In the realm of outdoor maintenance, comprehending the various elements that contribute to the functionality of lawn care machinery is essential. Each component plays a vital role, ensuring that the equipment operates smoothly and efficiently. A thorough grasp of these elements not only enhances the user experience but also aids in proper maintenance and troubleshooting.

The intricacies of these machines can often seem overwhelming, yet familiarity with their configuration can significantly simplify the maintenance process. By delving into the specifics of each component, users can better identify issues, perform necessary repairs, and ultimately prolong the life of their equipment. An organized overview of these parts can serve as a valuable reference for both novice and experienced users alike.

Moreover, having a clear understanding of how these components interact within the machine fosters a deeper appreciation for the technology involved. This knowledge empowers users to take proactive steps in caring for their equipment, ensuring optimal performance throughout its lifespan. Whether it’s routine maintenance or addressing specific challenges, being informed about these essential parts is crucial for successful lawn care operations.

This section delves into the essential elements that contribute to the efficient functioning of the equipment. Understanding these fundamental components is crucial for effective maintenance and optimal performance.

- Engine: The heart of the machine, responsible for powering the entire system.

- Chassis: The framework that supports all other components, ensuring stability and durability.

- Transmission: This mechanism facilitates the transfer of power from the engine to the wheels, affecting speed and control.

- Blades: Essential for cutting, these components need regular maintenance to ensure they operate efficiently.

- Wheels: They provide mobility and must be in good condition to ensure smooth operation on various terrains.

- Fuel System: This includes the tank and delivery systems, crucial for ensuring a steady supply of energy to the engine.

Familiarity with these components can aid in troubleshooting and enhance overall user experience. Regular inspection and understanding of their functions can lead to prolonged lifespan and improved performance of the machine.

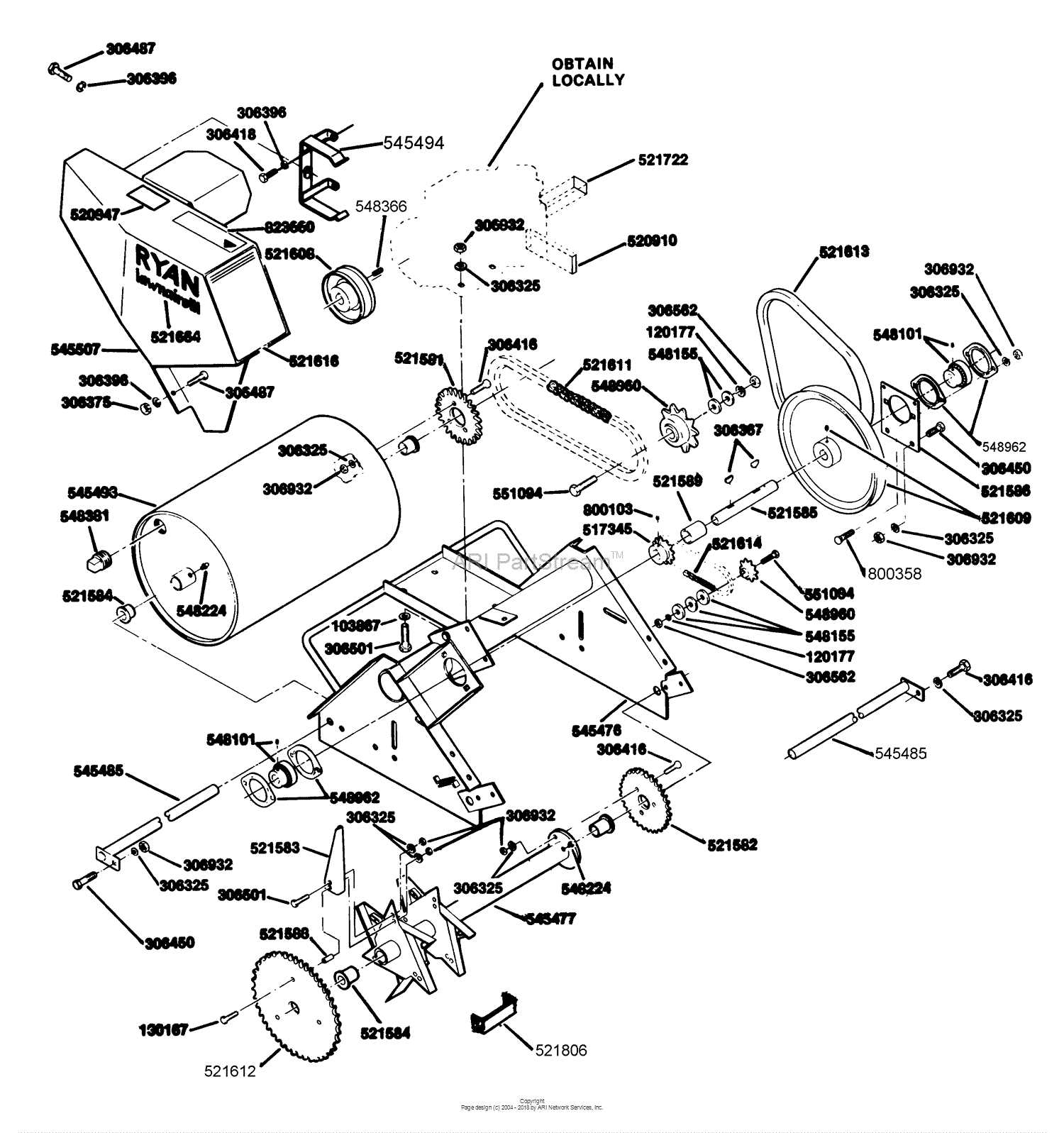

Understanding the Parts Diagram

Comprehending the layout of components in machinery is essential for effective maintenance and troubleshooting. A visual representation can enhance clarity, allowing users to quickly identify and understand the various elements involved in the equipment’s functionality. This overview aids in recognizing how each piece interacts within the system, ensuring better operational efficiency.

Importance of Component Identification

Proper identification of elements is crucial for any repair or adjustment task. Understanding the role of each component can significantly reduce the time spent on maintenance and increase the overall reliability of the machinery. By familiarizing oneself with the visual guide, operators can effectively pinpoint areas needing attention or improvement.

Utilizing Visual Aids for Better Understanding

Visual aids serve as valuable tools in the learning process. They provide a quick reference that can simplify complex machinery layouts. By studying these illustrations, users can grasp the arrangement and function of individual parts, leading to more informed decisions during maintenance procedures.

| Component | Description |

|---|---|

| Frame | The structural base that supports all other elements. |

| Engine | Drives the mechanism, providing necessary power. |

| Control System | Manages operation and allows user input. |

| Wheels | Enable mobility and facilitate movement across surfaces. |

| Fuel Tank | Holds the energy source required for operation. |

Common Issues with Parts

When dealing with various components in outdoor maintenance equipment, users often encounter a range of challenges that can impact performance and efficiency. Understanding these common concerns can help in identifying problems early and ensuring proper functionality.

One frequent issue is wear and tear, which can lead to reduced efficiency and performance. Over time, components may degrade, causing difficulties in operation or leading to complete failure if not addressed. Regular inspections can help identify signs of deterioration, allowing for timely replacements.

Another common challenge is improper installation or adjustment of components. Incorrect setup can result in malfunctioning machinery, impacting both safety and effectiveness. It is essential to follow guidelines carefully and ensure all elements are fitted correctly to avoid these problems.

Additionally, contamination from debris or environmental factors can affect the performance of various elements. Keeping equipment clean and well-maintained can significantly reduce the likelihood of these issues arising. Implementing routine cleaning practices will enhance longevity and functionality.

Maintenance Tips for Longevity

Proper upkeep is essential for ensuring the extended life of your equipment. By following a few straightforward guidelines, you can minimize wear and tear, enhance performance, and reduce the likelihood of costly repairs. Regular attention to maintenance tasks not only helps in achieving optimal functionality but also contributes to a safer operating environment.

Start with routine inspections to identify any signs of wear or damage. Checking essential components regularly allows for early detection of potential issues before they escalate. Cleaning is another crucial aspect; removing debris and buildup prevents operational inefficiencies and maintains peak performance. Additionally, lubrication of moving parts ensures smooth operation and reduces friction, which can lead to premature failure.

Following the manufacturer’s recommendations for service intervals is vital. Keeping a schedule for routine maintenance tasks such as oil changes and filter replacements helps sustain the equipment’s reliability. Lastly, storing your equipment in a protected area when not in use shields it from environmental elements, further enhancing its lifespan.

Replacing Worn-Out Components

Over time, certain elements of lawn care equipment may wear down due to prolonged use and exposure to various environmental conditions. Addressing these issues promptly is crucial to maintaining optimal performance and ensuring longevity. This section outlines the steps to effectively replace worn-out components, thereby enhancing the functionality of your equipment.

Identifying components that require replacement is the first step in this process. Common signs of wear include:

- Decreased efficiency in operation

- Unusual noises during use

- Visible damage or corrosion

- Inconsistent performance

Once you have pinpointed the affected components, it’s essential to gather the necessary tools and replacement items. Here is a list of basic tools you may need:

- Wrenches or sockets

- Screwdrivers

- Pliers

- Replacement parts

When ready, follow these steps for a successful replacement:

- Ensure the equipment is powered off and disconnected from any power source.

- Carefully remove the worn-out component using the appropriate tools.

- Install the new component, ensuring it is securely attached and correctly aligned.

- Test the equipment to confirm that the replacement has restored optimal functionality.

Regularly checking and replacing worn-out elements will not only improve performance but also extend the lifespan of your lawn care equipment.

Where to Find Replacement Parts

Locating the necessary components for equipment maintenance can be a crucial task for ensuring optimal performance. A variety of sources are available to assist in acquiring these essential items, allowing for efficient upkeep and repairs. Understanding where to seek these replacements can significantly enhance the maintenance process.

Online Retailers

Many online platforms specialize in selling various components for equipment. These retailers often provide detailed descriptions, compatibility information, and customer reviews, which can aid in making informed purchasing decisions. Exploring multiple websites can help you compare prices and availability.

Local Dealers and Repair Shops

In addition to online options, local dealers and repair facilities can be excellent resources for obtaining necessary components. These establishments typically have access to genuine replacements and can offer expert advice on installation and maintenance. Engaging with professionals in your area can ensure that you receive high-quality items tailored to your specific needs.

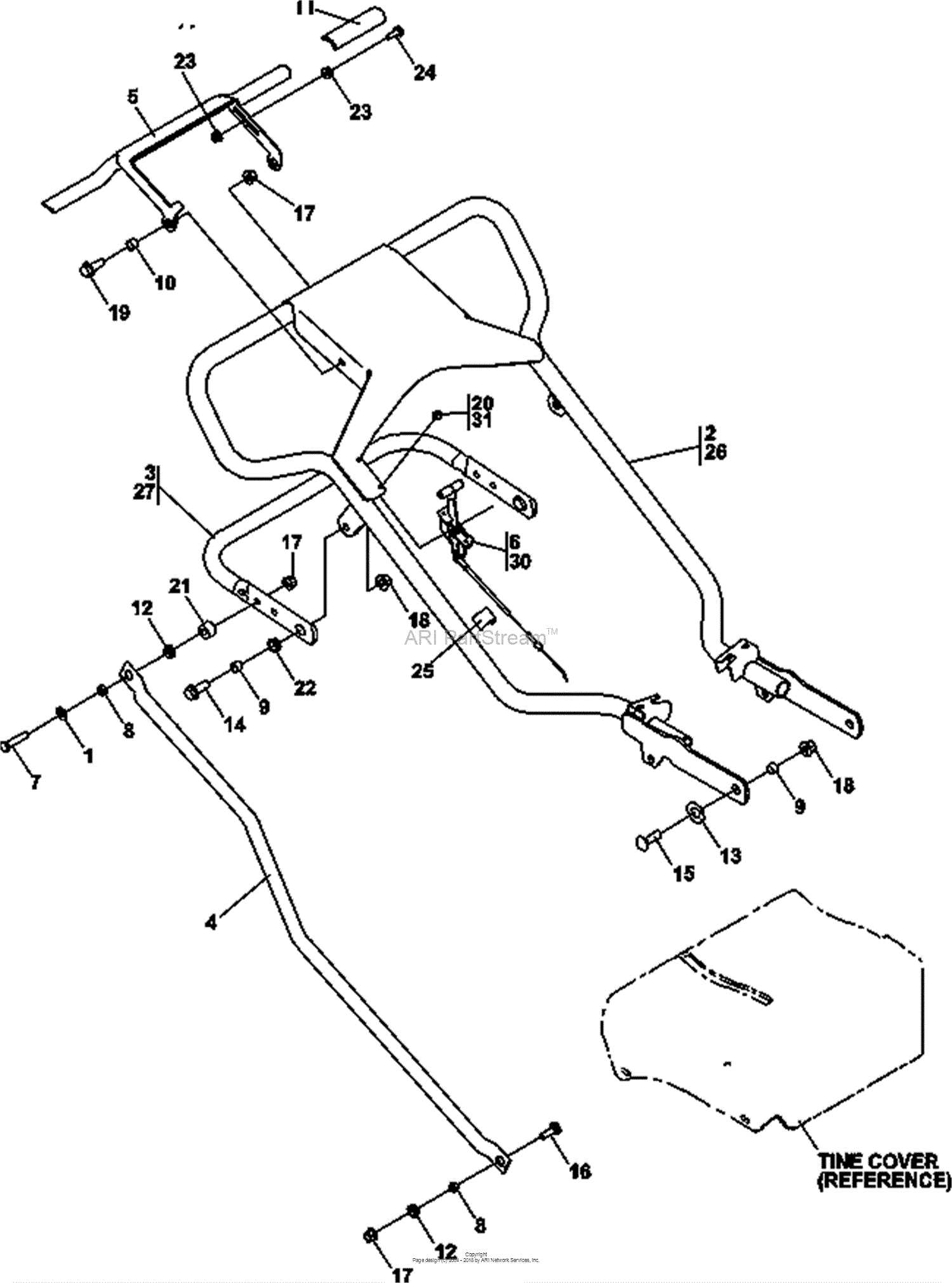

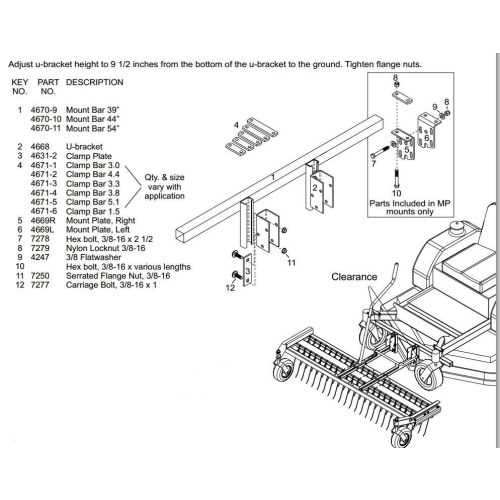

Visual Guide to Assembly

This section provides a comprehensive overview of the assembly process for your equipment, helping to streamline the setup and ensure everything functions optimally. By following the visual guide, users can easily navigate through the various components, making the assembly more intuitive and efficient.

Step-by-Step Instructions

Begin by laying out all the components in an organized manner. This will allow you to identify each piece and understand its role in the overall assembly. Refer to the accompanying visuals to match the components with their respective positions, ensuring a seamless construction process.

Tips for Successful Assembly

To achieve the best results, take your time and follow the illustrated instructions closely. Make sure to double-check each connection and fit, as this will enhance the longevity and performance of your machinery. Familiarizing yourself with the assembly order will also contribute to a more straightforward and error-free setup.

Frequently Asked Questions

This section aims to address common inquiries related to maintenance and components of lawn care machinery. Here, you will find answers to frequently posed questions that can assist users in understanding their equipment better and resolving typical issues encountered during operation.

| Question | Answer |

|---|---|

| What are the essential maintenance tips for my lawn care equipment? | Regularly check and clean the air filter, change the oil as recommended, and inspect the blades for sharpness. |

| How often should I replace the components of my machine? | It is advisable to replace parts according to the manufacturer’s guidelines or whenever you notice a decline in performance. |

| Where can I find a comprehensive list of components for my equipment? | Consult the user manual or visit the manufacturer’s website for a detailed list of components and specifications. |

| What should I do if my equipment does not start? | Check the fuel level, ensure the battery is charged, and inspect for any blockages in the fuel line. |