When it comes to maintaining a beautiful outdoor space, having a reliable machine is essential. Familiarizing yourself with the various components of this vital tool can significantly enhance its performance and longevity. A well-functioning unit requires attention to its intricate parts, each playing a crucial role in achieving optimal results.

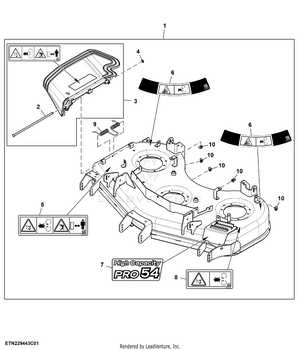

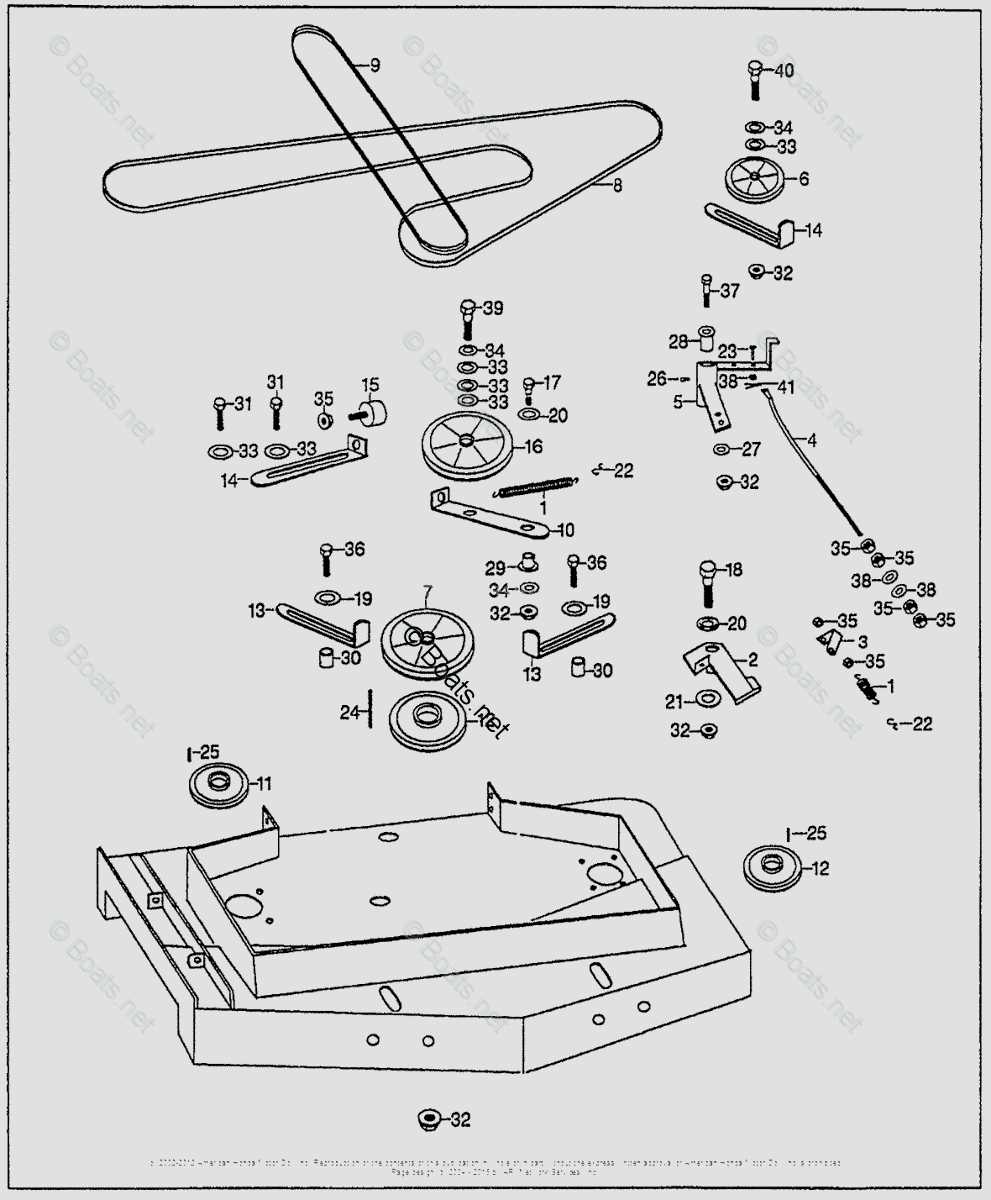

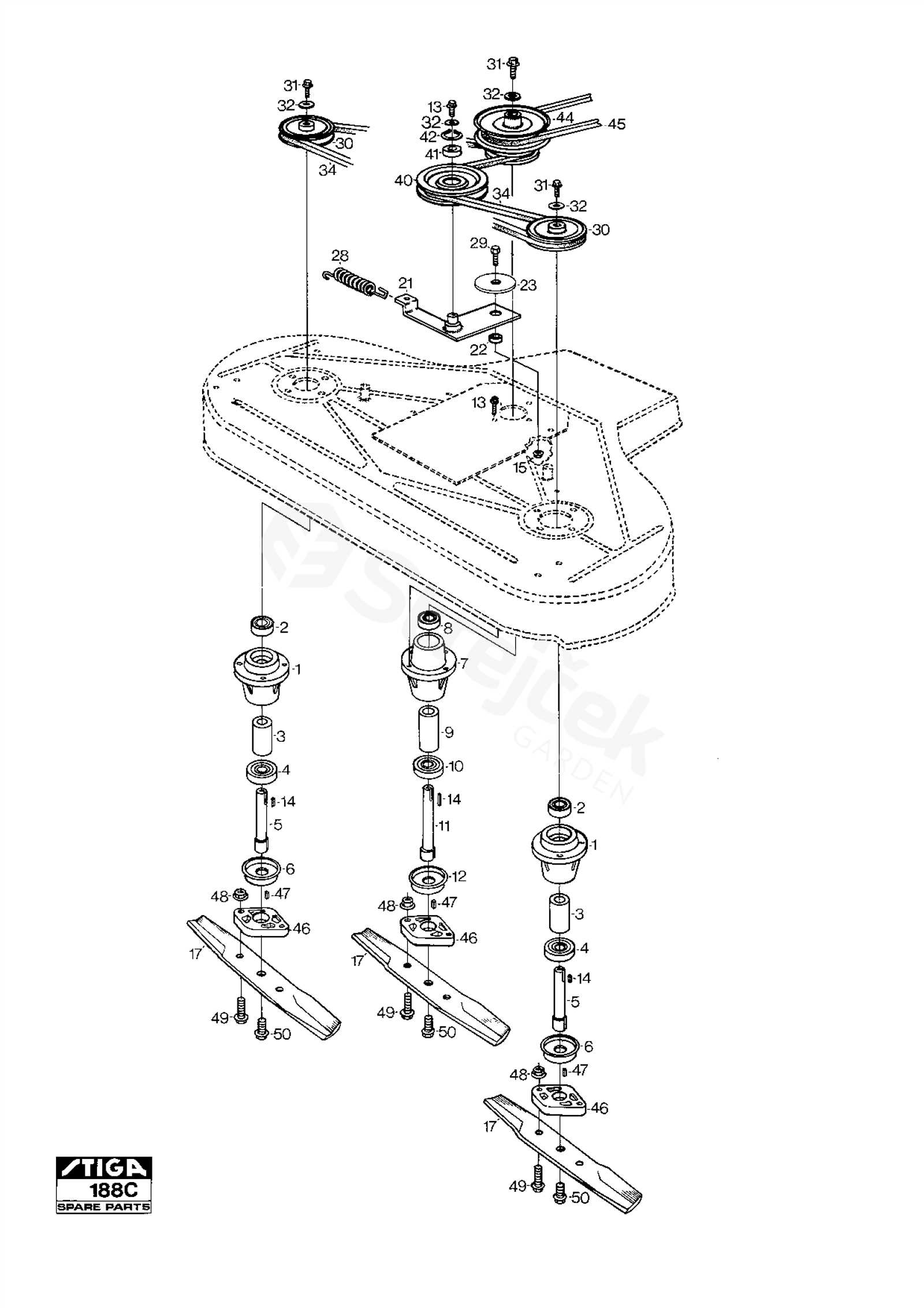

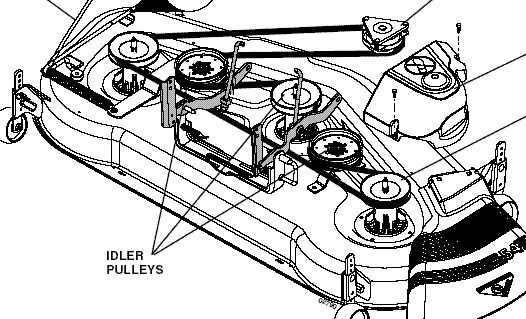

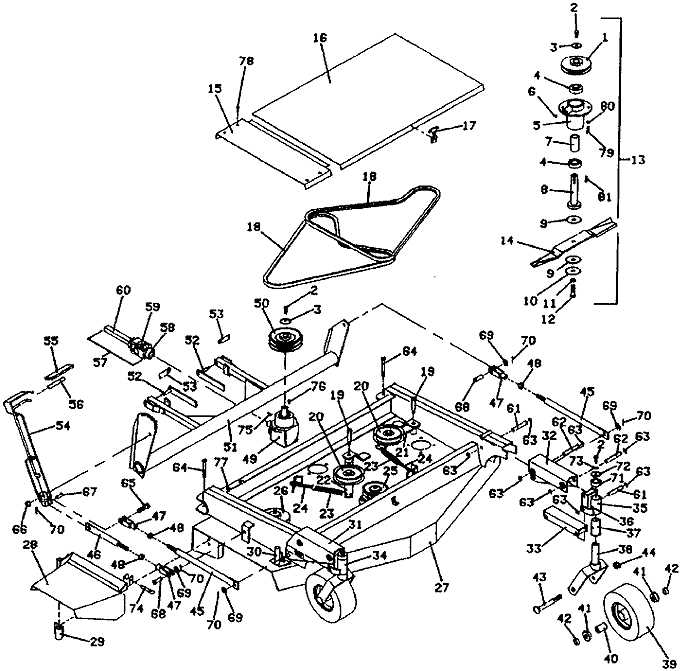

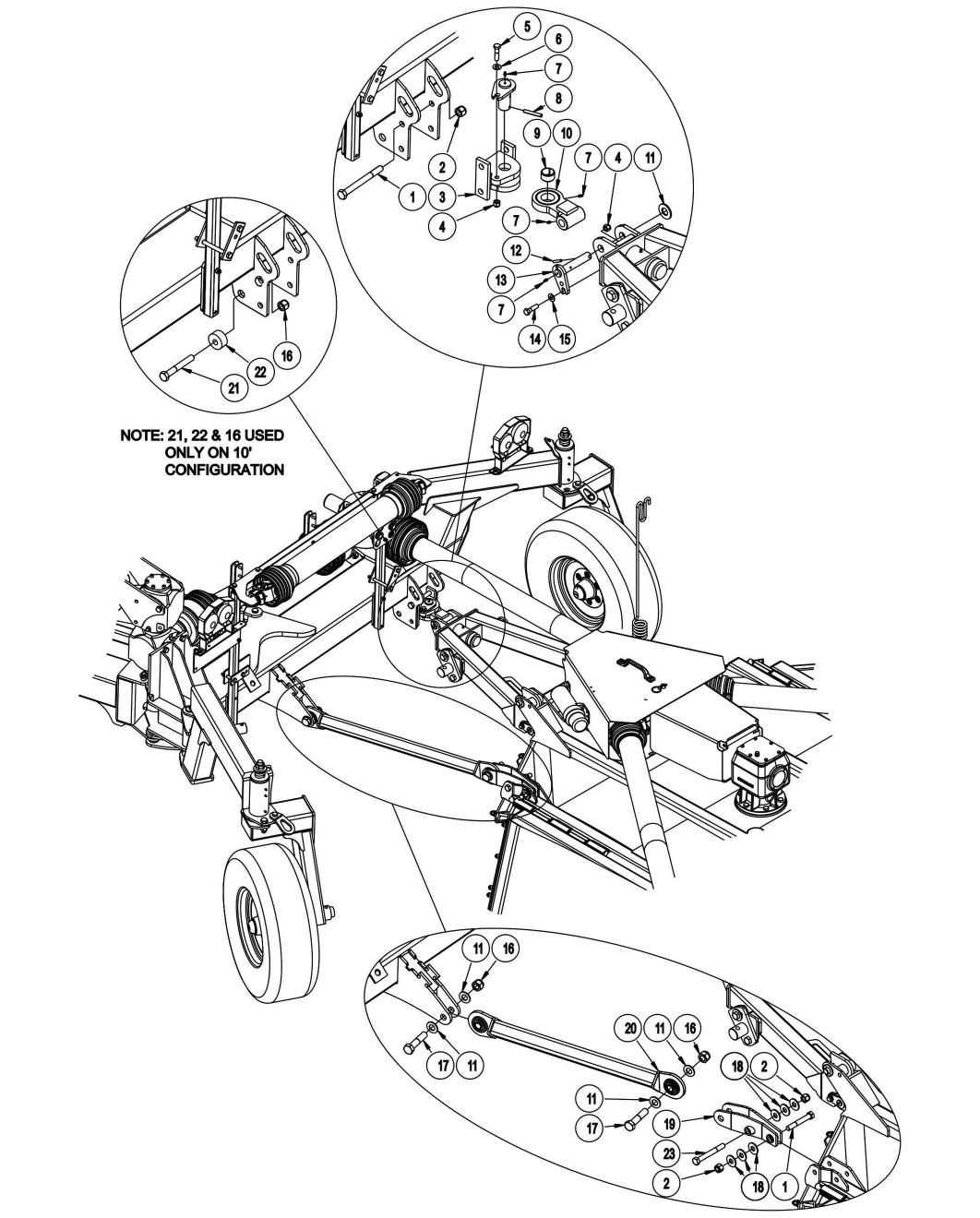

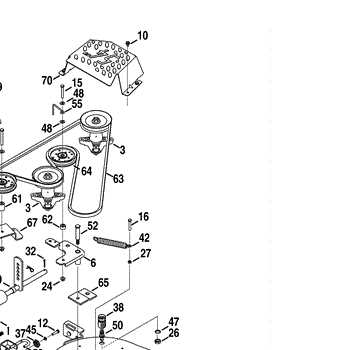

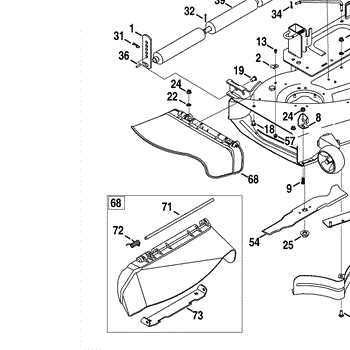

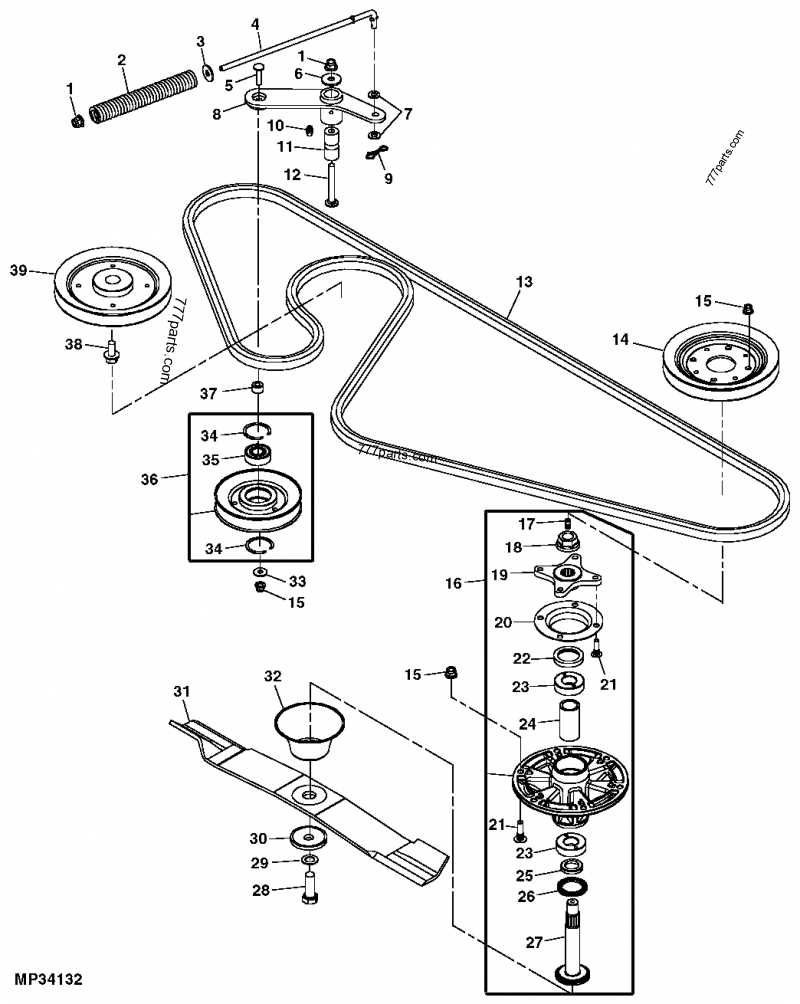

Visual aids can be incredibly beneficial for those seeking to comprehend the layout and functionality of these components. By examining detailed representations, users can quickly identify necessary items for maintenance or repair. This knowledge empowers operators to keep their equipment running smoothly, ensuring that the task of lawn care is efficient and effective.

Whether you are a seasoned professional or a weekend warrior, having access to comprehensive information about your machinery’s configuration is invaluable. By gaining insights into the specific elements involved, you can make informed decisions that lead to better upkeep and enhanced performance in your gardening endeavors.

Understanding Craftsman 54” Mower Deck

The equipment designed for lawn maintenance plays a crucial role in ensuring a well-manicured landscape. Familiarity with its components enhances efficiency and longevity. This section delves into the essential elements that contribute to the overall functionality of this specific apparatus.

Key Components: Each section of this machinery is designed with a unique purpose in mind. Understanding how these elements interact can lead to better performance. For instance, the blades are crucial for achieving a clean cut, while the housing protects them and facilitates airflow for optimal grass discharge.

Maintenance Tips: Regular upkeep is vital for sustaining high performance. Checking for wear and tear on the individual elements can prevent unexpected failures. Lubrication of moving parts and timely blade sharpening are practices that can greatly extend the life of the equipment.

Lastly, knowing how to assemble and disassemble the various sections allows for easier repairs and replacements. A comprehensive understanding of the mechanics involved not only enhances operational efficiency but also empowers users to tackle issues independently.

Essential Components of Mower Deck

Understanding the critical elements that contribute to the functionality of a cutting mechanism is vital for optimal performance. Each component plays a specific role, ensuring efficiency and durability. This knowledge helps in maintenance, troubleshooting, and enhancing the longevity of the equipment.

Key Elements

The primary components include the blade assembly, which is responsible for the actual cutting, and the housing that protects and supports the machinery. Additionally, the spindle serves as the rotating axis for the blades, while belts transmit power from the engine to the cutting assembly. Each of these parts must be well-maintained to ensure the overall effectiveness of the system.

Supportive Mechanisms

Supportive mechanisms such as the height adjustment system allow for customizable cutting lengths, catering to different grass types and conditions. Furthermore, the rollers or wheels facilitate smooth operation over varied terrains, enhancing maneuverability and stability. Regular inspection and care of these components are essential for peak performance.

Importance of Maintenance for Longevity

Regular upkeep is essential for ensuring the extended life of any equipment. Without proper care, even the most robust machines can suffer from wear and tear, leading to decreased performance and potential breakdowns. Establishing a routine maintenance schedule can greatly enhance efficiency and functionality, ultimately saving time and resources.

Consistent inspections play a crucial role in identifying issues before they escalate. By examining components regularly, users can detect early signs of damage or wear, allowing for timely repairs. This proactive approach not only extends the lifespan of the equipment but also promotes safety during operation.

Moreover, keeping parts clean and well-lubricated prevents unnecessary friction and overheating, which are common causes of premature failure. Regular cleaning removes debris and buildup that can hinder performance, while lubrication ensures smooth operation of moving parts. Investing time in these practices leads to a more reliable and durable machine.

In summary, prioritizing maintenance not only enhances the longevity of equipment but also maximizes its effectiveness. By committing to routine care, users can enjoy consistent performance and avoid costly repairs, ensuring a more productive experience overall.

Common Issues and Troubleshooting Tips

Understanding potential problems with your equipment is essential for maintaining optimal performance. This section outlines frequent challenges users encounter and provides practical solutions to address them effectively.

Common Problems

- Unusual Noises: Grinding, rattling, or excessive vibration during operation.

- Uneven Cutting: Grass not being cut uniformly, leaving patches untrimmed.

- Clogging: Accumulation of grass clippings, leading to reduced efficiency.

- Difficulty Starting: Engine fails to start or runs inconsistently.

Troubleshooting Steps

- Check for Debris: Inspect the area for any obstructions that may cause unusual sounds or clogs.

- Sharpen Blades: Dull blades can lead to uneven cutting; ensure they are sharp and properly aligned.

- Inspect Fuel System: Ensure fuel is fresh and that the filter is clean to help with starting issues.

- Adjust Height Settings: Verify that the cutting height is set appropriately for the type of grass being trimmed.

By following these guidelines, users can efficiently diagnose and resolve issues, ensuring their equipment operates smoothly and effectively.

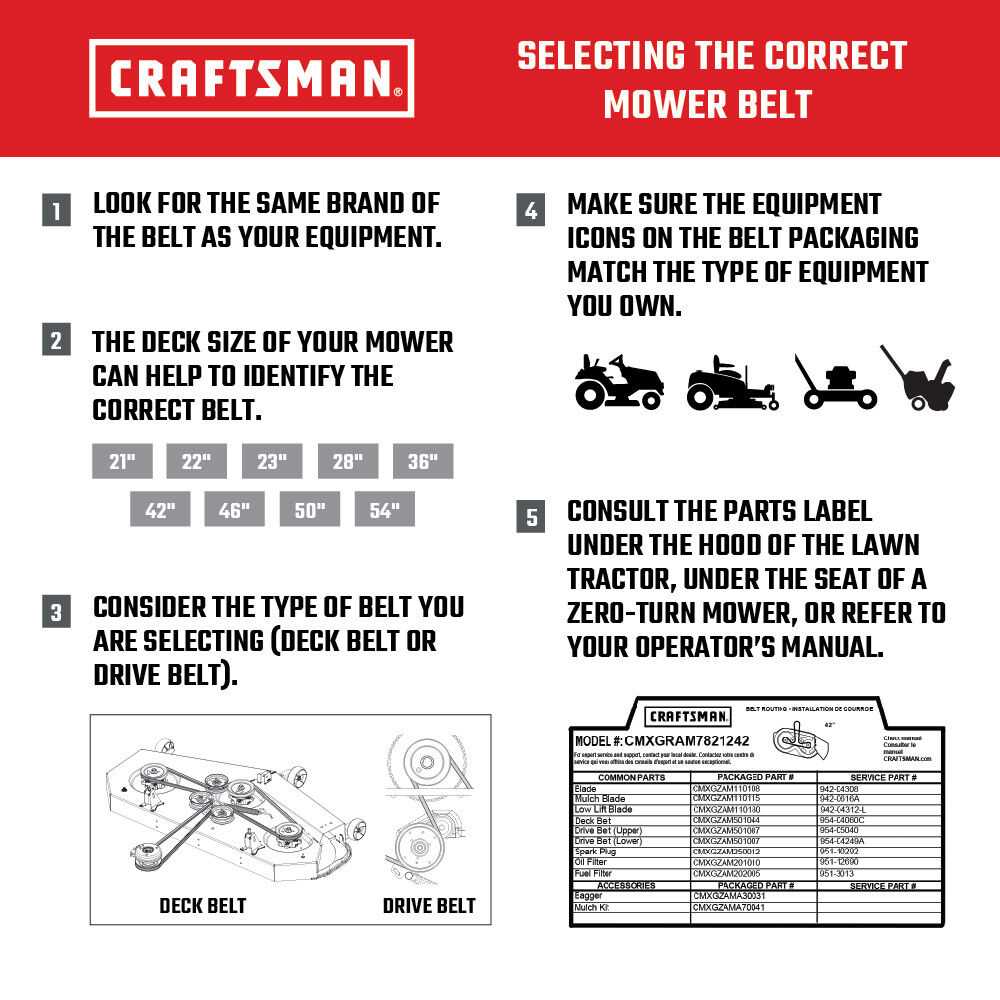

How to Identify Replacement Parts

Identifying the necessary components for your equipment can seem daunting, but it is essential for ensuring optimal performance. Whether you are dealing with a malfunction or simply looking to upgrade, understanding the elements involved will help you make informed decisions.

Start by examining the model number of your machine. This information is usually found on a label or plate, often located near the engine or chassis. Knowing the exact model is crucial as it ensures compatibility with the right components.

Next, consult the user manual, which typically includes a comprehensive list of required items. Manuals often feature diagrams that illustrate where each component is situated, making it easier to locate what you need.

Another useful approach is to take inventory of the existing elements. Inspect each piece for wear and damage. If possible, remove the item to check for any markings or numbers that can guide you to the correct replacements.

Additionally, online resources and forums can be invaluable. Many enthusiasts share insights and experiences regarding specific models, which can help you identify potential issues and appropriate alternatives.

Finally, consider visiting local retailers or contacting professionals. They can provide expert advice and may even assist in finding the right components, ensuring your equipment runs smoothly.

Step-by-Step Repair Guide

This section offers a comprehensive approach to restoring your equipment, ensuring optimal performance and longevity. By following these organized steps, you’ll be able to efficiently tackle any issues that arise.

- Assess the Damage:

- Inspect for visible wear or damage.

- Test functionality to identify specific problems.

- Gather Necessary Tools:

- Screwdrivers (flathead and Phillips)

- Wrenches and pliers

- Replacement components as needed

- Disassemble Carefully:

- Start by removing any covers or shields.

- Take note of the order of components for reassembly.

- Replace Damaged Parts:

- Install new components following manufacturer guidelines.

- Ensure a secure fit for each part.

- Reassemble:

- Reverse the disassembly steps.

- Double-check all connections and fastenings.

- Test Functionality:

- Run the equipment to ensure proper operation.

- Listen for unusual noises or performance issues.

By adhering to this structured guide, you can achieve the ultimate results in your repair efforts.

Benefits of Using OEM Parts

Choosing original equipment manufacturer components can significantly enhance performance and longevity. These parts are specifically designed to meet the exact specifications of the machinery, ensuring optimal functionality.

- Quality Assurance: OEM items undergo rigorous testing for durability and reliability.

- Perfect Fit: Designed to match the original specifications, ensuring seamless installation.

- Longevity: Built to last, reducing the need for frequent replacements.

- Warranty Protection: Often covered by manufacturer warranties, providing peace of mind.

- Resale Value: Using high-quality components can help maintain the equipment’s value over time.

Ultimately, investing in original components is a wise decision for maintaining equipment efficiency and reliability.

Upgrades for Enhanced Performance

Enhancing the efficiency of your lawn maintenance equipment can lead to improved results and a more enjoyable experience. Investing in the right upgrades not only boosts performance but also prolongs the lifespan of your machine. Here are several key modifications to consider for optimal results.

- High-Quality Blades: Upgrading to premium cutting blades can significantly improve cutting efficiency and provide a cleaner finish. Look for materials that resist wear and corrosion.

- Powerful Engine Add-ons: Enhancing engine performance through modifications such as air filters or exhaust systems can lead to better power output and fuel efficiency.

- Advanced Suspension Systems: Installing a superior suspension system can enhance stability and comfort during operation, reducing fatigue on uneven terrains.

- Smart Technology: Integrating smart technology, such as GPS tracking or automated height adjustment, can streamline your mowing tasks and improve precision.

- Better Tires: Upgrading to high-traction tires will enhance maneuverability and grip, making it easier to navigate various landscapes.

Each of these enhancements can contribute to a more effective and enjoyable maintenance routine, ensuring that your equipment performs at its best for years to come.

Resources for Mower Deck Diagrams

Finding reliable information for maintenance and repair tasks is essential for anyone looking to enhance the performance of their outdoor equipment. Various resources are available that can assist users in understanding the components and assembly of cutting machinery, ensuring they can troubleshoot effectively and conduct repairs with confidence.

Online forums and community groups serve as valuable platforms for sharing knowledge and experiences. Enthusiasts often post helpful guides, tips, and even visual aids that can clarify the intricacies of these machines. Additionally, many manufacturers provide detailed user manuals on their websites, which include exploded views and assembly instructions, allowing users to grasp the layout of the machinery more clearly.

Furthermore, dedicated websites specializing in equipment maintenance offer extensive libraries of diagrams and schematics. These resources often include downloadable files that can be printed for ease of reference during repairs. Video tutorials on popular platforms also demonstrate step-by-step processes, making it easier for users to visualize the tasks at hand.

Lastly, local repair shops can be an excellent source of information. Technicians often have experience with various models and may provide insights or even access to hard-to-find documentation. By leveraging these resources, users can ensure their equipment remains in optimal working condition.