The functionality and efficiency of any lawn care machine heavily rely on its internal mechanisms. A thorough grasp of these components not only enhances the user experience but also simplifies maintenance and repairs. Familiarizing yourself with each element will ensure optimal performance, extending the lifespan of your equipment.

In this guide, we delve into the intricacies of a specific model’s structure, examining various elements essential for operation. Each section will highlight crucial components, providing clarity on their roles and how they interact with one another. By understanding these aspects, users can better diagnose issues and undertake necessary adjustments or replacements.

Whether you are an avid gardener or a professional landscaper, recognizing the significance of each piece will empower you to make informed decisions. Explore the detailed layout of the system and discover how to enhance your lawn care tasks efficiently. Embrace the knowledge to keep your machinery running smoothly and effectively!

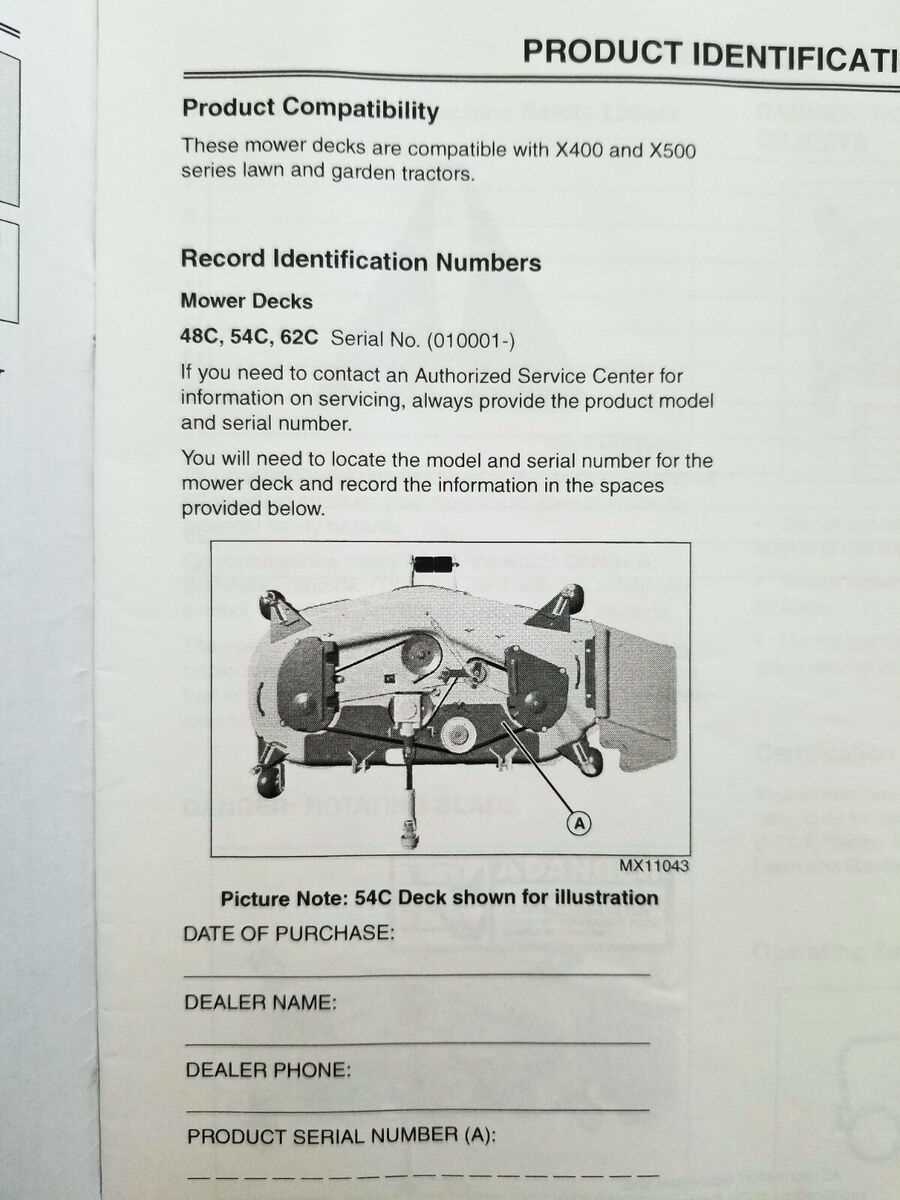

Understanding the John Deere 54C Mower Deck

This section explores the essential components and functions of a specific cutting mechanism designed for effective lawn maintenance. By examining its structure and operation, users can better appreciate how each element contributes to overall performance and efficiency.

Key Components

Every cutting apparatus consists of various integral parts that work in harmony. Understanding these elements is crucial for maintenance and optimal operation.

| Component | Description |

|---|---|

| Blade | Responsible for cutting grass with precision. |

| Spindle | Supports the blade and facilitates rotation. |

| Housing | Encases the components and directs clippings. |

Maintenance Tips

Regular upkeep is vital for longevity. Routine checks and timely replacements of worn parts ensure optimal functionality and performance.

Components of the Mower Deck

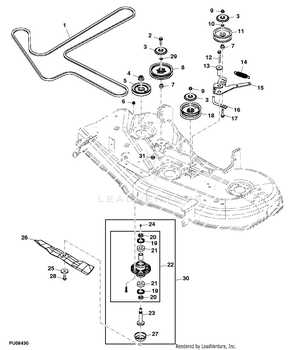

The assembly responsible for cutting grass consists of various essential elements, each contributing to the overall efficiency and performance. Understanding these components is crucial for maintenance and optimal functionality.

One of the primary elements is the cutting blade, which is designed to deliver a precise cut. Its sharp edges and robust construction ensure durability and effectiveness in various conditions. Additionally, the spindle assembly plays a vital role, as it houses the blade and facilitates its rotation.

Another important feature is the belt system, which transfers power from the engine to the blades, allowing for smooth operation. Proper tension and alignment of the belts are necessary to prevent wear and ensure consistent performance.

The housing structure serves as a protective cover, shielding the internal components while aiding in the grass collection process. Effective airflow design within this structure enhances the cutting performance and provides a clean finish.

Lastly, the adjustment mechanisms allow users to modify the cutting height, catering to different lawn conditions and preferences. Regular inspection and maintenance of these components will enhance longevity and improve cutting results.

Importance of Regular Maintenance

Benefits of Regular Upkeep

- Enhances Performance: Regular checks ensure that all components function effectively.

- Increases Lifespan: Proper care extends the operational life of machinery.

- Reduces Downtime: Preventive measures minimize unexpected breakdowns.

- Saves Money: Investing in routine maintenance reduces the likelihood of expensive repairs.

Key Maintenance Practices

- Regularly inspect all moving parts for wear and tear.

- Change fluids and filters according to the manufacturer’s guidelines.

- Clean components to prevent dirt buildup.

- Sharpen blades and check alignment to ensure efficiency.

How to Identify Worn Parts

Recognizing when components have degraded is crucial for maintaining optimal performance and safety. Worn elements can lead to decreased efficiency, increased wear on other pieces, and potential failure during operation. By understanding the signs of wear, you can ensure timely replacements and avoid costly repairs.

First, observe any visible signs of damage such as cracks, bends, or unusual wear patterns. Components should be inspected for irregularities that could indicate excessive stress or improper alignment. Listen for unusual noises during operation; grinding or rattling sounds may suggest that certain elements are no longer functioning smoothly.

Next, assess the operational effectiveness. If the equipment is not performing as expected, it may signal that specific parts have lost their integrity. Changes in performance, such as uneven cutting or decreased power, often point to underlying issues that need attention.

Finally, consider the age and usage of the components. Even with proper maintenance, materials can degrade over time. Regularly consulting the maintenance schedule and replacing items at recommended intervals can prevent unexpected failures and prolong the lifespan of the entire system.

Step-by-Step Repair Instructions

Repairing your equipment requires a systematic approach to ensure every component functions optimally. This guide outlines a clear sequence of actions, empowering you to tackle the task with confidence and precision.

Gather Necessary Tools and Materials

Before starting, collect all essential tools and replacement items. You will need a socket set, wrenches, screwdrivers, and possibly a torque wrench. Additionally, ensure you have the appropriate replacement components on hand to avoid interruptions during the repair process.

Disassembly Process

Begin by safely disconnecting the power source to prevent any accidents. Next, carefully remove the outer casing or cover to access the inner workings. Document the order in which components are removed; this will simplify reassembly. Take your time to inspect each part for wear and damage, and make a note of any necessary replacements.

Following these structured steps will facilitate an efficient and successful repair, restoring your equipment to optimal performance.

Finding Original Replacement Parts

When it comes to maintaining your equipment, sourcing genuine components is crucial for optimal performance and longevity. Ensuring that you use authentic pieces not only enhances functionality but also preserves the integrity of your machinery. Here are some essential tips for locating the right items for your specific needs.

Utilizing Authorized Dealers

One of the most reliable ways to find original components is through authorized retailers. These distributors specialize in offering verified products that meet the manufacturer’s standards. Engaging with them guarantees that you receive high-quality items designed specifically for your equipment.

Exploring Online Resources

The internet is a vast resource for discovering genuine components. Various websites and online marketplaces feature dedicated sections for original items, often accompanied by detailed descriptions and specifications. Be sure to verify the credibility of the seller to ensure you are purchasing authentic merchandise.

Common Issues and Troubleshooting Tips

Maintaining equipment can often lead to various challenges that may affect performance. Understanding these common issues and knowing how to address them can ensure smooth operation and longevity. This section outlines typical problems encountered and provides helpful solutions for effective management.

Typical Problems

- Inconsistent Cutting Quality

- Unusual Noises During Operation

- Difficulty Starting the Engine

- Vibrations or Shaking

- Clogging of the Cutting Mechanism

Troubleshooting Solutions

- Inconsistent Cutting Quality:

- Check blade sharpness and condition.

- Ensure the cutting height is properly adjusted.

- Inspect for debris buildup on the underside.

- Unusual Noises:

- Examine for loose components or fasteners.

- Inspect bearings and belts for wear.

- Ensure all parts are correctly lubricated.

- Difficulty Starting:

- Check the fuel level and quality.

- Inspect the battery and connections.

- Ensure the spark plug is in good condition.

- Vibrations:

- Examine the blades for damage or imbalance.

- Check the wheel alignment and tire pressure.

- Ensure that all fasteners are tightened properly.

- Clogging:

- Regularly clean the cutting area.

- Inspect for damaged parts that may obstruct flow.

- Consider using a different cutting height for dense grass.

Benefits of Upgrading Components

Enhancing machinery elements can lead to significant improvements in performance and efficiency. Upgrading components not only extends the lifespan of equipment but also optimizes its functionality.

- Improved Efficiency: New components often offer better design and technology, leading to lower fuel consumption and enhanced productivity.

- Enhanced Durability: Modern materials and engineering methods provide increased resilience against wear and tear.

- Better Performance: Upgraded parts can boost overall performance, making operations smoother and more reliable.

- Cost Savings: Although initial investments may be higher, long-term savings on repairs and fuel can be substantial.

- Increased Resale Value: Upgraded equipment often retains higher market value due to its improved condition and capabilities.

Investing in better components ultimately leads to a more efficient and reliable operational experience.

Resources for Further Information

For those seeking additional insights and detailed knowledge regarding equipment maintenance and component identification, a variety of resources are available. These can assist users in understanding assembly and operational guidelines while also providing visual aids and expert advice.

Online forums and community groups serve as excellent platforms for exchanging experiences and tips with fellow enthusiasts. Websites dedicated to machinery repair often feature extensive manuals and schematics that can help users navigate troubleshooting and repairs.

Additionally, official manufacturer websites usually offer downloadable resources, including user guides and technical specifications. Video tutorials on popular streaming platforms can also provide step-by-step demonstrations, making complex tasks more manageable.

Lastly, local equipment dealers and repair shops can be valuable sources of information, often providing personalized assistance and recommendations based on specific needs. Exploring these avenues can significantly enhance understanding and proficiency in equipment care.