For those who maintain large outdoor spaces, having the right equipment is essential. A reliable lawn tractor is one such machine that simplifies yard care and ensures efficiency in handling vast green areas. However, to ensure optimal performance, understanding how each element of the machine functions is key. Knowing the layout and positioning of various elements can help in performing maintenance and making adjustments, keeping the machine running smoothly.

In this guide, we will explore the intricate design and organization of a well-known riding mower. We will break down each mechanical segment, offering clarity on how all the individual sections come together to create a high-performing and durable piece of equipment. Whether you’re aiming to improve functionality or simply familiarize yourself with the key components, this detailed overview will provide valuable insight into what makes these machines operate so effectively.

Overview of the Craftsman T210 Mower

The lawn mower in question is a reliable tool designed to tackle medium to large yards with ease. It combines durability and efficiency, making it a great choice for both casual gardeners and more serious lawn enthusiasts. Its structure and components allow for smooth performance, ensuring a neat and even cut across different terrains.

Key Features

This machine is built with user convenience in mind, offering adjustable settings for various mowing needs. The steering system ensures precise handling, while its cutting deck provides ample width for quick work on lawns. Efficient fuel consumption and a well-engineered transmission add to its long-lasting performance.

Performance and Usability

Designed for comfort, the ergonomic seat and intuitive controls help reduce fatigue during extended use. The engine power offers a balance between speed and control, ensuring that even tougher patches of grass are managed without difficulty. With its sturdy frame, this mower delivers a

Understanding the Engine Components

The engine is the heart of any machine, driving its core functionality and ensuring smooth operation. Each element plays a critical role in converting energy into motion, allowing the entire system to work efficiently. To keep everything running smoothly, it’s important to grasp how these elements interact and contribute to the overall performance.

Cylinders serve as the chambers where fuel combustion occurs, generating the power that drives the machine forward. The pistons within the cylinders move up and down, creating the mechanical motion needed for energy transfer.

The crankshaft transforms the linear movement of the pistons into rotational energy, which then powers other mechanical systems. Alongside this, the valves manage the flow of air and fuel into the combustion chambers, as well as the release of exhaust gases.

Maintaining these components in good condition is crucial for overall efficiency. Understanding their

Exploring the Blade and Deck Assembly

The blade and deck system plays a pivotal role in maintaining an efficient mowing process. This assembly is designed to provide a clean, precise cut while ensuring smooth operation of the entire machine. By understanding the key components involved, one can ensure proper function and make informed adjustments to enhance performance.

Key Components of the Deck Assembly

- Cutting Blades: These are responsible for slicing through grass, providing a neat and uniform finish to your lawn.

- Spindle Assembly: Connects the blades to the deck, facilitating rotation and ensuring steady performance.

- Belt System: Transfers power from the motor to the blades, allowing them to spin at the required speed.

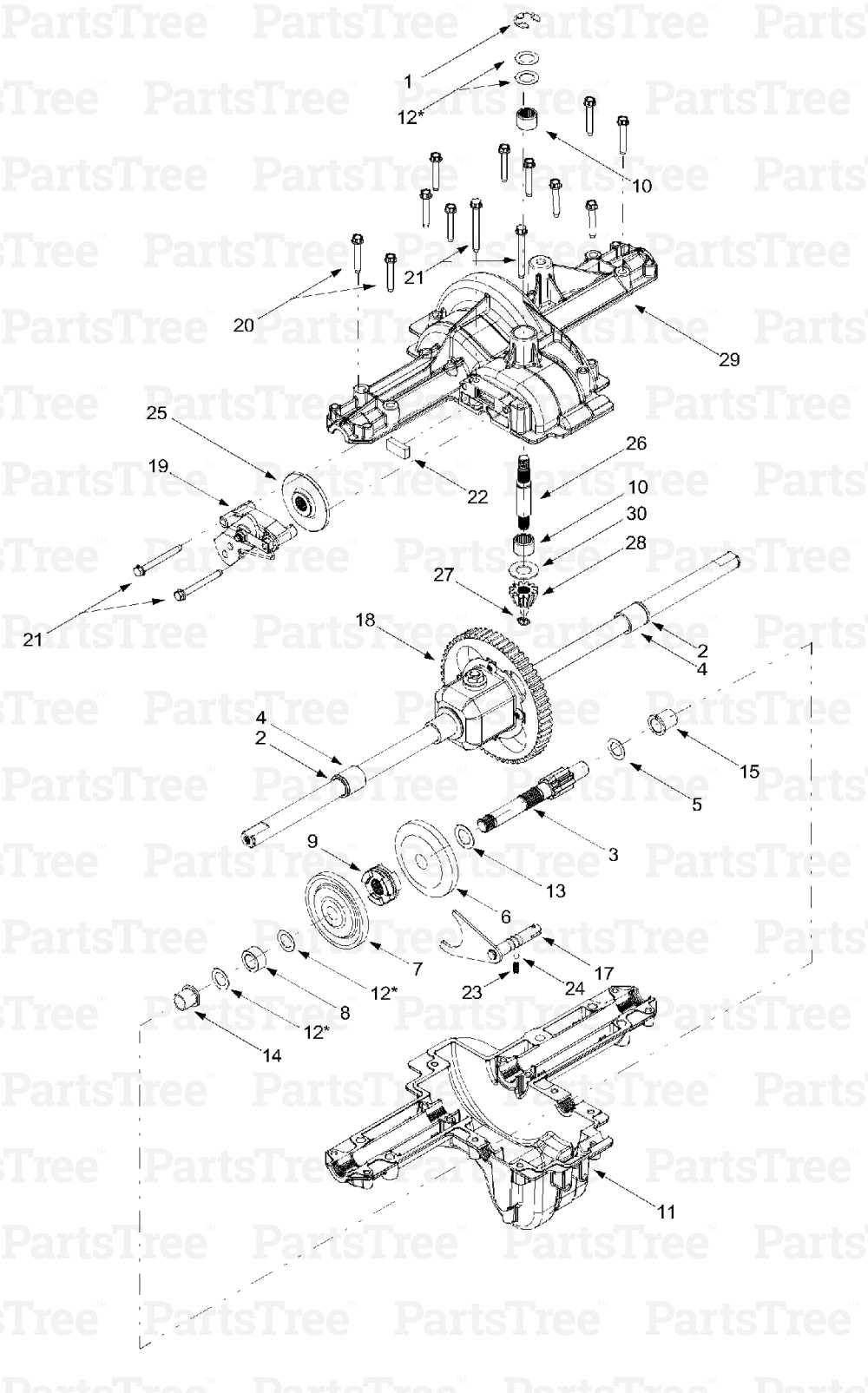

Transmission and Drive System Breakdown

The transmission and drive system are central to ensuring smooth and efficient motion, converting power into movement. This section delves into the arrangement and interplay of key components, offering insight into how the vehicle maintains balance between force and control. Understanding this system is essential for diagnosing potential issues or optimizing performance.

Drive Mechanism Overview

The drive mechanism is responsible for transferring energy from the motor to the wheels, ensuring consistent motion. It includes a set of gears and belts that work together, allowing for both acceleration and deceleration. Proper maintenance of these elements ensures prolonged efficiency and reduces wear and tear.

Transmission Functionality

The transmission serves as the system’s heart, controlling speed and torque distribution. It adjusts to different terrains and loads, shifting seamlessly between gears to provide the necessary power output. Regular inspection of this mechanism ensures optimal operation and prevents mechanical failure during usage.

Wheels and Steering Mechanism Insights

The stability and control of any riding equipment depend heavily on the synergy between its wheels and steering system. A well-designed steering mechanism ensures smooth navigation, while the wheels must provide proper traction and balance across different terrains. Together, these components create a seamless user experience, enhancing both maneuverability and safety.

Wheel Composition and Performance

- Durable materials to withstand rough surfaces

- Optimized tread design for grip and handling

- Balanced weight distribution to support even motion

Steering System Functionality

- Precision in turning, enhancing directional control

- Ergonomically designed for comfortable handling

- Responsive connection to the front wheels, allowing quick adjustments

Seat, Frame, and Body Structure

The seating arrangement, structural frame, and overall body composition are vital components that contribute to the functionality and durability of any machine. A well-engineered assembly not only enhances user comfort but also ensures stability during operation. Understanding these elements is essential for maintaining optimal performance and longevity.

Seating is designed for ergonomic support, providing a comfortable experience for the operator. It is crafted to absorb vibrations and minimize fatigue during extended use, allowing for better control and maneuverability. The materials used in the construction of the seat play a significant role in durability and ease of cleaning.

The frame serves as the backbone of the equipment, providing strength and resilience. Made from robust materials, it is engineered to withstand various stresses encountered during operation. Analyzing the frame’s design reveals how weight distribution and structural integrity affect performance and safety.

Finally, the body structure encompasses the exterior casing and additional components that protect internal mechanisms. This outer layer not only contributes to the aesthetics of the machine but also shields critical parts from environmental factors. A well-designed body structure promotes airflow and cooling, ensuring efficient operation.

Electrical System and Battery Layout

The electrical framework of a lawn tractor plays a crucial role in ensuring its optimal performance and reliability. This system encompasses various components that work together to power the engine, control the ignition, and operate additional features. Understanding the configuration of these elements is essential for effective maintenance and troubleshooting.

Key Components

The primary elements of the electrical setup include the battery, ignition switch, starter motor, and various wiring connections. Each of these components has a specific function that contributes to the overall functionality of the machine. A well-maintained electrical system ensures smooth operation and prevents unexpected failures.

Battery Specifications

The power source is vital for starting the engine and powering electrical accessories. It is important to select a battery that meets the required specifications to ensure compatibility and performance.

Component Specifications Battery Type Lead-acid Voltage 12V Capacity 200 CCA (Cold Cranking Amps) Dimensions 7.25 x 6.5 x 7.5 inches Maintenance Essentials for Key Parts

Proper upkeep of vital components is crucial for ensuring the longevity and performance of your equipment. Regular inspections and timely replacements not only enhance functionality but also prevent unexpected failures. By understanding the fundamental aspects of maintenance, users can significantly improve the reliability of their machines.

Routine Checks

Conducting frequent evaluations of critical elements is essential. Look for signs of wear, such as fraying or cracking, which can indicate the need for replacement. Additionally, ensuring that all moving parts are well-lubricated can prevent unnecessary friction and prolong their lifespan. It is advisable to consult the manufacturer’s recommendations for specific maintenance schedules and procedures.

Replacement and Upgrades

When components show significant signs of wear or degradation, prompt replacement is necessary. Using high-quality replacements can greatly enhance the overall performance of your machinery. Consider upgrading to newer models that may offer improved efficiency and durability, as technology advancements can lead to better operational capabilities.

Troubleshooting Common Issues with the T210

Addressing frequent problems associated with this outdoor equipment can enhance its performance and extend its lifespan. Understanding typical malfunctions and their solutions will help users maintain optimal functionality and avoid unnecessary repairs.

Here are some common issues that may arise:

- Engine Won’t Start:

- Check the fuel level and ensure it’s fresh.

- Inspect the ignition system for faults or wear.

- Examine the battery for adequate charge.

- Uneven Cutting:

- Verify that the blades are sharp and properly aligned.

- Ensure that the cutting height is set correctly.

- Look for debris buildup around the deck.

- Strange Noises:

- Identify any loose or damaged components.

- Check for debris caught in moving parts.

- Inspect belts and pulleys for wear or misalignment.

Regular maintenance and timely troubleshooting can prevent these issues from escalating and ensure smooth operation of your machinery.