M Outdrive

Regular care and attention to your marine propulsion system can significantly enhance its performance and lifespan. Proper upkeep ensures that all components work efficiently, helping to prevent costly repairs and unexpected breakdowns. This section highlights essential practices to maintain your boat’s drive system and keep it operating at optimal levels.

Inspect Seals and Gaskets

Ensure that seals and gaskets are in good condition to prevent water ingress. Check for any visible wear, cracks, or damage. Replace any compromised seals immediately to avoid potential water contamination, which could lead to corrosion and internal damage.

Lubrication and Fluid Levels

Maintaining the correct lubrication is vital for the smooth operation of moving parts. Regularly check and top up the gear oil as per the manufacturer’s recommendations. Ensure there are no leaks that could lead to insufficient lubrication, which may cause overheating or excessive wear.

| Maintenance Task |

Frequency |

| Seal Inspection |

Every 100 hours or annually |

| Lubricant Check |

Every 50 hours or as needed |

| Gasket Replacement |

As required |

Common Issues and Solutions

Mechanical systems in watercraft propulsion often encounter problems due to regular wear and tear or environmental factors. Recognizing these issues early can help prevent further damage and ensure optimal performance.

- Overheating: Cooling system blockages or inadequate water flow can lead to engine overheating. Regular inspection of the cooling system and cleaning filters can prevent this issue.

- Vibration: Excessive vibration may indicate worn bearings, misalignment, or propeller damage. Immediate attention to these components is crucial to avoid further complications.

- Oil Leaks: Seal failures or cracked components can cause oil leakage. Replacing faulty seals and regularly checking for leaks ensures smooth operation.

- Corrosion: Saltwater exposure accelerates the corrosion of metal parts. Applying protective coatings and using sacrificial anodes can significantly reduce corrosion risks.

- Shifting Problems: Difficulty in shifting gears may result from cable misalignment or internal wear. Proper adjustment or replacement of worn parts will resolve this issue.

Comparing Outdrive Models and Variants

When examining different propulsion systems for boats, it’s important to understand how various models and their versions compare in terms of performance, reliability, and adaptability. Each design comes with its own set of features that suit specific boating conditions and needs, providing either more power, better fuel efficiency, or easier maintenance.

Several key factors distinguish these models. The material used in construction affects durability and longevity, while the design of the propeller and transmission mechanisms influences how the vessel handles under different conditions. Additionally, newer variants often come with advanced technologies that enhance maneuverability and reduce drag, making them more suitable for high-speed cruising or heavy-duty tasks.

Ultimately, choosing the right model depends on understanding the balance between power output, ease of use, and the specific requirements of the boat. By carefully comparing the different systems available, it’s possible to select the best option for a wide range of watercraft applications.

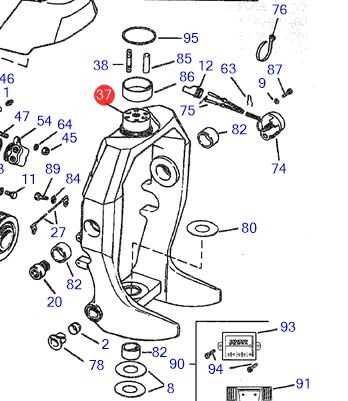

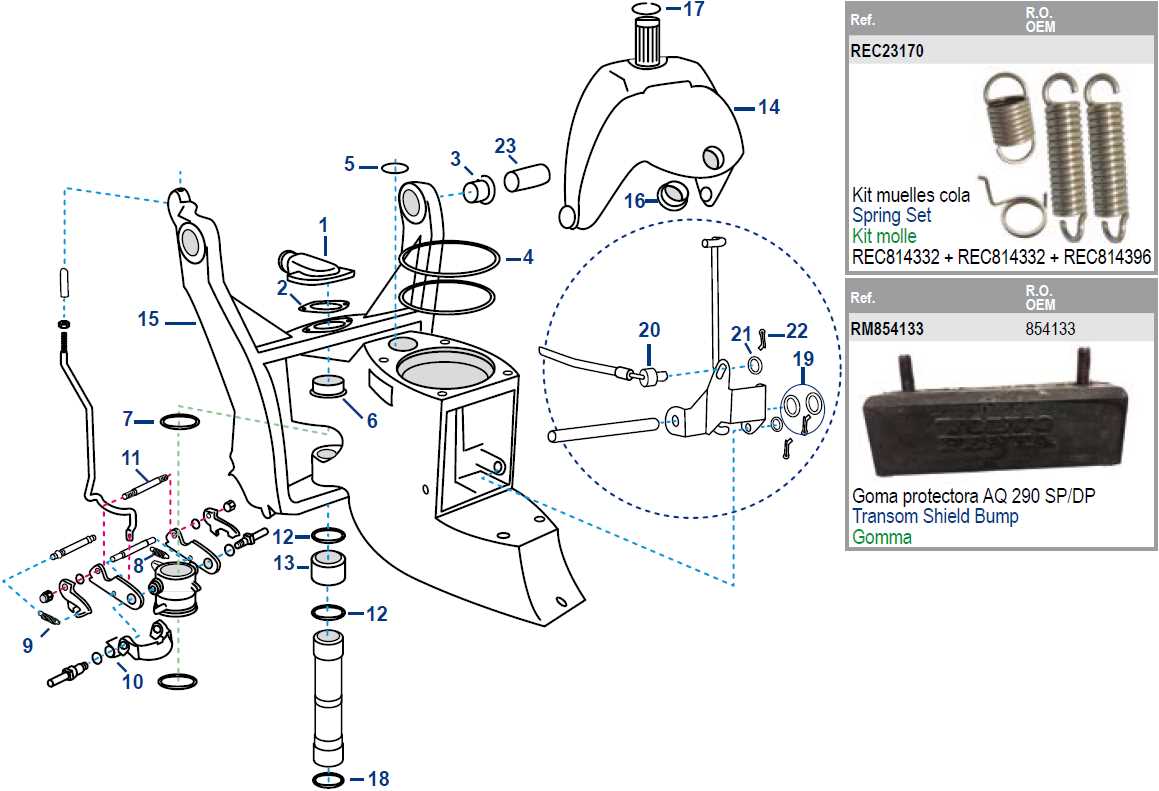

Replacement Parts and Compatibility

Finding the right components for marine equipment is crucial for maintaining optimal performance. Ensuring that each element fits properly into the existing system guarantees not only functionality but also long-term durability.

Compatibility between different mechanical elements can vary based on the manufacturer and model specifications. It’s important to match replacements precisely to avoid any potential malfunctions or inefficiencies. Paying attention to details such as dimensions, materials, and engineering standards will ensure a seamless fit.

When selecting substitutes, always consider the age and wear of surrounding components, as this can impact the effectiveness of the installation. Well-chosen parts extend the operational life of the entire system.

Tools Needed for Outdrive Repairs

Repairing marine propulsion systems requires a specific set of tools to ensure a proper and safe restoration process. Having the right equipment is essential for both minor adjustments and major overhauls. Using suitable instruments not only improves efficiency but also ensures precision during the repair process.

Wrenches and Sockets: These are necessary for loosening and tightening various bolts and fasteners. A set of metric and standard sizes will be required to accommodate different components.

Torque Wrench: To ensure proper tightening specifications, a torque wrench is essential. This tool helps avoid over-tightening, which can damage parts, and ensures secure fitting.

Grease Gun: Lubrication is crucial for smooth operation and preventing corrosion. A grease gun allows for precise application of lubricant in hard-to-reach areas.

Pliers and Screwdrivers: Basic tools like pliers and screwdrivers are necessary for gripping, pulling, and tightening small components. It’s important to have both flathead and Phillips screwdrivers in various sizes.

Seal Puller: This tool makes the removal of old seals much easier and

Resources for Further Assistance

If you’re looking for additional guidance or technical information, there are various resources available to help with maintenance and repairs. Whether you’re a beginner or an experienced mechanic, it’s essential to find reliable materials to support your work.

Online Technical Forums

Technical forums are excellent places to connect with others who share your interests. These communities often include discussions on repair techniques, troubleshooting tips, and recommendations for specific tools. Many experts actively participate, providing advice and answering detailed questions.

Service Manuals and Guides

Service manuals and maintenance guides are crucial for anyone needing in-depth information. These documents cover everything from basic upkeep to more complex fixes, offering detailed instructions and diagrams that simplify the repair process. Many of these manuals can be accessed online or through professional service providers.