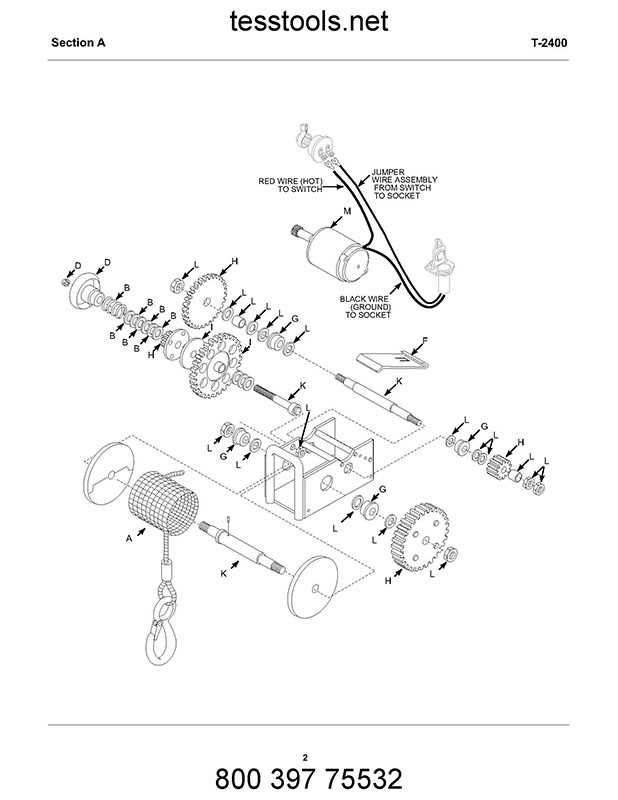

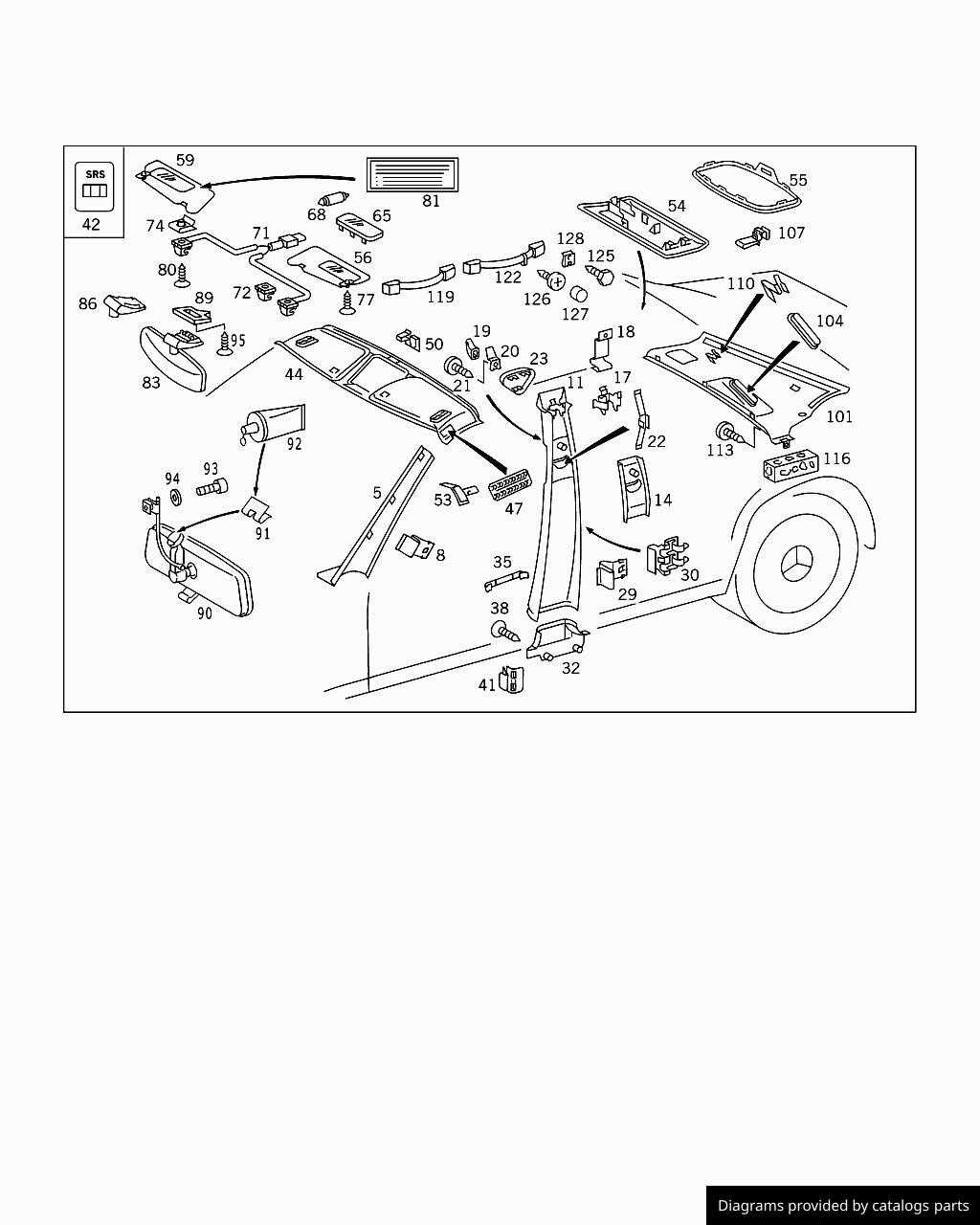

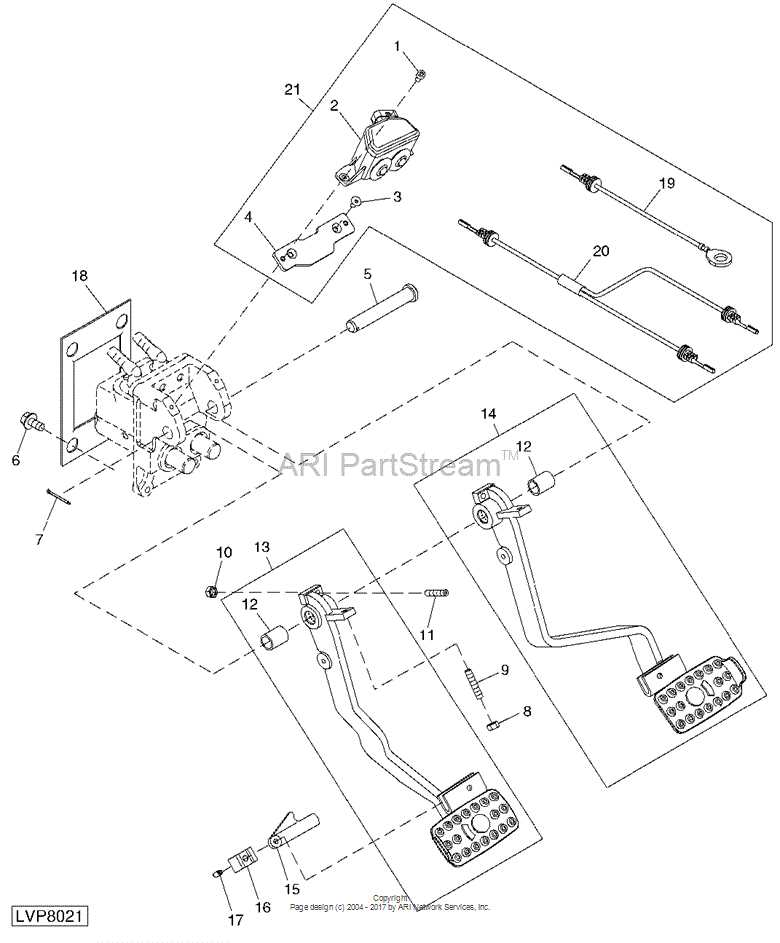

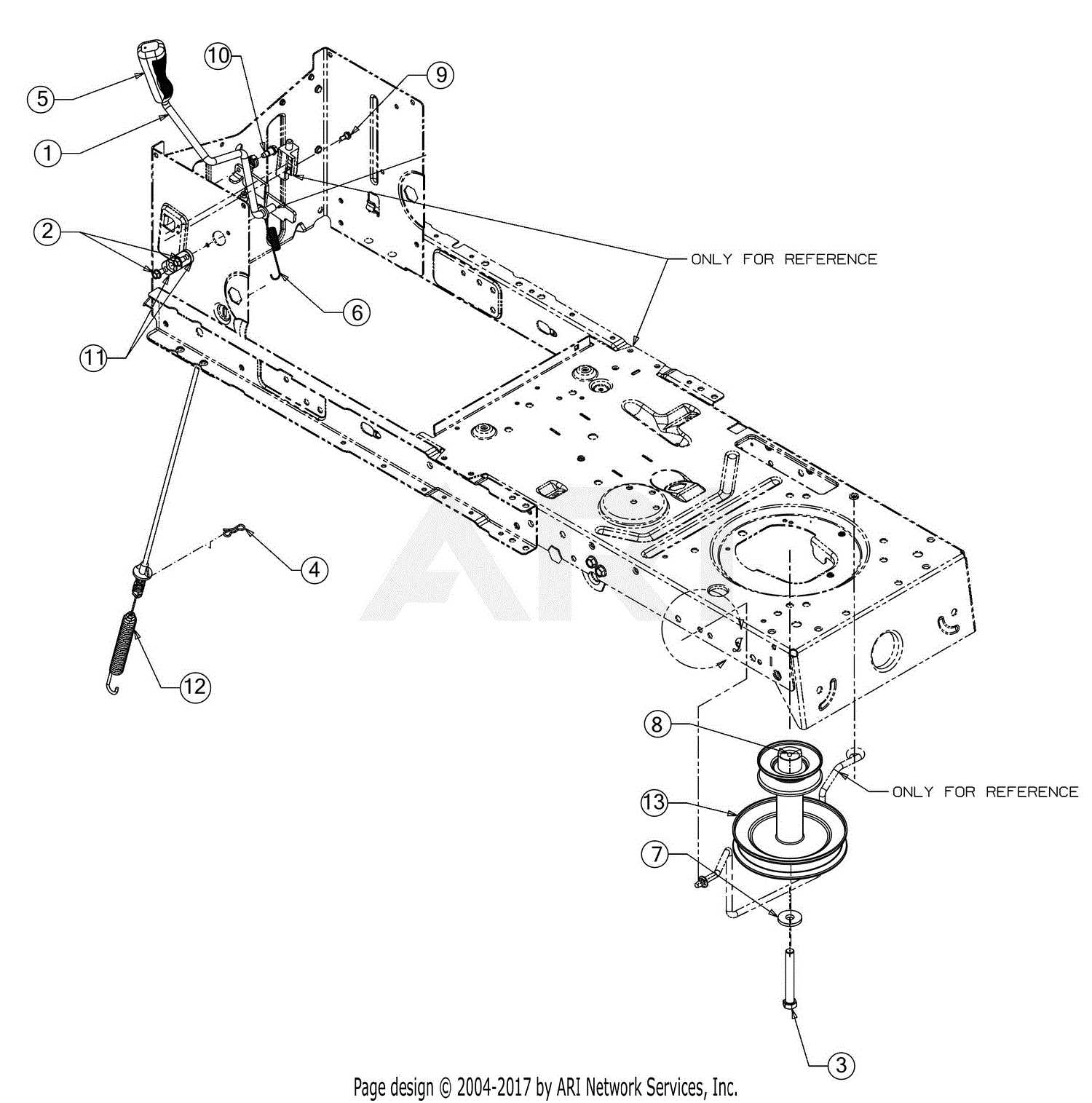

When it comes to maintaining and repairing machinery, having a clear visual representation of its components can be invaluable. Such illustrations not only simplify the process of identification but also enhance your ability to manage repairs efficiently. Whether you’re a seasoned technician or a DIY enthusiast, understanding how each element fits into the overall system is essential for optimal performance.

In this section, we delve into the intricacies of specific models, focusing on their essential components and the relationships between them. By familiarizing yourself with these visual guides, you can gain deeper insights into the functionality of your tools, making it easier to diagnose issues and plan maintenance effectively.

Moreover, the ability to reference a detailed illustration helps streamline the process of sourcing replacements when needed. This resource serves as a crucial tool in ensuring that your equipment remains in peak condition, ultimately prolonging its lifespan and enhancing your productivity.

Understanding Craftsman T2400 Overview

This section provides a comprehensive insight into a popular model known for its reliability and functionality. With a solid build and versatile features, this equipment serves a variety of tasks, making it a favorite among users seeking efficiency and durability.

Key Features

- Robust construction ensures longevity.

- User-friendly design for easy operation.

- Variety of attachments available for enhanced versatility.

- Efficient performance suitable for both residential and light commercial use.

Maintenance and Care

- Regularly inspect the equipment for wear and tear.

- Keep moving parts lubricated to ensure smooth operation.

- Store in a dry place to prevent rust and damage.

- Follow manufacturer guidelines for service intervals.

Understanding the fundamental aspects of this machinery will enhance user experience and prolong the lifespan of the device.

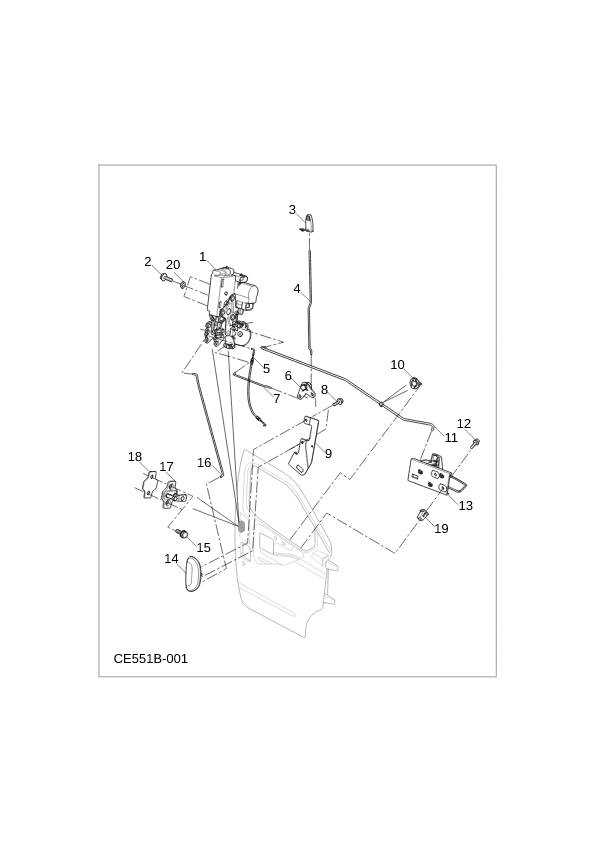

Importance of Parts Diagrams

Understanding the intricate details of a machine is essential for effective maintenance and repair. Visual representations serve as invaluable tools that help users identify components and their relationships within a system. These illustrations not only enhance comprehension but also streamline the process of disassembly and reassembly.

Benefits of Visual Guides

- Clarity: Diagrams provide a clear view of how different elements fit together, reducing confusion during repairs.

- Efficiency: Users can quickly locate necessary components, saving time and effort when troubleshooting issues.

- Precision: Accurate visuals help ensure that the right parts are replaced or repaired, minimizing the risk of errors.

Facilitating Communication

Visual aids also play a significant role in collaboration among technicians, suppliers, and users. When discussing repairs or ordering replacements, having a visual reference fosters clearer communication.

- Standardization: Common references allow for consistent terminology and understanding across different users.

- Documentation: Having a visual record supports maintenance logs and historical tracking of repairs.

Common Issues with T2400 Components

Understanding the frequent challenges associated with various components can significantly enhance performance and longevity. Identifying these issues early can help in efficient troubleshooting and maintenance.

- Wear and Tear: Regular use can lead to degradation, affecting overall functionality.

- Electrical Failures: Issues with wiring or connections can result in malfunctions or power loss.

- Fuel System Problems: Clogs or leaks in the fuel lines can disrupt operation and efficiency.

- Cooling Issues: Overheating due to blocked vents or low coolant levels may lead to serious damage.

- Mechanical Failures: Misalignments or broken parts can hinder performance and require immediate attention.

Regular inspections can help mitigate these problems, ensuring optimal performance and extending the life of the equipment.

Step-by-Step Repair Guide

This guide provides a comprehensive approach to fixing mechanical devices by breaking down the process into manageable steps. Whether you’re addressing a minor issue or undertaking a significant repair, following a structured method ensures efficiency and effectiveness.

Step 1: Begin by assessing the problem thoroughly. Identify symptoms and any unusual behavior that may indicate the root cause of the malfunction.

Step 2: Gather the necessary tools and materials for the repair. A well-equipped workspace can significantly streamline the process and prevent delays.

Step 3: Disassemble the device carefully, taking note of the order and placement of components. This will aid in reassembly and ensure no parts are misplaced.

Step 4: Inspect each part for wear or damage. Replace any faulty components with new ones that match the specifications of the original.

Step 5: Reassemble the device meticulously, following the notes made during disassembly. Ensure all connections are secure and components are aligned correctly.

Step 6: Test the repaired device to confirm it functions as intended. Monitor its performance and make any additional adjustments if necessary.

Step 7: Finally, maintain a record of the repair process, noting any insights or lessons learned for future reference.

Where to Find Replacement Parts

When it comes to maintaining your equipment, sourcing the right components is essential for ensuring optimal performance. Whether you need a specific item for repair or a general upgrade, knowing where to look can save time and effort.

Online Retailers: Numerous websites specialize in offering a wide range of components for various tools and machines. These platforms often provide detailed descriptions, customer reviews, and even visual aids to help you make informed decisions.

Local Hardware Stores: Visiting a nearby store can be beneficial, especially if you prefer to see items in person. Many establishments carry a selection of essential components and can often place special orders for specific needs.

Manufacturer’s Website: Checking the official site of the brand can lead you directly to authentic items. These websites usually feature a dedicated section for replacements and accessories, ensuring you receive quality goods.

Online Marketplaces: Websites that facilitate peer-to-peer sales often have listings for both new and used components. This can be a cost-effective option, but ensure to verify the condition and compatibility before purchasing.

Forums and Community Groups: Engaging with fellow enthusiasts through online forums or social media can yield valuable insights. Members often share recommendations on where to find specific components or might have extras they’re willing to sell or trade.

By exploring these avenues, you can efficiently locate the necessary items to keep your equipment running smoothly.

Benefits of Genuine Craftsman Parts

Choosing authentic components for your equipment ensures optimal performance and longevity. These high-quality items are designed specifically for compatibility, enhancing overall functionality.

Durability is a key advantage, as genuine components are crafted from superior materials, reducing wear and tear over time. This leads to fewer replacements and repairs.

Enhanced Safety is another vital aspect. Authentic parts undergo rigorous testing to meet safety standards, providing peace of mind during operation.

Furthermore, using original items can maintain the warranty of your machinery, protecting your investment and ensuring ongoing support from the manufacturer.

Ultimately, opting for genuine components translates to efficiency and reliability, making it a wise choice for any equipment owner.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for extending the lifespan of your equipment. By following a few simple practices, you can ensure optimal performance and reliability for years to come.

- Regular Cleaning: Keep the surfaces free from dirt and debris. Use a soft brush or cloth to remove any buildup.

- Lubrication: Apply appropriate lubricants to moving parts as recommended in the user manual to minimize wear and tear.

- Inspection: Frequently check for signs of damage or wear. Address any issues immediately to prevent further problems.

- Storage: When not in use, store the device in a dry, protected area to avoid exposure to the elements.

In addition to these practices, it is wise to follow the manufacturer’s guidelines for maintenance schedules and procedures. This proactive approach can save you time and money in the long run.

- Check Filters: If applicable, replace or clean filters regularly to maintain airflow and efficiency.

- Battery Care: For battery-operated devices, ensure batteries are charged correctly and replaced when necessary.

- Professional Servicing: Consider having your equipment professionally serviced periodically to ensure everything is functioning as intended.

By implementing these tips, you can significantly enhance the durability and effectiveness of your tools, ensuring they serve you well for many years ahead.

DIY vs. Professional Repairs

When it comes to fixing tools or machinery, many individuals face the choice between tackling repairs themselves or seeking help from a skilled technician. Each approach has its own set of advantages and challenges, influencing the final outcome and overall satisfaction with the repair process.

Advantages of DIY Repairs

Opting for self-repair can be rewarding. It not only saves money but also provides a sense of accomplishment. Many people find that taking matters into their own hands allows them to learn new skills and gain a deeper understanding of their equipment. With the wealth of information available online, finding guidance and tutorials has never been easier, making DIY an appealing option for those willing to invest time and effort.

Benefits of Professional Assistance

On the other hand, enlisting the help of an expert can ensure a high-quality fix. Professionals bring experience, specialized tools, and knowledge that can lead to faster, more reliable repairs. This can be especially important for complex issues that may not be apparent to an inexperienced individual. Additionally, professionals often provide warranties for their work, offering peace of mind that the repair will hold up over time.

Ultimately, the decision between DIY and professional repairs depends on individual skills, the complexity of the issue, and the desired outcome.