When it comes to maintaining and operating a versatile cutting tool designed for elevated tasks, understanding its individual components is crucial. Each element plays a significant role in ensuring the overall functionality and efficiency of the equipment. Familiarity with these parts can enhance performance and aid in troubleshooting issues that may arise during use.

Exploring the various sections and elements of this cutting implement reveals how they work in harmony to deliver effective results. From the motor assembly to the cutting mechanism, each part contributes to the tool’s ability to handle various tasks with ease. Moreover, knowing how these components fit together can assist in identifying replacement options when repairs are needed.

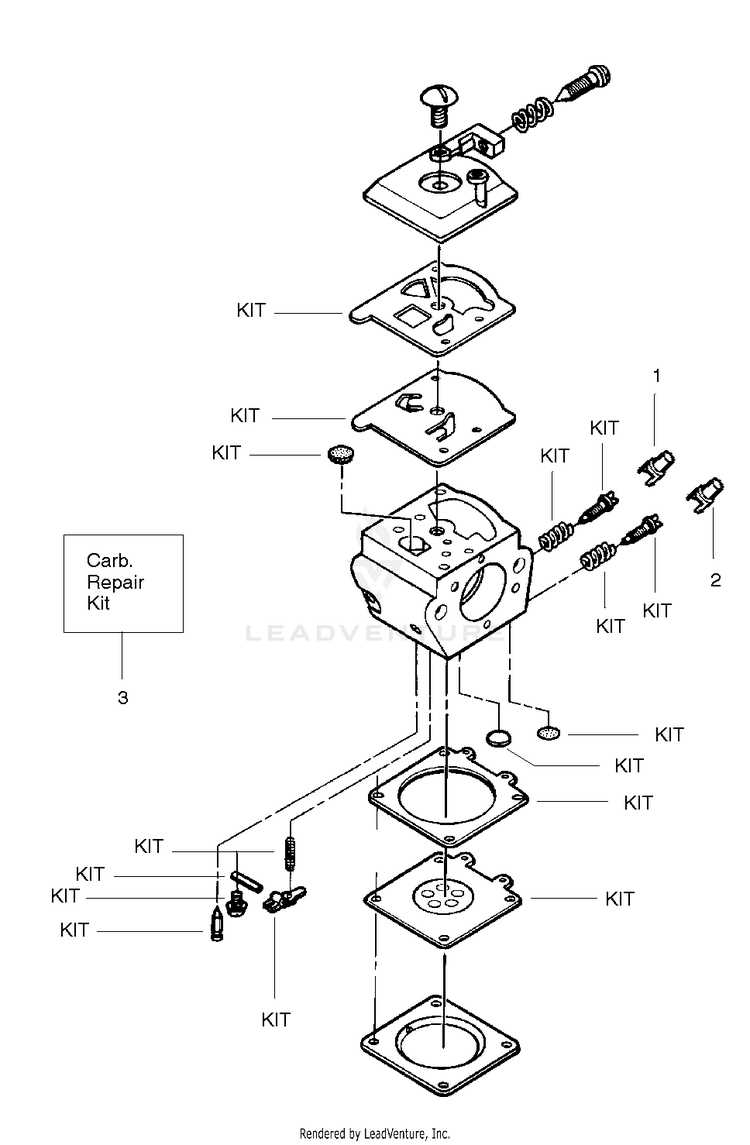

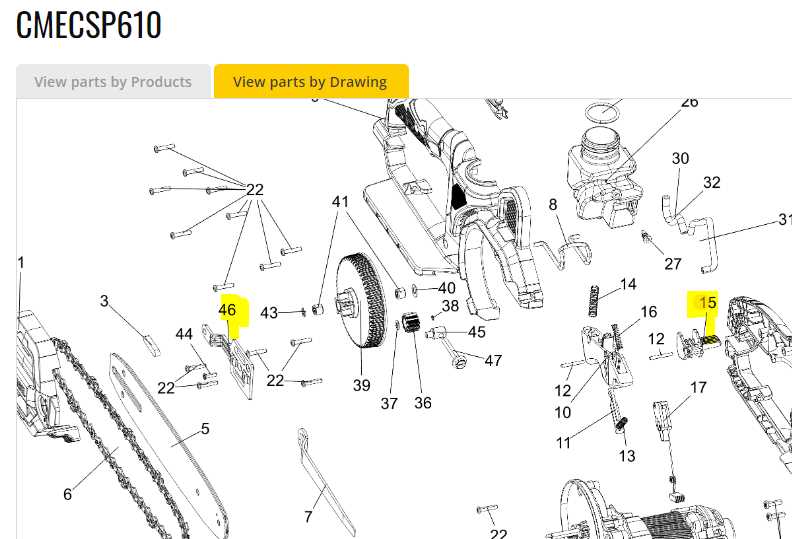

For those who appreciate hands-on maintenance, a visual reference showcasing the arrangement and connection of these parts is invaluable. This resource not only simplifies the repair process but also empowers users to optimize the tool’s capabilities, ensuring it remains a reliable ally for all cutting endeavors.

Understanding Craftsman Pole Saw Components

This section aims to explore the essential elements that make up a cutting tool designed for reaching high branches and trimming foliage. Familiarity with these components can enhance maintenance, improve functionality, and aid in troubleshooting. Each part plays a significant role in the overall performance and safety of the equipment.

| Component | Description |

|---|---|

| Power Unit | The engine or motor that provides the necessary energy to operate the device. |

| Extension Shaft | A lengthened rod that allows the user to reach greater heights without the need for a ladder. |

| Cutting Head | Houses the cutting mechanism, including blades or chains designed for efficient trimming. |

| Handle | Offers a grip for maneuvering and controlling the tool during operation. |

| Safety Guard | A protective cover that minimizes the risk of accidental contact with the cutting mechanism. |

| Fuel Tank | Stores the fuel required for combustion engines, ensuring uninterrupted operation. |

Identifying Key Parts in Diagrams

Understanding the essential components illustrated in schematics is crucial for effective maintenance and repair tasks. By familiarizing oneself with the visual representation of elements, users can efficiently troubleshoot issues and perform necessary replacements. Recognizing each segment’s role enhances comprehension and enables users to follow assembly instructions accurately.

| Component | Description |

|---|---|

| Handle | The grip area that allows for easy maneuverability and control. |

| Power Unit | The engine or motor that drives the mechanism for operation. |

| Cutting Mechanism | The assembly responsible for executing the cutting action. |

| Safety Guard | A protective cover designed to minimize accidental injuries during use. |

| Adjustment Knob | A feature that allows users to modify settings for optimal performance. |

How to Use the Parts Diagram

Understanding the layout and components of your tool is essential for effective maintenance and repairs. A visual representation can serve as a valuable resource, allowing users to identify individual elements and their functions. By familiarizing yourself with this resource, you can enhance your ability to troubleshoot issues and replace components when necessary.

Identifying Components

The first step in utilizing the visual representation is to become acquainted with the various elements it showcases. Each section typically includes labeled illustrations that detail the specific parts and their respective locations. This can aid in recognizing components you may need to address, whether for routine upkeep or repairs.

Planning Repairs and Maintenance

Once you can identify the elements, you can effectively plan your maintenance or repair tasks. Referencing the illustration will help you understand which components require attention. Additionally, it can guide you in sourcing the correct replacements and ensure that you follow the proper procedures for disassembly and reassembly.

| Component Name | Function |

|---|---|

| Blade | Responsible for cutting through material |

| Handle | Provides grip and maneuverability |

| Motor | Drives the cutting mechanism |

| Safety Guard | Protects the user from debris |

Common Issues with Pole Saw Parts

Maintaining outdoor cutting tools can sometimes lead to challenges that require attention. Various components of these devices may encounter issues that affect their performance and longevity. Understanding these common problems can aid in ensuring efficient operation and extending the life of your equipment.

1. Wear and Tear: Over time, exposure to harsh conditions can lead to deterioration of various elements. Regular inspection is essential to identify signs of fatigue or damage that may impact functionality.

2. Improper Alignment: Misalignment of critical components can result in reduced efficiency and increased strain on the mechanism. Ensuring proper alignment can prevent premature failure and enhance performance.

3. Lubrication Issues: Insufficient lubrication can lead to increased friction and overheating. Regularly checking and applying the appropriate lubricant is vital for smooth operation and to avoid excessive wear.

4. Debris Accumulation: The build-up of dirt and debris can obstruct moving parts, leading to operational difficulties. Regular cleaning helps maintain optimal performance and reduces the risk of malfunctions.

5. Electrical Failures: For models with electric components, issues like short circuits or faulty wiring can arise. Regular inspection of electrical systems is crucial to ensure safety and reliability.

6. Fuel System Problems: In gasoline-powered devices, issues with fuel lines or carburetors can lead to starting problems or inefficient operation. Regular maintenance of the fuel system is essential for reliable performance.

Maintenance Tips for Your Saw

Ensuring the longevity and efficiency of your cutting tool requires regular upkeep and attention. Implementing proper care techniques not only enhances performance but also guarantees safety during operation. Below are essential practices to keep your equipment in optimal condition.

Routine Checks

- Inspect blades regularly for signs of wear or damage.

- Clean the cutting edges after each use to remove debris and sap.

- Check all fasteners and connections to ensure they are secure.

Lubrication and Storage

- Apply appropriate lubricants to moving parts to minimize friction.

- Store the tool in a dry, sheltered area to prevent rust and deterioration.

- Ensure the storage environment is clean and organized to avoid accidental damage.

Replacement Parts: What You Need

When maintaining outdoor equipment, understanding the components that may require replacement is essential for optimal performance. Regular inspections can help identify worn or damaged elements that impact functionality. Knowing which items to look for can save time and ensure efficient operation.

Key components often needing replacement include:

- Blades or cutting elements

- Battery or power source

- Drive belts

- Filters for air intake

- Handles and grips for comfort

- Safety guards

Before purchasing replacements, it is advisable to consult the user manual to verify compatibility. Ensuring you have the right specifications can prevent issues during installation and usage. Consider sourcing components from reputable suppliers to guarantee quality and durability.

In summary, staying informed about the essential components of your equipment can enhance its longevity and performance. Regular maintenance and timely replacements are key to effective outdoor work.

Assembly Instructions for Craftsman Models

This section provides essential guidance for properly assembling various models in this product line. Clear instructions ensure that users can efficiently put together the components for optimal performance and safety. Following these guidelines will facilitate a smoother assembly process and enhance the overall experience.

Preparation Steps

- Gather all necessary tools, such as wrenches and screwdrivers.

- Ensure that all components are available by reviewing the provided list.

- Work in a clean, well-lit environment to prevent misplacement of parts.

Assembly Process

- Begin by attaching the main body to the supporting framework, securing it with bolts.

- Connect the handle components, ensuring they align properly.

- Install the safety features, including guards and triggers, to prevent accidental operation.

- Check all connections for tightness and stability before proceeding.

- Finally, perform a test to verify functionality and make any necessary adjustments.

Benefits of Knowing Your Equipment

Understanding the components and functionality of your tools is crucial for effective maintenance and optimal performance. This knowledge not only enhances your ability to use them efficiently but also extends their lifespan. By familiarizing yourself with the intricate details, you can make informed decisions about repairs and upgrades, ultimately ensuring that your investments serve you well for years to come.

Improved Safety

Familiarity with your equipment promotes a safer working environment. Recognizing how each part functions allows you to identify potential hazards and address them proactively. This awareness reduces the likelihood of accidents, ensuring that you can operate your tools with confidence.

Enhanced Efficiency

When you know the ins and outs of your machinery, you can maximize productivity. Understanding the correct usage of each component enables you to execute tasks more effectively and efficiently. This not only saves time but also enhances the quality of your work, allowing you to achieve better results with less effort.

Where to Find Replacement Components

Finding suitable replacements for your outdoor equipment can be essential for maintaining performance and ensuring longevity. Several avenues exist for sourcing these components, whether through authorized retailers, online marketplaces, or local hardware stores.

Here are some reliable options to consider:

| Source | Description | Benefits |

|---|---|---|

| Authorized Dealers | Official retailers that provide genuine components. | Quality assurance and manufacturer support. |

| Online Marketplaces | Websites such as Amazon or eBay offering various components. | Convenience and often competitive pricing. |

| Local Hardware Stores | Nearby shops that carry a range of equipment parts. | Immediate availability and personalized assistance. |

| Specialized Repair Shops | Shops focusing on repair and replacement of outdoor tools. | Expert advice and potentially custom solutions. |

By exploring these resources, you can ensure that your equipment remains functional and efficient.