Keeping a lawn mower in optimal working condition requires knowledge about the individual elements that contribute to its performance. By familiarizing yourself with these various mechanisms, you can ensure smooth operation and timely repairs whenever necessary. Whether you’re dealing with routine maintenance or troubleshooting, understanding the inner workings of your machine is key to extending its lifespan.

Key mechanical elements in a lawn mower serve various functions that, when properly maintained, provide efficient and consistent cutting. From the engine to the smaller accessories, each piece plays a crucial role in the overall functionality of the equipment. Identifying and caring for these elements helps to avoid common issues and maintain peak performance.

Regular upkeep and replacing worn components can prevent larger problems from developing. It’s important to know which items need attention over time to keep your lawn mower running smoothly. In this guide, we’ll explore the essential elements of a typical model and how they contribute to the machine’s overall operation.

Understanding Key Components

Recognizing the individual elements of a lawn care tool is essential for proper maintenance and efficient operation. Each part has a specific role in ensuring the machine runs smoothly, and knowing these roles can help users address potential issues early on.

- Engine: The heart of the machine, responsible for powering the movement and cutting mechanisms.

- Blades: These sharp components are designed to trim grass with precision, ensuring a clean and even cut.

- Wheels: Provide stability and allow the tool to move smoothly over various terrains.

- Handle: The control point where the user steers and operates the machine.

- Fuel system: Supplies the engine with the necessary fuel for operation, ensuring it runs efficiently.

By understanding how these components work together, users can maintain the tool effectively and ensure long-term performance.

Importance of Parts Diagrams

Detailed schematics play a crucial role in understanding how different mechanical systems are structured and how components interact. They offer a clear visual representation of each element’s location, which simplifies the process of maintenance and repair.

Visual guides help users identify specific components quickly and accurately, saving time and reducing the likelihood of mistakes. These breakdowns are particularly useful for troubleshooting, ensuring that every step in disassembling or reassembling machinery is precise.

- Enhances clarity during repairs

- Minimizes the risk of errors

- Provides a quick reference for maintenance tasks

- Assists in identifying necessary components for replacement

Ultimately, using detailed technical illustrations streamlines the maintenance process and ensures equipment longevity by providing a reliable reference for both seasoned technicians and beginners alike.

Common Issues with M100 Parts

There are several frequent concerns that arise with various components of this model. These issues often stem from normal wear and tear, as well as environmental factors, which can lead to performance inefficiencies.

Engine Troubles

- Difficulty starting after extended periods of use

- Reduced power during operation, especially under load

- Overheating during prolonged activity, potentially caused by airflow obstruction

Blade Performance

- Blades becoming dull quicker than expected

- Unusual vibrations or noise while cutting

- Issues with the blade engaging or disengaging properly

To prevent these issues, regular maintenance and timely replacement of worn-out elements are crucial.

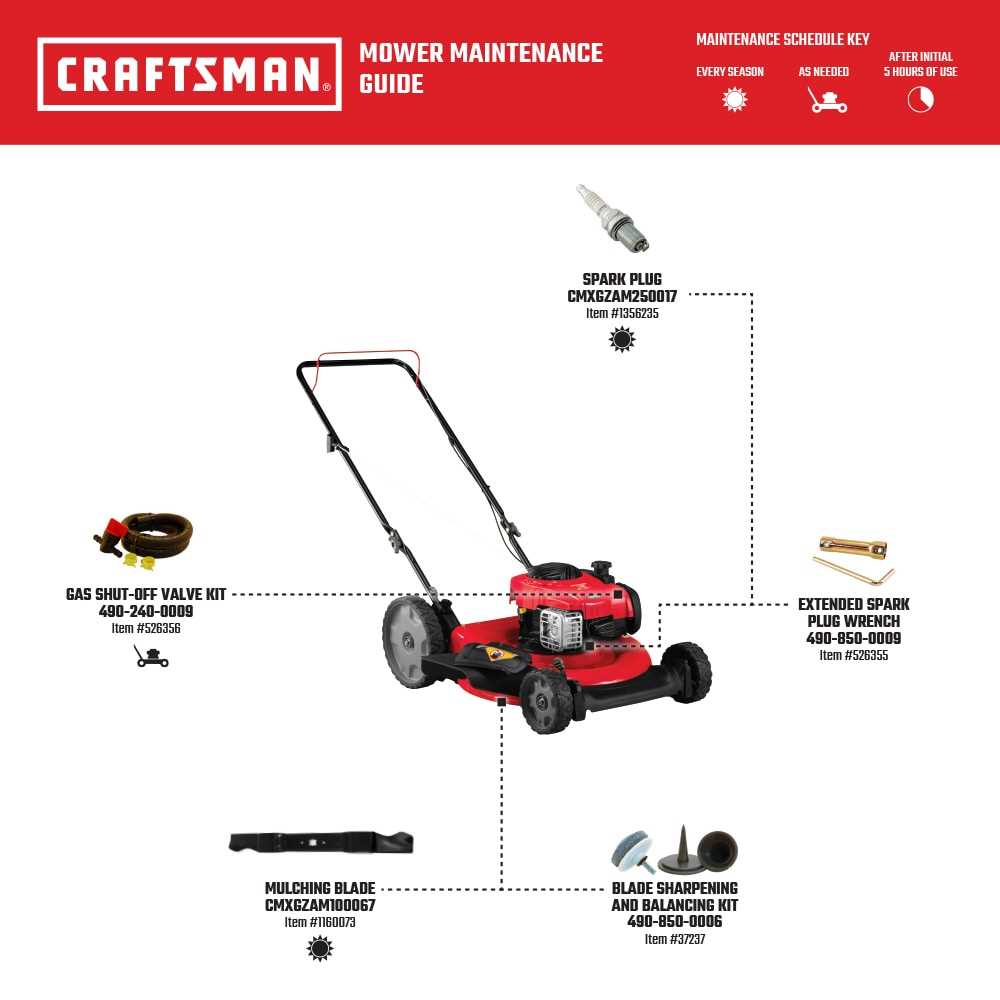

How to Identify Replacement Parts

Understanding the process of locating suitable components for your equipment is crucial for efficient maintenance and repair. Whether you are replacing a worn-out item or upgrading to enhance performance, knowing where to look and how to recognize the right piece is essential.

Check Model and Specifications

The first step in identifying the correct replacement is to verify the model and technical details of the equipment. These specifications often determine compatibility with different elements, ensuring the new component will function properly. Make sure to cross-reference these details with available options to avoid potential mismatches.

Examine Existing Components

Carefully inspecting the current component can provide vital clues about its replacement. Look for unique markings, numbers, or shapes that can help narrow down your search. Additionally, measure key dimensions such as length, width, or diameter to further ensure you select the correct replacement part.

Maintenance Tips for M100 Users

Regular upkeep of your equipment is essential to ensure optimal performance and longevity. By following simple care routines, you can avoid common issues and keep the machine functioning smoothly for years. Paying attention to key maintenance areas will prevent breakdowns and reduce the need for frequent repairs.

Regular Cleaning

After each use, it’s important to thoroughly clean all surfaces. Remove any debris or buildup that can interfere with proper operation. Keeping the equipment clean helps maintain its efficiency and prolongs the life of various components.

Lubrication and Inspection

Routinely lubricate moving parts to minimize friction and wear. Regularly inspect for any signs of damage or excessive wear to identify potential issues early. Timely intervention can prevent major malfunctions and ensure the system runs smoothly over time.

Where to Find Genuine Parts

Locating authentic components for your equipment is essential to ensure its longevity and reliable performance. Whether you’re replacing a worn-out item or upgrading a specific feature, knowing where to source the right elements is critical for keeping your machine in top condition.

Authorized Retailers

One of the most reliable options is purchasing from official retailers. These stores offer certified components that are specifically designed for your equipment, ensuring compatibility and durability.

- Physical stores with dedicated service centers

- Authorized online retailers

- Manufacturer’s official website

Specialized Repair Shops

Another option is visiting specialized repair shops that focus on maintaining similar types of machinery. They often carry genuine replacements and have expert knowledge to assist with proper selection and installation.

- Experienced technicians

- Guaranteed quality replacements

- Advice on long-term maintenance

Comparing M100 with Other Models

When analyzing the performance and features of this model, it’s essential to evaluate how it stands against other similar options in the market. By doing so, one can better understand the strengths and limitations, providing a clearer picture of what makes it stand out or blend in.

Performance and Efficiency

In terms of operational efficiency, this model offers competitive performance. However, comparing it to other options, you might notice differences in power output and ease of use. Certain alternatives may provide more advanced functionality, but this one excels in simplicity and reliability, making it a preferred choice for those seeking straightforward solutions.

Durability and Maintenance

When comparing the build quality, this model showcases robust construction, ensuring long-term usage. Yet, other models may offer additional features that enhance durability, such as reinforced materials or improved maintenance accessibility. Each model has its own advantages, but for basic upkeep and resilience, this one remains a strong contender.

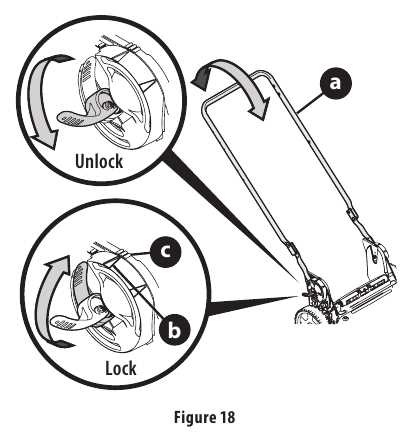

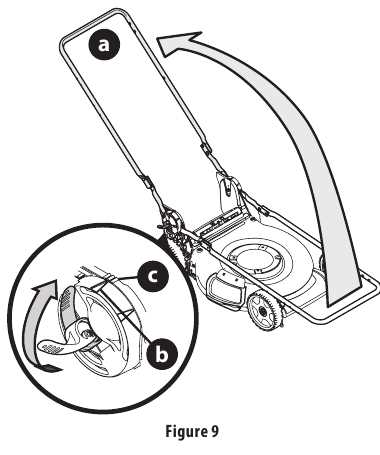

Assembly Process Explained

The assembly of outdoor equipment can seem daunting, but by following the right steps, it becomes a straightforward task. This section outlines a clear process to guide you through putting everything together efficiently.

Step-by-Step Instructions

- Start by organizing all necessary tools and components in a well-lit workspace.

- Refer to the instruction manual for any specific details regarding the arrangement of smaller elements.

- Begin with the main structural frame, ensuring all connections are secure before proceeding.

- Attach secondary components, such as handles or wheels, in the designated order.

- Double-check all fastenings for stability and adjust them as needed.

Final Adjustments

- Once the assembly is complete, inspect the entire setup for any loose fittings or misplaced components.

- Make sure all moving parts are functioning smoothly.

- Tighten any bolts or screws that may need extra attention after assembly.

By following these instructions carefully, you ensure that your equipment is properly assembled and ready for use.

Upgrading Features of Your Mower

In this section, we explore enhancing the capabilities and performance of your mower beyond its standard configuration. By modifying key components and optimizing operational settings, you can significantly improve efficiency and output quality. Let’s delve into practical upgrades that elevate the functionality and usability of this equipment.

Performance Enhancements

To boost cutting precision and overall performance, consider upgrading blade types and sharpening techniques. Efficient blade management ensures smoother operation and enhances grass cutting efficiency.

Operational Adjustments

Adjusting deck height settings optimizes cutting height, ensuring the mower adapts to various terrains effectively. This adjustment improves maneuverability and enhances the overall lawn maintenance experience.

| Upgrade blades | Sharpening techniques |

| Adjust deck height | Optimize cutting precision |