The internal setup of multi-tool engines plays a crucial role in their efficient functioning and longevity. By exploring the various elements and how they interact, one can gain valuable insights into maintenance and troubleshooting, ensuring reliable operation over time. Analyzing the detailed layout of these components allows for a better grasp of their arrangement and purpose within the machine.

Comprehensive knowledge about the internal configuration aids users in identifying potential issues before they become serious problems. This understanding not only simplifies routine maintenance but also ensures that each part performs optimally, contributing to a seamless experience during usage. Awareness of how these elements fit together empowers users to make informed decisions regarding care and replacement.

Stihl KM56RC Parts Diagram Overview

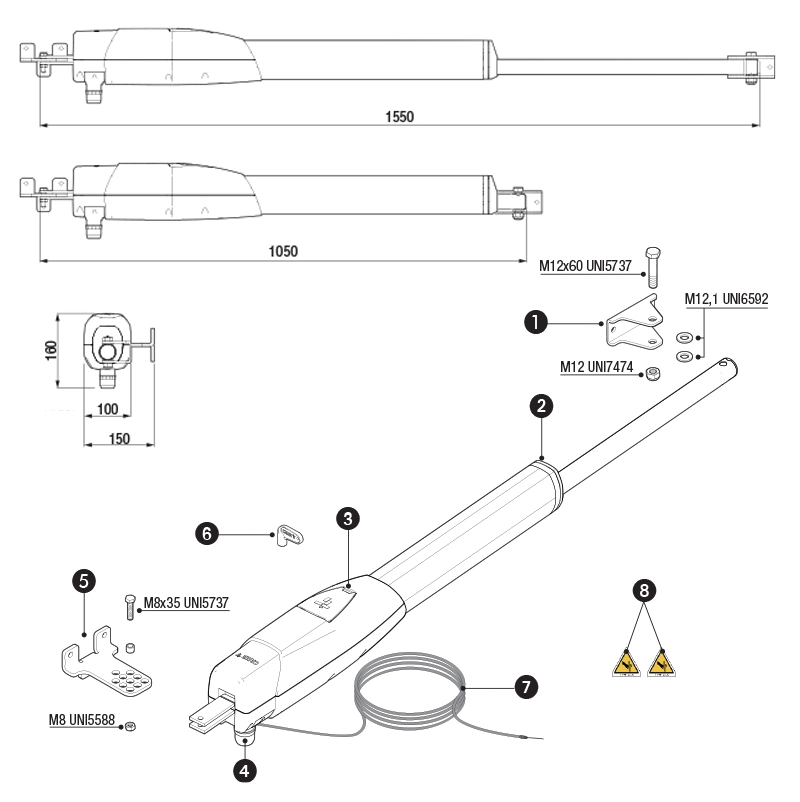

The component layout provides a clear visual representation of how various elements interact, aiding in understanding the tool’s internal structure. This layout helps users identify individual pieces and their connections, making it easier to pinpoint specific components when maintenance or repairs are needed.

Understanding the arrangement is essential for anyone looking to perform routine upkeep or troubleshoot issues. By examining the connections and positions of various pieces, users can gain insights into the functionality of each element. The diagram serves as a practical guide for recognizing where adjustments or replacements may be necessary.

Exploring this visual guide not only enhances knowledge about the tool’s design but also empowers users to perform efficient maintenance. Whether addressing wear or ensuring optimal performance, familiarity with the layout contributes to better care and longevity of the equipment.

Understanding the Key Components

Exploring the essential elements of a versatile trimmer can help users maintain and optimize their equipment for long-term use. Each component plays a crucial role in ensuring the tool functions efficiently, providing the power, stability, and precision needed for various tasks. Recognizing how these parts work together is important for troubleshooting, regular maintenance, and making any necessary adjustments.

Engine Assembly: The engine serves as the power source, driving the entire operation. It transforms fuel energy into mechanical motion, propelling the cutting mechanism with consistent force.

Drive Shaft: The drive shaft transfers energy from the motor to the cutting head. It connects these elements, allowing seamless operation while minimizing vibration for smoother handling.

Cutting Head: This section houses the cutting

Common Replacement Parts Explained

Maintaining a versatile tool for yard work often involves replacing some components over time. These items can wear out or get damaged, affecting the overall efficiency and smooth operation. Understanding which parts typically require attention and why they are essential for the machine’s functionality can help ensure its long-lasting performance.

The air filter is one such item that needs regular inspection and replacement. It helps prevent dust and debris from reaching the engine, ensuring smooth operation and reducing the risk of mechanical issues. Over time, the filter can become clogged, restricting airflow and causing poor performance.

Spark plugs are another crucial component that may need replacement to maintain optimal engine ignition. A worn-out spark plug can cause difficulties in starting or lead to misfiring, affecting the efficiency of the equipment.

The fuel line is also a part that requires occasional attention, as it can develop cracks or leaks due to constant exposure to fuel and vibrations. Replacing the fuel line helps avoid fuel delivery issues and ensures the machine runs smoothly.

Finally, the trimmer head may experience wear, particularly if used frequently on

How to Identify Part Numbers

Understanding how to recognize component identifiers is crucial for finding the correct replacement or upgrade. Each item is typically assigned a unique identifier that helps differentiate it from other similar components. Learning the right approach for locating these identifiers ensures accurate ordering and maintenance.

Check the Product Label

Start by examining the product label, which usually contains essential information. The label may display various codes, including the unique identifier, model details, or manufacturing date. Look for combinations of numbers and letters that stand out as potential identifiers.

Consult the User Manual

The user manual often lists identifiers for various components used in the equipment. It typically includes detailed tables or diagrams that map these identifiers to specific items. Referencing the manual can be a reliable way to confirm the right component.

- Look for Engravings: Some components may have identifiers engraved or stamped directly on their surface.

- Use Online Resources: Many websites provide searchable databases where you can input a partial identifier to find the full code.

- Maintaining Your Stihl KM56RC

Proper care of your equipment ensures long-lasting performance and reliable operation. Regular upkeep not only extends the lifespan of your machine but also helps prevent unexpected issues during use. By following basic maintenance routines, you can keep your tool in top condition for a variety of tasks.

Cleaning and Inspection

Keeping your device clean is essential for optimal functioning. After each use, wipe away dirt and debris from the exterior and examine for any visible wear or damage. Pay special attention to the air filter, which should be checked and cleaned periodically. A dirty filter can restrict airflow and reduce efficiency.

Regular Lubrication and Fuel Management

Proper lubrication of moving parts helps reduce friction and wear. Use the recommended lubricant for your machine and apply it to areas such as the gearbox. Additionally, always use fresh fuel and mix it according to the manufacturer’s instructions to avoid residue build-up that could clog components. Regular fuel replacement ensures smooth and efficient operation.

Routine maintenance will significantly reduce downtime and keep your equipment performing at its best. Make it a habit to inspect, clean, and

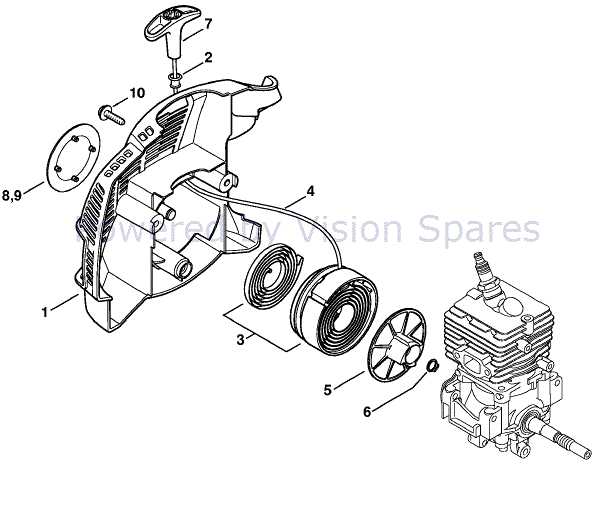

Exploring Different Engine Parts

Understanding the various components of a motor is crucial for effective maintenance and troubleshooting. Each section plays a vital role in ensuring optimal performance and longevity. By familiarizing oneself with these elements, operators can make informed decisions regarding upkeep and repairs, ultimately enhancing the efficiency of the machinery.

Component Function Cylinder Houses the piston and allows for combustion. Piston Moves up and down within the cylinder, compressing the fuel-air mixture. Crankshaft Converts linear motion of the piston into rotational motion. Fuel Injector Delivers fuel into the combustion chamber at the correct pressure and timing. Exhaust System Expels gases produced during combustion away from the engine. Ignition Coil Generates high voltage to create a spark for igniting the fuel-air mixture. Handle and Throttle Assembly Guide

The assembly of the control components is crucial for ensuring optimal performance and safety in handheld equipment. This section provides a detailed overview of the assembly process, highlighting the key elements involved in connecting the handle and throttle mechanism. Understanding the correct configuration is essential for maintaining functionality and user comfort during operation.

Understanding the Components

Before beginning the assembly, it is important to familiarize yourself with the main components of the handle and throttle assembly. The grip provides a comfortable hold, while the throttle control allows for precise speed adjustments. Ensuring that these parts are compatible and correctly aligned is vital for smooth operation.

Assembly Steps

To assemble the handle and throttle system, start by securing the grip onto the designated area of the shaft. Once in place, connect the throttle cable to the control lever, ensuring it moves freely without obstruction. It is important to double-check all connections to prevent any operational issues. Regular maintenance and inspections of these components can prolong the lifespan of your equipment.

Troubleshooting Part Issues Easily

Addressing component-related problems can be a straightforward process with the right approach. Understanding how various elements function and interact allows for effective identification and resolution of issues. This section provides insights and steps to simplify the troubleshooting process.

Common Symptoms to Watch For

- Unexpected noises during operation

- Frequent stalling or failure to start

- Reduced performance or power loss

- Visible damage or wear on components

- Inconsistent operation under load

Steps for Effective Resolution

- Begin with a thorough inspection of all visible components for signs of damage or wear.

- Consult the user manual for guidance on the functionality and specifications of each element.

- Check all connections and fastenings to ensure everything is secure and properly fitted.

- Test the system after making adjustments to assess whether issues persist.

- If problems continue, consider seeking assistance from a qualified technician or service provider.

Choosing the Right Spare Parts

Selecting appropriate components for your outdoor equipment is essential for maintaining its functionality and performance. Properly matched elements not only ensure smooth operation but also extend the lifespan of the machinery. Understanding how to identify suitable replacements can greatly enhance the overall efficiency of your tools.

Understanding Compatibility

When searching for replacements, compatibility with existing machinery is crucial. Each piece must align with specific models and configurations to ensure seamless integration. Referencing a detailed visual guide can assist in recognizing which parts are necessary for your specific equipment.

Quality Over Price

While it may be tempting to opt for less expensive options, prioritizing quality is vital. High-grade components offer better durability and performance, often resulting in fewer repairs and replacements in the long run. Investing in reliable items ensures your machinery remains efficient and dependable.