Maintenance Tips for Efficient Lawn Equipment Care

To ensure that your lawn equipment performs optimally and lasts longer, regular upkeep is essential. Proper maintenance not only improves the lifespan but also helps in achieving consistent and precise results. Keeping the cutting components in good condition, lubricating the necessary areas, and inspecting various mechanical elements are key practices for efficient operation.

Sharpening and Cleaning the Blades

One of the most important maintenance tasks is to keep the blades sharp and free of debris. Dull edges can lead to uneven cutting and strain on the machinery, while accumulated grass or dirt can cause corrosion. It’s recommended to clean and sharpen the blades periodically to ensure smooth operation.

Lubrication and Fastener Check

Lubricating moving parts and checking all fasteners for tightness is crucial for the equipment’s longevity. Regular oil

Common Issues with 42C Mower Deck

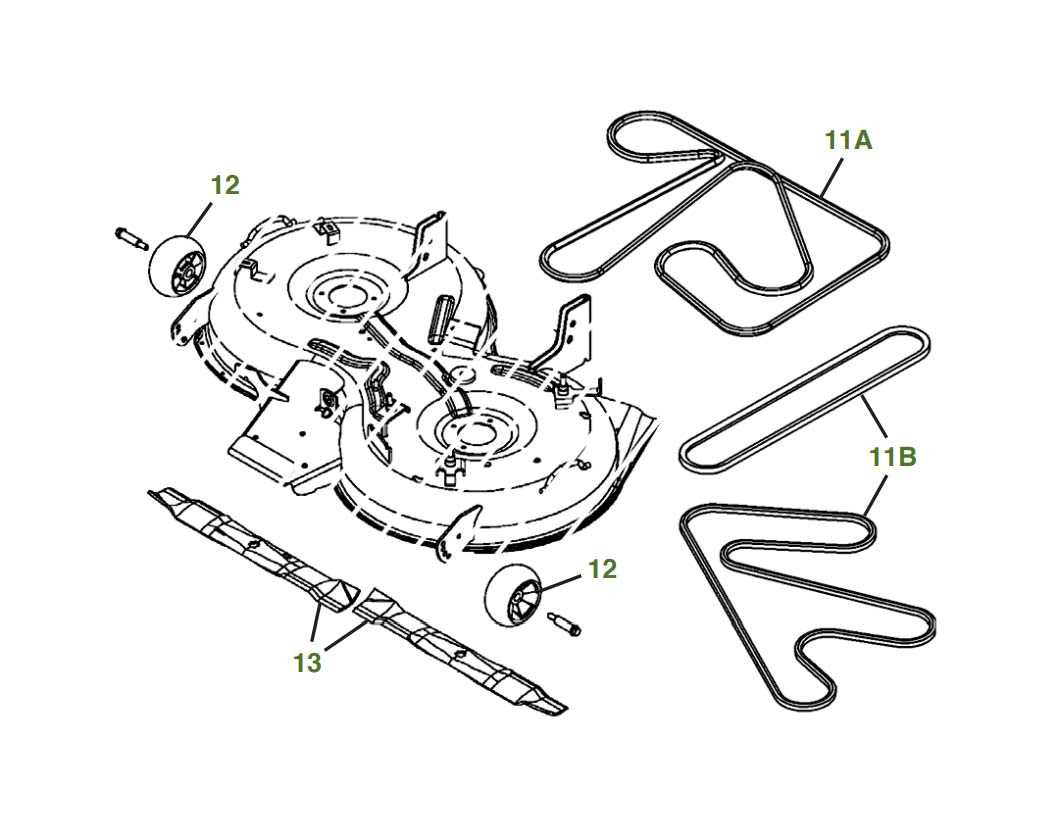

Maintaining your equipment in good condition requires understanding some of the frequent problems that can arise. Various components of the cutting system may experience wear and tear over time, leading to inefficiencies in performance. Knowing these common issues will help in addressing them before they escalate into costly repairs.

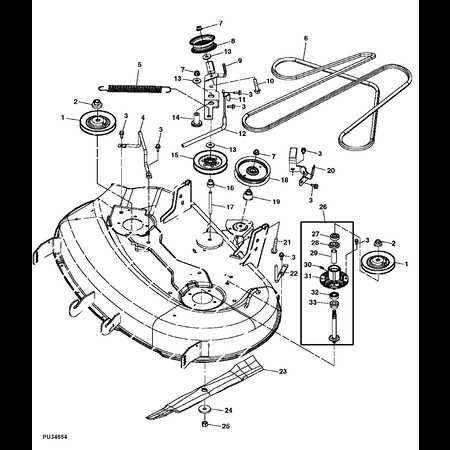

Belt Slippage

One of the most common challenges involves the belt slipping during operation. This can happen due to improper tension, wear, or damage. Ensuring the belt is properly aligned and in good condition is crucial for smooth functioning.

Uneven Cutting

Another issue frequently encountered is uneven grass cutting. This may be caused by dull blades, uneven tire pressure, or incorrect adjustments in the cutting mechanism. Regular inspection and maintenance of the blades and tires will help avoid this problem.

How to Replace Mower Deck Parts

Maintaining your grass-cutting equipment is essential for ensuring smooth and efficient performance. Over time, certain components may become worn or damaged and require replacement. This guide will help you through the process of swapping out those critical elements, ensuring your machine operates at its best.

Step-by-Step Guide to Component Replacement

Follow these steps to replace the worn or broken parts of your equipment:

- Start by ensuring the machine is turned off and properly secured. Always disconnect the power source before beginning any repairs.

- Use a wrench to remove any bolts or fasteners holding the worn-out element in place.

- Carefully detach the damaged component, being cautious of any remaining parts that may be sharp or heavy.

- Place the new item in the correct position, ensuring it aligns properly with the mounting points.

- Tighten all bolts and fasteners securely to prevent any movement during operation.

- Reconnect the power source and test the equipment to verify the new part is functioning as expected.

Key Tips for a Smooth Replacement Process

- Always consult the equipment manual for specific instructions related to part replacement.

- Keep a set of basic tools such as wrenches and screwdrivers handy for easier access during the process.

- Wear protective gloves and safety goggles to avoid injury when handling parts and tools.

- Inspect all other parts for wear and tear while replacing the damaged component, as it may indicate the need for further maintenance.

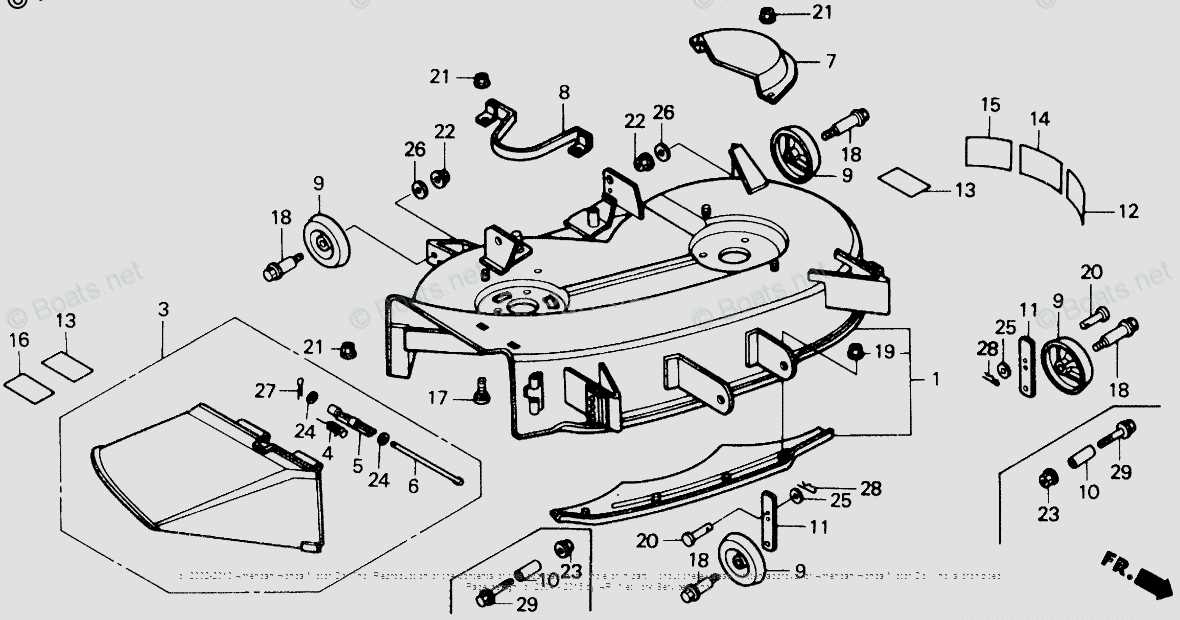

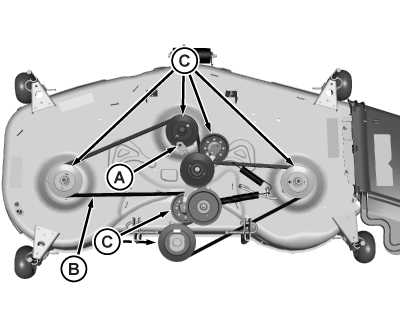

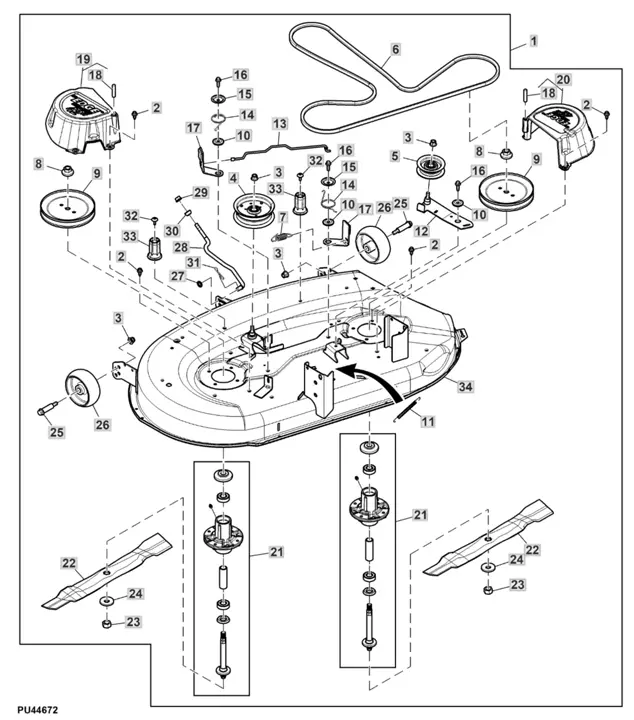

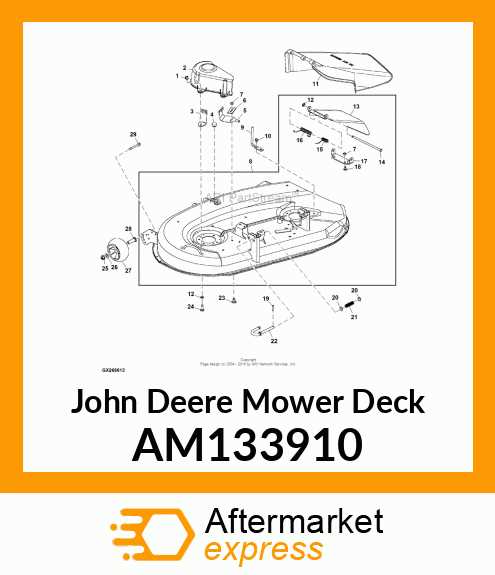

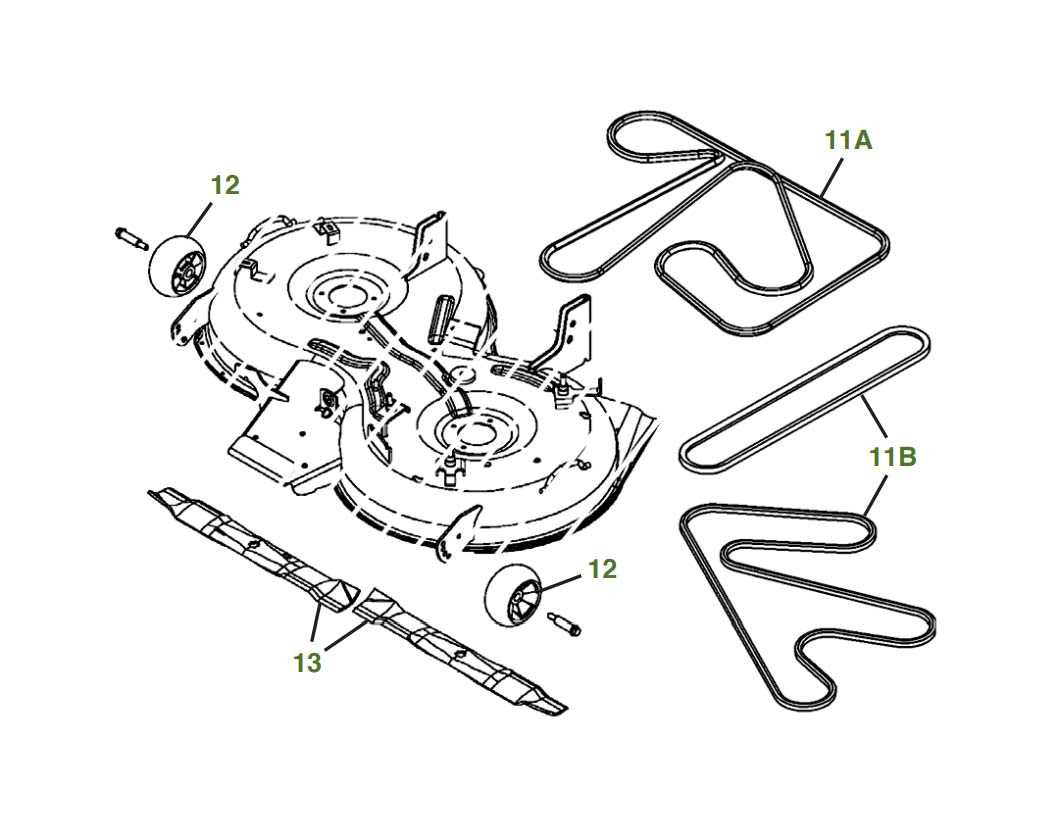

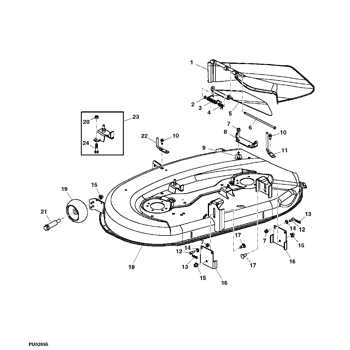

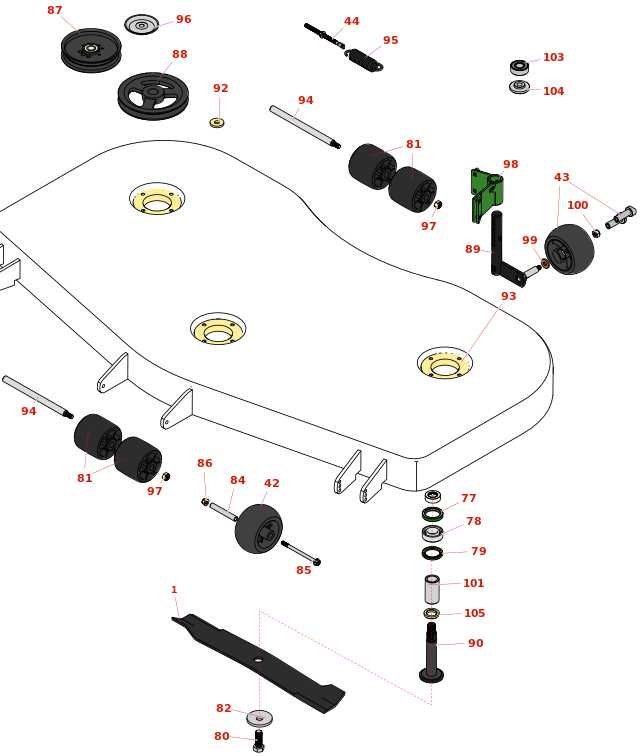

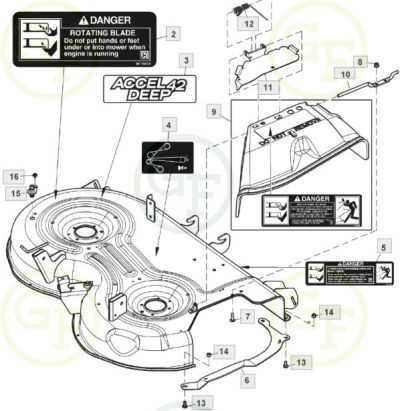

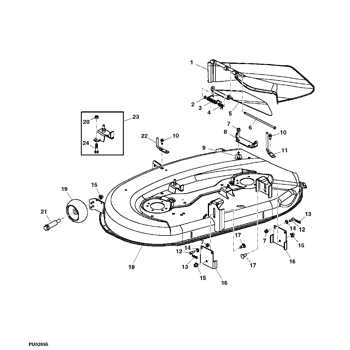

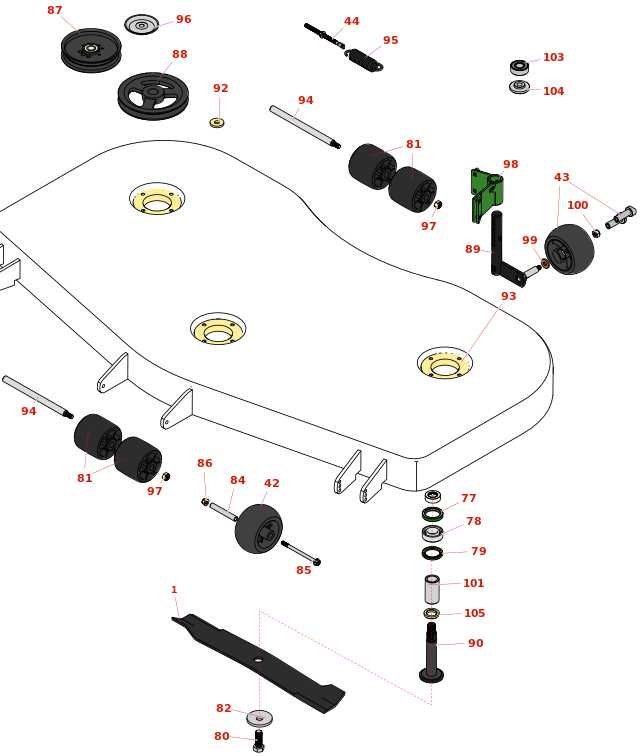

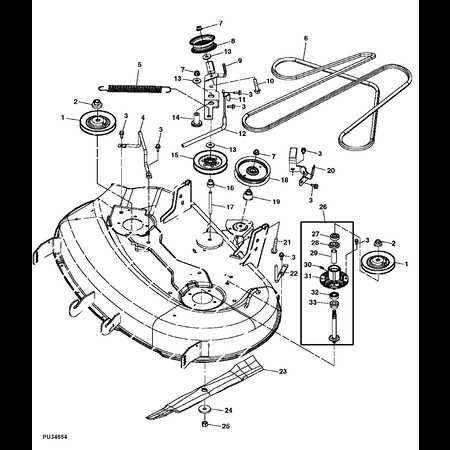

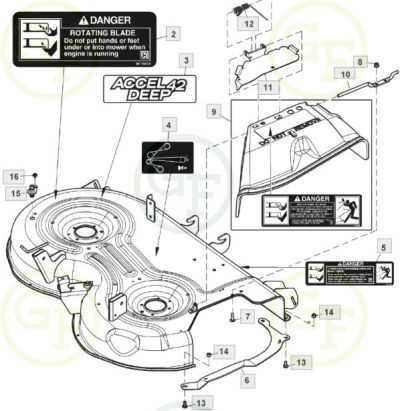

Diagram Overview of the 42C Deck System

The visual representation of this cutting mechanism offers a clear breakdown of its components and how they interact to ensure optimal functionality. It highlights key elements and their arrangement, providing insights into the design that supports efficient grass cutting and maintenance. Understanding this layout can assist in the proper upkeep and troubleshooting of the system.

Key Components

- Blade assembly: Central to the cutting process, responsible for grass trimming.

- Pulley system: Transfers motion to the blades for efficient operation.

- Spindle housing: Supports and stabilizes the blade mechanism.

- Lift mechanism: Allows for adjusting the height of the cutting blades.

- Guarding components: Ensures safety by enclosing moving parts.

System Functionality

The configuration of these components ensures synchronized movement and precision cutting. The interaction between the blade assembly, pulleys, and spindle housing is crucial for achieving a clean, even cut across various terrains. Each element in the system is designed to handle specific tasks, contributing to the overall efficiency and durability of the mechanism.

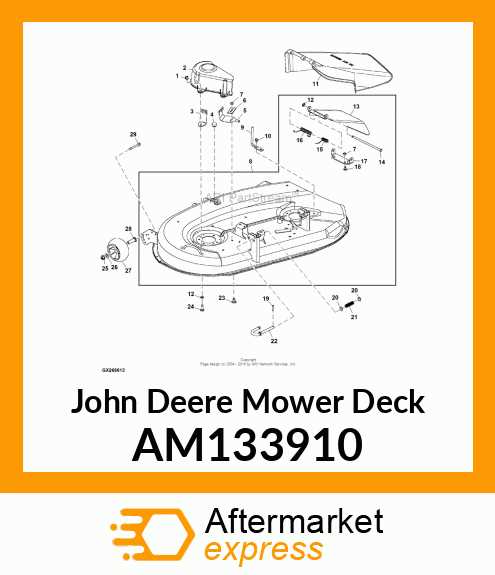

Choosing the Right Replacement Parts

When maintaining your equipment, selecting the correct components is essential for ensuring optimal performance and longevity. The key is to match the right items that fit your machine’s specific needs, ensuring they meet both quality standards and functional requirements. By understanding the various types of replacements available, you can make informed decisions that enhance the efficiency of your tool.

Consider Compatibility

It’s important to verify that the components you choose are compatible with your model. Using mismatched items can lead to inefficiency or even damage. Always refer to the specifications of your model to ensure that the parts you select will fit correctly and function as expected.

Focus on Durability and Quality

Opting for high-quality replacements can extend the life of your machine. While it might be tempting to go for cheaper options, investing in durable, premium components can save you money in the long run by reducing frequent repairs and replacements.

Safety Tips for Mower Deck Maintenance

Proper upkeep of your lawn care equipment is essential not only for performance but also for personal safety. Regular inspection and maintenance can prevent accidents and ensure smooth operation. Following specific safety protocols when handling and servicing the components is crucial to avoiding injuries.

General Safety Guidelines

Before starting any maintenance work, always disconnect the power source to prevent accidental activation. Wear appropriate protective gear such as gloves and safety goggles to protect against sharp blades and debris. Additionally, ensure the equipment is cool and properly secured before attempting any repairs.

Important Maintenance Precautions

While performing maintenance tasks, it’s important to remain cautious around moving parts. Never attempt to adjust or clean the blades while they are still in motion. Regularly check for loose bolts and worn-out components that may pose safety risks. Dispose of old parts and materials safely to prevent hazardous situations.

| Task |

Safety Measure |

| Disconnect power |

Ensure the equipment is turned off and the power is disconnected |

| Wear protective gear |

Gloves, goggles, and sturdy footwear are recommended |

| Inspect blades |

Check for sharpness and secure fitting before working |

| Check for loose parts |

Tighten bolts and fasteners to avoid malfunction |