The intricate design of a high-performance vehicle involves a multitude of interconnected elements that work harmoniously to ensure optimal functionality. Grasping the layout and role of each component is crucial for both enthusiasts and professionals alike. This section delves into the essential features that contribute to the overall efficiency and power of the system.

By breaking down the various segments, one can appreciate how each piece influences performance, durability, and reliability. From the core mechanisms that drive energy conversion to the auxiliary systems that enhance operation, understanding these aspects provides valuable insights into maintenance and upgrades.

In this exploration, we will focus on identifying the key components, outlining their functions, and illustrating their relationships. Whether you’re a seasoned technician or a curious learner, this knowledge will empower you to navigate the complexities of these advanced machines with confidence and expertise.

Understanding the 6.7 Powerstroke Engine

This section explores the intricacies of a highly regarded diesel motor, known for its robust performance and efficiency. As a critical component of modern heavy-duty vehicles, this power unit combines advanced technology with engineering excellence to deliver remarkable power output and reliability. Understanding its structure and functionality is essential for anyone interested in optimizing performance and maintenance.

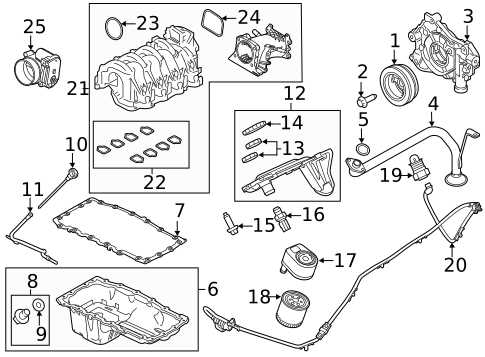

The architecture of this motor is a marvel of contemporary design, featuring components that work in harmony to ensure seamless operation. From the fuel delivery system to the exhaust management, each element plays a vital role in enhancing performance and reducing emissions.

| Component | Function |

|---|---|

| Fuel Injectors | Deliver precise amounts of fuel to the combustion chamber for efficient burning. |

| Turbocharger | Increases the amount of air entering the combustion chamber, improving power output. |

| Intercooler | Cools the air from the turbocharger before it enters the combustion chamber, increasing efficiency. |

| Oil Pump | Maintains proper lubrication and cooling throughout the system. |

| Exhaust System | Manages emissions and enhances engine breathing, contributing to overall performance. |

In summary, delving into the specifics of this powerful unit reveals a well-crafted system designed to meet the demands of both performance and sustainability. Understanding these elements not only aids in maintenance but also enhances the driving experience, ensuring reliability and power when it is needed most.

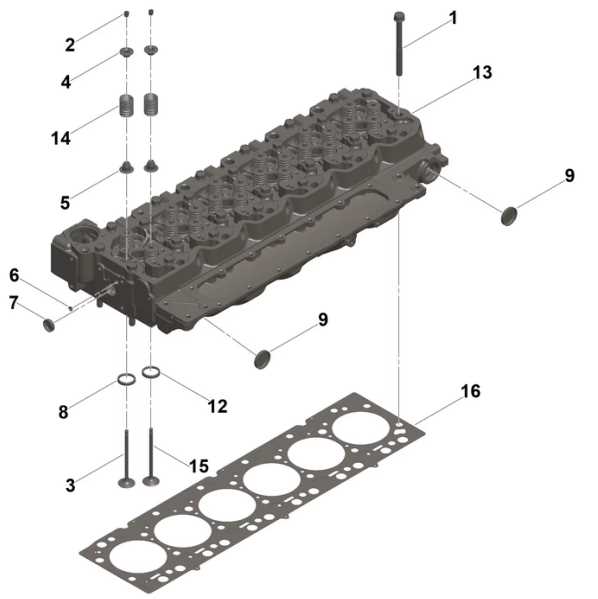

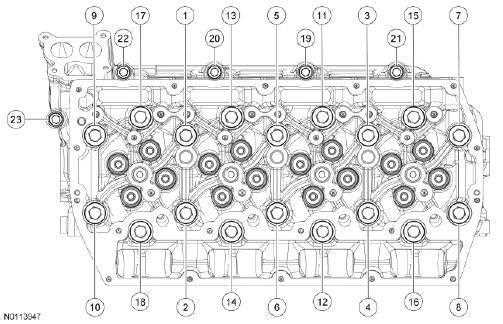

Key Components of the Engine System

Understanding the essential elements of a motor assembly is crucial for maintaining optimal performance. Each component plays a vital role in ensuring the overall functionality and efficiency of the system. Below are the primary components that contribute to its operation.

- Cylinders: The core of the combustion process, where fuel and air mix to produce power.

- Pistons: Move up and down within the cylinders, converting the energy from combustion into mechanical motion.

- Cylinder Head: Houses vital components like valves and spark plugs, crucial for the intake and exhaust process.

- Crankshaft: Transforms linear motion from the pistons into rotational energy that powers the vehicle.

- Valvetrain: Regulates the opening and closing of valves, ensuring proper airflow during the combustion cycle.

- Fuel System: Delivers the necessary fuel mixture to the combustion chamber for efficient operation.

- Cooling System: Maintains optimal temperature, preventing overheating and ensuring smooth functioning.

- Lubrication System: Reduces friction between moving parts, extending the lifespan of the assembly.

Each of these components works in harmony to provide the necessary power and efficiency. Regular maintenance and understanding of their functions are essential for any operator seeking to optimize their vehicle’s performance.

Benefits of Upgrading Engine Parts

Enhancing the components of your vehicle can lead to significant improvements in performance, efficiency, and longevity. Upgrading allows for better compatibility with modern technologies and can address common issues associated with older designs. As a result, these enhancements not only boost functionality but also improve the overall driving experience.

One of the most notable advantages of component upgrades is increased horsepower and torque. By selecting high-performance alternatives, you can achieve greater power delivery, making acceleration more responsive. Additionally, improved fuel efficiency can result from optimizing the system, leading to cost savings over time.

Another critical benefit is enhanced reliability. Upgraded materials and engineering can reduce wear and tear, minimizing the risk of breakdowns and extending the lifespan of your vehicle. This means fewer repairs and a more dependable performance in various driving conditions.

Finally, modern components often come with advanced features that enhance overall handling and safety. This can include better cooling systems, improved fuel injection technologies, and more efficient exhaust systems. All these factors contribute to a smoother, safer ride, ensuring that you can enjoy the full potential of your vehicle.

| Benefit | Description |

|---|---|

| Increased Performance | Boosts horsepower and torque for better acceleration. |

| Improved Efficiency | Optimizes fuel usage, leading to cost savings. |

| Enhanced Reliability | Reduces wear and tear, minimizing breakdowns. |

| Advanced Features | Offers better handling and safety enhancements. |

Common Issues and Troubleshooting Tips

Maintaining high-performance machinery often involves encountering a range of typical challenges. Understanding these common pitfalls can significantly enhance the efficiency and longevity of the system. This section provides valuable insights into potential problems and effective solutions.

Overheating is a frequent concern. It can result from inadequate cooling fluid levels, a malfunctioning thermostat, or a blocked radiator. Regularly check fluid levels and clean the cooling components to prevent this issue.

Starting difficulties may arise from battery issues or fuel system failures. Ensure the battery is charged and inspect fuel lines for clogs or leaks. If the problem persists, examining the ignition system could reveal further complications.

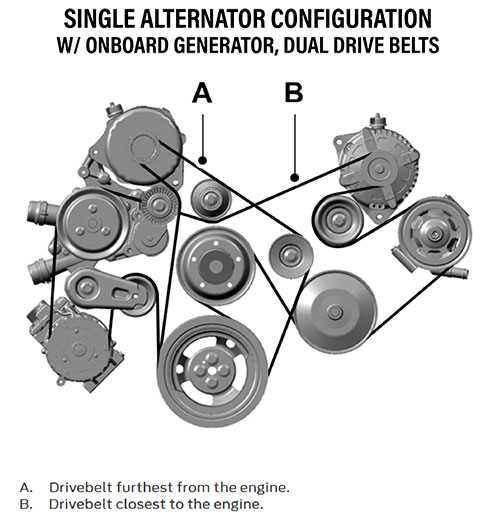

Unusual noises can indicate mechanical wear or misalignment. Listening carefully to any strange sounds can help pinpoint issues early. Regular inspections of belts, pulleys, and bearings can mitigate severe damage.

Lastly, excessive smoke can signal combustion problems. Blue smoke may indicate oil leakage, while black smoke could suggest over-fueling. Analyzing the fuel injection system and checking for leaks will help address these symptoms effectively.

Importance of Regular Maintenance Checks

Routine inspections are crucial for ensuring the longevity and optimal performance of any machinery. Regular assessments help identify potential issues before they escalate into significant problems, thus safeguarding your investment and enhancing reliability.

Preventive measures play a vital role in maintaining efficiency. By adhering to a consistent maintenance schedule, operators can detect wear and tear, ensuring that components function smoothly and efficiently. This proactive approach not only minimizes downtime but also extends the lifespan of the equipment.

Additionally, consistent upkeep contributes to safety. Machines that are regularly checked and maintained are less likely to malfunction, reducing the risk of accidents and injuries. This is particularly important in environments where heavy machinery is in operation.

Lastly, regular evaluations can lead to improved fuel efficiency and performance. Well-maintained systems consume less energy and operate more effectively, resulting in cost savings over time. Investing in routine checks ultimately translates to better overall performance and lower operational costs.

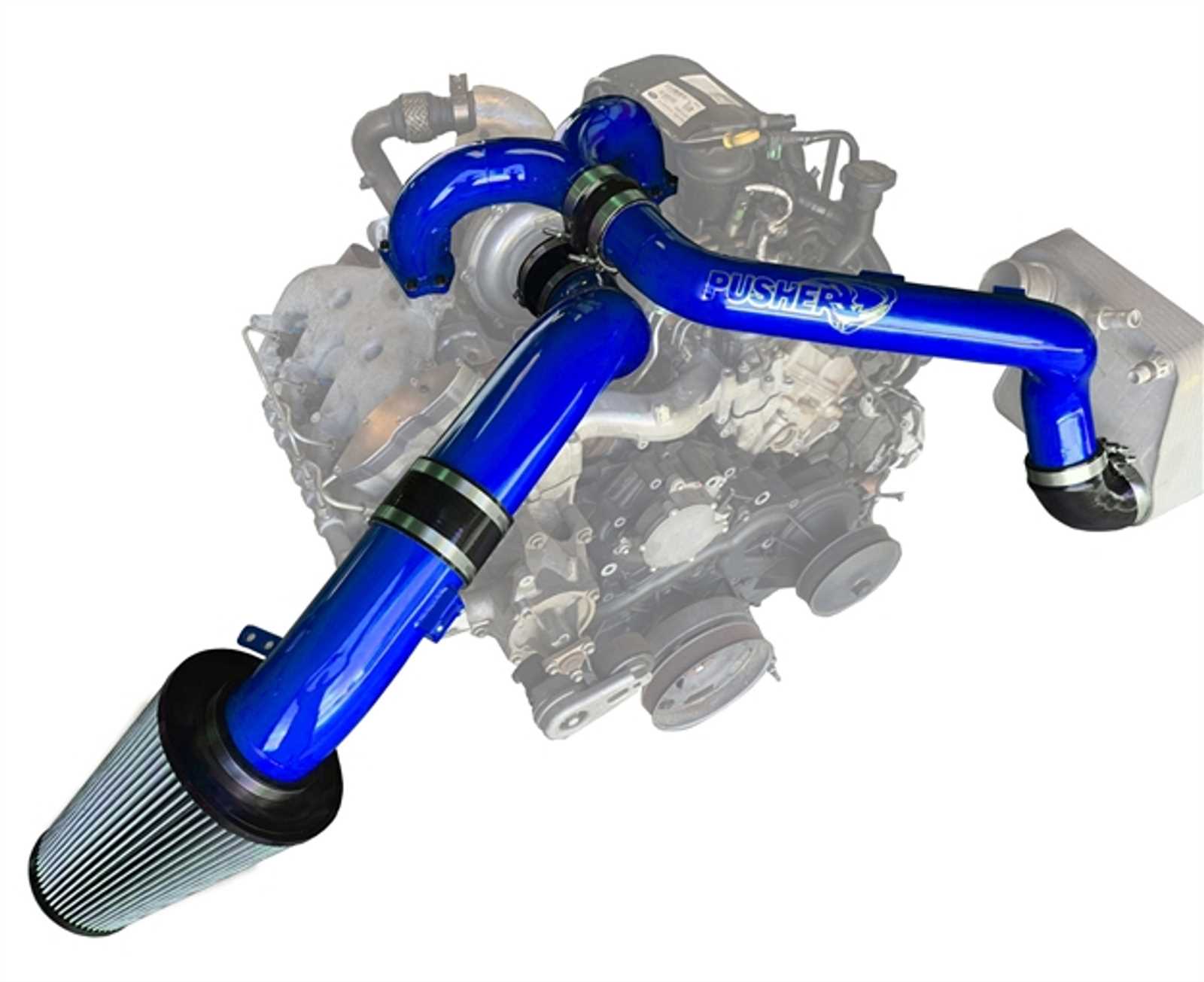

Performance Enhancements for 6.7 Engines

Improving the efficiency and output of diesel systems is a common goal among enthusiasts. Various modifications can be implemented to enhance power delivery, fuel efficiency, and overall driving experience. Below are some popular upgrades that can lead to significant improvements.

Common Upgrades

- Air Intake Systems: Upgrading to high-flow air intakes increases airflow, allowing for better combustion and improved performance.

- Exhaust Modifications: Aftermarket exhaust systems can reduce back pressure, enhancing exhaust flow and boosting horsepower.

- Tuning Solutions: ECU remapping or tuning devices optimize fuel delivery and timing, resulting in better acceleration and efficiency.

Advanced Enhancements

- Turbocharger Upgrades: Installing a larger or more efficient turbo can significantly increase boost pressure, translating to higher power levels.

- Fuel Injectors: Upgraded injectors provide a more precise fuel spray, improving combustion and performance across the RPM range.

- Intercoolers: Larger intercoolers lower intake temperatures, which enhances engine efficiency and prevents overheating under heavy loads.

Implementing these enhancements can lead to a more responsive and powerful system, transforming the driving experience. Each modification should be chosen based on specific performance goals and compatibility.

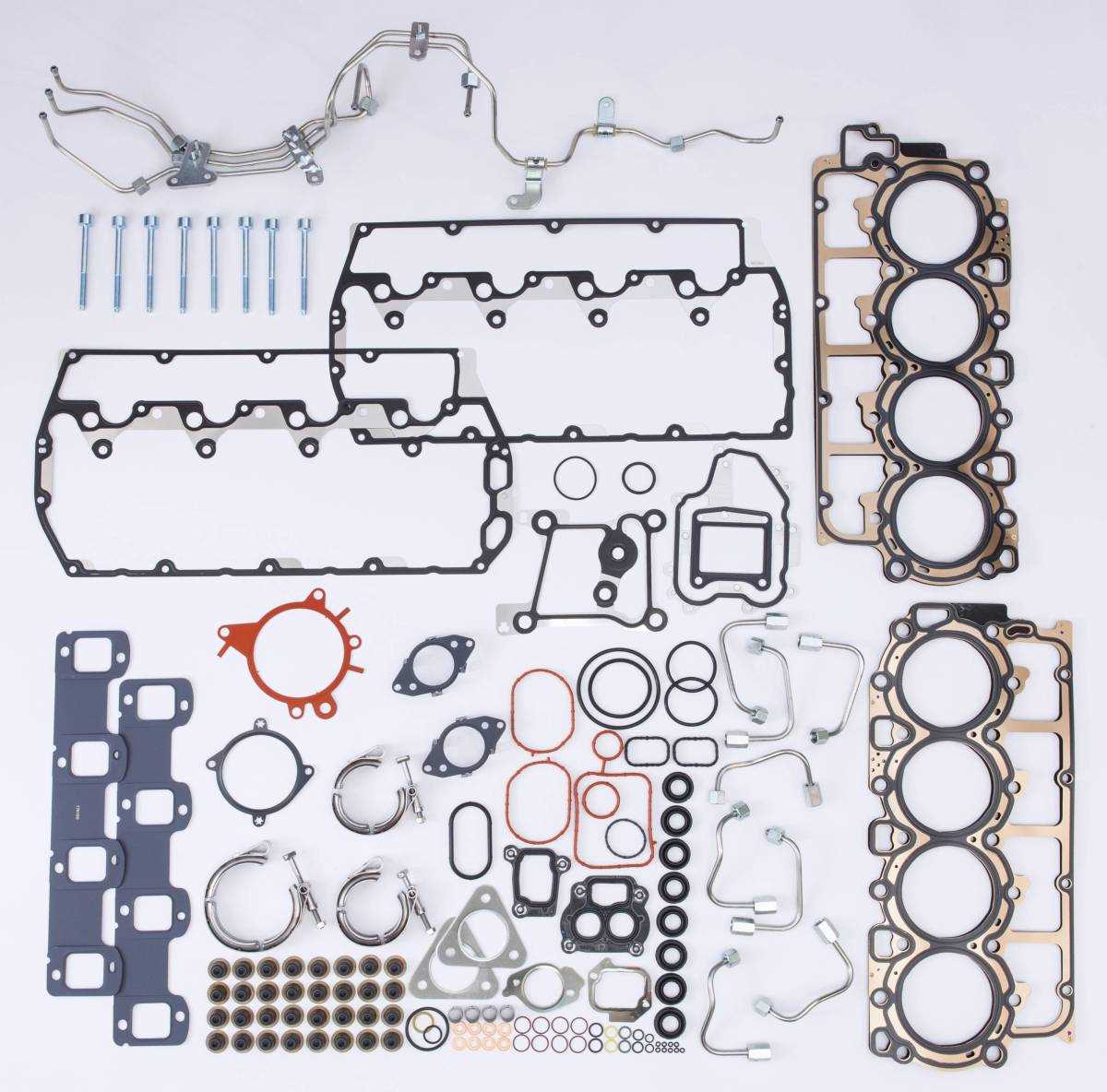

Comparing OEM vs Aftermarket Parts

When it comes to maintaining and enhancing your vehicle, choosing between original equipment manufacturer (OEM) and alternative solutions can significantly impact performance and longevity. Each option presents distinct advantages and disadvantages, making it essential to understand the differences before making a decision.

OEM components are produced by the same manufacturer that created the original parts in your vehicle. They typically ensure a precise fit and compatibility. Conversely, aftermarket alternatives are created by third-party companies and can vary widely in quality and performance.

- Quality Assurance: OEM products often come with stringent quality controls, whereas aftermarket items may not always meet the same standards.

- Cost: Aftermarket options are frequently more affordable, which can be appealing for budget-conscious consumers. However, this can sometimes come at the expense of quality.

- Availability: Aftermarket solutions often provide a wider variety of options, including performance upgrades that may not be available through OEM channels.

- Warranty: OEM components usually come with a warranty, providing peace of mind. Aftermarket parts may vary in warranty offerings.

Ultimately, the choice between these two options will depend on individual needs, preferences, and budget considerations. Weighing the benefits and drawbacks of each can help you make a more informed decision tailored to your specific situation.

DIY Repairs: What You Need to Know

Undertaking repairs on your vehicle can be both rewarding and cost-effective. With the right tools and knowledge, you can address common issues and maintain performance without the need for professional assistance.

Before diving into any repair project, it’s essential to equip yourself with the necessary understanding and resources. Here are some key points to consider:

- Research: Familiarize yourself with the specific components involved. Online forums, manuals, and instructional videos can provide valuable insights.

- Tools: Ensure you have the proper tools at your disposal. A basic toolkit should include:

- Wrenches and sockets

- Screwdrivers

- Torque wrench

- Jack and stands

By preparing adequately and approaching each task methodically, you can enhance your vehicle’s performance while gaining valuable hands-on experience.

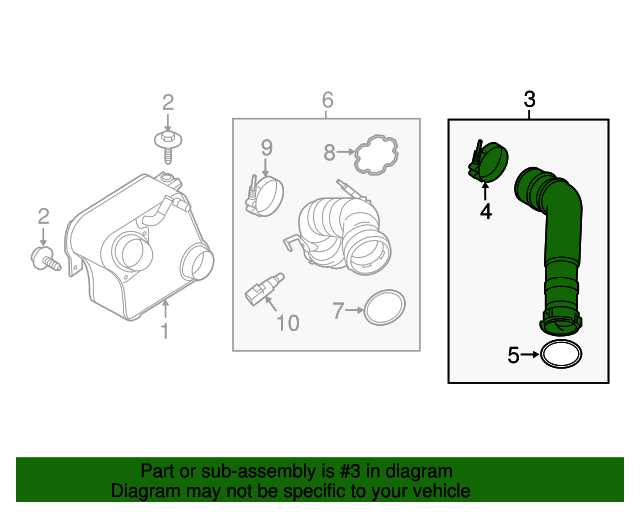

Resources for Engine Parts Diagrams

This section provides valuable references for visual representations of components, helping enthusiasts and professionals alike understand the intricate details of their machinery. Accessing these resources can simplify repairs and enhance knowledge of various systems.

Online Resources

Numerous websites offer comprehensive collections of visual guides. These platforms frequently include detailed illustrations, specifications, and installation instructions, making them essential tools for anyone working with automotive systems.

Printed Manuals

For those who prefer tangible resources, printed manuals are available for purchase. These publications often include high-quality visuals and thorough explanations that can aid in understanding complex assemblies.

| Resource Type | Example Sources |

|---|---|

| Online Platforms | Manufacturer Websites, Forums |

| Printed Guides | Haynes Manuals, Chilton Guides |