The assembly and structure of outdoor equipment often involve a variety of essential elements working together in harmony. Understanding how these individual elements connect and function is crucial for maintaining and repairing your machine efficiently. This section will provide insights into the primary components and their layout, helping you grasp the intricacies behind the device’s operation.

Each section of the equipment plays a vital role in ensuring smooth operation. From the cutting mechanism to the propulsion system, every part is designed with precision to perform specific tasks. By familiarizing yourself with their arrangement and functions, you can easily identify issues and perform necessary replacements or adjustments.

Detailed knowledge of these mechanisms allows for better upkeep and can significantly extend the lifespan of the equipment. Regular inspections and understanding the layout will empower you to tackle minor issues before they turn into major problems.

Troy Bilt TB240 Overview

This section provides an in-depth look at a popular self-propelled lawn mower designed for ease of use and efficiency. It’s built to offer a powerful and reliable cutting performance, making yard maintenance simpler for homeowners. With a focus on convenience, it integrates features that enhance control, maneuverability, and comfort.

Key Features

- Self-propelled functionality for smooth operation on various terrains.

- Powerful engine designed to handle tough grass and uneven lawns.

- Adjustable cutting heights to suit different lawn conditions and preferences.

- Compact design for easy storage and transport.

Ease of Maintenance

- Simple oil change system for quick maintenance.

- Washout port allows for easy cleaning of the undercarriage.

- Durable materials used to ensure long-lasting performance and reduced wear.

Overall,

Key Components and Functions

This section provides an overview of the essential elements and their roles in the machine’s operation. Understanding these components can help in maintaining and optimizing its performance, ensuring smooth functionality during use.

Engine and Drive System

- Engine: The heart of the machine, responsible for powering all other systems. It drives both the cutting mechanism and the movement system.

- Drive System: Enables easy maneuvering by controlling the speed and direction, making it efficient on various terrains.

Cutting Mechanism

- Blades: Sharp cutting tools designed to slice through grass with precision, ensuring an even and clean cut.

- Height Adjustment: A control mechanism that allows users to modify the cutting height according to their needs, offering flexibility for different grass types.

Each of these key parts plays a crucial role in ensuring the machine runs

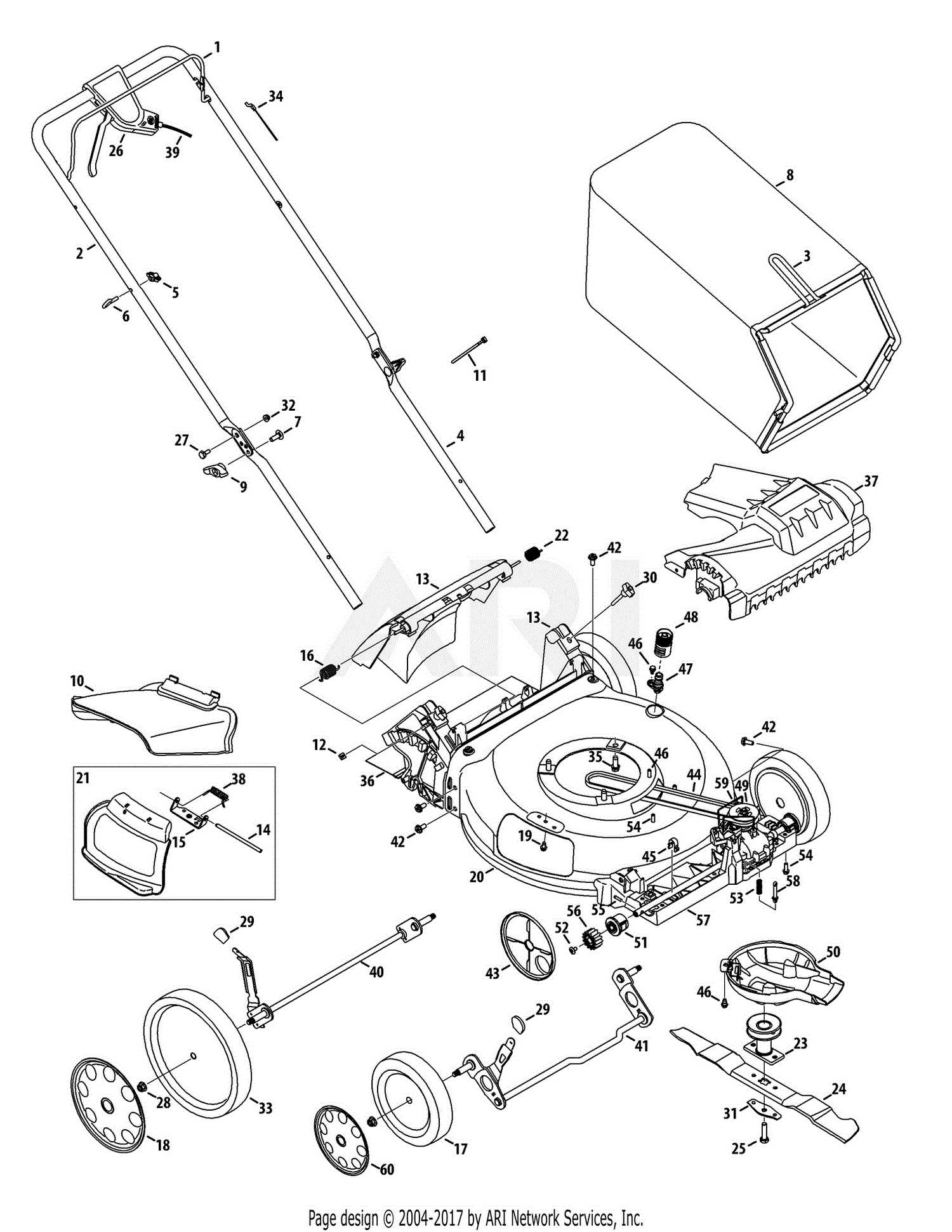

Identifying Essential Parts of TB240

The functionality of any equipment relies on understanding its main components. Each element plays a role in ensuring efficient operation, contributing to the overall performance. Recognizing these key elements helps maintain the equipment in top condition and addresses any potential issues early on.

Main Components Overview

This section highlights the primary elements that enable smooth functioning. These include mechanisms responsible for movement, power transmission, and user control. Each component is designed to fulfill a specific function, working in harmony to ensure reliability and ease of use.

Critical Maintenance Elements

Routine care and understanding of core elements are crucial for long-lasting performance. This involves regularly checking wear-prone sections and ensuring that all mechanisms are functionin

Recognizing Critical Mechanisms

Understanding the essential components of any machine is key to maintaining its functionality and ensuring smooth operation. By identifying these important elements, one can more easily diagnose issues and perform necessary adjustments or repairs. This knowledge helps in sustaining the equipment’s efficiency and extending its lifespan.

Below is an overview of some of the most vital systems and their corresponding roles in the proper functioning of machinery:

| Component | Function | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Drive Assembly | Transfers power to the moving parts, ensuring motion and control. | ||||||||||||||||||

| Cutting Mechanism | Handles the primary task, often involving precise mechanical action. | ||||||||||||||||||

| Control System | Regulates the operation, providing necessary

How to Find Replacement PartsWhen maintaining or repairing your equipment, locating the correct components is essential for keeping it running smoothly. Understanding where to search for replacement items ensures that you get compatible and durable solutions for your needs. Step 1: Start by identifying the specific model of your equipment. This information is crucial for finding the correct components that match its specifications. Typically, this information can be found in the user manual or on a label attached to the machine. Step 2: Visit authorized retailers or manufacturers’ websites. These sources offer a wide range of replacement items, ensuring the highest compatibility and quality. You Guidelines for Locating ComponentsIdentifying various elements within a mechanical assembly is essential for effective maintenance and repair. A systematic approach can simplify the process, ensuring that each component is correctly understood and accessed. Start by reviewing the overall layout of the equipment. Familiarize yourself with its structure and the function of each segment. This foundational knowledge will aid in pinpointing specific items during inspections or replacements. Utilize detailed illustrations or schematics that outline the configuration of the unit. These resources provide a visual reference, making it easier to comprehend where each element resides within the assembly. Pay attention to labels and annotations that may indicate measurements or specifications relevant to the components. When searching for a particular part, focus on its physical characteristics, such as shape, size, and color. These attributes can significantly narrow down your search, especially in more complex systems where multiple similar items may exist. If possible, consult the manufacturer’s manual or online resources. These documents often contain valuable information regarding the positioning and identification of parts, further enhancing your ability to locate what you need efficiently. Maintaining the Troy Bilt TB240

Regular upkeep is essential for ensuring the longevity and optimal performance of your outdoor equipment. By adhering to a consistent maintenance routine, you can prevent common issues and enhance the overall efficiency of the machine. This guide will provide essential tips to keep your device running smoothly. Start by checking the oil levels frequently. Using the right type of oil is crucial for the engine’s performance. Change the oil as recommended in the user manual to avoid sludge buildup, which can lead to engine wear. Sharpen the cutting blade periodically to maintain effective operation. A sharp blade not only provides cleaner cuts but also reduces strain on the engine, promoting efficiency. Additionally, inspect the blade for any damage and replace it if necessary. Clean the air filter regularly to ensure optimal airflow to the engine. A clogged filter can cause performance issues and increase fuel consumption. Depending on the model, you may either wash or replace the filter as part of your maintenance routine. Lastly, ensure that all fasteners are tight and in good condition. Loose or worn parts can lead to vibrations that may damage components over time. Regular inspections and tightening of bolts and screws will contribute to the longevity of your equipment. Best Practices for LongevityMaintaining equipment effectively is crucial for ensuring its durability and efficiency. Adopting best practices can significantly extend the lifespan of machinery, ultimately leading to better performance and reduced costs over time. Here are some key strategies to keep your device running smoothly for years to come.

By incorporating these practices into your routine, you can enhance the reliability of your equipment and enjoy its benefits for a longer period. Common Issues with TB240 PartsWhen dealing with outdoor equipment, users may encounter a variety of common challenges that can affect performance and usability. Understanding these issues is crucial for maintaining optimal functionality and extending the lifespan of the machine. Recognizing the signs of wear and tear can help prevent further damage and ensure efficient operation. Wear and TearDegradation of components over time is a frequent concern. Common symptoms include difficulty in starting, irregular operation, and decreased efficiency. Regular inspections can help identify parts that require replacement or servicing to prevent larger complications. Improper AssemblyOccasionally, users may experience problems due to incorrect installation of components. Misalignment or loose fittings can lead to operational failures. It is essential to follow the manufacturer’s guidelines meticulously to ensure each element is correctly positioned and secured. Diagnosing Problems with ComponentsIdentifying issues with machinery components is crucial for maintaining optimal performance and longevity. Understanding how different parts interact can aid in troubleshooting various malfunctions effectively. Regular inspection and systematic testing can uncover underlying problems that may not be immediately apparent. When facing operational challenges, it is essential to assess each component methodically. The following table outlines common components, potential issues, and recommended diagnostic steps:

By following these diagnostic steps and understanding the roles of various components, users can effectively address and resolve operational issues. |