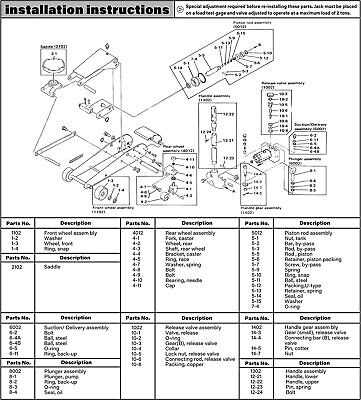

When working with heavy machinery or performing maintenance tasks, having the right equipment to lift and secure vehicles is essential. A reliable tool is indispensable for lifting loads safely and efficiently. The various elements of these tools play a crucial role in ensuring functionality and durability. Familiarity with each component’s function and how they interact can greatly enhance both performance and safety during usage.

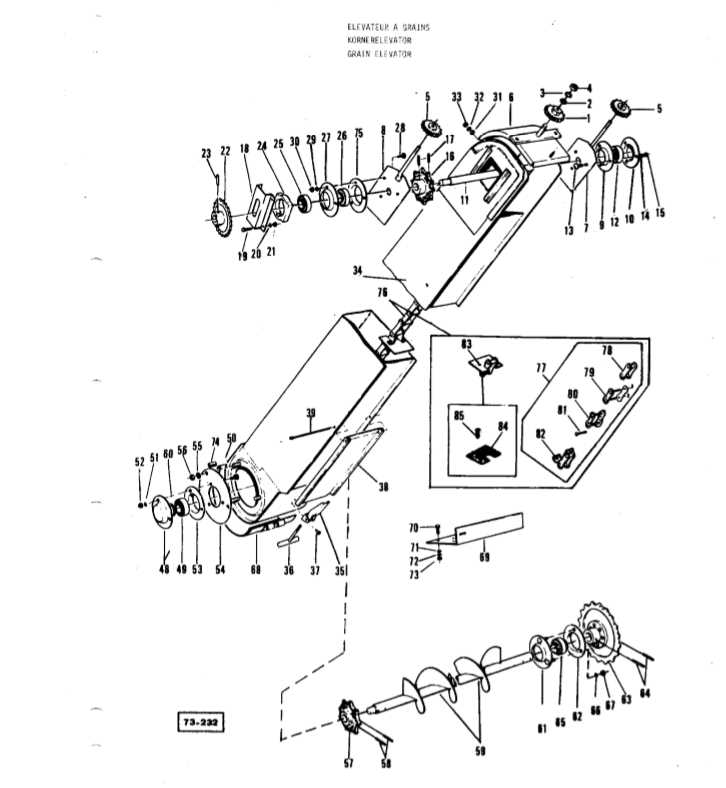

Exploring the individual components and their arrangement helps users understand how to maintain and troubleshoot these devices. With an intricate system of hydraulics, levers, and supports, it is vital to have a clear overview of how each part works together. Whether replacing a worn-out piece or making adjustments, a thorough knowledge of these systems will lead to smoother operations and extend the lifespan of the tool.

Having access to a visual guide that illustrates the layout of each element is particularly beneficial. Such a reference not only aids in identifying parts but also in understanding their specific roles within the entire system. Properly maintaining and assembling the device with attention to each detail will ensure effective and safe use over time.

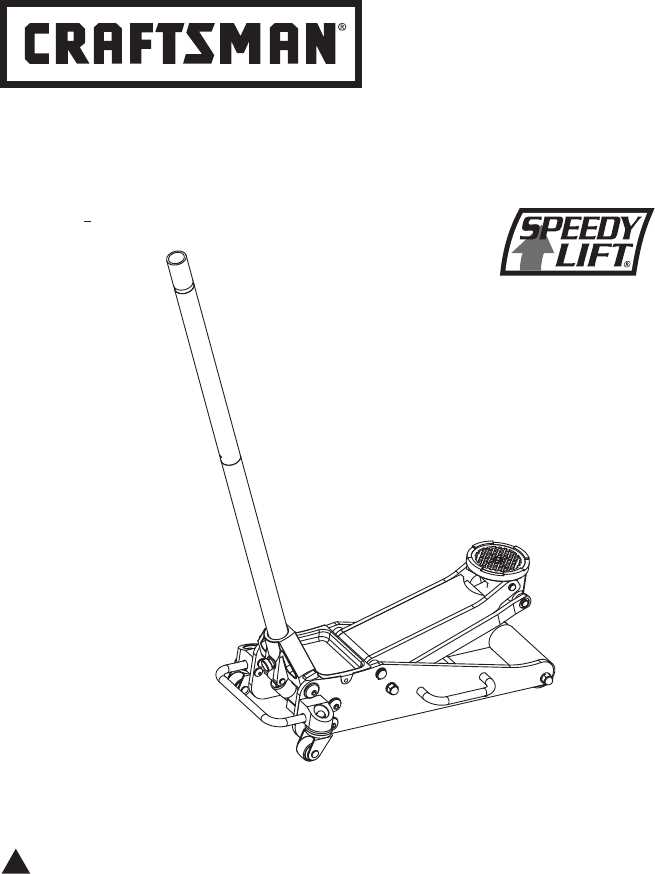

Overview of Craftsman 2 Ton Floor Jack

The equipment discussed here is designed for lifting heavy loads with ease and precision, ensuring smooth and efficient operation in various mechanical and automotive tasks. Its sturdy construction and reliable hydraulic system make it an indispensable tool for those who require a dependable solution for raising vehicles or other heavy objects. Built with user-friendly features, it offers enhanced stability and durability, ideal for both professional and home garage use.

With its compact design, the tool is both portable and easy to store, making it convenient for quick usage when needed. The high-quality materials used in its build ensure long-lasting performance, while its ergonomic handle offers comfort during operation. Whether for routine maintenance or emergency situations, this device stands as a go-to solution for those who prioritize safety and efficiency in their lifting tasks.

The functionality of this lifting apparatus is further supported by its advanced mechanisms, which help users achieve the required lifting height effortlessly. Its versatility allows for a broad range of applications, making it a popular choice among individuals working on cars, trucks, and other equipment. It not only improves workflow but also reduces manual labor involved in heavy lifting.

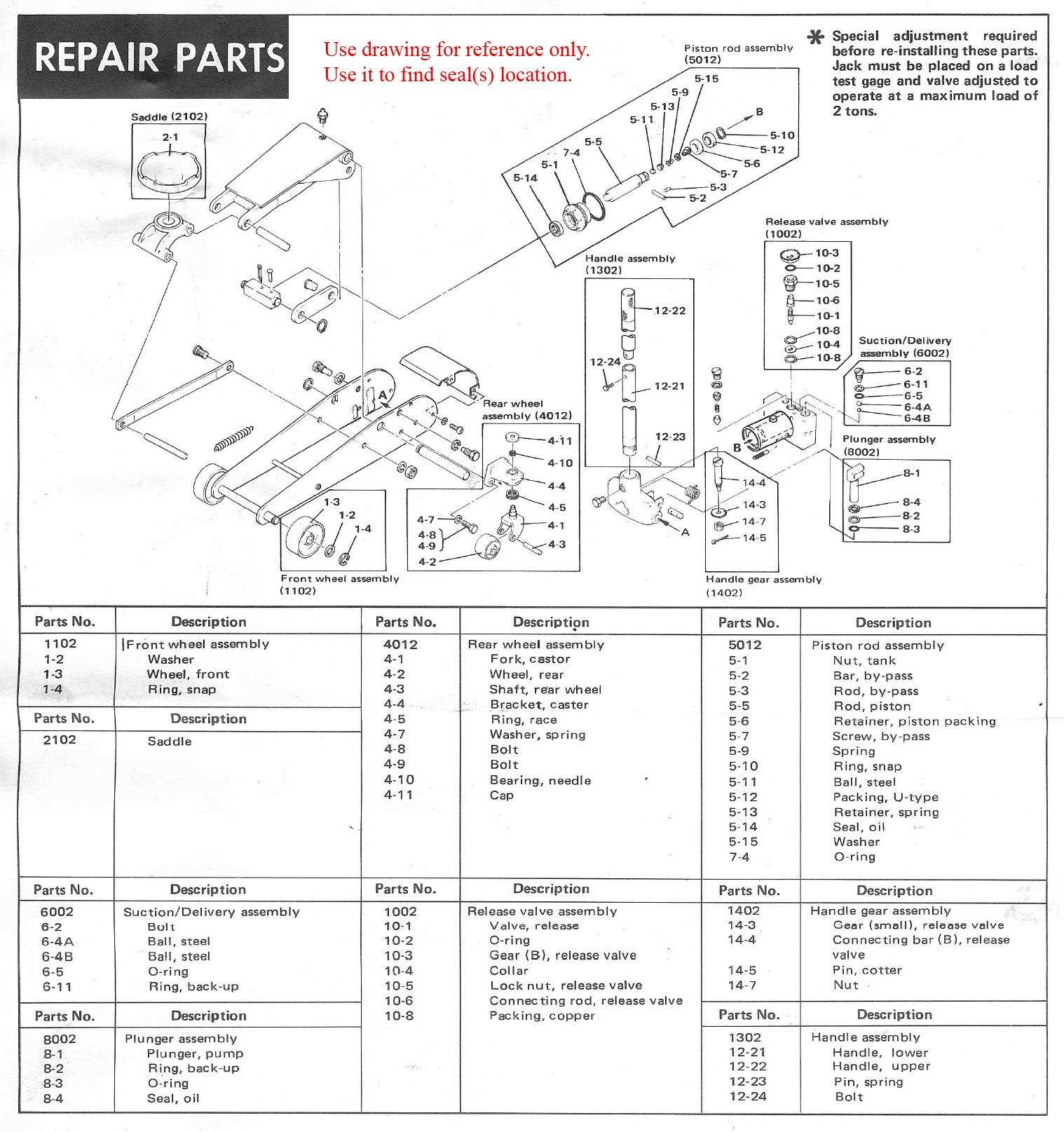

Key Components of the Floor Jack

When working with lifting equipment, understanding the essential elements that make up its functionality is crucial. Each tool is designed with several integral components that contribute to its overall performance and safety. By recognizing these parts, users can ensure optimal operation and maintenance of their equipment.

Hydraulic Pump Mechanism

The hydraulic pump is responsible for generating the pressure required to lift heavy objects. This system converts manual force into hydraulic energy, allowing the device to elevate its load effortlessly. It plays a critical role in ensuring the efficiency and strength of the lifting action.

Lifting Arm and Saddle

The lifting arm, often equipped with a saddle, is the component that directly interacts with the load. The saddle serves as a stable platform that supports the item being raised, while the arm moves upward and downward to adjust the height. Together, these parts provide stability and control during the operation.

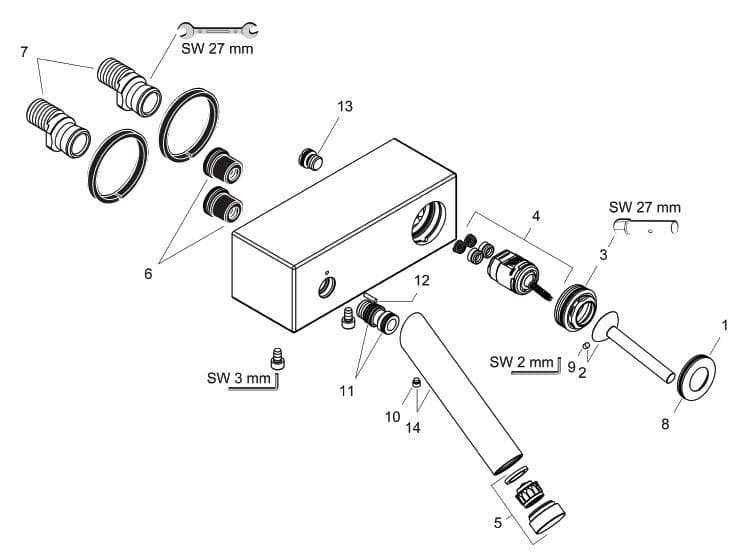

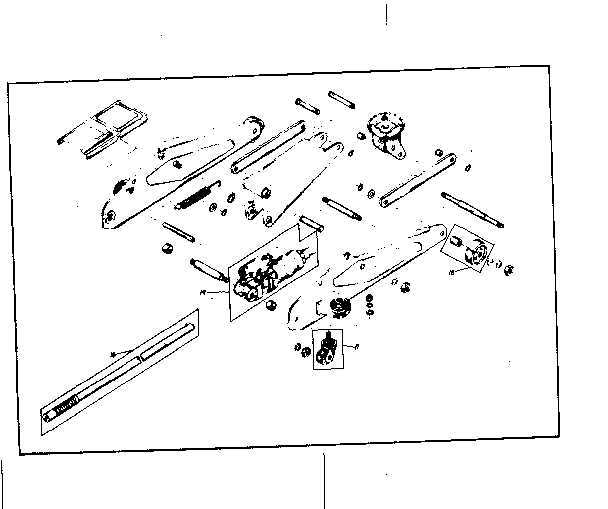

Step-by-Step Assembly Instructions

Assembling mechanical equipment can seem like a daunting task, but with careful attention to detail and proper organization, the process becomes straightforward. This guide will walk you through each stage of the assembly, ensuring that you are equipped to complete it efficiently and safely. The following steps will help you understand how to put together the essential components without confusion.

Preparation

Before starting the assembly, make sure you have all the necessary tools and components at hand. Check that each element is free from damage and is appropriate for the assembly. Follow these preliminary steps:

- Ensure you have a clean, level surface to work on.

- Lay out all the components to confirm nothing is missing.

- Gather essential tools, such as wrenches, screws, and lubricants, if needed.

- Review the manual to familiarize yourself with the process ahead.

Assembly Procedure

Follow these sequential steps to complete the assembly process:

- Begin by attaching the base frame to the primary structure. Ensure it is aligned properly and all screws are tightened securely.

- Proceed to mount the lifting mechanism, aligning the gears or hydraulic units as indicated in the manual. Tighten all connections firmly.

- Next, install the support arms. These should be fastened tightly to avoid any wobbling or misalignment during operation.

- Attach any additional components, such as handles or safety locks, according to the instructions. Double-check that all moving parts function smoothly.

- After all major components are assembled, test the mechanism to ensure it operates correctly. If necessary, adjust any parts to ensure smooth movement.

Once these steps are completed, you should have a fully assembled unit ready for use. Always remember to follow safety guidelines to ensure proper operation and longevity of the equipment.

Common Issues and Repair Solutions

When working with hydraulic lifting equipment, certain problems may arise that can hinder performance or lead to malfunction. Understanding common issues and knowing how to troubleshoot and repair them is essential for maintaining the equipment’s functionality and ensuring safety. Below are some of the most frequent problems encountered, along with their potential solutions.

- Leaking Fluid: A common issue is hydraulic fluid leakage, often due to worn seals or damaged hoses. If you notice a puddle of fluid underneath the equipment, inspect the seals and hoses for any visible cracks or holes.

- Equipment Not Lifting Properly: If the equipment fails to lift or raises slowly, this could be a sign of low hydraulic fluid or air trapped in the system. Ensure the fluid levels are adequate and bleed the air if necessary.

- Unsteady Lifting: If the load is not stable during the lift, it may indicate an issue with the piston or the alignment of the components. Check for debris or damage that may be causing uneven movement.

- Difficulty in Lowering: If the equipment doesn’t lower smoothly, the release valve may be clogged or damaged. Inspect and clean the valve or replace it if needed.

- Noisy Operation: Excessive noise during operation may indicate insufficient lubrication or worn-out internal components. Lubricate moving parts and check for signs of wear or damage.

Regular maintenance and prompt attention to these common issues can extend the life of the equipment and ensure that it functions safely and efficiently. In some cases, replacing faulty components or repairing specific sections may be necessary to restore optimal performance.

Craftsman Jack Maintenance Tips

To ensure the longevity and optimal performance of your lifting equipment, regular upkeep is essential. Proper maintenance not only enhances functionality but also promotes safety during use. This guide provides practical advice for maintaining your equipment in peak condition, helping you avoid costly repairs and ensuring reliability in any task.

Regular Inspection

Routine inspections are crucial to identify potential issues before they become major problems. Check the following components regularly:

- Check for visible signs of wear or damage on all moving parts.

- Inspect the hydraulic system for leaks or irregularities.

- Ensure all bolts and fasteners are tightened and secure.

- Look for any rust or corrosion, which can weaken the structure.

Lubrication and Fluid Checks

Proper lubrication and fluid maintenance are key to smooth operation. Follow these steps:

- Apply grease to all moving parts, including pivots and bearings, to prevent friction and wear.

- Check the hydraulic fluid level regularly and refill as necessary with the correct type of fluid.

- Clean out any debris or buildup in the system to avoid clogs and ensure efficient performance.

Choosing the Right Replacement Parts

When maintaining or repairing lifting equipment, selecting the appropriate components is crucial to ensure safety, efficiency, and long-term reliability. Incorrect replacements may lead to operational issues or even compromise the safety of the device. It is important to consider key factors before deciding which items to use in your maintenance projects.

Key Factors to Consider

- Compatibility: Ensure that the component is designed to fit the specific model and brand. This will prevent improper functioning or damage to other parts.

- Durability: Choose components made from high-quality materials that can withstand the stresses and pressures of regular use.

- Manufacturer Specifications: Refer to the original specifications for accurate sizing and functionality requirements.

- Cost vs. Quality: While it can be tempting to opt for cheaper alternatives, prioritize long-term performance and safety over short-term savings.

Where to Find Reliable Replacements

- Official manufacturers or certified dealers often provide the best quality components.

- Authorized repair centers may offer a range of suitable options and can help ensure compatibility with your equipment.

- Online marketplaces and specialized websites may have quality alternatives, but always verify the reputation of the seller.

How to Safely Operate Your Jack

Operating a lifting tool correctly is crucial to ensure both personal safety and the proper functioning of the equipment. Understanding the basic steps and precautions will help prevent accidents and equipment damage. Proper handling and careful attention to instructions can make a significant difference in ensuring a smooth and secure operation.

Before beginning, always inspect the device to ensure that it is in good condition and free from any visible damage. Using an unmaintained or faulty tool can lead to serious consequences. Additionally, be sure to position the device on a flat, stable surface, as uneven ground can cause the equipment to malfunction.

| Step | Action | Safety Tip |

|---|---|---|

| 1 | Place the equipment on a solid, even surface. | Never use on soft or uneven ground to avoid tipping. |

| 2 | Check the lifting mechanism for damage. | Ensure that there are no cracks, leaks, or missing parts. |

| 3 | Carefully raise the load with a controlled motion. | Never lift a load too quickly or without proper support underneath. |

| 4 | Release the load slowly and evenly once the task is complete. | Avoid sudden drops to prevent damaging the load or the tool. |

Following these basic guidelines will help ensure a smooth and safe lifting experience. Proper training and awareness of your surroundings are key to preventing accidents while using this equipment.

Warranty and Customer Support Information

When purchasing any equipment, understanding the warranty coverage and available support services is essential for a smooth ownership experience. This section provides details on the guarantee provided by the manufacturer, as well as how to access assistance should issues arise with your tool. The warranty ensures that you are protected against manufacturing defects for a specified period, while customer support is always ready to assist with troubleshooting, repairs, or inquiries.

- Warranty duration: Typically, the manufacturer offers a multi-year warranty for defects in materials or workmanship.

- Exclusions: Certain conditions, such as misuse or accidental damage, may not be covered by the warranty.

- How to claim: You may contact customer support either by phone or online. Proof of purchase and serial numbers might be required.

- Repair services: In case of malfunction, the tool may be repaired, replaced, or refunded, depending on the situation.

If you have any issues or need assistance with your equipment, the manufacturer’s customer support team is available to guide you through the process. Detailed instructions for returning or exchanging items are often provided on the manufacturer’s website or through customer service representatives.

- Phone support: Accessible during business hours to answer questions and facilitate warranty claims.

- Online support: Visit the official website to chat with a representative or find detailed troubleshooting guides and FAQs.

- Authorized service centers: For more severe repairs or replacements, the manufacturer may direct you to certified repair centers for service.