When it comes to maintaining and repairing your outdoor machinery, having a clear understanding of its elements is essential. Knowing how each component interacts can significantly enhance your ability to troubleshoot and perform upgrades.

In this section, we will explore the intricate layout of various assemblies, allowing you to visualize their relationships. This knowledge not only simplifies repairs but also empowers you to make informed decisions when sourcing replacements or enhancements.

By delving into the specifics of each section, you will gain insights that lead to the ultimate efficiency in upkeep. This resource serves as a guide to ensure your machinery operates at its best for years to come.

Understanding Craftsman LT2000 Components

When exploring the intricate elements of a specific riding mower, it’s essential to grasp the various components that contribute to its functionality and efficiency. Each part plays a vital role, ensuring smooth operation and optimal performance.

Engine: The heart of the machine, providing the necessary power for movement and cutting tasks.

Transmission: This component manages the power transfer from the engine to the wheels, enabling speed control and maneuverability.

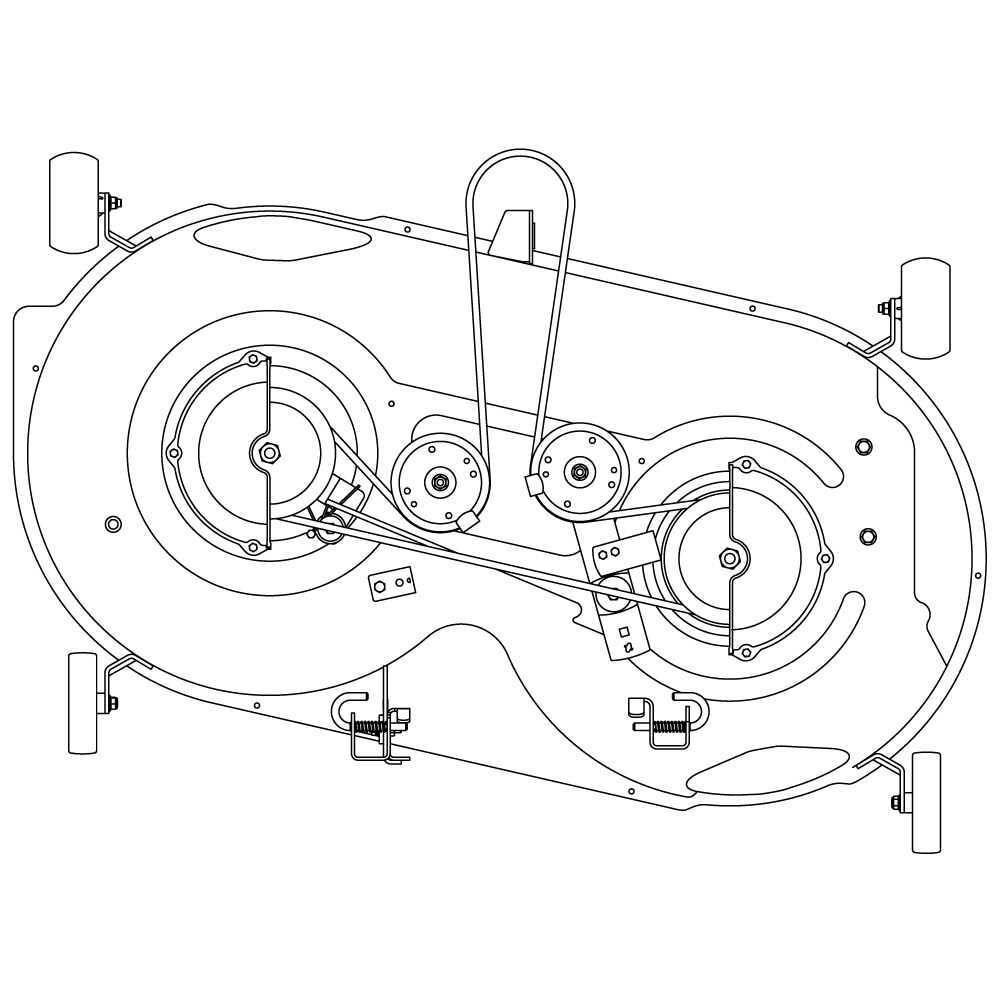

Deck: The cutting assembly that houses the blades, crucial for achieving a precise and clean cut on your lawn.

Wheels: These elements support the mower, facilitating easy navigation over various terrains while ensuring stability.

Controls: The interface for the operator, allowing for adjustments in speed, direction, and other essential functions.

By delving into these components, one can appreciate the ultimate design that enhances the overall mowing experience.

Importance of Accurate Parts Diagrams

Having precise schematics is crucial for the effective maintenance and repair of any machinery. They provide a clear visual representation of components, helping users understand how each piece fits together and functions within the system. This clarity not only facilitates troubleshooting but also ensures that replacements are executed seamlessly.

Moreover, reliable illustrations significantly reduce the risk of errors during repairs. When individuals can delve into detailed representations, they are less likely to misidentify components or overlook essential parts, leading to improved overall efficiency. In the long run, utilizing accurate visuals contributes to a longer lifespan for equipment and a higher satisfaction rate among users.

Common Issues with LT2000 Parts

Understanding frequent challenges associated with machine components is crucial for effective maintenance and operation. These issues can lead to decreased performance and potential breakdowns, impacting overall functionality.

Frequent Problems

Several common malfunctions often arise, including wear and tear, misalignment, and corrosion. These can affect various mechanisms, leading to inefficiencies or failures.

Preventive Measures

Regular inspections and timely replacements can mitigate many of these issues. Staying proactive helps ensure smooth operation and prolongs the lifespan of the machinery.

| Issue | Description | Solution |

|---|---|---|

| Wear | Components may degrade over time, affecting performance. | Regular checks and timely replacements. |

| Misalignment | Incorrect positioning can lead to operational inefficiencies. | Frequent alignment checks and adjustments. |

| Corrosion | Rust and corrosion can weaken parts. | Use protective coatings and proper storage. |

Finding Replacement Parts Online

Locating suitable components for your machinery can often be a daunting task. However, the internet provides a wealth of resources that simplify this process, allowing enthusiasts and professionals alike to maintain their equipment efficiently. With the right approach, you can ensure that you find exactly what you need with minimal effort.

Popular Online Resources

- Manufacturer Websites

- Specialized Retailers

- Marketplaces

- Forums and Community Groups

Tips for a Successful Search

- Use specific keywords related to the item you need.

- Check multiple sources for the best prices and availability.

- Read reviews to gauge the reliability of sellers.

- Consider second-hand options for cost savings.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and efficiency of your equipment. Implementing a consistent maintenance routine can significantly extend its lifespan and enhance performance, ultimately saving you time and money.

Regular Cleaning

- Remove debris and dirt after each use.

- Use appropriate cleaning solutions for different surfaces.

- Inspect filters and replace them as needed.

Periodic Inspections

- Check for loose or worn components regularly.

- Lubricate moving parts to reduce friction.

- Monitor fluid levels and replace as necessary.

By adhering to these practices, you can help ensure that your machinery operates at its peak for years to come.

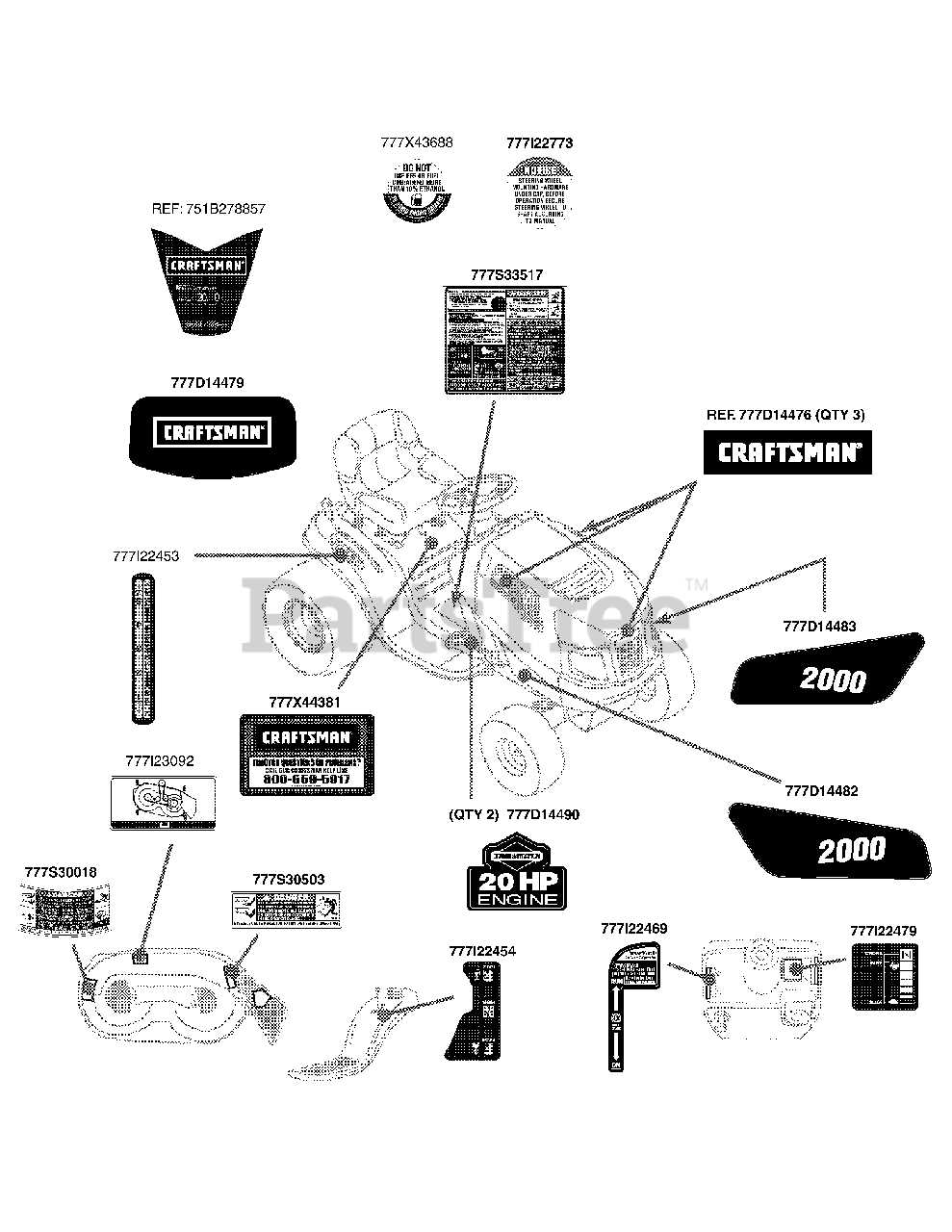

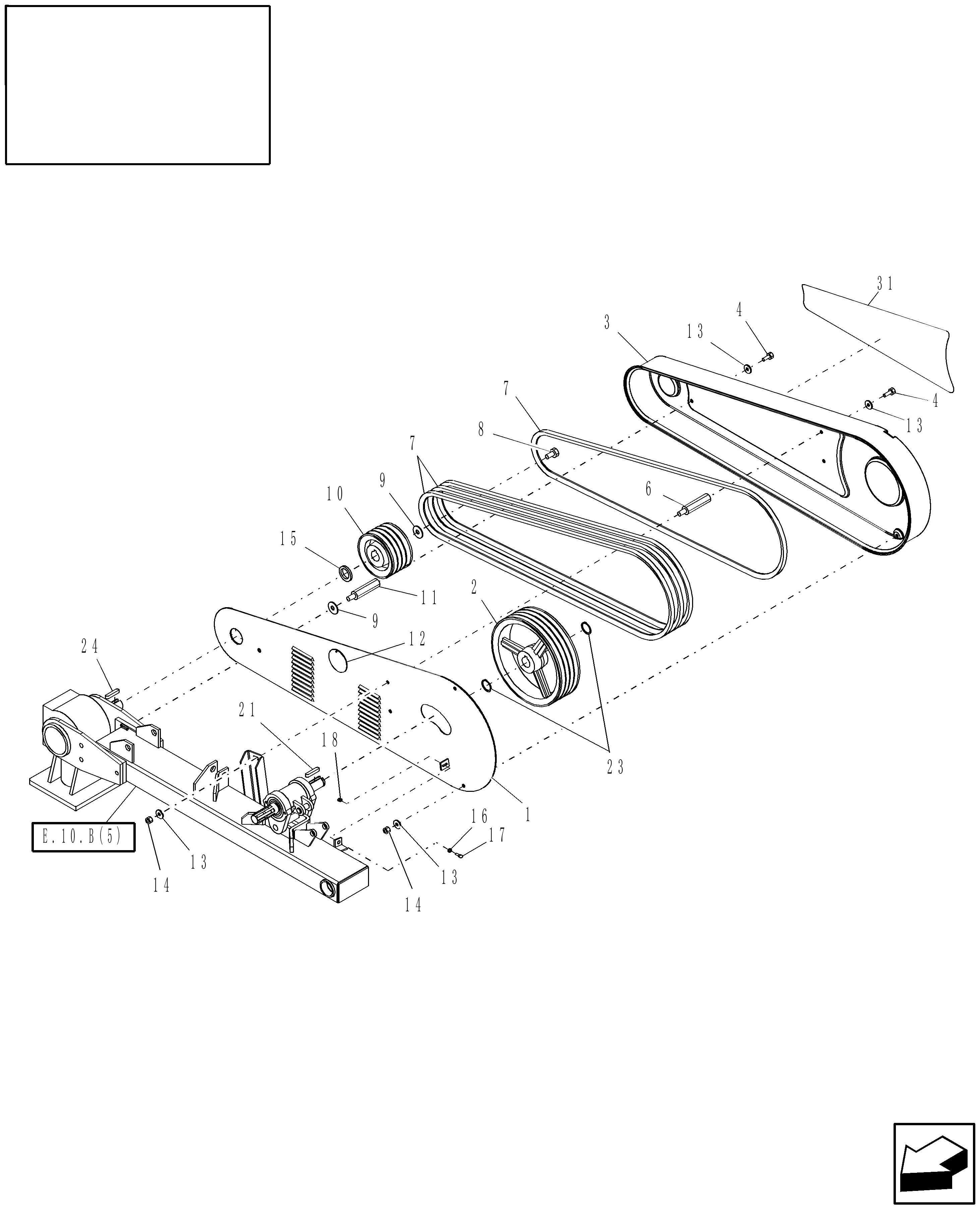

How to Read Parts Diagrams

Understanding visual schematics is essential for anyone looking to maintain or repair machinery. These illustrations provide a detailed view of components, their arrangement, and how they function together. Familiarity with these visuals can enhance your ability to identify necessary items and facilitate effective troubleshooting.

Key Elements to Identify

- Labels: Each part is usually marked with a unique identifier, often a number or letter. These correspond to a list that details specifications.

- Connections: Pay attention to lines and arrows that indicate how components link and interact with each other.

- Views: Diagrams may present multiple perspectives, such as top-down or side views, to give a comprehensive understanding of the layout.

Tips for Effective Interpretation

- Start with the Legend: Always check for a legend that explains symbols and notations used in the visual.

- Familiarize Yourself with Components: Knowing the function of each part will help you understand its role within the entire system.

- Cross-Reference: Use the identifiers found in the schematic with inventory lists to confirm availability.

- Take Your Time: Analyze each section methodically, ensuring you comprehend how each piece fits into the larger assembly.

Tools Needed for Repairs

When undertaking any repair task, having the right tools is essential for achieving optimal results. These instruments not only streamline the process but also enhance safety and efficiency. Below is a list of necessary equipment that can assist in any maintenance endeavor.

Essential Tools

- Screwdrivers (various sizes)

- Wrenches (adjustable and socket)

- Pliers (needle-nose and standard)

- Hammers (claw and rubber)

- Utility knife

Additional Equipment

- Measuring tape

- Torque wrench

- Multimeter for electrical diagnostics

- Workbench or sturdy surface

- Safety goggles and gloves

Equipping yourself with these tools will ultimately make repairs more manageable and effective.

Upgrading Your LT2000 Equipment

Enhancing your machinery can significantly boost its performance and longevity. Whether you’re looking to increase efficiency, improve functionality, or simply refresh the look, thoughtful upgrades can make a remarkable difference.

Consider focusing on key components that often wear out or could benefit from advancements in technology. Below is a table outlining potential enhancements and their benefits:

| Component | Upgrade Option | Benefits |

|---|---|---|

| Engine | High-performance variant | Increased power and efficiency |

| Deck | Reinforced material | Improved durability and cut quality |

| Wheels | All-terrain tires | Enhanced traction and stability |

| Controls | Upgraded steering system | Better maneuverability and comfort |

By delving into these options, you can ensure your equipment meets your needs and stands the test of time, leading to the ultimate satisfaction in its performance.

Customer Reviews and Experiences

This section explores the insights and opinions shared by users regarding their encounters with a specific brand of equipment. Feedback from customers provides valuable information about performance, reliability, and overall satisfaction, helping potential buyers make informed decisions. Reviews often highlight both positive experiences and areas for improvement, offering a well-rounded perspective on the product’s value.

Positive Feedback

Many users praise the durability and ease of use of the equipment. Common themes in their reviews include efficient performance, straightforward assembly, and excellent customer support. Here are some summarized points based on user testimonials:

| Feature | User Feedback |

|---|---|

| Durability | Consistently holds up under heavy use. |

| Ease of Use | Simple to operate, even for beginners. |

| Customer Support | Responsive and helpful service team. |

Areas for Improvement

Despite the positive remarks, some users have noted certain drawbacks. These often relate to specific components and maintenance requirements. Feedback highlights the following concerns:

| Issue | User Comments |

|---|---|

| Maintenance | Requires regular upkeep to maintain performance. |

| Part Availability | Occasional difficulty finding replacement components. |

| Noisy Operation | Some users reported louder than expected operation. |

Overall, the shared experiences paint a comprehensive picture that can guide potential purchasers in understanding what to expect from the equipment.