When working with any machinery or tools, having a clear understanding of their individual components is crucial for effective maintenance and repair. Knowing how different elements fit together can simplify troubleshooting and enhance the longevity of your equipment.

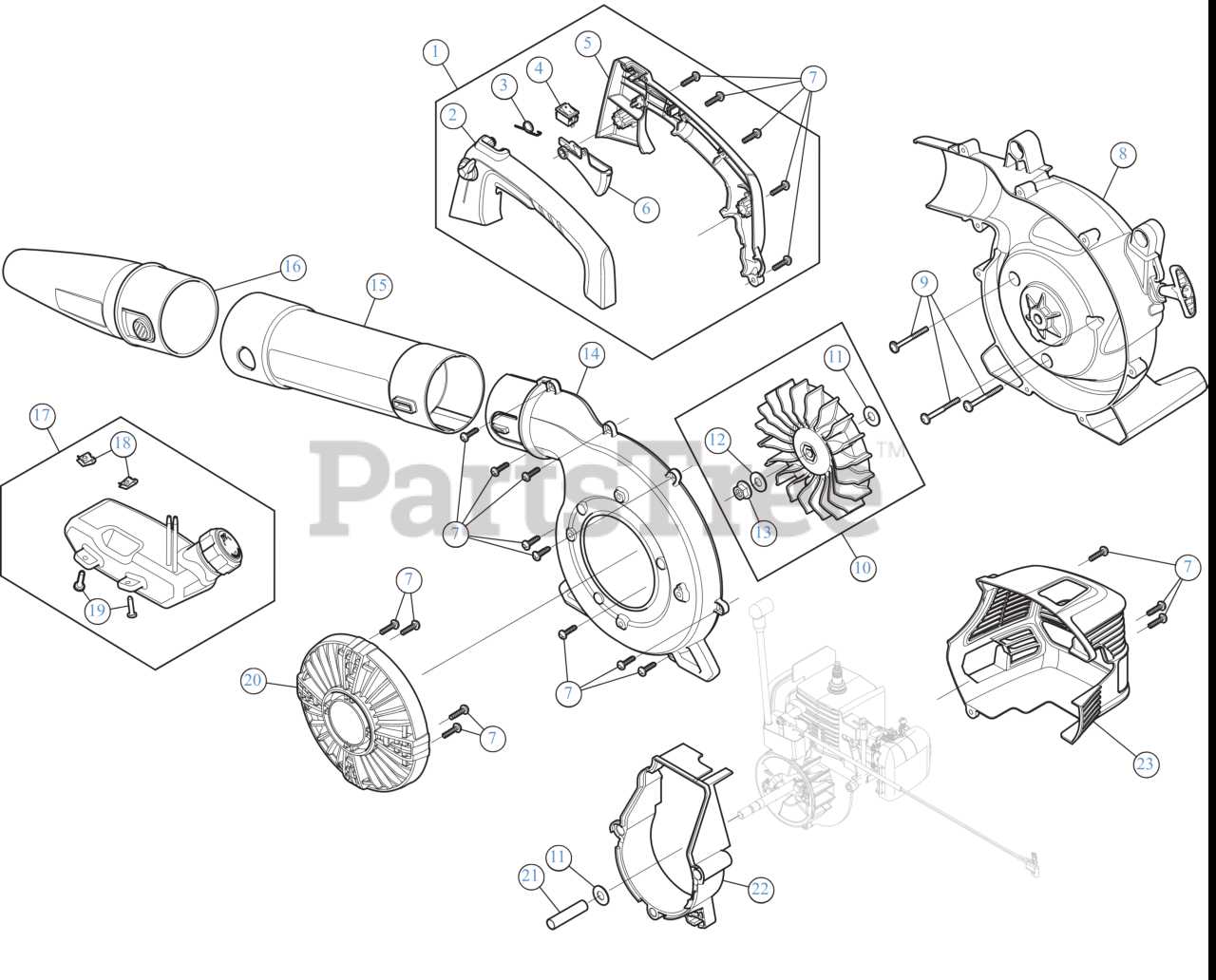

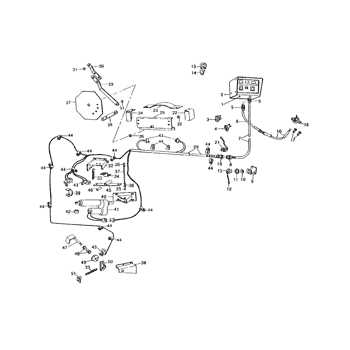

Visual representations of these essential parts serve as valuable guides, allowing users to pinpoint specific areas that may require attention. These schematics not only illustrate how various elements interconnect but also aid in identifying compatible replacements and upgrades.

In this article, we will explore detailed layouts that provide insight into the construction of your device, making it easier to navigate through repairs and improvements. Understanding these configurations will empower you to tackle challenges with confidence and ensure your tools perform at their best.

Understanding Craftsman T2500 Components

This section aims to provide insights into the essential elements of a specific machine model, focusing on their functions and interactions. Each component plays a crucial role in the overall performance and efficiency of the device, and understanding these parts can greatly enhance maintenance and troubleshooting efforts.

Key Elements of the System

Among the various segments, the engine stands out as the powerhouse, responsible for converting fuel into mechanical energy. Coupled with the transmission, it ensures the smooth transfer of this energy to the wheels, facilitating movement. Additionally, the frame acts as a supportive structure, housing and protecting the internal components, while also providing stability during operation.

Maintenance Considerations

Regular upkeep of these individual elements is vital for longevity and optimal performance. For instance, routine checks of the ignition system and fuel lines can prevent potential failures. Furthermore, understanding the role of belts and pulleys in the drive mechanism is essential for ensuring that power is efficiently transmitted throughout the apparatus.

By familiarizing oneself with the intricate details of each segment, operators can not only enhance their operational knowledge but also improve the reliability of the entire system.

Importance of Parts Diagrams

Visual representations of components play a crucial role in the maintenance and repair of machinery. They provide clarity on how various elements interact, facilitating efficient troubleshooting and assembly. Understanding these visuals can significantly enhance the user experience and ensure longevity of the equipment.

| Benefits | Description |

|---|---|

| Clarity | Helps in understanding complex systems. |

| Efficiency | Reduces time spent on repairs and maintenance. |

| Accuracy | Ensures correct reassembly and part identification. |

| Guidance | Serves as a reference for both novices and experts. |

Common Issues with T2500 Parts

When working with various mechanical components, users often encounter specific challenges that can hinder performance and efficiency. Understanding these issues is crucial for maintaining optimal functionality and ensuring longevity of the equipment.

Wear and Tear

Over time, regular usage can lead to significant deterioration. Components may experience wear, resulting in decreased efficiency. Regular inspections can help identify early signs of damage, allowing for timely replacements.

Compatibility Problems

Using non-compatible elements can lead to operational failures. It is essential to ensure that replacements match the required specifications. Double-checking compatibility will save time and prevent future complications.

How to Read Parts Diagrams

Understanding technical illustrations is essential for anyone involved in maintenance or repair tasks. These visual representations serve as guides, showcasing the components and their arrangement within a machine. By mastering the interpretation of these images, you can enhance your efficiency and accuracy when working on various projects.

Here are some key steps to effectively analyze these illustrations:

- Familiarize Yourself with Symbols: Many illustrations use specific symbols to represent various elements. Learning these symbols will aid in quickly identifying parts.

- Identify Key Components: Focus on the main elements depicted in the illustration. Usually, these are labeled clearly, helping you understand their function within the overall system.

- Pay Attention to the Layout: The arrangement of components often indicates how they interact with each other. Look for connections or alignments that show their relationships.

- Note Any Numbers or Labels: Many visuals include reference numbers or labels. These can correspond to a list of components or indicate specific instructions for assembly or disassembly.

- Consult Accompanying Documentation: Sometimes, additional resources accompany the illustrations. These documents can provide further insights and instructions, enhancing your understanding.

By following these steps, you can effectively navigate through technical visuals, making your repair or maintenance tasks smoother and more efficient.

Finding Replacement Parts Online

Locating suitable components for your equipment has never been easier, thanks to the vast resources available on the internet. Whether you are repairing a lawnmower, generator, or any other machinery, online platforms provide a convenient way to source what you need. By utilizing various websites and search tools, you can efficiently find high-quality alternatives that match your specifications.

Utilizing Online Marketplaces

One of the most effective methods to discover necessary components is by exploring popular e-commerce sites. These platforms often feature extensive catalogs, user reviews, and competitive pricing. Make sure to search for the model number and include specific keywords related to the item you seek. This strategy increases the chances of finding the right fit.

Manufacturer and Specialized Websites

Many manufacturers maintain dedicated websites where you can browse their entire range of items. Additionally, specialized retailers focus on particular types of equipment, offering tailored assistance and expert advice. When using these resources, look for sections that provide detailed information about compatibility and installation to ensure a successful replacement.

Maintenance Tips for T2500 Owners

Regular upkeep is essential for ensuring the longevity and optimal performance of your equipment. By following a structured maintenance routine, you can prevent potential issues, enhance efficiency, and extend the lifespan of your machine. Here are some key practices to consider for effective maintenance.

Routine Checks

Conducting regular inspections is vital. Look for signs of wear, loose components, and any unusual noises. Keep an eye on the following areas:

| Component | Inspection Frequency | Notes |

|---|---|---|

| Filters | Every 20 hours | Clean or replace as necessary to ensure airflow. |

| Belts | Every 50 hours | Check for fraying or excessive wear. |

| Fluids | Monthly | Check levels and top off or change as needed. |

Cleaning and Storage

Keeping your equipment clean is crucial. After each use, remove debris and dirt to prevent buildup. Proper storage is equally important; ensure it is kept in a dry and secure location to avoid rust and damage. Consider covering it with a protective sheet to shield it from dust and moisture.

Tools Needed for Repairs

When tackling any maintenance or repair task, having the right equipment on hand is crucial for efficiency and effectiveness. This section outlines essential tools that will aid in your repair endeavors, ensuring that you are well-prepared to address various issues.

- Screwdrivers: A set of both flathead and Phillips screwdrivers will help you manage screws of different types.

- Wrenches: Adjustable wrenches and a set of socket wrenches will assist in loosening and tightening nuts and bolts.

- Pliers: Needle-nose and standard pliers are invaluable for gripping and manipulating small components.

- Utility Knife: A sharp utility knife can be useful for cutting through materials or opening packages.

- Measuring Tape: Accurate measurements are vital, so a retractable measuring tape is necessary for precise work.

In addition to these primary tools, consider having the following items readily available:

- Hammer: A sturdy hammer is essential for driving nails and making adjustments.

- Drill: A power drill speeds up the process of making holes and fastening screws.

- Level: Ensuring that your work is straight and even is important, making a level a must-have.

- Flashlight: Adequate lighting can make a significant difference in visibility during repairs.

- Safety Gear: Always prioritize safety with goggles, gloves, and masks when necessary.

Having these tools at your disposal will greatly enhance your ability to perform repairs efficiently and effectively, minimizing frustration and maximizing results.

DIY Repairs vs. Professional Help

When it comes to fixing machinery or equipment, individuals often face the decision of whether to tackle repairs themselves or seek assistance from a skilled technician. Each option has its own set of advantages and challenges that can significantly impact the outcome and efficiency of the repair process. Understanding these differences is crucial for making an informed choice.

| Aspect | DIY Repairs | Professional Help |

|---|---|---|

| Cost | Generally lower, as it eliminates labor fees. | Higher due to service charges and expertise. |

| Time | Can be time-consuming, especially for beginners. | Typically quicker, leveraging experience and resources. |

| Skill Level | Requires a certain level of knowledge and experience. | Professionals possess specialized training and expertise. |

| Outcome Quality | Results may vary based on skill and tools available. | High-quality results due to professional standards. |

| Risk | Potential for mistakes that could worsen the problem. | Minimized risk with established procedures and experience. |

Ultimately, the decision between self-repair and hiring a professional hinges on individual capabilities, the complexity of the issue, and the desired outcome. Evaluating these factors can lead to a more efficient and effective resolution.

Upgrading Your Craftsman Equipment

Enhancing your tools can significantly improve performance and extend their lifespan. By selecting appropriate upgrades, you can ensure your equipment remains efficient and effective for various tasks. Here are some key considerations when thinking about enhancements.

- Assess Your Needs: Determine which aspects of your tools require improvement. Are you looking for better power, increased efficiency, or improved ergonomics?

- Research Compatible Accessories: Explore available accessories and upgrades that align with your specific equipment model. This may include new attachments, enhanced blades, or improved handles.

- Invest in Quality Components: Choose high-quality materials to ensure durability and reliability. Quality parts can make a significant difference in performance.

- Regular Maintenance: Incorporate maintenance routines that complement your upgrades. Regular cleaning and servicing can enhance the overall performance of your equipment.

Upgrading is not just about replacing old parts; it’s about maximizing the potential of your tools for better results. Consider these strategies to make informed decisions and elevate your equipment’s capabilities.