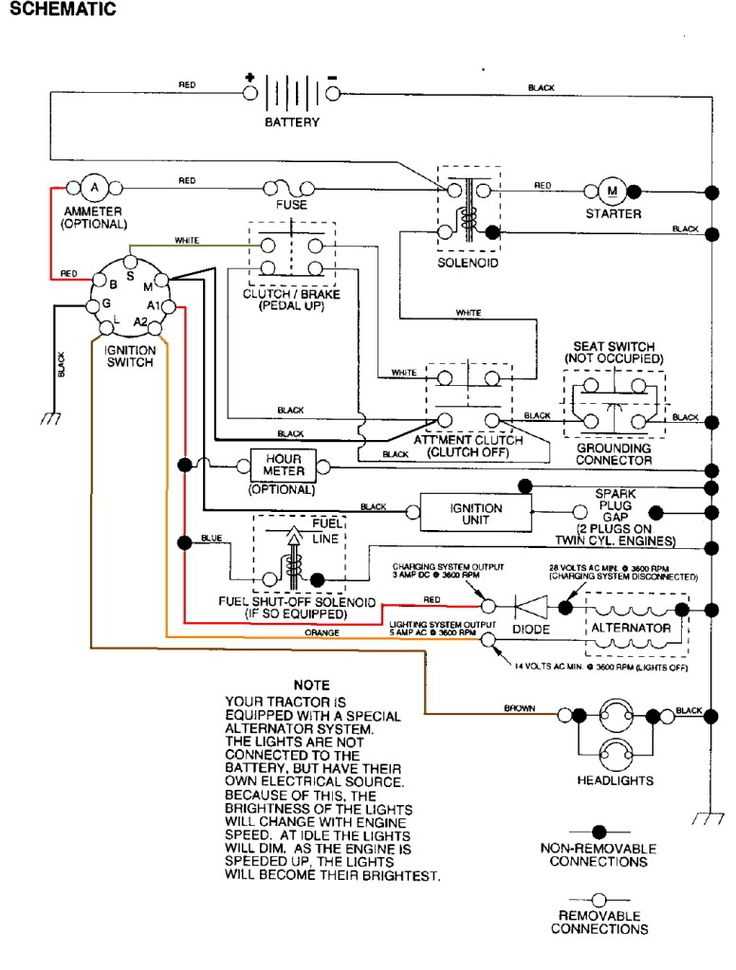

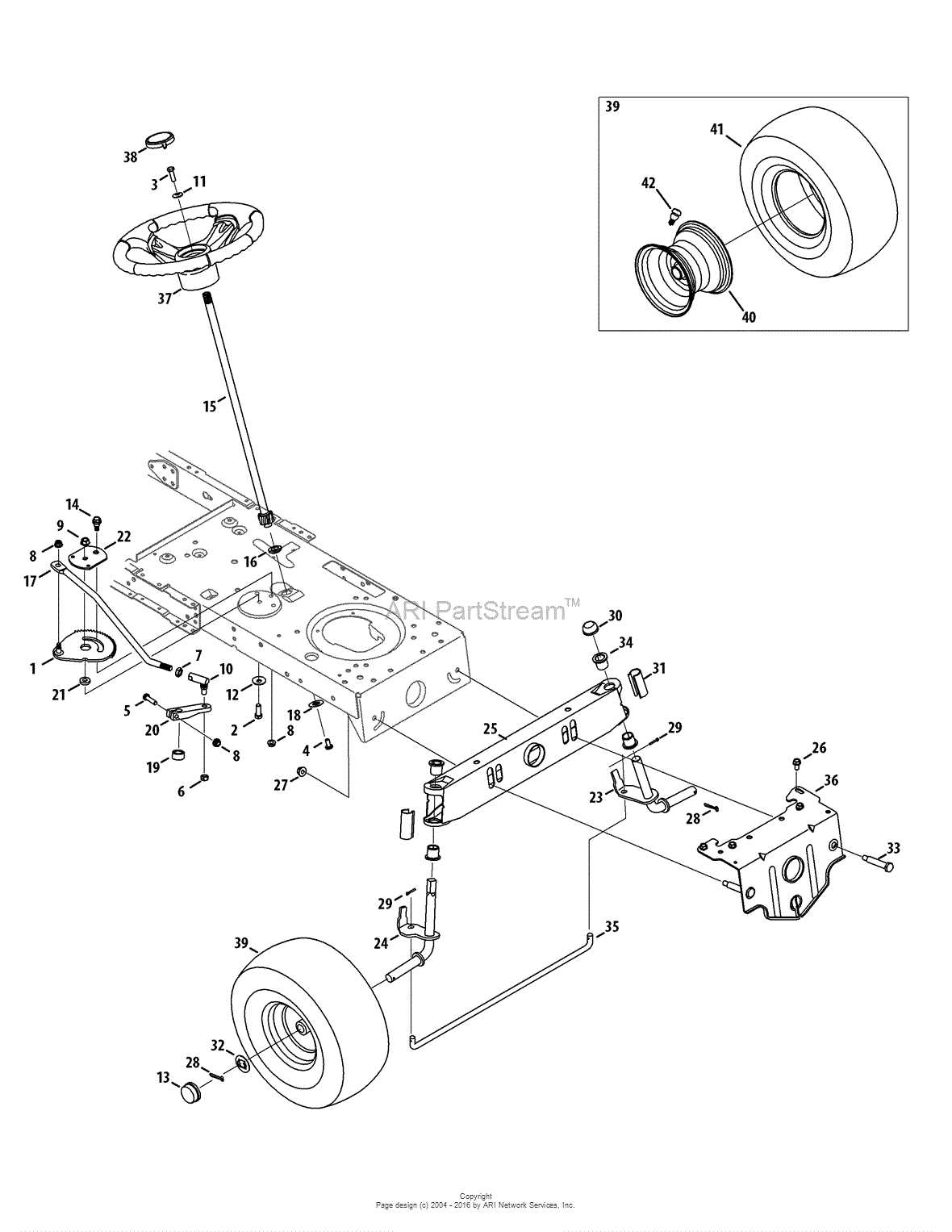

Maintaining and repairing outdoor machinery can be a daunting task, especially when it comes to understanding its intricate components. A clear visual representation of these elements is essential for effective troubleshooting and replacement. Knowing how each part interacts within the system enhances your ability to keep your equipment running smoothly.

In this guide, we will explore a detailed layout of the various segments that make up your lawn equipment. By familiarizing yourself with the configuration and functionality of each piece, you will gain valuable insights into maintenance practices that can prolong the life of your machinery.

Whether you are an experienced technician or a novice enthusiast, having access to a comprehensive schematic will empower you to tackle repairs with confidence. Let’s delve into the essential components and discover how they work together to ensure optimal performance.

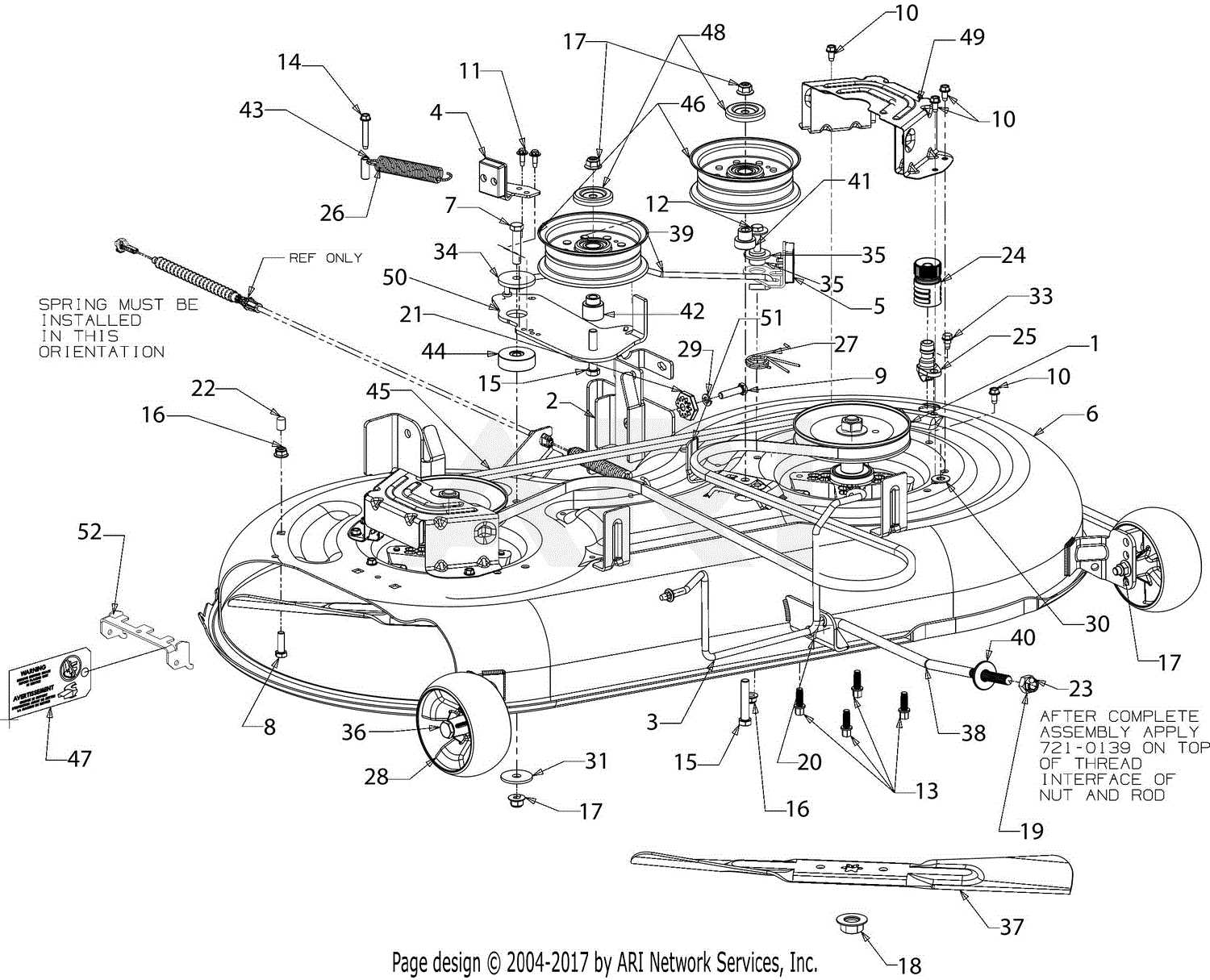

Understanding the Craftsman YT3000 Deck

This section focuses on the key components and functionality of a specific outdoor machine used for maintaining lawns. By exploring its structure, users can enhance their knowledge of its operation and ensure optimal performance.

Key components play a vital role in the efficiency of the machine. Each element contributes to the overall functionality, affecting performance and longevity.

| Component | Description |

|---|---|

| Frame | The backbone structure that supports all other parts. |

| Blades | Essential for cutting grass, varying in design for specific tasks. |

| Spindles | Connects the blades to the engine, ensuring smooth rotation. |

| Belts | Transmit power from the engine to various components. |

Understanding these components allows users to effectively maintain their equipment and troubleshoot any issues that may arise.

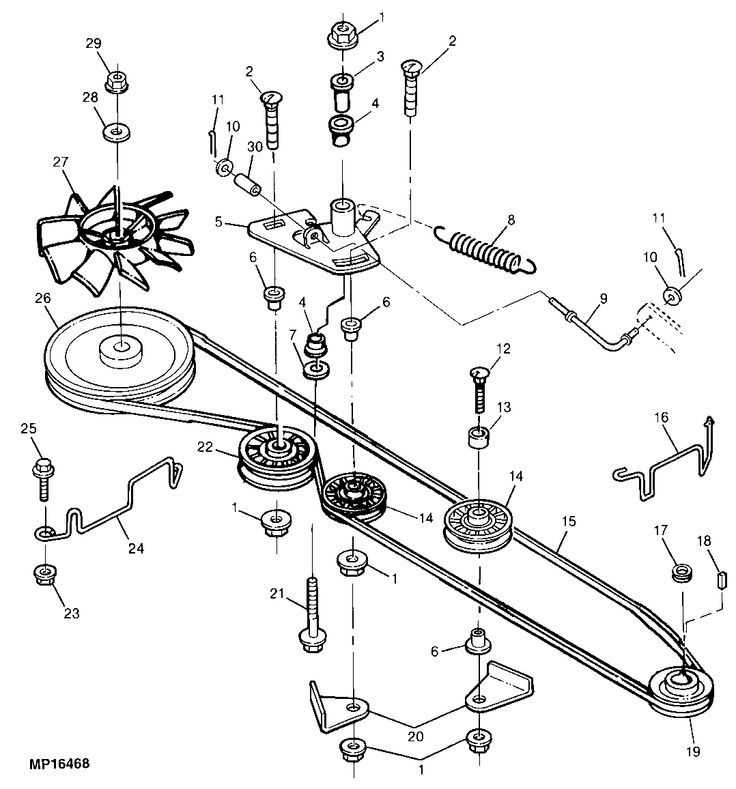

Key Components of the Deck Assembly

The structure that supports cutting and other essential functions in lawn maintenance consists of several integral elements. Understanding these components is crucial for proper maintenance and efficient operation. Each part plays a specific role in ensuring optimal performance and longevity of the assembly.

Primary Elements

Among the vital sections of this framework, a few stand out due to their significance. These parts interact seamlessly to facilitate smooth operation and enhance durability.

| Component | Description |

|---|---|

| Chassis | The main structure providing stability and support for the assembly. |

| Blade Holder | Holds the cutting blade securely in place for efficient grass trimming. |

| Spindle Assembly | Enables the rotation of the cutting blade, crucial for effective operation. |

| Deflector Shield | Protects the user by directing clippings away from the operator. |

| Height Adjustment Mechanism | Allows users to modify the cutting height for different grass types. |

Maintenance Tips

Regular upkeep of these components is essential to ensure optimal functionality. Checking for wear and tear, cleaning debris, and lubricating moving parts can significantly extend the lifespan of the assembly and improve overall performance.

Benefits of Using Quality Parts

Opting for superior components in machinery and tools not only enhances performance but also extends the lifespan of the equipment. Quality materials often lead to fewer breakdowns, reducing the need for frequent repairs and replacements.

Improved Performance

High-quality components are designed to fit perfectly and work seamlessly together, ensuring optimal operation. This precision minimizes friction and wear, resulting in a smoother and more efficient performance.

Long-Term Savings

Investing in top-notch materials can lead to significant savings over time. By reducing the frequency of repairs and increasing durability, users can enjoy reliable service without the recurring costs associated with inferior options.

Common Issues with YT3000 Decks

Many users encounter recurring challenges with their lawn maintenance equipment. Understanding these common problems can help in effective troubleshooting and maintenance, ensuring a smooth operation throughout the mowing season.

Wear and Tear

Over time, components can experience degradation due to exposure to harsh conditions. This wear may lead to decreased performance and require timely replacement to maintain functionality.

Uneven Cutting

A frequent complaint is uneven grass cutting, which may stem from misalignment or dull blades. Regular checks and adjustments are essential to achieve a uniform finish and optimal efficiency.

How to Access the Parts Diagram

Finding a visual representation of components can greatly simplify maintenance and repairs. This section provides a clear guide on how to locate these illustrations effectively.

Follow these steps to access the necessary schematics:

- Visit the official website of the manufacturer.

- Navigate to the support or resources section.

- Look for the option labeled ‘manuals’ or ‘technical documents.’

- Enter the model number in the search bar to find the specific resources.

- Select the appropriate link to view or download the schematic.

Additionally, consider these alternative sources:

- Online forums dedicated to repair enthusiasts.

- Video tutorials on platforms like YouTube.

- Local repair shops that may offer printed guides.

Accessing these illustrations will enhance your understanding and facilitate any repair tasks you may encounter.

Maintenance Tips for Longevity

Ensuring the durability and performance of your equipment requires consistent care and attention. Implementing a routine maintenance schedule not only enhances functionality but also extends the lifespan of essential components. By following a few key practices, you can keep your machinery in optimal condition and avoid costly repairs.

Regular Inspections: Conduct thorough inspections of all vital elements at least once a month. Look for signs of wear and tear, loose connections, or any unusual noises. Early detection of issues can prevent more significant problems down the line.

Cleaning: Keeping the equipment clean is crucial for preventing debris buildup that can hinder performance. After each use, wipe down surfaces and remove any grass, dirt, or other residues that may accumulate.

Lubrication: Apply appropriate lubricants to moving parts regularly. This reduces friction and helps prevent corrosion, ensuring smooth operation. Always refer to the manufacturer’s guidelines for the correct types of lubricants.

Blade Maintenance: For devices equipped with cutting elements, sharp blades are essential. Regularly check the sharpness and replace or sharpen them as necessary to achieve clean cuts and reduce strain on the motor.

Storage: When not in use, store your equipment in a dry, sheltered location. This protects it from the elements and minimizes the risk of rust or damage. Covering it with a protective tarp can also help keep dust and debris away.

By adhering to these maintenance guidelines, you can ensure that your machinery operates efficiently and remains reliable for years to come.

Where to Buy Replacement Parts

Finding suitable components for your outdoor equipment can be a straightforward process if you know where to look. Various retailers and online platforms offer a wide selection of items to ensure your machinery runs smoothly. It’s essential to choose trusted sources that provide quality and reliability for the specific parts you need.

Local hardware stores often carry essential components and can be a great first stop. Many of these establishments have knowledgeable staff who can assist you in locating the right items. Additionally, specialty shops focusing on outdoor equipment may stock specific components that cater to your needs.

Online marketplaces also provide an extensive range of options. Websites dedicated to gardening and landscaping tools typically offer detailed listings and specifications, making it easier to find exactly what you need. Furthermore, you can compare prices and read reviews to make an informed decision.

Manufacturer websites are another valuable resource. They often feature sections dedicated to replacement components, ensuring that you are purchasing the correct items designed for your equipment. This option guarantees authenticity and quality, giving you peace of mind with your purchase.

In conclusion, whether you opt for local stores or online resources, numerous avenues are available to acquire the necessary components for your machinery. Exploring these options will help you keep your equipment in optimal condition for years to come.

DIY Repairs for Deck Components

Understanding how to address common issues with outdoor machinery can enhance longevity and performance. This section explores straightforward methods for tackling repairs on various structural elements, ensuring a smooth operation without the need for professional assistance.

Identifying Common Issues

Begin by assessing the functionality of the components. Look for signs of wear, such as rust or cracks, which may hinder performance. A keen eye for detail will help pinpoint areas needing attention, making repairs more manageable.

Repair Techniques

For minor damages, consider using epoxy adhesives for cracks, as they provide a strong bond and are resistant to the elements. If parts require replacement, sourcing compatible components is crucial for maintaining integrity. Regular maintenance, including cleaning and lubrication, can prevent further issues and extend the lifespan of your equipment.

Comparing YT3000 with Other Models

In the realm of lawn care equipment, understanding the differences between various models is crucial for making informed decisions. This section explores the distinctions between one specific unit and its competitors, focusing on performance, durability, and user experience. By examining these elements, potential buyers can better assess which machine best meets their needs.

Performance and Efficiency

When comparing different models, performance is often the most critical factor. The examined unit typically boasts a powerful engine that ensures optimal cutting speed and efficiency. In contrast, some alternatives may sacrifice power for energy consumption, leading to slower operation times. Additionally, features such as cutting width and speed settings can greatly influence overall effectiveness, making it essential to evaluate these aspects when selecting the right machine.

Durability and Maintenance

Another key area of comparison lies in the durability of the equipment. The model in question is known for its robust construction, allowing it to withstand rigorous use over time. Other variants might use lighter materials, which could affect longevity and require more frequent maintenance. Understanding the maintenance needs of each option can provide insight into long-term ownership costs and ease of use, further guiding the decision-making process.