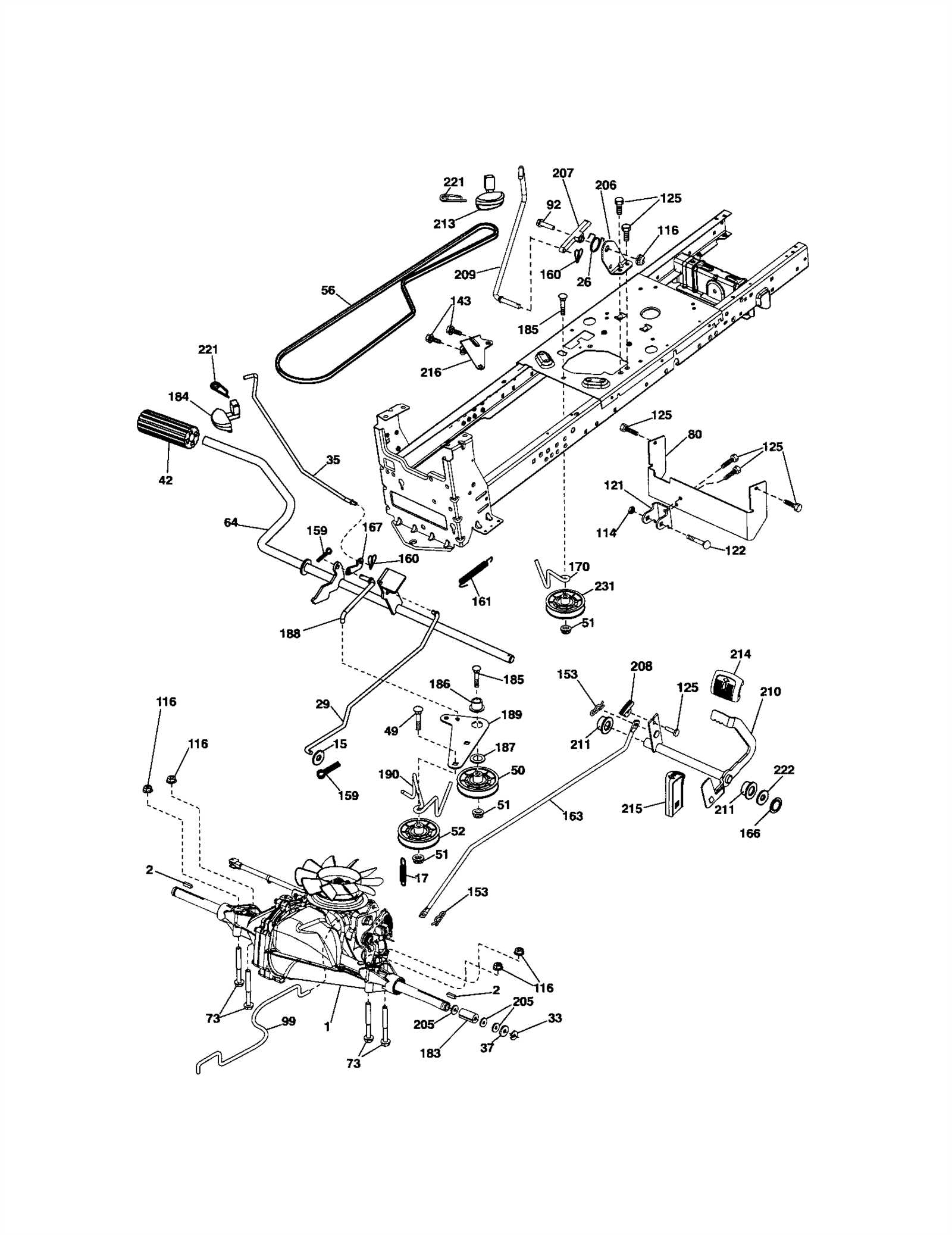

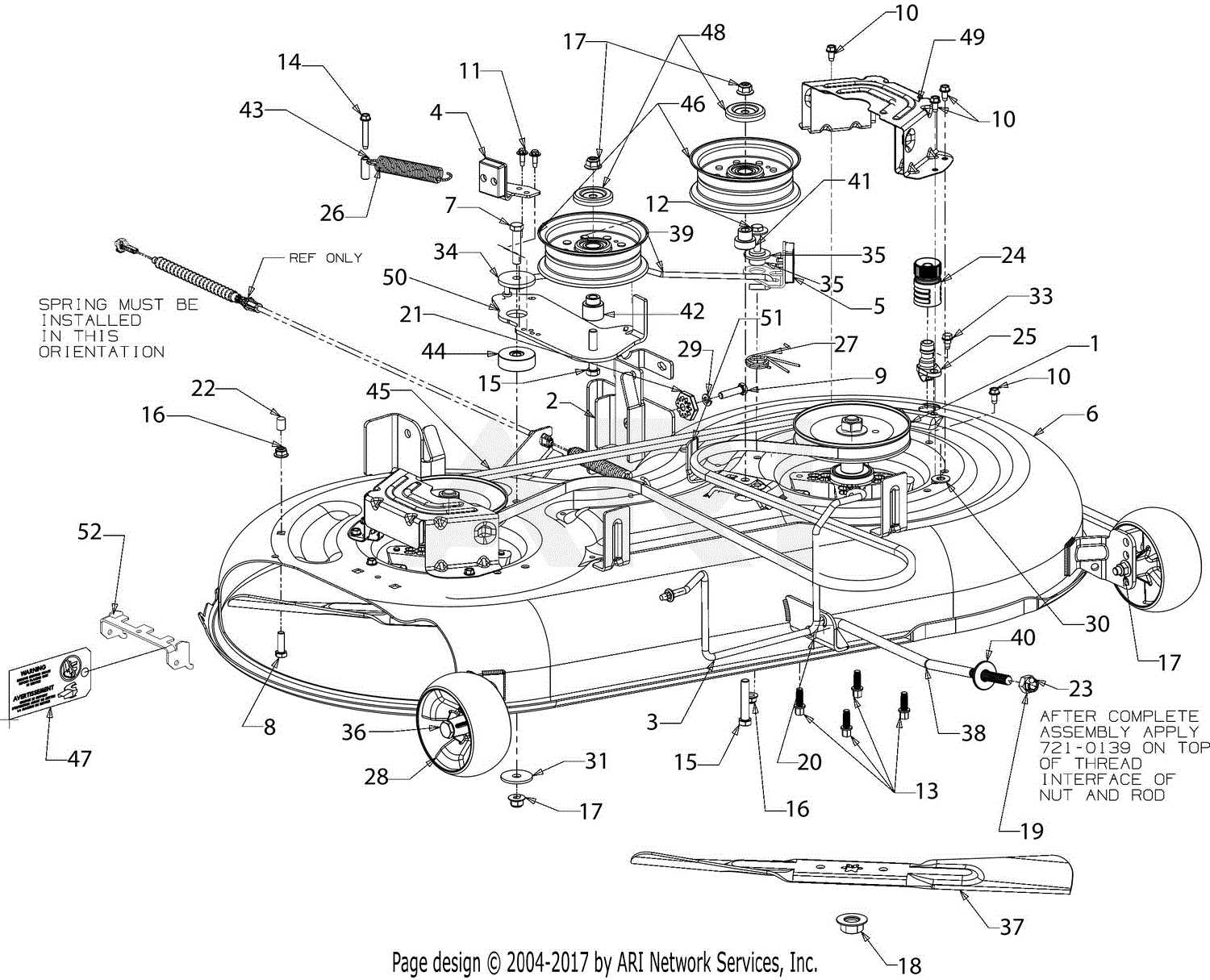

Maintaining lawn care machinery is essential for ensuring optimal performance and longevity. A comprehensive visual representation can significantly aid in identifying and understanding the various elements that make up these machines. By familiarizing yourself with the individual components, you can more effectively manage repairs and replacements as needed.

In this section, we will explore a detailed illustration showcasing the essential components of your equipment. This resource will serve as a valuable guide for both novice and experienced users, allowing for easier troubleshooting and maintenance. Gaining insight into the structure of your machinery will empower you to make informed decisions regarding repairs, thereby enhancing the overall efficiency of your gardening tasks.

Whether you’re looking to replace a worn-out part or simply want to deepen your understanding of your equipment’s mechanics, having access to a clear and informative reference can be incredibly beneficial. Equipped with this knowledge, you’ll be better prepared to tackle any issues that may arise and ensure your lawn care routine remains uninterrupted.

Understanding Craftsman YT3000 Components

Exploring the various elements of a lawn tractor reveals how each component plays a crucial role in its overall functionality. By gaining insights into these individual parts, users can enhance their understanding of maintenance, repair, and efficient operation.

Key Elements of the Tractor

- Engine: The powerhouse that drives the machine, providing the necessary energy for operation.

- Transmission: This component facilitates the transfer of power from the engine to the wheels, enabling movement.

- Chassis: The frame that supports all other components, ensuring structural integrity and stability.

- Deck: The section responsible for cutting grass, often featuring adjustable heights for various lawn types.

Maintenance Considerations

- Regularly check fluid levels to ensure optimal performance.

- Inspect belts and cables for wear and tear, replacing them as needed.

- Keep the cutting deck clean to maintain efficiency and prolong its lifespan.

Overview of Lawn Tractor Parts

This section provides a comprehensive look at the various components found in riding mowers, highlighting their functions and importance in maintaining optimal performance. Understanding these elements is essential for effective operation and maintenance.

Riding lawn mowers consist of several key components, each serving a specific role:

- Engine: The heart of the mower, providing the necessary power for operation.

- Transmission: Responsible for transferring power from the engine to the wheels, allowing for different speed settings.

- Deck: The area housing the cutting blades, designed for efficient grass cutting.

- Wheels: Essential for mobility, these components support the mower’s weight and facilitate movement across various terrains.

- Fuel System: Includes the tank and lines, ensuring the engine receives the right amount of fuel for operation.

- Steering Mechanism: Allows the operator to control the direction of the mower.

- Electrical System: Powers the lights, starter, and other electronic components.

Proper knowledge of these components can enhance the user experience and ensure the longevity of the machine.

Identifying Key Mechanisms in YT3000

This section delves into the essential components that constitute the operational framework of the machine. Understanding these critical elements aids in maintenance and troubleshooting, ensuring optimal performance. Each mechanism plays a significant role, and recognizing their functions can enhance user experience and reliability.

Core Components Overview

The following table outlines the main mechanisms, their functions, and common issues encountered. This structured representation facilitates quick reference for those seeking to understand the intricacies involved.

| Component | Function | Common Issues |

|---|---|---|

| Engine | Powers the entire system, providing necessary energy for operation. | Overheating, oil leaks, and starting difficulties. |

| Transmission | Transfers power from the engine to the wheels, enabling movement. | Slipping gears, unusual noises, and fluid leaks. |

| Steering Mechanism | Allows for directional control, essential for maneuverability. | Unresponsive steering, excessive play, and alignment issues. |

Importance of Regular Inspection

Routine checks of these mechanisms are vital for longevity and performance. Early detection of potential issues can prevent more significant problems down the line. Familiarity with each component not only enhances maintenance efforts but also empowers users to perform minor repairs confidently.

Maintenance Tips for Longevity

Ensuring the durability and efficient operation of your equipment requires regular upkeep and attention. Implementing a consistent maintenance routine can significantly extend the lifespan of your machinery while enhancing its performance. This section outlines key practices to keep your devices in optimal condition.

Regular Inspections

Frequent evaluations help identify wear and tear before it escalates into major issues. Pay attention to the following components:

- Check for loose connections or signs of damage.

- Inspect belts and hoses for cracks or fraying.

- Monitor fluid levels and replenish as needed.

Cleaning and Lubrication

Maintaining cleanliness and proper lubrication is essential for smooth operation. Follow these steps:

- Remove debris from air filters and cooling systems regularly.

- Use appropriate lubricants on moving parts to minimize friction.

- Wipe down surfaces to prevent rust and corrosion.

By adhering to these maintenance tips, you can ensure that your equipment operates effectively for years to come.

Common Issues and Solutions

When maintaining and operating outdoor machinery, users often encounter various challenges that can hinder performance and efficiency. Understanding these typical problems and their corresponding solutions can significantly enhance the longevity and functionality of equipment.

Engine Troubles

One of the most frequent issues is engine failure to start. This can be attributed to a variety of factors, including insufficient fuel, a clogged air filter, or a dead battery. To address this, check the fuel level and quality, replace or clean the air filter, and ensure the battery is charged and properly connected.

Cutting Performance Issues

Another common concern involves subpar cutting performance. This may arise from dull blades or improper height settings. Regularly inspect and sharpen the blades as needed, and verify that the cutting height is appropriately adjusted for the intended task. Timely maintenance can prevent further complications and ensure optimal results.

Parts Replacement Guidelines

Maintaining the efficiency and functionality of your equipment often requires timely substitutions of various components. Knowing when and how to replace these elements is crucial for ensuring long-term performance. This section provides essential recommendations to guide you through the replacement process.

When considering component substitution, adhere to the following guidelines:

- Identify the Component:

- Examine the malfunctioning part closely.

- Consult the owner’s manual for identification and specifications.

- Source Quality Replacements:

- Purchase from reputable dealers or authorized retailers.

- Verify compatibility with your specific model.

- Follow Manufacturer Instructions:

- Refer to the guidelines provided for correct installation.

- Ensure all necessary tools are available before starting.

- Test Functionality:

- After installation, perform thorough checks to confirm proper operation.

- Address any issues immediately to prevent further complications.

- Regular Maintenance:

- Schedule routine inspections to preemptively identify parts needing attention.

- Keep a record of all replacements for future reference.

By following these guidelines, you can ensure that your equipment remains in optimal condition, minimizing downtime and enhancing performance.

Where to Find Replacement Parts

Locating suitable components for maintenance or repairs can be essential for keeping your equipment running smoothly. Numerous resources are available for individuals seeking to replace worn or broken elements. From local retail outlets to online platforms, options abound for sourcing the necessary items efficiently.

Local Retail Stores: Many hardware and home improvement shops stock a variety of accessories that may meet your needs. Visiting these establishments allows you to consult with knowledgeable staff who can assist in identifying the correct items.

Online Retailers: The internet offers a vast selection of marketplaces where you can browse and purchase the required items from the comfort of your home. Websites specializing in outdoor equipment or general hardware often provide detailed descriptions to help you make informed decisions.

Manufacturer’s Website: The official site of the equipment’s manufacturer is an excellent starting point. They typically offer a catalog of available items, along with specifications, ensuring compatibility with your model.

Community Forums: Engaging with online communities dedicated to maintenance and repairs can provide valuable insights. Fellow enthusiasts often share their experiences, recommendations, and even links to trusted sellers where specific components can be obtained.

By exploring these avenues, you can enhance your chances of finding the ideal replacements to ensure the longevity and performance of your equipment.

Diagrams for Easy Assembly

Visual representations play a crucial role in facilitating the assembly process of various equipment. They serve as comprehensive guides that outline the relationships between components, ensuring a smoother and more efficient construction. Utilizing such illustrations can significantly reduce the time and effort required to put together intricate machinery.

Detailed visuals not only clarify the placement of individual elements but also help in identifying necessary tools and techniques. By following these schematics, users can effectively avoid common pitfalls, such as misalignment or improper fitting of components. This structured approach promotes confidence and accuracy during the assembly phase.

Furthermore, these guides can be invaluable for both novices and experienced individuals, providing a reference point that enhances understanding and mastery of the assembly process. Engaging with well-designed illustrations can transform a potentially challenging task into an accessible and rewarding experience.