Maintaining a lawn tractor involves knowing its individual components and how they work together. Every model has its unique assembly, and familiarizing yourself with the various elements is essential for smooth operation and efficient repairs. A comprehensive overview of these components ensures that users can troubleshoot issues or plan upgrades without difficulty.

The correct identification of the key parts makes it easier to determine where problems might lie. This type of reference serves as a valuable guide when seeking replacements or servicing the machine. It helps both seasoned professionals and novice users to visualize how everything connects, making the repair process faster and more effective.

Whether you are trying to fix a malfunction or simply performing routine maintenance, understanding the internal structure of a tractor can save time and prevent unnecessary confusion. A well-organized guide will aid you in pinpointing the correct pieces, ensuring you can get your equipment back to working order as quickly as possible.

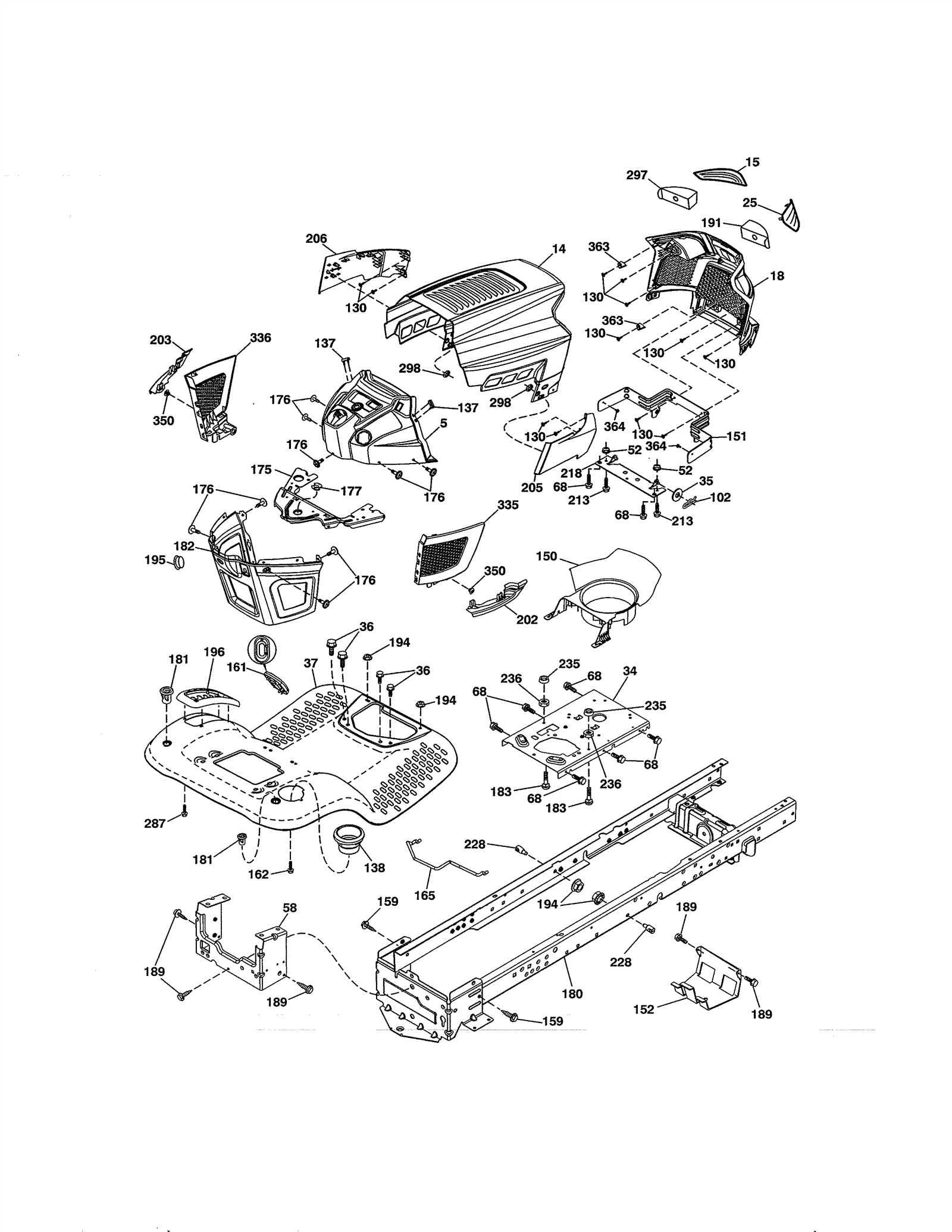

Essential Components of Craftsman T3200

When it comes to lawn maintenance, understanding the key elements that keep the machine running smoothly is vital. Whether for routine upkeep or repairs, a good grasp of the machine’s core components ensures efficient performance. These elements are crucial to how the equipment functions and its overall longevity. Below are some of the primary sections that play a significant role in the effective operation of any high-performance outdoor machinery.

Key Sections

- Engine: The heart of the equipment, responsible for powering all other functions.

- Transmission: Allows smooth movement and controls speed and direction.

- Fuel System: Provides the necessary energy for the engine to run efficiently.

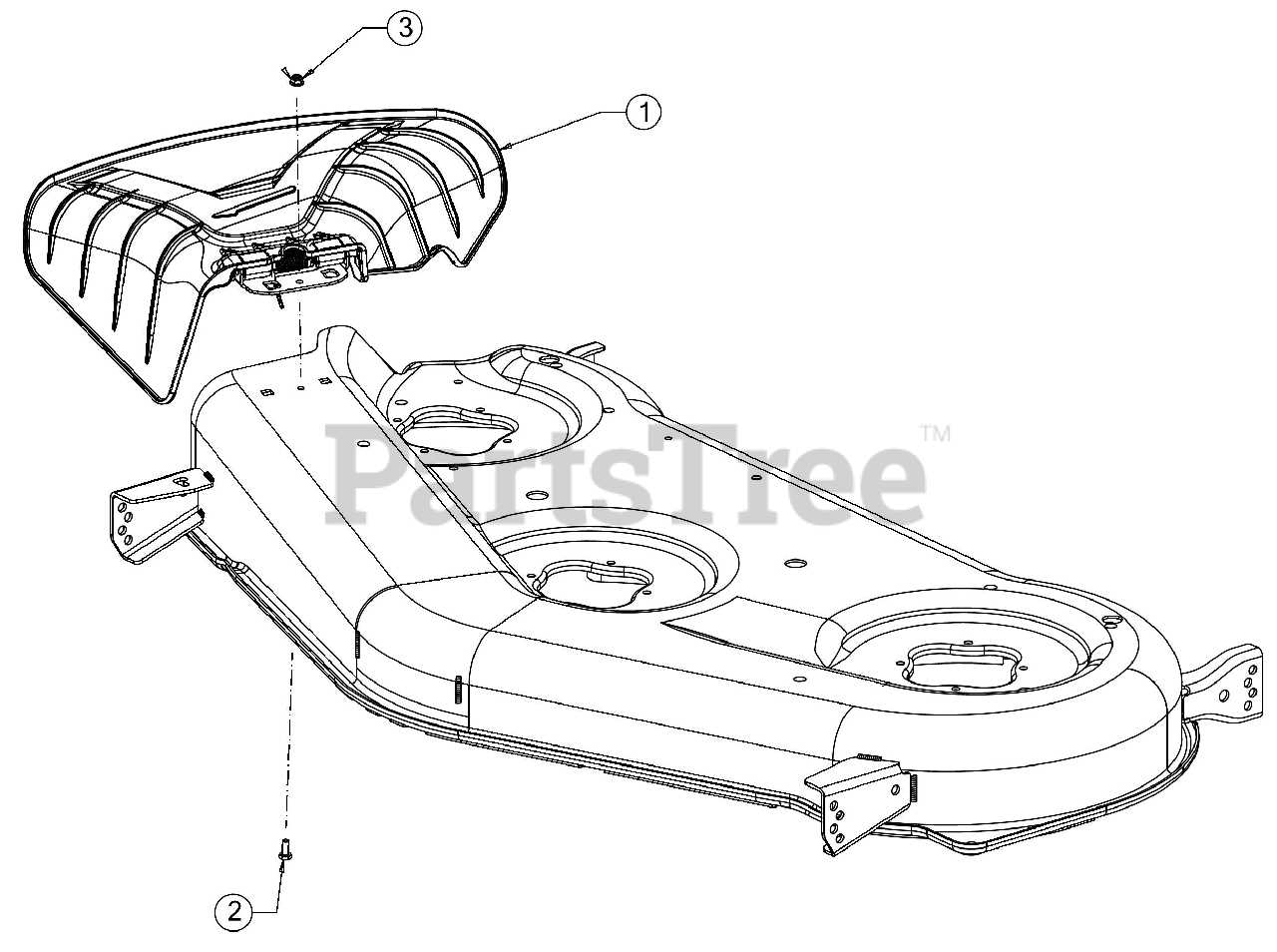

- Deck Assembly: Includes blades and related components responsible for cutting grass.

Additional Vital Elements

- Control Mechanism: The interface that allows the user to manage all machine functions.

- Wheels and Axles: Facilitate smooth movement and support the machine’s weight during operation.

- Electrical System: Powers lights, indicators, and safety features.

These essential components work in tandem to ensure optimal functionality and performance. Regular checks and maintenance on these areas help avoid costly breakdowns and prolong the lifespan of the machine.

Understanding the Engine Parts Diagram

When working with an engine, having a clear visual guide to its components is essential for successful maintenance and repairs. A comprehensive chart of engine elements allows for a better understanding of how each component interacts and functions. Knowing the layout of various machine elements can help in identifying problems more efficiently and ensuring smooth operation.

Every engine consists of several key units, from the ignition system to the cooling system, each playing a crucial role in the machine’s performance. By examining a visual reference, one can pinpoint where specific parts are located and how they connect with one another. This insight proves invaluable when troubleshooting or replacing faulty components.

Understanding the layout of the engine helps in avoiding common mistakes during disassembly and reassembly. Each component has a unique place, and recognizing their position ensures that repairs are carried out with precision and efficiency.

In addition, being familiar with the entire system makes routine checks and upkeep easier to perform. Knowing which parts are susceptible to wear and tear allows for timely interventions, preventing major breakdowns. Overall, mastering the details of the machine’s inner workings is crucial for extending its lifespan and maintaining peak performance.

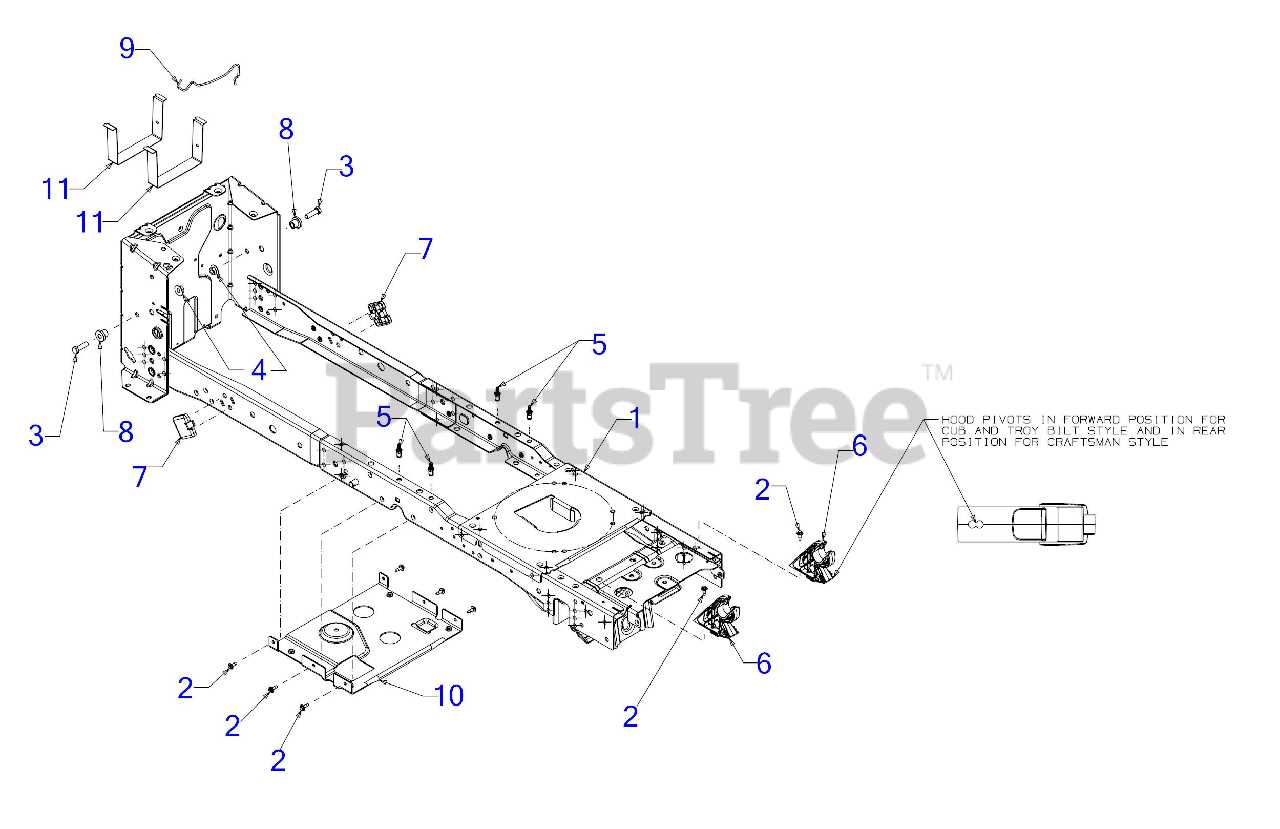

How to Identify Craftsman T3200 Subsystems

Understanding the individual components and systems of a machine is crucial for proper maintenance and troubleshooting. Identifying these subsystems can greatly improve your ability to diagnose issues and ensure optimal performance. A detailed examination of the unit’s structure helps in recognizing which areas may require attention, be it mechanical or electrical systems. This process begins by recognizing the major functional groups that make up the overall system.

To begin identifying the subsystems, follow these steps:

- Locate the engine compartment and identify the primary power source.

- Check the transmission and drivetrain, ensuring proper engagement and operation of wheels or belts.

- Inspect the steering mechanism, including the linkage and control system for smooth operation.

- Assess the electrical subsystems such as the ignition system, battery, and wiring connections.

- Finally, examine the exterior features like the cutting mechanism or other auxiliary attachments that are part of the machine’s functionality.

Each subsystem interacts with others, and recognizing these interactions can aid in better troubleshooting and repairs. A systematic approach to identifying these areas helps you maintain efficiency and longevity in operation.

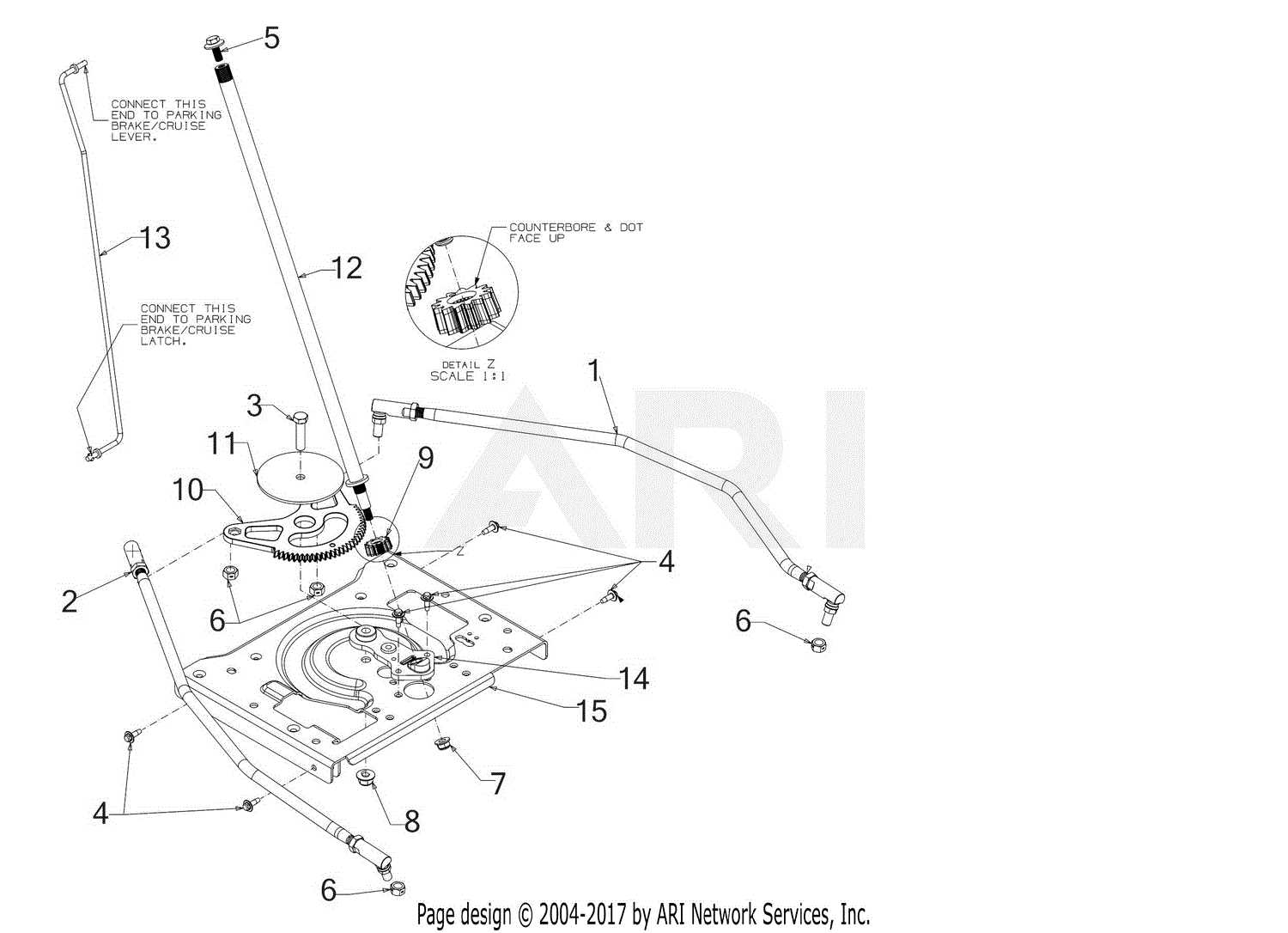

Exploring the Transmission and Drive Mechanism

The transmission and drive system play a crucial role in the operation of any lawn tractor, providing the necessary power to move the machine and control its speed. This section delves into the essential components and functions that make up this complex mechanism. Understanding how each part interacts with the others can help troubleshoot issues and maintain smooth operation.

- Transmission Assembly: This component is responsible for transferring power from the engine to the wheels. It consists of various gears and belts that enable the machine to operate efficiently across different speeds.

- Drive Belt: A key element in the drive system, the belt connects the engine to the transmission, facilitating the transfer of energy. Proper tension and alignment of the belt are vital for optimal performance.

- Axles and Gears: The axles transmit motion to the wheels, while the gears regulate the speed and torque. Together, they ensure that the vehicle can handle various terrain and workload demands.

- Clutch Mechanism: The clutch allows for disengaging the drive system, enabling smoother starts and stops. It ensures that power is delivered efficiently to the wheels when needed.

Understanding these components and how they work together helps in diagnosing performance issues, ensuring that your lawn tractor runs at its best. Regular inspection and maintenance of the transmission and drive system can prevent costly repairs and enhance longevity.

Key Maintenance Parts for Craftsman T3200

Ensuring proper upkeep of your machine requires attention to several crucial components. Regular maintenance of these elements will guarantee smooth operation and extend the lifespan of the equipment. Each part plays a vital role in the functionality, safety, and overall performance. Knowing which elements to focus on can make a significant difference in maintaining efficiency and avoiding costly repairs.

Essential Components for Regular Upkeep

The most critical aspects include the engine, transmission, and wheel assembly. Maintaining the engine is fundamental, as it powers the machine. Keep it clean and ensure the air and fuel filters are replaced regularly. The transmission should be inspected for any issues with belts or fluids. Any wear in this system can directly impact the performance of the entire machine. Lastly, proper maintenance of the wheel assembly ensures smooth movement and stability during operation.

Additional Parts to Consider

Aside from the core components, don’t forget the lubrication system and safety features. Regularly check the oil and replace it when necessary to maintain optimal engine performance. The safety features, such as brakes and the blade assembly, should also be inspected to ensure user safety and reliability. Neglecting these systems could lead to more severe malfunctions down the line.

Common Issues with Craftsman T3200 Assembly

Assembling a riding mower can present a variety of challenges, especially when certain components are misaligned or improperly installed. Even experienced users might encounter difficulties when working with such machinery. Several factors can contribute to these issues, from missing connections to incorrect sequences during the build. Identifying and addressing common problems early can save time and prevent damage to essential elements.

Misalignment of Key Components

One frequent issue during assembly is the misalignment of major components like the wheels and deck. If these parts are not properly aligned, the mower may not function as expected. This could lead to uneven cutting or, in more severe cases, mechanical failure. Ensuring that all parts are aligned according to the manual’s guidelines is crucial for smooth operation.

Incorrect Bolts or Fasteners

Another common problem occurs when the wrong bolts or fasteners are used during the assembly process. Using the wrong size can cause parts to not fit correctly, potentially leading to stripped threads or loose connections. Double-checking the specifications and matching each bolt with its designated position can prevent these issues from arising.

Additional attention to detail is required for assembly to be successful. Minor mistakes, like missing washers or improperly tightened screws, can have lasting effects on performance. By carefully following the manual and confirming the position of every element, users can avoid most of these typical assembly errors.

Regular maintenance and occasional checks on the integrity of assembled parts are recommended to ensure the equipment stays in optimal condition.

Wiring and Electrical Layout

Understanding the electrical system of a lawn tractor is essential for proper maintenance and troubleshooting. This section explores the internal wiring setup, including key components and connections that power various functions. Whether you’re dealing with starting issues, malfunctioning lights, or other electrical concerns, familiarity with the system helps identify and resolve problems effectively.

Key Electrical Components

The core elements of the electrical system are designed to ensure the proper operation of essential features such as the ignition, lights, and control systems. These parts include the battery, ignition switch, fuses, relays, and wiring harnesses. Each component plays a vital role in delivering power and controlling different functions of the machine.

Electrical Connections

Wiring connections are carefully arranged to direct power from the battery to various parts of the vehicle. A series of connectors, junctions, and protective conduits ensure the system is both efficient and safe. Below is a simplified overview of the electrical layout.

| Component | Function | Connection Points |

|---|---|---|

| Battery | Provides power for starting and operation | Connected to ignition switch and fuses |

| Ignition Switch | Controls starting sequence and power distribution | Connected to battery and safety switches |

| Fuses | Protects the system from overcurrent | Connected to wiring harnesses and various electrical circuits |

| Relays | Acts as switches to control current to key components | Connected to ignition system and safety components |

By reviewing these components and their connections, users can better troubleshoot and maintain the electrical system. Regular checks of the wiring, fuses, and connectors will help avoid electrical malfunctions and ensure the long-term performance of the machine.

Craftsman T3200 Parts Replacement Tips

Replacing key components in outdoor equipment requires attention to detail and a solid understanding of the machinery. Whether you’re updating worn-out elements or upgrading for better performance, it’s important to approach the process with care. This guide provides practical advice for efficiently handling component replacement and ensuring optimal function.

1. Identifying the Correct Components

Before starting, it’s crucial to identify the specific elements that need to be replaced. While some items may be clearly worn or broken, others might require a closer look. Regularly inspecting for wear, damage, or inefficiency can help you maintain equipment longevity. Using a reference guide or manual will streamline the identification process, ensuring you select the correct replacements.

2. Step-by-Step Replacement Process

Once the necessary components are identified, follow these general steps for a smooth replacement process:

| Step | Action | Notes |

|---|---|---|

| 1 | Turn off the equipment and disconnect the power source. | Always prioritize safety first. |

| 2 | Remove the damaged or worn components carefully. | Take note of how components are assembled to simplify reinstallation. |

| 3 | Install the new components securely, following manufacturer instructions. | Ensure each part is fully connected and tightened as needed. |

| 4 | Test the equipment to ensure proper functionality. | Check for smooth operation before resuming normal use. |

By adhering to these guidelines, you’ll improve your machinery’s efficiency, extend its service life, and avoid unnecessary breakdowns.

Finding Genuine Craftsman T3200 Spare Parts

When it comes to maintaining your equipment, using original components is crucial to ensure optimal performance and longevity. Finding authentic replacement items may seem challenging, but there are effective ways to secure high-quality, durable alternatives that are designed to work seamlessly with your machine.

Start by reaching out to authorized sellers or official distributors. These sources typically provide products that are directly manufactured for your model, offering the perfect fit and functionality. Be cautious of generic or third-party options, as they may compromise performance or safety.

Additionally, online platforms and specialized retailers often have detailed catalogs or searchable databases, where you can identify specific components based on your machine’s serial number or model type. This ensures you are purchasing exactly what is needed, rather than settling for a potentially incompatible substitute.

Before purchasing, make sure to review customer feedback and seller ratings. This will give you a better understanding of the quality and reliability of the items offered. Additionally, checking for warranties or return policies can provide extra peace of mind, ensuring you are protected if any issues arise with the component.