When it comes to accessing underground resources, certain mechanisms play a crucial role in facilitating this process. These devices rely on a variety of interconnected elements that work together seamlessly to ensure efficiency and reliability. Grasping the layout and function of each component is essential for anyone interested in maintenance or repair.

Visualizing the structure of these systems can significantly enhance one’s comprehension of their operation. Each element has a specific purpose, contributing to the overall functionality. By exploring the arrangement and interrelation of these components, users can better understand how to troubleshoot issues or perform enhancements.

In this discussion, we will delve into the intricate design of these essential tools, providing insight into their individual roles. Whether for educational purposes or practical applications, gaining familiarity with the intricacies of these assemblies can empower users to optimize their performance and longevity.

Understanding Pitcher Pump Mechanics

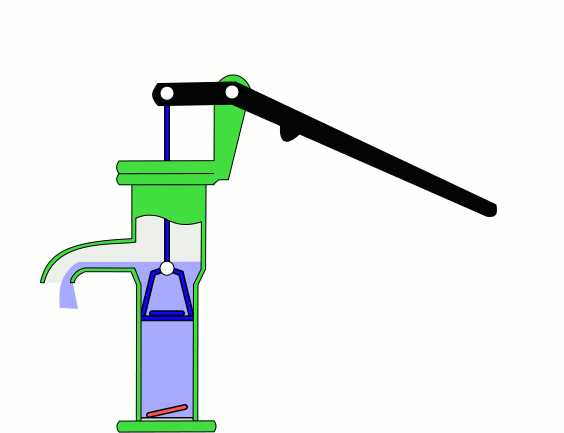

The functionality of a specific type of liquid extraction device relies on a series of interconnected components that work harmoniously to facilitate fluid movement. At its core, this mechanism transforms manual effort into hydraulic action, drawing liquid from underground sources and delivering it to the surface. This intricate interplay of elements underscores the importance of each segment in achieving optimal performance.

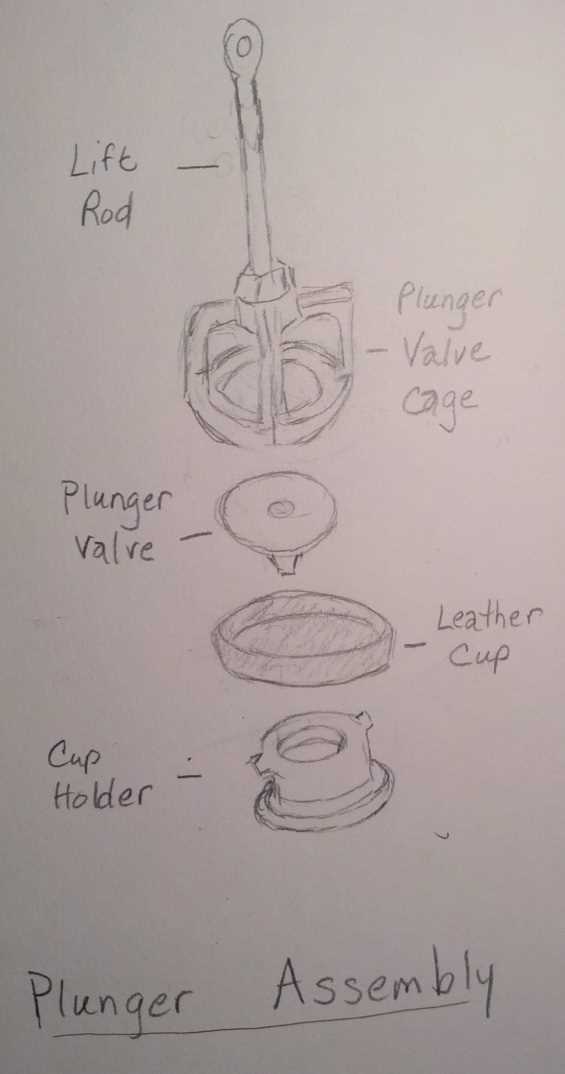

Key components include a cylinder, a plunger, and a suction mechanism, each playing a vital role in the operation. The cylinder houses the plunger, which creates a vacuum effect, allowing liquid to be drawn in as it is pulled upward. Meanwhile, the suction mechanism ensures that the flow remains uninterrupted, preventing backflow and maintaining efficiency.

Understanding these dynamics is essential for troubleshooting and maintenance, as any disruption in this system can lead to reduced efficacy. By examining each element, one can delve deeper into the intricacies of liquid extraction, ensuring that the entire apparatus functions at its ultimate potential.

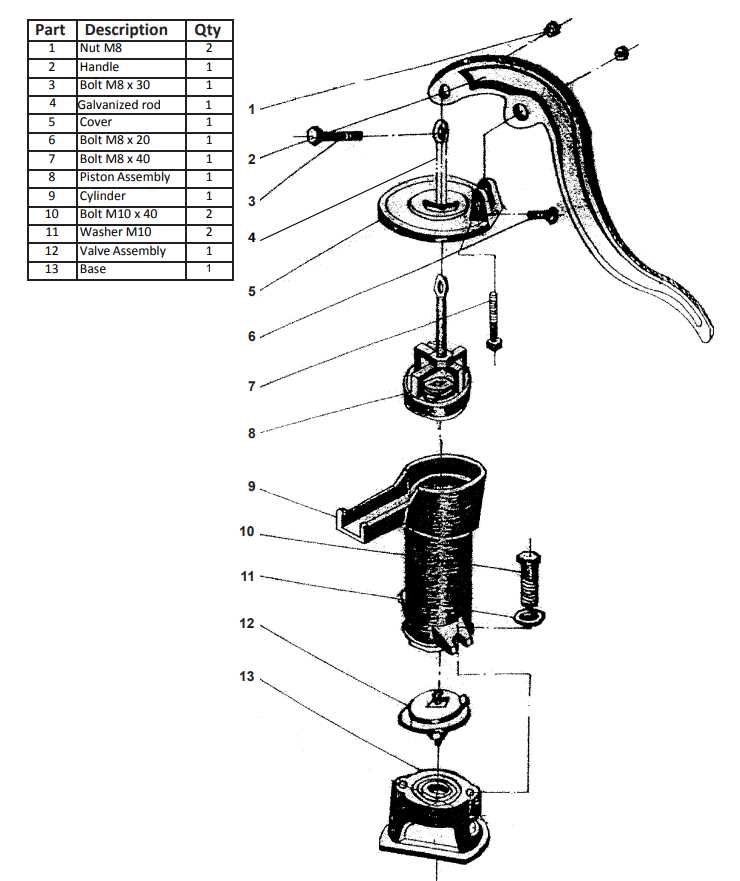

Essential Components of Pitcher Pumps

Understanding the fundamental elements of a manual water lifting device is crucial for effective operation and maintenance. Each component plays a significant role in ensuring the device functions smoothly and efficiently.

The main elements include:

- Handle: The user-operated lever that initiates the lifting mechanism.

- Barrel: The vertical chamber where water is drawn from the source.

- Piston: A cylindrical component that moves up and down to create suction.

- Check Valve: A one-way valve that prevents backflow, ensuring that water moves in the desired direction.

- Foot Valve: Located at the bottom, this component keeps water in the barrel when not in use.

Additionally, there are other important aspects to consider:

- Seals: These prevent leaks and maintain pressure within the system.

- Mounting Base: The sturdy foundation that supports the entire assembly.

- Connection Fittings: Ensure a secure attachment to the water source.

Each of these components contributes to the overall efficiency and reliability of the water lifting system, making them vital for effective water retrieval in various applications.

How to Read Pump Diagrams

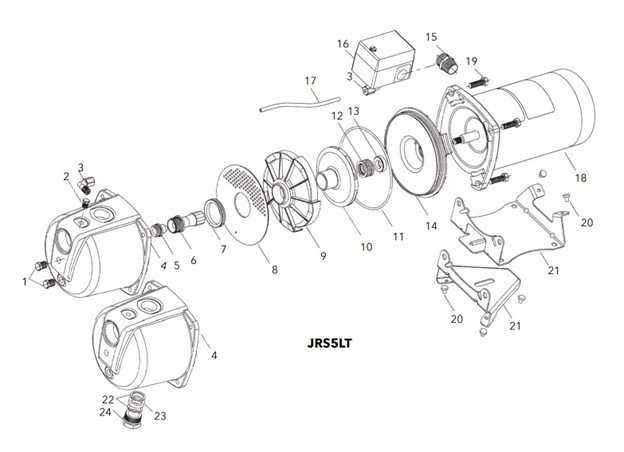

Understanding technical illustrations is essential for effective maintenance and troubleshooting. These visual representations provide a wealth of information, including the configuration, functionality, and interrelationships of various components. Familiarity with these visuals can greatly enhance your ability to interpret and apply the information they convey.

1. Familiarize Yourself with Symbols: Each illustration uses specific icons and notations to represent different elements. Learning these symbols is the first step toward effective interpretation. Look for a legend or key that explains what each symbol means.

2. Identify Key Components: Focus on recognizing the major elements depicted in the illustration. Understanding how these components fit together will help you grasp the overall function. Pay attention to connections, orientations, and any labels that may clarify their roles.

3. Follow the Flow: Most illustrations depict the direction of movement or flow. Arrows and lines can indicate how materials or forces interact within the system. Following these indicators can help you understand the operational sequence and identify potential issues.

4. Review Annotations: Additional notes or labels often accompany the visual. These can provide critical information regarding specifications, maintenance tips, or troubleshooting guidance. Take time to read these annotations, as they can enhance your understanding significantly.

5. Practice with Examples: Like any skill, reading technical visuals improves with practice. Look for various illustrations related to similar systems to reinforce your understanding. Over time, you’ll become more adept at quickly interpreting the necessary information.

Common Issues in Pump Operation

When it comes to fluid movement systems, several challenges can hinder their efficiency and effectiveness. Understanding these common problems is crucial for maintaining optimal performance and ensuring longevity. Below are some frequent issues encountered in these systems along with their potential causes and solutions.

| Issue | Potential Causes | Suggested Solutions |

|---|---|---|

| Inadequate Flow Rate | Clogs, worn components, air leaks | Inspect and clear any blockages, replace damaged parts, check seals |

| Noise and Vibration | Misalignment, cavitation, loose fittings | Realign components, check for air bubbles, tighten connections |

| Overheating | Insufficient lubrication, excessive load, environmental factors | Ensure proper lubrication, reduce load, improve cooling |

| Leaking Seals | Wear and tear, improper installation, material degradation | Replace seals, verify correct installation, choose suitable materials |

Addressing these issues promptly can prevent further damage and enhance the overall functionality of the system. Regular maintenance and inspections are essential to keep operations running smoothly.

Maintenance Tips for Pitcher Pumps

Proper upkeep is essential to ensure the longevity and efficient operation of your water-lifting device. Regular attention to its components can prevent unexpected breakdowns and enhance performance. Here are some practical suggestions to keep your system in optimal condition.

First, regularly inspect the exterior for any signs of wear or damage. Check for cracks or rust that could compromise the structure. Additionally, ensure that all seals and connections are tight to prevent leaks, which can lead to reduced efficiency.

Next, clean the interior components periodically to remove any debris or buildup. This will help maintain smooth operation and prevent clogging. Use a soft brush or cloth to gently remove dirt without damaging sensitive parts.

Lubrication is crucial for moving elements. Apply the appropriate grease to reduce friction and wear. Be mindful to use products that are compatible with the materials of your device to avoid degradation.

Finally, consider seasonal maintenance checks. Extreme weather conditions can affect functionality. Preparing your system for winter or heavy rains can save you from costly repairs and ensure reliable performance year-round.

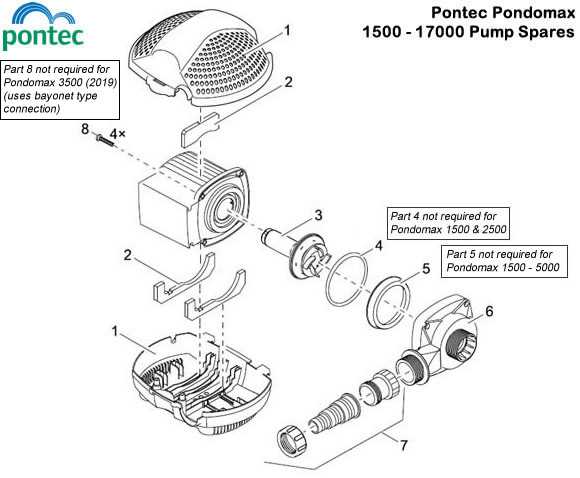

Comparing Different Pump Models

This section explores various designs and their functionalities, focusing on their distinct features and suitability for diverse applications. Understanding these variations can aid users in selecting the most efficient model for their needs.

When evaluating different designs, consider the following criteria:

- Efficiency: Assess how effectively each model converts energy into fluid movement.

- Durability: Look for materials and construction that ensure longevity under various conditions.

- Maintenance: Consider how easy it is to service and repair each model.

- Flow Rate: Examine the capacity and speed at which fluid can be transferred.

- Cost: Compare initial investment and long-term operational expenses.

By examining these factors, users can delve into their options and make informed decisions tailored to their specific requirements.

Applications of Pitcher Pumps Today

The versatility of manual water extraction systems has led to their continued relevance across various sectors. These devices are employed in both rural and urban settings, providing reliable access to water without the need for electricity. Their design allows for easy maintenance and operation, making them ideal for diverse applications.

Agricultural use remains one of the primary areas where these systems shine. Farmers utilize them for irrigation, ensuring crops receive adequate hydration without incurring high energy costs. Additionally, emergency water supply in disaster-stricken regions highlights their importance. During crises, these systems can quickly provide essential water resources when other methods fail.

Furthermore, they find applications in community projects, where groups establish wells for local water access, enhancing sustainability. In remote areas, these systems serve as a critical solution for drinking water needs, especially where modern infrastructure is lacking. Overall, their simplicity and efficiency ensure they remain an ultimate choice for many water-related needs today.

Historical Development of Pump Designs

The evolution of fluid-moving mechanisms reflects humanity’s quest for efficiency and innovation. Over centuries, various cultures have contributed to the refinement of these devices, adapting them to meet the demands of agriculture, industry, and daily life. Understanding this progression provides insight into the technological advancements that have shaped modern systems.

Early Innovations

In ancient civilizations, simple tools like the Archimedes screw represented initial attempts to elevate water. These early creations showcased ingenuity in utilizing gravity and mechanical advantage. As societies advanced, so did their need for more sophisticated solutions, leading to the development of various mechanical designs.

Industrial Revolution and Beyond

The Industrial Revolution marked a pivotal moment in the enhancement of these devices, introducing steam power and intricate machinery. Innovations during this era laid the groundwork for contemporary models, incorporating materials and techniques that improved efficiency and reliability. Today, these mechanisms continue to evolve, integrating digital technologies for enhanced performance.

Innovations in Pump Technology

Recent advancements in fluid movement systems have revolutionized how industries manage liquid transfer and distribution. With a focus on efficiency, sustainability, and user-friendly designs, these innovations are setting new standards in performance and reliability. Emerging technologies not only enhance operational capabilities but also reduce environmental impact, making them essential for modern applications.

Smart Technologies and Automation

The integration of smart technologies has transformed traditional mechanisms into intelligent systems capable of real-time monitoring and control. Sensors and IoT connectivity enable predictive maintenance, reducing downtime and operational costs. Automation ensures precise flow regulation and energy efficiency, adapting to varying demands with minimal human intervention.

Eco-Friendly Solutions

As environmental concerns grow, innovations focused on sustainability have gained traction. New materials and designs aim to minimize energy consumption while maximizing output. Advanced systems utilize renewable energy sources and are designed for easy recyclability, contributing to a more sustainable future. These eco-friendly solutions not only meet regulatory standards but also appeal to environmentally conscious consumers.