When working with a lawn tractor, it is essential to have a clear understanding of its internal structure and how various components connect and function together. Having access to a detailed visualization of these connections can significantly aid in troubleshooting, maintenance, and repairs. By breaking down the machine into its individual elements, one can better appreciate the complexity and design that contribute to its overall performance.

Each system within the vehicle, from the engine to the transmission, plays a vital role in ensuring smooth operation. Being familiar with these mechanisms allows users to make informed decisions when it comes to replacing or upgrading specific components. Whether you’re addressing an issue or simply looking to enhance the efficiency of your machine, understanding how everything works together is key.

Having a well-organized reference for the internal layout not only saves time but also ensures that the task at hand is completed with precision. This guide aims

Overview of the Craftsman GT5000

This versatile and powerful machine is designed to handle a wide variety of outdoor tasks. Engineered for both durability and efficiency, it stands out for its reliable performance in tough conditions. With a robust build and an efficient engine, it allows users to accomplish various activities, from mowing large lawns to towing small equipment. Its design emphasizes ease of use, making it accessible to both seasoned operators and those new to such equipment.

A strong emphasis is placed on comfort and convenience, featuring ergonomic controls and an intuitive interface. Its versatility is one of its key advantages, capable of adapting to different environments and tasks through additional accessories. Whether used for routine maintenance or more demanding projects, this machine provides the power and flexibility needed to get the job done efficiently.

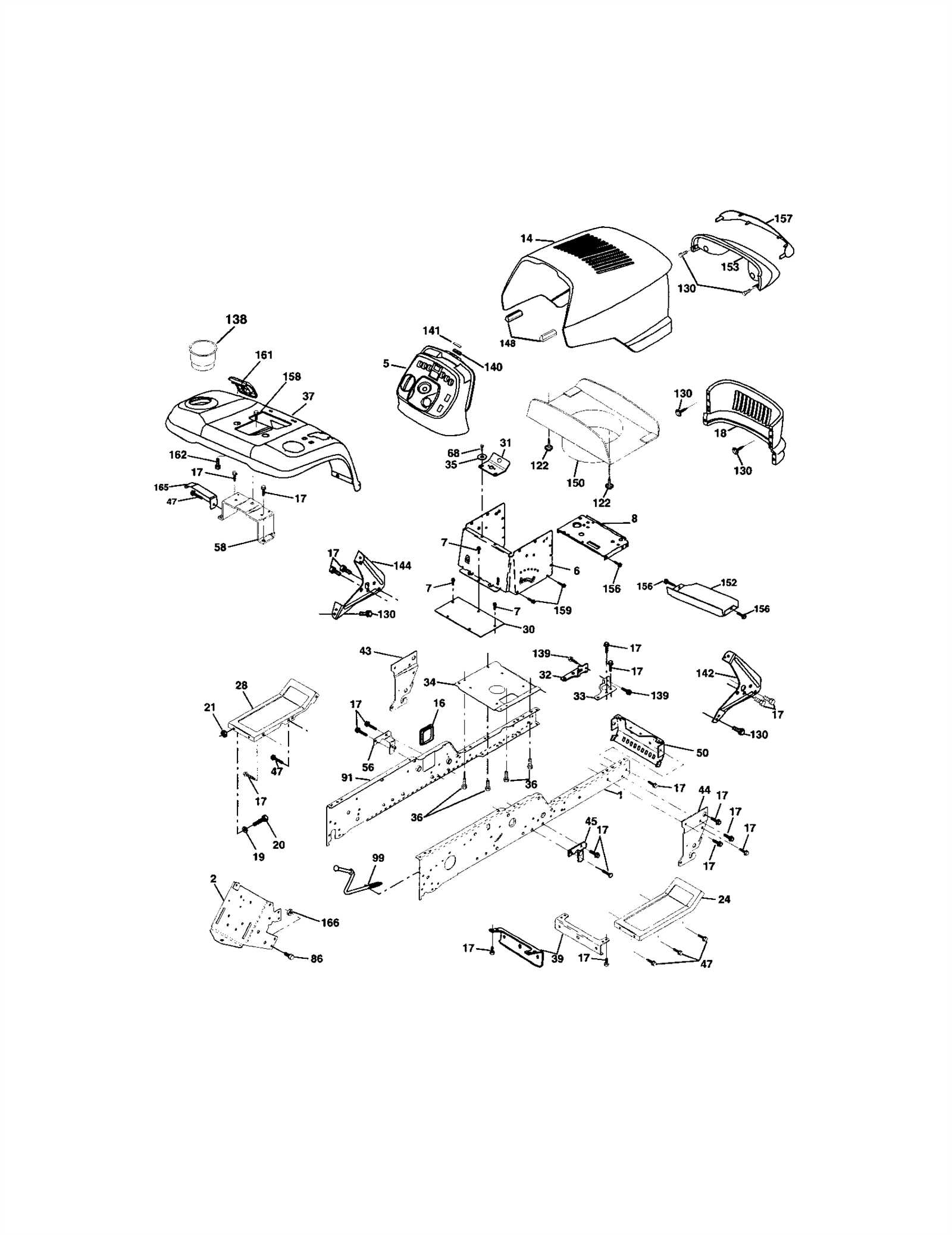

Main Components of the GT5000

Understanding the essential elements of a robust riding lawn machine allows for proper maintenance and efficient operation. Each unit is carefully designed with specific key structures that work together to ensure optimal performance during lawn care activities. These vital components help the operator handle the equipment with ease while ensuring durability and functionality over time.

Engine System

The power source is the heart of the machine, providing the necessary energy to drive the equipment. It is equipped with a high-capacity engine designed for long-term performance, featuring advanced cooling mechanisms to prevent overheating. The engine also supports various cutting attachments, enabling versatile usage.

Transmission and Drive System

The transmission system plays a crucial role in controlling the speed and movement of the equipment. It allows for smooth transitions between gears, ensuring precise handling. The drive system includes a durable axle

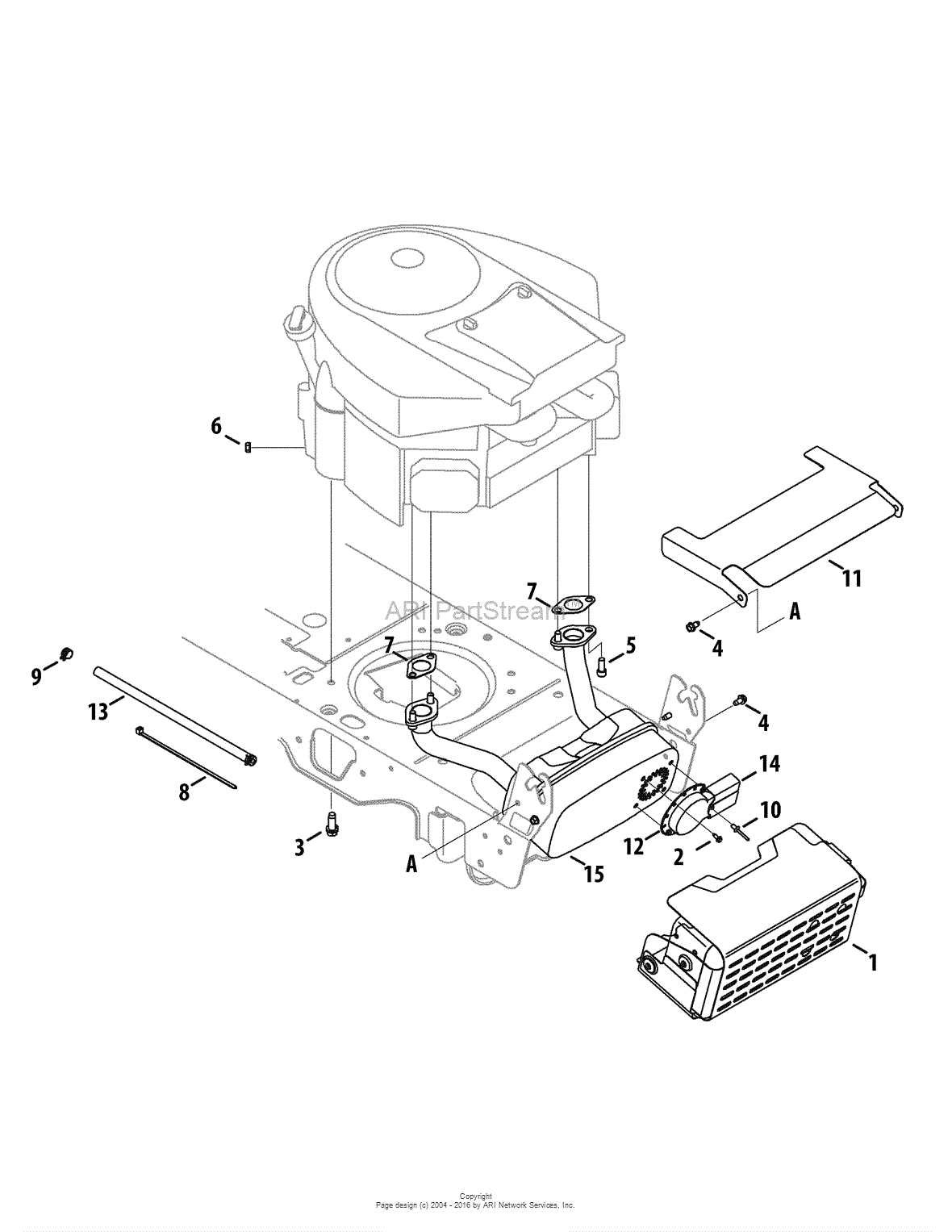

Understanding the Engine and Transmission

The engine and transmission are the core components that drive the performance and functionality of a riding vehicle. These systems work in unison to convert fuel into motion, allowing the machine to move efficiently across different terrains. Grasping how these elements operate provides insight into the overall mechanics and helps in maintaining the vehicle for optimal performance.

The Role of the Engine

The engine serves as the primary power source, using internal combustion or another energy method to generate force. This power is then transferred through various components, turning mechanical energy into the movement of the vehicle. Understanding the engine’s structure and function is essential for ensuring smooth operation and longevity of the system.

How Transmission Works

The transmission plays a crucial role by regulating the power generated by the engine. It adjusts the speed and torque delivered to the wheels, ensuring that the vehicle can accelerate or maintain speed under different conditions. Proper transmission function is vital for smooth shifting and overall control during operation, making it an indispensable part of the mechanical system

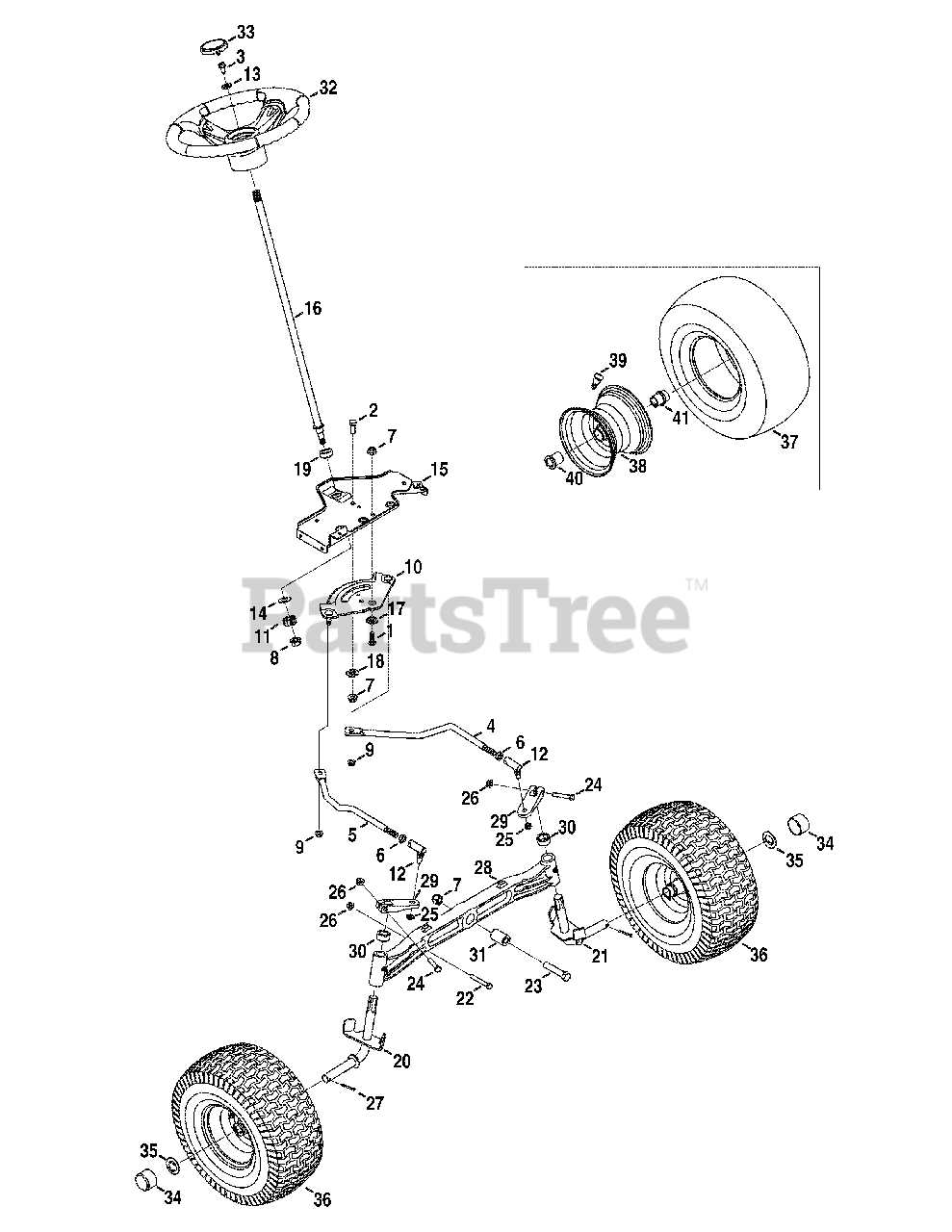

Detailed Look at the Steering System

The steering mechanism is a crucial aspect of any riding machine, ensuring precise control and maneuverability. It is responsible for translating the operator’s input into directional changes, allowing smooth and effective navigation on various terrains. Understanding how the different elements work together can help in maintaining and adjusting the setup for optimal performance.

Steering Wheel and Linkages: The process starts with the turning of the wheel, which connects to a series of linkages. These linkages transfer motion down through the steering column, directing the movement to the front wheels. Proper alignment of these components is vital for accurate response during operation.

Pivot Points and Bearings: At the heart of the system are the pivot points, allowing for fluid movement of the front wheels. These are supported by bearings that reduce friction, ensuring that the steering remains responsive over time. Regular lubrication of these points is necessary to prevent wear and ensure longevity.

Adjustments and Maintenance: Over time, adjustments may be required to maintain precise control. Components like tie rods and bushings can wear out, causing play in the system

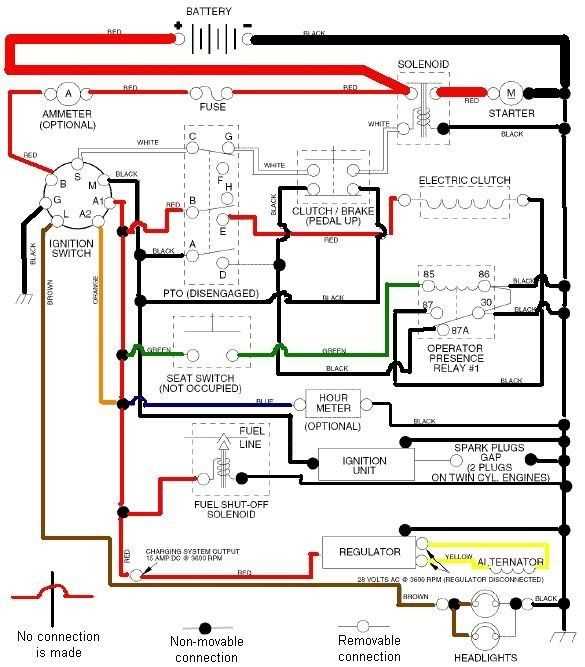

Exploring the Electrical System

The electrical setup plays a critical role in ensuring the smooth operation of various components. Understanding its layout and functionality can help in troubleshooting issues and optimizing performance. This section outlines the key elements involved in powering and controlling essential systems.

- Power Source: The heart of the electrical network is the power supply, which ensures energy flows to the essential components.

- Wiring: A well-organized network of wires connects all systems, delivering energy where needed while protecting against short circuits or overloads.

- Switches and Controls: These devices regulate the flow of electricity, enabling the user to activate specific systems as required.

- Fuses and Relays: Safety devices such as fuses and relays protect against electrical surges, preventing damage to the circuitry.

By maintaining the electrical components and ensuring proper connections, users can enhance the longevity and

Key Features of the Mower Deck

The mower deck is a vital component of any lawn maintenance equipment, designed to enhance cutting efficiency and ensure a uniform finish. Its construction and features play a crucial role in the overall performance, durability, and usability of the machine.

| Feature | Description |

|---|---|

| Material | Constructed from high-quality steel for improved strength and resistance to wear. |

| Cutting Height Adjustment | Allows operators to easily modify the cutting height for different grass types and conditions. |

| Blade Configuration | Equipped with multiple blades for an even cut and enhanced grass dispersal. |

| Deck Design | Engineered for optimal airflow, resulting in superior grass lifting and cutting performance. |

| Easy Maintenance | Features accessibility options for straightforward cleaning and blade replacement. |

Understanding these essential features helps users make informed decisions regarding maintenance and operation, leading to better results in lawn care tasks.

Maintenance Tips for GT5000 Parts

Proper upkeep of essential components is crucial for ensuring optimal performance and longevity of your machine. Regular maintenance not only enhances efficiency but also prevents costly repairs in the future. Here are some effective strategies to keep your equipment in top shape.

- Regular Inspections: Frequently check all vital elements for wear and tear. Look for signs of damage or malfunction, and address any issues promptly to avoid further complications.

- Cleanliness: Keep components free of dirt and debris. Regularly cleaning helps prevent buildup that can hinder performance. Use appropriate cleaning solutions for specific materials.

- Lubrication: Ensure moving parts are adequately lubricated. This reduces friction and wear, contributing to smoother operation and extending the lifespan of the equipment.

- Replacement Schedule: Follow a replacement schedule for worn components. Knowing when to replace parts will prevent unexpected breakdowns and maintain efficiency.

- Consult the Manual: Refer to the user manual for specific maintenance recommendations. It contains valuable information tailored to your machine’s requirements.

By incorporating these maintenance practices, you can ensure your machinery remains reliable and efficient throughout its lifespan. Consistency in upkeep will lead to enhanced performance and durability.

Common Issues and Their Solutions

In any mechanical system, occasional problems may arise that can hinder performance and functionality. Understanding these issues and knowing how to address them can significantly enhance the longevity and efficiency of your equipment. Below are some prevalent challenges encountered along with their respective solutions.

Engine Difficulties

- Starting Problems: If the engine fails to start, check the battery for charge, inspect the ignition system, and ensure fuel is reaching the engine. Replacing a faulty battery or spark plug may resolve the issue.

- Overheating: Regularly monitor the cooling system for leaks and ensure that the coolant level is adequate. Cleaning the cooling fins and replacing a malfunctioning thermostat can help prevent overheating.

Drive Train Malfunctions

- Transmission Issues: If shifting becomes difficult, inspect the fluid levels and look for leaks. Flushing and replacing old fluid may improve performance.

- Noise During Operation: Unusual sounds can indicate worn-out gears or bearings. Conduct a thorough inspection and consider lubricating or replacing components as needed.

Where to Find Replacement Parts

Finding suitable components for your equipment can enhance its performance and longevity. Whether you are dealing with worn-out pieces or looking to upgrade specific features, knowing where to source these items is essential for effective maintenance.

Here are several reliable sources to consider when searching for components:

- Manufacturer’s Website: The official site often provides direct access to genuine items, along with detailed specifications and compatibility information.

- Local Retail Stores: Many hardware and garden supply shops carry a range of components. Visiting a physical store allows you to consult with staff for advice on suitable options.

- Online Marketplaces: Websites like eBay, Amazon, and specialized marketplaces offer a vast selection of items from various sellers. Always check the reviews and ratings before purchasing.

- Repair Shops: Local repair professionals might have access to specific components or can help locate them for you.

- Forums and Community Groups: Online communities dedicated to equipment maintenance often share tips and resources for sourcing components. Engaging with fellow enthusiasts can lead to valuable recommendations.

By exploring these avenues, you can find the necessary components to keep your equipment running smoothly and efficiently.