When it comes to maintaining outdoor machinery, having a clear understanding of its individual elements is crucial for optimal performance. Familiarizing yourself with each component not only aids in effective troubleshooting but also ensures smooth operation throughout its lifespan.

Whether you’re planning to perform routine maintenance or tackle a specific repair, a comprehensive overview of the various segments of your equipment can be incredibly beneficial. By delving into the intricate relationships between parts, you can identify the ultimate areas of focus for any enhancements or replacements needed.

Equipped with a visual reference, you can navigate the complexities of your machinery with confidence. This guide will illuminate the essential features, allowing you to enhance your skills and knowledge in equipment care and repair.

Understanding the Craftsman YT4500

This section explores a popular model of lawn care machinery, emphasizing its key components and functionalities. By grasping the essential elements of this machine, users can enhance their maintenance practices and overall performance.

- Engine Specifications

- Transmission Details

- Deck Design

- Steering Mechanisms

- Safety Features

Each of these aspects contributes to the ultimate efficiency and reliability of the equipment, making it crucial for operators to familiarize themselves with these features.

- Identify the engine type and horsepower for optimal performance.

- Understand the transmission options to choose the right driving experience.

- Review the deck size to suit your mowing needs.

- Learn about steering for improved maneuverability.

- Familiarize with safety measures to ensure secure operation.

By delving into these areas, users can better appreciate the intricacies of this lawn care solution and maximize its potential.

Essential Components of the YT4500

Understanding the vital elements that constitute a high-performance lawn tractor is crucial for maintaining its efficiency and longevity. Each part plays a specific role, ensuring seamless operation and reliability in various tasks. From the engine to the wheels, every component contributes to the overall functionality of the machine.

Engine and Transmission

The powerhouse of any riding mower is undoubtedly its engine. This component generates the necessary energy to drive the entire system. Coupled with a robust transmission, it allows for smooth gear transitions, optimizing power delivery to the wheels. Regular maintenance of these parts is essential for preserving performance.

Cutting Deck and Blades

The cutting deck is the heart of the mowing process, housing the blades that perform the actual trimming of grass. High-quality, sharp blades ensure a clean cut, promoting a healthier lawn. Adjustments to the cutting height and regular cleaning of this area can enhance performance and prevent wear.

Overall, familiarity with these essential parts can lead to better maintenance practices, ultimately extending the life of the equipment.

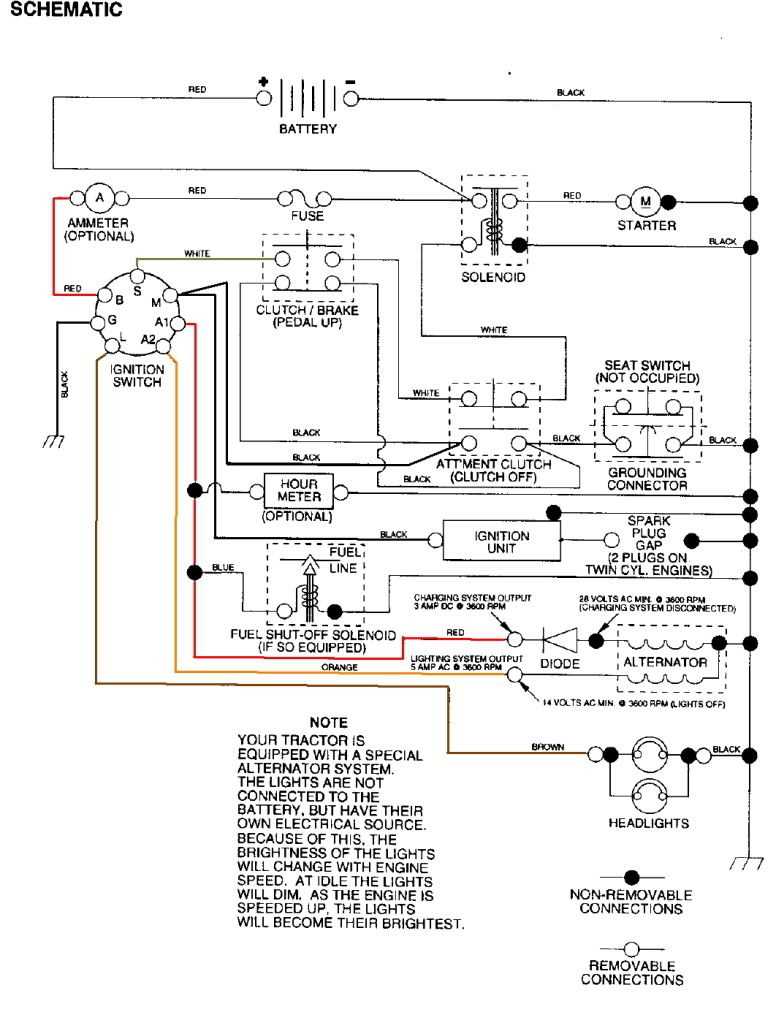

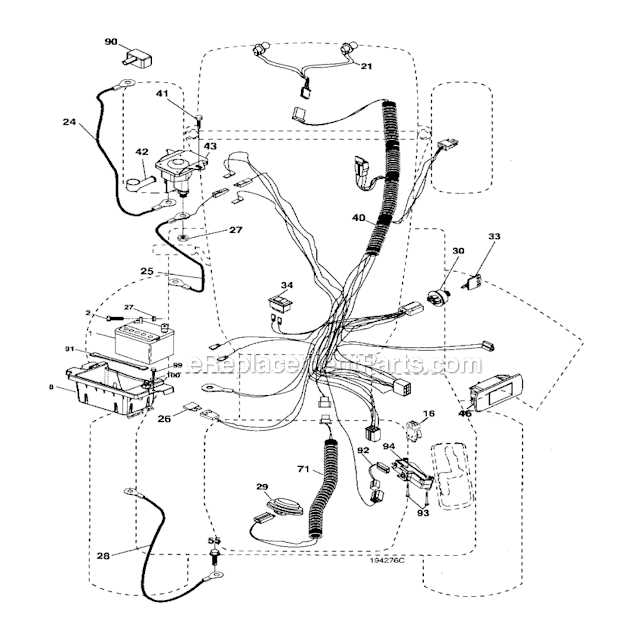

How to Read Parts Diagrams

Understanding visual schematics is essential for effective maintenance and repair. These illustrations provide crucial information about components, their arrangement, and interconnections. Familiarizing oneself with these visuals can significantly enhance your ability to troubleshoot and replace items accurately.

Key Elements of Visual Schematics

- Symbols: Each shape represents a specific component, so knowing the meaning of each symbol is vital.

- Labels: Components are often labeled with numbers or letters, which correspond to lists or tables detailing their specifications.

- Connections: Lines indicate how parts are connected, highlighting pathways for electricity, fluid, or mechanical movement.

Steps to Interpret the Illustrations

- Identify the overall layout and orientation of the schematic.

- Look for the legend or key that explains the symbols used.

- Follow the connections to understand how each piece interacts with others.

- Cross-reference labels with the provided lists for detailed information.

Common Repairs for Craftsman YT4500

Maintaining a lawn machine often involves addressing typical issues that arise with regular use. Understanding these common repairs can help users efficiently troubleshoot and keep their equipment running smoothly.

Engine Troubles

- Difficulty starting: Check the spark plug and fuel levels.

- Unusual noises: Inspect for loose components or worn belts.

- Overheating: Ensure the cooling fins are clean and unobstructed.

Cutting Deck Issues

- Uneven cutting: Adjust the deck height and check blade sharpness.

- Clogging: Regularly clean the underside of the deck to prevent buildup.

- Blade replacement: Replace dull blades for optimal performance.

Locating Replacement Parts Easily

Finding the necessary components for your machinery can be a straightforward task if you know where to look. Understanding the common sources and methods for obtaining these items can save you time and ensure your equipment is back in working order quickly.

Online Resources

The internet is a treasure trove of information and resources for sourcing components. Various websites specialize in offering catalogs, allowing users to search by model or part type. Utilizing these platforms often provides access to detailed specifications and user reviews, aiding in informed decisions.

Local Retailers and Supply Stores

Visiting nearby hardware stores or specialty supply shops can yield positive results. Many of these establishments maintain an inventory of essential items and can assist in identifying suitable replacements. Building relationships with local retailers can also lead to valuable insights and recommendations.

| Source Type | Benefits |

|---|---|

| Online Retailers | Wide selection, detailed descriptions, user reviews |

| Local Stores | Immediate availability, expert assistance, personal service |

| Manufacturer Websites | Official parts, accuracy, warranty information |

Maintenance Tips for Longevity

Ensuring the extended lifespan of your equipment involves a series of proactive measures. Regular upkeep not only enhances performance but also prevents premature wear and costly repairs. By adhering to specific practices, you can maintain optimal functionality and reliability over time.

Here are some essential maintenance tips to keep your machinery in top shape:

| Task | Frequency | Description |

|---|---|---|

| Oil Change | Every 50 hours | Replace old oil with fresh to ensure smooth operation and reduce engine wear. |

| Air Filter Cleaning | Every 25 hours | Remove and clean the air filter to maintain airflow and engine efficiency. |

| Blade Sharpening | As needed | Keep blades sharp for effective cutting and to reduce strain on the engine. |

| Tire Pressure Check | Monthly | Ensure tires are properly inflated for optimal traction and handling. |

| Battery Inspection | Every season | Check terminals for corrosion and ensure the battery is charged and functioning well. |

By following these straightforward recommendations, you can significantly enhance the durability and performance of your equipment, ensuring it serves you well for years to come.

Identifying Common Issues

Understanding potential problems in machinery can greatly enhance maintenance and troubleshooting efforts. By recognizing the signs of wear and tear, users can prevent more significant failures and ensure optimal performance. This section highlights typical challenges that might arise, guiding users in early detection and resolution.

Engine Performance Problems

One of the most frequent concerns involves engine efficiency. Users may notice decreased power or increased fuel consumption. These symptoms could indicate issues such as a clogged air filter, fuel delivery problems, or spark plug wear. Regular checks can help maintain engine health and prolong its lifespan.

Transmission Issues

Another area to monitor is the transmission system. Signs of difficulty in shifting gears or unusual noises can signal malfunctions. Potential causes may include low fluid levels, worn gears, or misaligned components. Prompt attention to these issues is essential to avoid further damage and ensure smooth operation.

Upgrading Your YT4500 Performance

Enhancing the capabilities of your mower can significantly improve efficiency and effectiveness in lawn care. By focusing on various components, you can achieve a smoother operation and better overall performance. This process often involves selecting high-quality replacements and making thoughtful modifications that align with your mowing needs.

One of the key areas to consider is the engine. Upgrading to a more powerful engine can provide increased torque and speed, making it easier to tackle tougher terrains. Additionally, examining the fuel system can lead to improved fuel efficiency and responsiveness, ensuring your machine runs optimally.

Another aspect to explore is the cutting deck. Investing in a more advanced deck can result in a cleaner cut and better grass handling, contributing to a healthier lawn. Furthermore, enhancing the wheel and tire setup can improve traction and maneuverability, allowing for smoother navigation on varied landscapes.

Finally, regular maintenance and tuning are crucial. Keeping parts well-lubricated and properly adjusted will ensure that your mower remains in peak condition, prolonging its lifespan and enhancing its overall performance. By delving into these upgrades, you can achieve the ultimate in mowing efficiency and satisfaction.

Resources for Further Assistance

When tackling maintenance or repair tasks, having access to the right resources can make all the difference. Whether you are seeking expert guidance, detailed illustrations, or community support, various platforms offer valuable information to enhance your understanding and skills.

Online Forums and Communities: Engaging with dedicated forums allows you to connect with fellow enthusiasts and professionals. These platforms often feature discussions, troubleshooting tips, and personal experiences that can provide insights not found elsewhere.

Manufacturer’s Website: The official website of the manufacturer usually provides a wealth of information, including manuals, specifications, and troubleshooting guides. Utilizing these resources ensures you have the most accurate and reliable information at your fingertips.

Video Tutorials: Many individuals find visual aids to be incredibly helpful. Platforms like YouTube host numerous video tutorials that demonstrate various repair techniques and maintenance procedures, offering step-by-step guidance to simplify complex tasks.

Local Repair Shops: If you prefer hands-on assistance, consider visiting local repair shops. Experienced technicians can provide personalized advice and may even offer workshops or demonstrations to enhance your knowledge.

Utilizing these resources can empower you to tackle any project with confidence, ensuring successful outcomes and fostering a deeper understanding of your equipment.