In the world of gardening and landscaping, maintaining the health and productivity of soil is crucial. One essential tool that aids in this endeavor is a robust cultivator, designed to prepare and aerate the ground effectively. This section delves into the intricate components of this machinery, offering insights into its various elements and how they function together to enhance your gardening experience.

By familiarizing yourself with the internal structure and functionality of your cultivator, you can better understand its operation and maintenance. This knowledge not only empowers you to perform routine checks but also assists in identifying any potential issues that may arise over time. Moreover, having a clear view of the individual components can simplify the process of repairs and replacements, ensuring your machine remains in peak condition.

Here, we will explore a detailed representation of the essential elements involved in the operation of this equipment. Understanding these components will enhance your ability to troubleshoot and optimize performance, allowing you to cultivate your garden with confidence and ease.

Overview of Craftsman Tiller Model 917

This section provides a comprehensive look at a specific gardening implement designed for soil preparation. The equipment is known for its robust performance and user-friendly features, making it an essential tool for both novice and experienced gardeners. Understanding its components and functionality can greatly enhance its usage and maintenance, ensuring that the device operates efficiently for years to come.

Key Features and Functionality

The implement is equipped with a powerful engine, allowing it to tackle various soil types and conditions. Its adjustable depth settings enable users to customize their gardening tasks according to the specific requirements of different plants. Additionally, the ergonomic design ensures comfort during operation, reducing fatigue and making it easier to maneuver through garden spaces.

Maintenance and Care

Regular upkeep is crucial for maintaining the efficiency of this equipment. Routine checks on the engine, tines, and belts can prevent potential issues and extend the lifespan of the implement. Keeping the machine clean and properly lubricated will ensure optimal performance, making gardening tasks more enjoyable and less time-consuming.

Key Components of Tiller Design

The efficiency and functionality of a gardening machine rely heavily on its essential elements. Understanding these components can enhance both performance and maintenance, ensuring optimal results in the garden. Each part plays a vital role in the overall operation, from the engine to the cutting mechanism, contributing to the machine’s effectiveness in soil cultivation.

1. Power Source

The heart of any gardening equipment is its engine, which provides the necessary energy for operation. Whether it’s a gasoline or electric unit, the power source dictates the machine’s capabilities and efficiency. A robust engine enhances performance, enabling it to handle various soil types and conditions effectively.

2. Cutting Mechanism

At the forefront of soil preparation, the cutting system is designed to break up and aerate the ground. This mechanism typically consists of rotating blades or tines that dig into the earth, facilitating soil turnover. The design and arrangement of these components significantly influence the depth and quality of tilling, making them crucial for successful gardening.

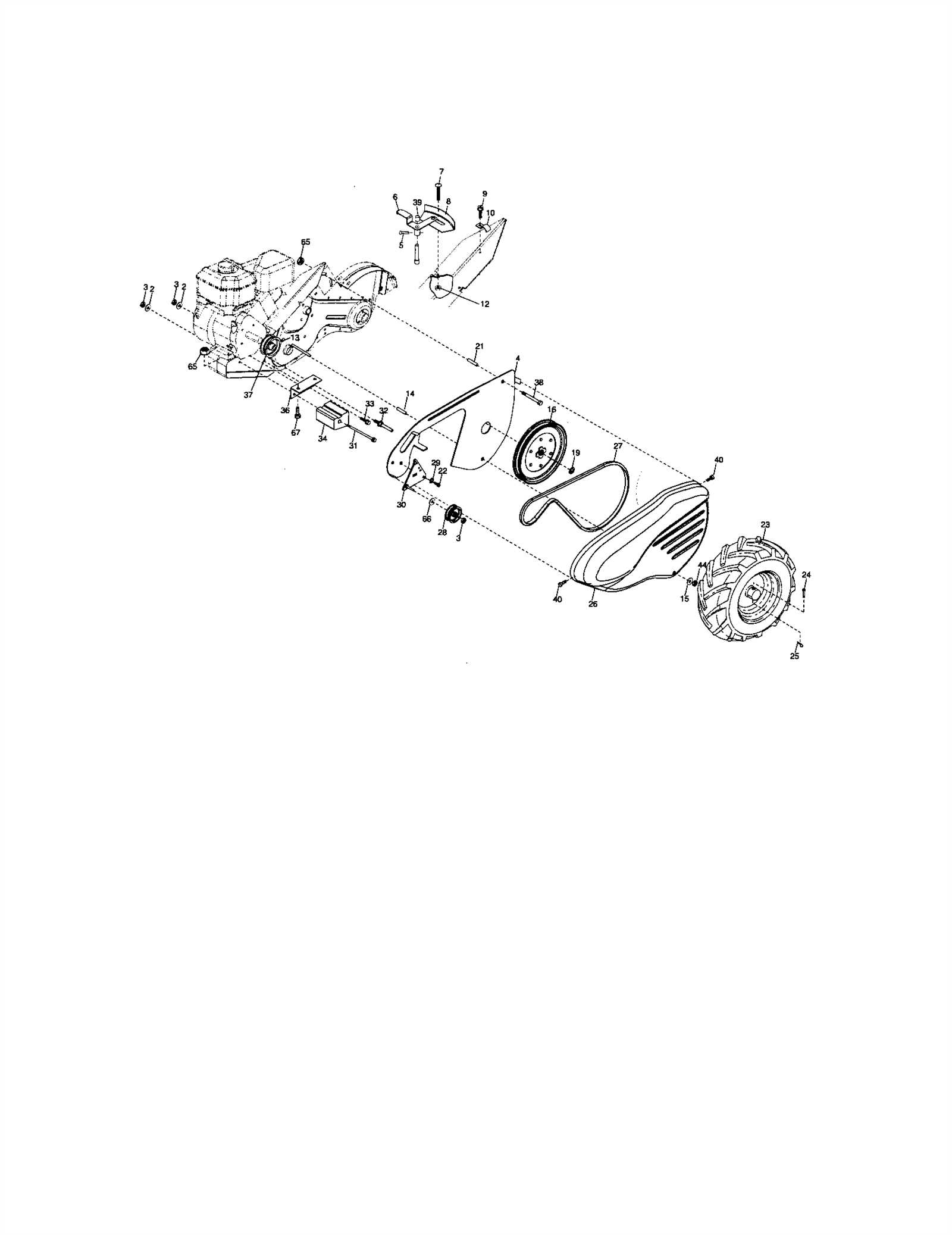

Understanding the Parts Diagram

A visual representation of components is essential for anyone looking to comprehend the structure and functionality of a piece of equipment. These illustrations offer a detailed overview, highlighting each element’s role and interrelation, thus facilitating efficient repairs and maintenance.

Analyzing the schematic allows users to identify individual components quickly, understanding how they contribute to the overall performance. It serves as a valuable reference, ensuring that any replacement or adjustment can be made with precision, ultimately enhancing the longevity and effectiveness of the machinery.

Moreover, a thorough grasp of this illustration can prevent potential errors during assembly or disassembly. Familiarity with the layout not only streamlines the repair process but also empowers users to troubleshoot issues more effectively. Understanding these visuals is a crucial step toward mastering equipment care and ensuring optimal operation.

Common Issues with Tiller Models

Operating a soil cultivation device can present a range of challenges that users may encounter over time. These issues can arise from various factors, including mechanical wear, improper maintenance, or environmental conditions. Understanding these common problems can help users effectively address them, ensuring efficient performance and prolonged lifespan of the equipment.

Mechanical Failures

One frequent issue involves mechanical failures that can hinder functionality. Common signs of these failures include unusual noises, vibrations, or a lack of responsiveness when in operation. Identifying the root cause often requires inspection of the internal components and their connections.

Fuel and Engine Problems

Another prevalent category of issues relates to fuel and engine performance. Users might experience difficulties with starting or maintaining engine operation, often due to fuel quality or blockage in the fuel system. Regular checks and maintenance of the fuel system can mitigate these concerns.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Unresponsive Operation | Worn belts or connections | Inspect and replace faulty components |

| Engine Starting Problems | Poor fuel quality | Use high-quality fuel and check filters |

| Excessive Vibration | Loose or damaged parts | Tighten or replace damaged components |

Replacing Parts on Craftsman Tillers

Maintaining your gardening equipment in optimal condition is crucial for its performance and longevity. When components wear out or become damaged, timely replacement can prevent further issues and enhance functionality. Understanding how to effectively swap out these elements is essential for any enthusiast looking to keep their equipment running smoothly.

Before embarking on the replacement process, it’s important to gather the necessary tools and new components. Referencing the owner’s manual can provide valuable insights into the specifications required for each element. Ensure you have a clean workspace and all the needed tools at hand, such as wrenches, screwdrivers, and safety gear.

When replacing a specific component, start by disconnecting the power source to ensure safety. Carefully remove any covers or shields to access the area in question. Take note of how the original component is installed, as this will guide you during reassembly. Once you have the damaged item removed, install the new component by following the reverse steps, ensuring everything is securely fastened.

After installation, it’s advisable to check the functionality of the equipment before putting it back into regular use. Conduct a brief test run to confirm that the new component operates as intended. Regular checks and timely replacements can significantly enhance the efficiency and reliability of your gardening machinery.

Maintenance Tips for Optimal Performance

Regular upkeep is essential for ensuring the longevity and efficiency of your gardening equipment. By following a few straightforward guidelines, you can enhance its functionality and prevent potential issues. Consistent care will not only prolong the life of your machine but also improve its performance during use.

Routine Checks

- Inspect the fuel system for leaks or damage.

- Check the oil level and replace it as needed to maintain smooth operation.

- Examine the air filter and clean or replace it to ensure proper airflow.

- Look for loose or worn belts and tighten or replace them as necessary.

Seasonal Maintenance

- At the start of each season, thoroughly clean the machine to remove dirt and debris.

- Sharpen or replace cutting tools to ensure effective performance.

- Inspect all moving parts for wear and lubricate them to reduce friction.

- Store the equipment in a dry place to prevent rust and deterioration during off-seasons.

By adhering to these maintenance strategies, you can significantly improve the efficiency and durability of your gardening tools, ensuring they remain in peak condition for years to come.

Tools Required for Repairs

Effective maintenance and restoration of equipment necessitate a variety of instruments. Having the right tools on hand can significantly simplify the repair process, ensuring that each task is executed efficiently and accurately. Below are essential tools that every technician should consider when addressing issues related to this type of machinery.

Essential Hand Tools

- Wrenches: Various sizes to fit different bolts and nuts.

- Screwdrivers: Both flathead and Phillips for different screw types.

- Pliers: Useful for gripping, twisting, and cutting wires or small parts.

- Socket Set: For loosening and tightening fasteners with ease.

- Hammer: Helpful for gentle persuasion and aligning parts.

Specialized Tools

- Torque Wrench: Ensures that bolts are tightened to the correct specifications.

- Multimeter: Assists in diagnosing electrical issues by measuring voltage, current, and resistance.

- File Set: For smoothing edges and fitting parts together.

- Grease Gun: Necessary for lubricating moving components.

- Diagnostic Tools: For checking engine performance and troubleshooting issues.

Having these tools readily available can enhance the repair process, making it smoother and more efficient. Proper maintenance ensures longevity and optimal performance of the equipment.

Where to Find Replacement Parts

Locating the necessary components for your gardening equipment can enhance its performance and longevity. Whether you are repairing or upgrading, it’s essential to know where to source reliable and compatible items. Here are some effective methods to help you find what you need.

| Source | Description |

|---|---|

| Manufacturer’s Website | Visit the official site of the brand for direct access to original components and resources. |

| Authorized Dealers | Check with local dealers who specialize in your equipment; they often have genuine items in stock. |

| Online Retailers | Explore various e-commerce platforms that offer a wide range of aftermarket and OEM selections. |

| Local Repair Shops | Consult local repair centers that may carry or can order the specific components you require. |

| Online Marketplaces | Utilize marketplaces to find new or used items from various sellers at competitive prices. |

| Community Forums | Join gardening or equipment forums where members often share resources and recommendations. |

Benefits of Using a Tiller

Employing a soil cultivation machine offers numerous advantages for both amateur and professional gardeners. This powerful tool enhances the efficiency of soil preparation, making it easier to cultivate and enrich the earth. By loosening the ground, it promotes healthier plant growth and ensures better yields.

Enhanced Soil Aeration

One of the primary benefits of utilizing a soil cultivation machine is improved aeration. This process involves breaking up compacted soil, allowing air, water, and nutrients to penetrate deeper. Enhanced aeration leads to:

- Stronger root development

- Increased microbial activity

- Improved drainage

Time and Labor Savings

Another significant advantage is the reduction in time and effort required for gardening tasks. Traditional methods can be labor-intensive, but a mechanized approach streamlines the process. This efficiency results in:

- Faster land preparation

- Less physical strain on the user

- More time to focus on planting and maintaining plants