Every gardening enthusiast knows the importance of maintaining their trimming equipment to ensure optimal performance. Familiarity with the various components of these machines is essential for effective repairs and upgrades. This section delves into the essential elements that make up these powerful tools, offering insights into their functionality and maintenance.

By comprehensively exploring the assembly of these devices, users can identify potential issues and carry out necessary replacements or adjustments. A clear understanding of the structure not only aids in troubleshooting but also enhances the overall user experience, leading to more efficient gardening tasks.

In this guide, you will discover a detailed overview of the key components, their roles, and how they interact. Whether you are a seasoned gardener or a newcomer to the craft, grasping the intricacies of your trimming apparatus will empower you to tackle any challenge that arises in your outdoor endeavors.

Understanding Craftsman Weed Eater Parts

When it comes to maintaining your outdoor power equipment, comprehending its various components is essential for ensuring optimal performance and longevity. Each element plays a significant role in the functionality of the machine, contributing to its overall efficiency and effectiveness in tackling yard tasks.

Key Components and Their Functions

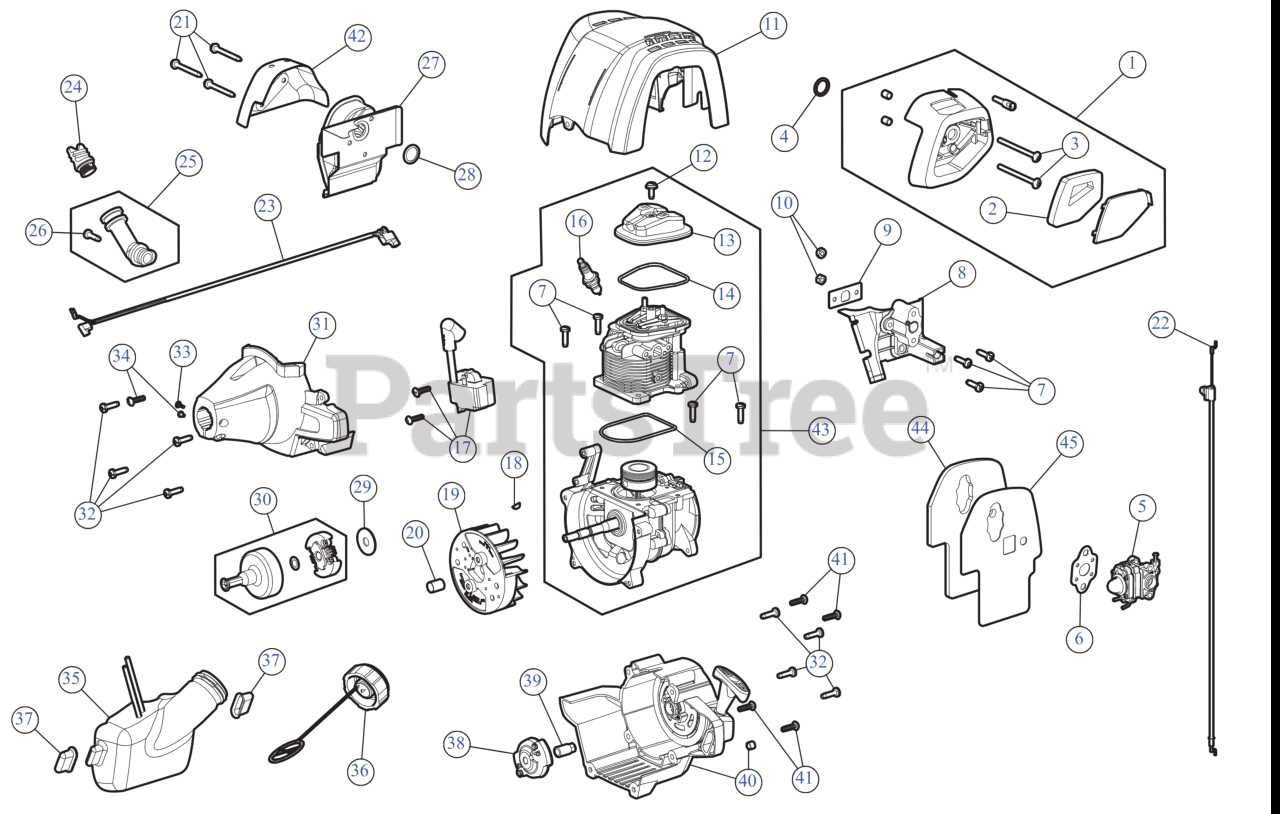

The primary elements of these devices include the motor, cutting mechanism, and fuel system. The motor serves as the heart, providing the necessary power to operate the tool. The cutting mechanism is responsible for trimming and shaping vegetation, while the fuel system ensures that the engine runs smoothly and efficiently. Understanding how these components interact can aid in troubleshooting and repairs.

Maintenance Tips for Longevity

Regular upkeep is crucial for extending the life of your equipment. Checking for wear and tear on the cutting blades, ensuring the motor is clean, and replacing any worn-out elements can significantly enhance performance. Additionally, consulting a visual reference of the components can assist in identifying specific areas that may require attention or replacement.

Components of a Weed Eater Explained

Understanding the various elements of a trimming device is crucial for effective maintenance and operation. Each component plays a specific role in ensuring the tool functions efficiently, allowing users to achieve optimal performance. This section delves into the key constituents that make up such a tool, offering insight into their functions and significance.

| Component | Description |

|---|---|

| Motor | The power source that drives the entire system, converting fuel or electrical energy into mechanical movement. |

| Trimming Head | The part that holds the cutting line or blades, responsible for executing the actual cutting process. |

| Cutting Line | A flexible line that rotates at high speeds to trim grass and small plants effectively. |

| Handle | The grip that allows users to maneuver the tool comfortably while providing control during operation. |

| Guard | A safety feature designed to protect the user from debris and to ensure the cutting area is contained. |

| Shaft | The elongated part that connects the motor to the cutting head, transmitting power for movement. |

| Throttle Control | A mechanism that allows users to adjust the speed and power of the motor during operation. |

| Fuel Tank | A reservoir that holds the fuel needed for combustion engines, ensuring the motor operates smoothly. |

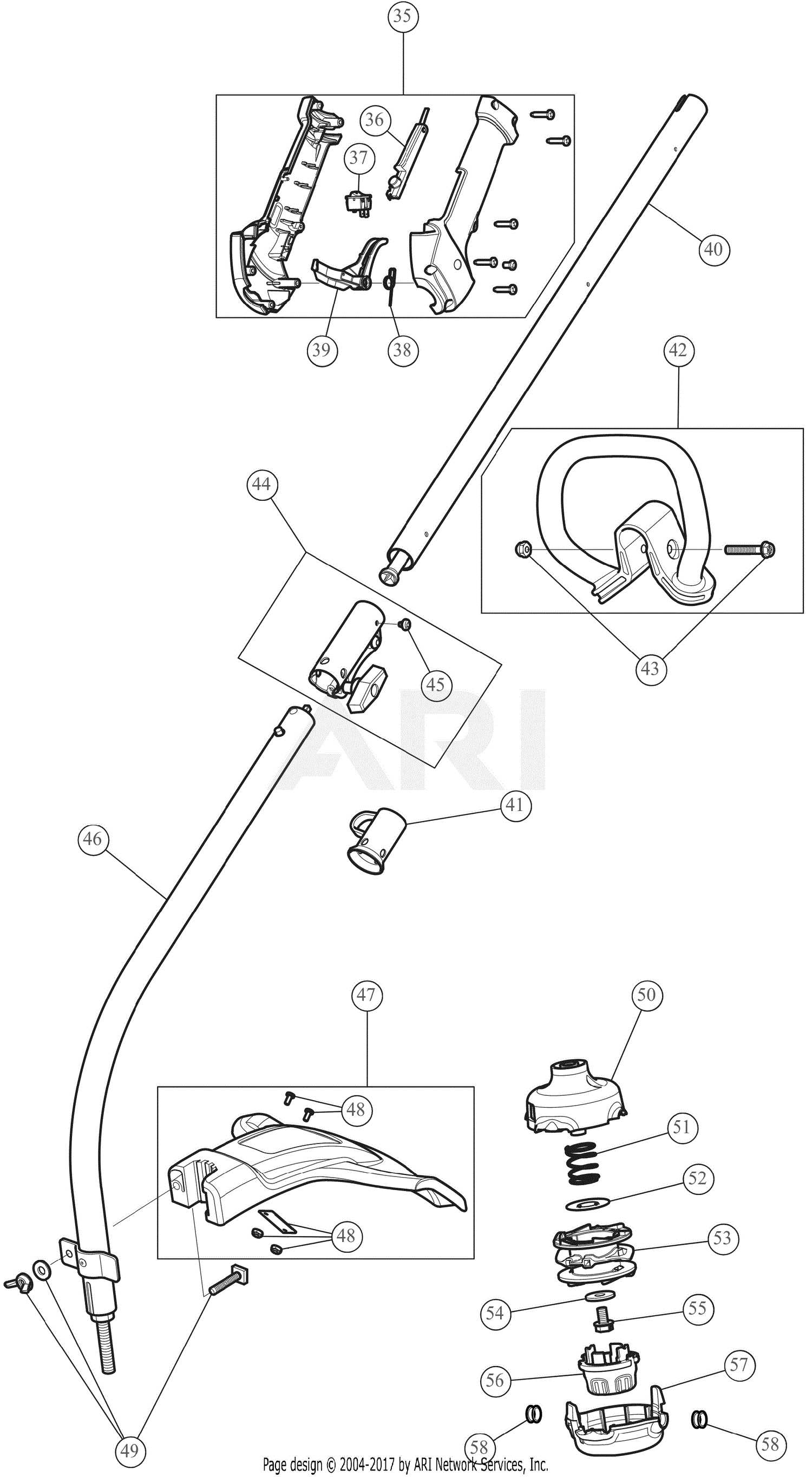

How to Identify Parts Diagrams

Understanding technical illustrations is essential for maintaining and repairing various tools. These visual guides serve as a map, helping users locate and recognize each component of the device. By becoming familiar with the layout and symbols used in these illustrations, one can streamline the process of troubleshooting and reassembling equipment.

First, familiarize yourself with common terminology. Knowing the names and functions of the components will aid in deciphering the visual cues presented. Many illustrations feature labels or annotations that clarify what each part does, making it easier to grasp the overall structure.

Next, pay attention to the visual hierarchy. Key components are often highlighted or presented in a larger scale, while smaller parts may be grouped together. Understanding this arrangement can provide insight into how different elements interact with one another.

Finally, use reference materials. Consult manuals, online resources, or community forums that discuss similar tools. These resources can offer additional context and examples, enhancing your ability to interpret the illustrations effectively.

Importance of Regular Maintenance

Regular upkeep of your outdoor equipment is essential for optimal performance and longevity. Proper maintenance not only enhances efficiency but also prevents potential breakdowns, saving you both time and money in the long run.

Benefits of Consistent Care

Ensuring that your machinery is well-maintained leads to improved functionality. Regular inspections and servicing can identify wear and tear before they become major issues. This proactive approach helps maintain peak performance and reduces the risk of unexpected failures.

Safety and Efficiency

Keeping your tools in top condition is crucial for safety. Equipment that is regularly serviced is less likely to malfunction, which can pose risks to the operator. Furthermore, efficient machinery consumes less fuel and operates with greater effectiveness, allowing you to complete tasks more swiftly and safely.

Common Replacement Parts Overview

In the realm of outdoor power tools, understanding essential components is crucial for maintenance and longevity. This section provides an insight into the frequently needed elements that ensure optimal performance of your equipment. Recognizing these items can facilitate timely replacements and enhance your tool’s efficiency.

One of the primary elements often requiring attention is the cutting mechanism, which directly impacts the effectiveness of your device. Over time, wear and tear can diminish its performance, making timely swaps necessary. Another critical component is the motor, responsible for powering the entire operation. If issues arise, it may be essential to inspect or replace this unit to restore functionality.

Additionally, the fuel system, including filters and lines, plays a vital role in ensuring smooth operation. Blockages or leaks can severely affect performance, necessitating prompt intervention. Lastly, ergonomic features such as grips and handles may also require attention, as they contribute to user comfort and control during operation.

Tools Needed for Repairs

Proper maintenance of outdoor equipment requires a set of essential tools to ensure efficient and effective repairs. Having the right instruments on hand not only simplifies the process but also enhances safety and reliability. Below is a list of tools that are typically necessary for performing repairs on various types of equipment.

Essential Tools

| Tool | Purpose |

|---|---|

| Screwdriver Set | Used for loosening and tightening screws in various components. |

| Wrench Set | Ideal for adjusting nuts and bolts securely. |

| Pliers | Helpful for gripping, twisting, and cutting wires or small parts. |

| Socket Set | Allows for easier access to fasteners in tight spaces. |

| Replacement Blades | Essential for maintaining cutting efficiency and performance. |

| Lubricants | Used to reduce friction and prevent wear on moving parts. |

Safety Equipment

In addition to the basic tools, safety gear is crucial during repairs. This includes gloves to protect hands from sharp objects, goggles to shield eyes from debris, and sturdy footwear to ensure stability. Prioritizing safety ensures a more efficient and secure repair process.

Step-by-Step Repair Guide

When it comes to maintaining outdoor equipment, having a clear approach can make all the difference. This guide aims to provide a systematic method for troubleshooting and fixing common issues that may arise, ensuring your machine operates at its best. By following these steps, you can gain confidence in your repair skills and save on service costs.

Tools and Materials Needed

Before starting any repair, it’s essential to gather the necessary tools and materials. Below is a list to help you prepare:

| Tool/Material | Purpose |

|---|---|

| Screwdriver Set | For removing and securing screws |

| Wrench | For loosening and tightening bolts |

| Replacement Components | To swap out damaged or worn parts |

| Cleaning Supplies | For removing debris and ensuring optimal performance |

| Safety Gear | To protect yourself during the repair |

Repair Process

Follow these steps to ensure a successful repair:

- Identify the Issue: Observe any symptoms that indicate malfunction.

- Consult the Manual: Refer to the user manual for specific guidance related to your model.

- Disassemble Carefully: Use the screwdriver and wrench to take apart the necessary components.

- Inspect for Damage: Look for any broken or worn parts that need replacement.

- Replace Components: Install new parts as needed, ensuring a secure fit.

- Reassemble: Put everything back together in the reverse order of disassembly.

- Test the Equipment: Run a test to verify that the issue has been resolved.

By adhering to this structured guide, you can effectively tackle repair challenges and maintain the efficiency of your outdoor equipment.

Where to Find Original Parts

Finding authentic components for your outdoor power equipment can significantly enhance its performance and longevity. It’s essential to source these items from reliable suppliers to ensure compatibility and quality. This section outlines various avenues to acquire genuine replacements effectively.

Manufacturer’s Website: The first place to check is the official website of the equipment’s manufacturer. They often provide a comprehensive catalog of available items, along with detailed specifications to help you make informed choices.

Authorized Dealers: Another reliable option is to visit authorized retailers or local dealers. These establishments typically stock original replacements and can offer expert advice regarding compatibility and installation.

Online Marketplaces: Reputable online platforms can also be a valuable resource. Look for listings that specify the authenticity of the components, and pay attention to seller ratings and reviews to ensure you’re purchasing from a trusted source.

Repair Shops: Local repair shops specializing in outdoor equipment may have access to genuine items or can assist in sourcing them. Their expertise can also provide insights into which components are necessary for optimal performance.

By exploring these options, you can confidently find the right components to keep your equipment running smoothly and efficiently.

Tips for Preventing Damage

Proper maintenance and careful usage can significantly extend the lifespan of your outdoor power tools. By implementing a few simple practices, you can minimize wear and tear, ensuring your equipment operates efficiently and remains in good condition.

Regular Maintenance

Routine inspections are essential. Check for any signs of wear or damage, and clean the components regularly to prevent buildup that can lead to malfunction. Keeping your device free from debris will help maintain optimal performance.

Safe Operating Practices

Always follow the manufacturer’s guidelines when using your equipment. Using the correct technique reduces the risk of accidents and damage. Additionally, avoid operating in adverse weather conditions, which can compromise the tool’s functionality.