When maintaining a lawn mower, it’s essential to understand how its individual elements work together to ensure smooth operation. The efficiency of cutting grass and maintaining an even finish largely depends on how well the key components are assembled and maintained. Knowing how these parts are connected and function can help in troubleshooting and repairing any issues that may arise during use.

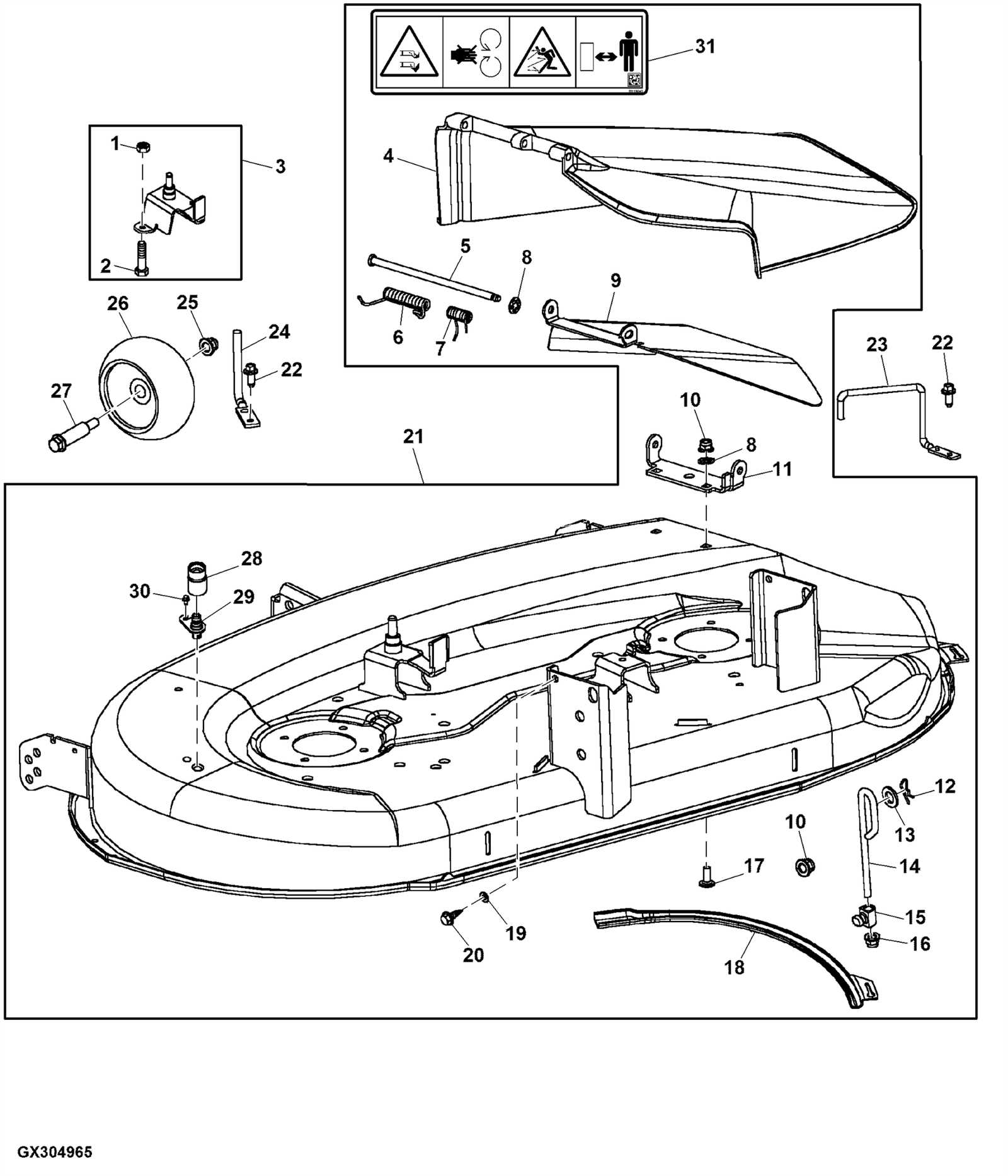

In this guide, we explore the intricate layout of the essential components that make up the cutting mechanism. Each part plays a vital role in the mower’s overall performance, from the rotating blades to the pulleys and the drive system. Proper identification and understanding of these components can make a significant difference when performing maintenance tasks, ensuring longevity and optimal operation.

We’ll provide a detailed breakdown of the critical elements, focusing on how they interact with each other. Whether you’re looking to replace a worn-out component or simply perform routine upkeep, knowing the function and placement of each piece can save both time and money in the long run.

Understanding John Deere L120 Components

When maintaining or repairing a riding mower, understanding the key components is essential for efficient operation and longevity. Each element plays a critical role in ensuring the mower functions smoothly, providing excellent results. In this section, we will break down the essential parts that make up the mower’s cutting mechanism, focusing on their design, function, and how they work together to achieve optimal performance.

The assembly consists of several interconnected pieces, each serving a distinct function, from generating power to directing grass clippings. Knowing these components helps not only in repairs but also in regular maintenance and troubleshooting potential issues that may arise during use.

| Component | Description |

|---|---|

| Blade | The primary tool for cutting grass. It spins at high speed to achieve an even cut. |

| Spindle Assembly | This part houses the blade and connects it to the motor, providing rotation and stability. |

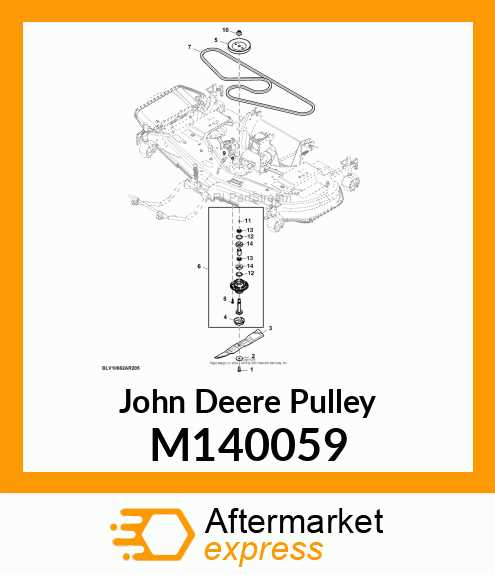

| Pulley | Used to transfer rotational force from the engine to the spindle, ensuring the blade rotates effectively. |

| Drive Belt | A flexible loop that transmits power from the engine to other moving parts, including the pulley and spindle. |

| Deck Housing | The protective shell that houses the blade and spindle assembly, directing grass clippings to the side. |

| Anti-scalp Roller | Prevents the mower from digging into the ground, helping maintain a consistent cutting height. |

| Height Adjustment Mechanism | Allows the operator to modify the cutting height, ensuring the desired grass length is achieved. |

Importance of Deck Maintenance

Proper upkeep of essential components on lawnmowers or garden tractors is crucial for ensuring their efficient performance. Neglecting regular maintenance can lead to a variety of issues, including decreased cutting efficiency, uneven grass trimming, and potential damage to surrounding parts. Keeping the undercarriage and related mechanisms clean and in good working condition not only enhances performance but also extends the lifespan of the equipment.

Cleaning and inspecting these components regularly is important to prevent the buildup of grass clippings, dirt, and debris, which can hinder the functioning of critical parts. This buildup can create resistance, leading to strain on the motor and, ultimately, higher fuel consumption or increased wear. Regular inspections help identify any worn-out or damaged elements, allowing for timely repairs before more significant problems arise.

Additionally, lubrication plays a key role in maintaining smooth operation. Moving parts, such as pulleys and spindles, benefit from proper lubrication, reducing friction and preventing premature wear. Without this attention, these components may seize or break down, leading to costly repairs or replacements.

In summary, proactive care for the mowing system not only prevents unnecessary repairs but also ensures a more effective and efficient lawn care experience. Taking time to perform regular maintenance can save money in the long run and keep your equipment running at its best season after season.

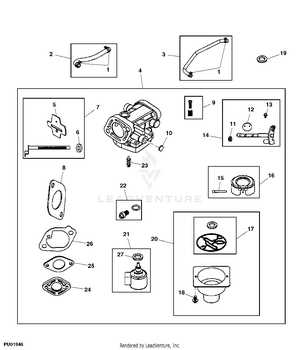

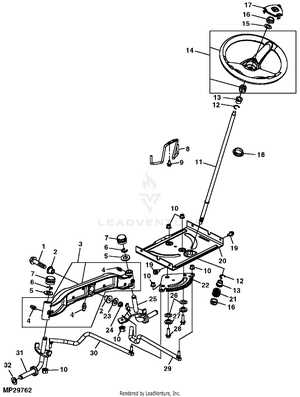

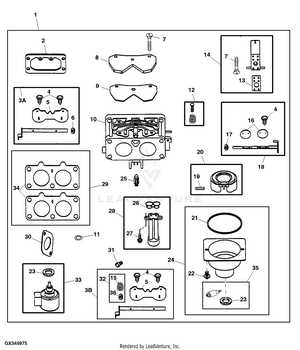

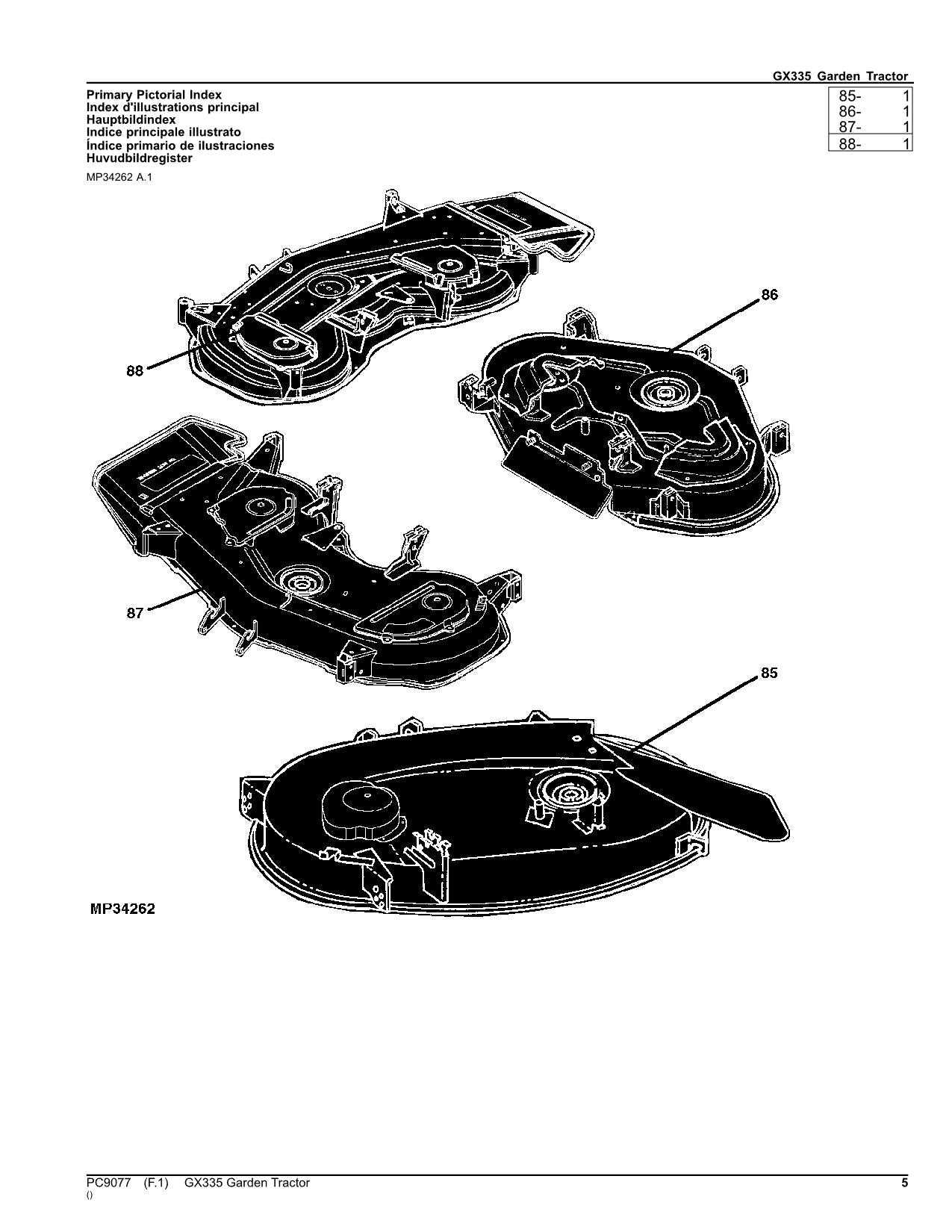

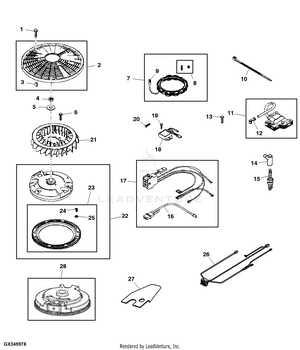

How to Read Parts Diagrams

Understanding schematic representations is essential for anyone involved in maintenance or repair tasks. These visuals provide a comprehensive overview of components, facilitating easier identification and replacement. Mastering the ability to interpret these illustrations can save time and enhance efficiency in any project.

Key Elements to Identify

When examining a schematic, there are several crucial aspects to pay attention to:

| Element | Description |

|---|---|

| Labels | Numerical or alphabetical indicators that correspond to specific items. |

| Connections | Lines showing how different components are linked or interact with one another. |

| Legend | A key that explains symbols and notations used in the visual representation. |

Tips for Effective Interpretation

To make the most of these visual aids, consider the following tips:

- Start by familiarizing yourself with the legend to understand symbols.

- Trace connections to grasp how components work together.

- Cross-reference labeled items with physical components for accurate identification.

Common Issues with L120 Deck

When using lawn equipment, several frequent complications can arise with the cutting mechanism. These problems can range from issues with uneven grass cutting to more serious malfunctions that affect performance. Regular maintenance and prompt attention to these concerns can ensure that the mower operates efficiently and provides a clean, even finish to your lawn.

Uneven Cutting

One of the most common problems owners face is uneven grass cutting. This can be caused by a number of factors such as a misaligned blade, worn-out parts, or improper height adjustments. When the cutting edges are not level, certain areas of the lawn may appear taller than others. It’s essential to check the blade alignment regularly and ensure that all components are securely fastened and functioning properly.

Clogging and Blockages

Another issue is clogging, often due to grass clippings accumulating in the undercarriage. This can lead to reduced performance and strain on the engine. A buildup of debris can block airflow, causing overheating or damaging vital components. Regularly cleaning the underside of the mower after use and ensuring that drainage areas are clear can help minimize this problem.

Essential Replacement Parts Overview

Understanding the fundamental components necessary for maintenance can significantly enhance the longevity and performance of your equipment. Each element plays a crucial role in ensuring smooth operation, preventing potential failures, and maximizing efficiency.

Key Components

Critical elements include blades, belts, and pulleys, each designed to withstand specific operational stresses. Regular inspection and timely replacement of these components can help avoid costly repairs and extend the lifespan of the machinery.

Maintenance Tips

To maintain optimal performance, it is advisable to follow a regular maintenance schedule, checking for wear and tear. Keeping a stock of essential components will allow for immediate replacements, ensuring that your equipment remains in peak condition.

Step-by-Step Repair Process

Repairing your mower’s components can seem daunting, but breaking it down into manageable steps can simplify the task. This guide provides a clear path to ensure you efficiently restore functionality, enhancing performance and prolonging the lifespan of your equipment.

1. Gather Tools and Materials: Before starting, assemble all necessary tools and replacement items. This may include wrenches, screwdrivers, and any specific components needed for your repair.

2. Disconnect the Power Source: Safety is paramount. Always ensure the equipment is powered off and disconnected from any power source to prevent accidents during the repair process.

3. Remove the Housing: Carefully take off the protective cover to access the internal mechanisms. Use the appropriate tools to avoid damaging any surrounding parts.

4. Inspect and Identify Issues: Thoroughly examine the internal components for wear and tear. Look for signs of damage or malfunction, which will guide you on what needs replacement or repair.

5. Replace Damaged Components: Once identified, replace any faulty parts. Ensure that the new components are compatible and securely installed, following any manufacturer guidelines.

6. Reassemble the Equipment: After completing the necessary replacements, carefully reattach the housing. Make sure all screws and fasteners are tightened properly to prevent future issues.

7. Test the Equipment: Once reassembled, reconnect the power source and perform a test run. Monitor the operation to ensure everything is functioning smoothly and efficiently.

8. Maintain Regular Checks: To prevent future problems, establish a routine maintenance schedule. Regular inspections will help catch issues early, ensuring your mower operates at its best.

Finding Authentic John Deere Parts

When it comes to maintaining and repairing outdoor machinery, using genuine components is crucial for optimal performance and longevity. Authentic replacements are designed to meet strict quality standards, ensuring that the equipment operates smoothly and efficiently over time. Choosing the right components is key to keeping your machinery in top condition, and sourcing them from reputable suppliers guarantees compatibility and durability.

There are several ways to ensure you’re purchasing original components for your machinery. One of the most reliable methods is to consult the manufacturer’s official network or authorized dealers, which typically carry a wide range of genuine parts. It’s important to avoid third-party suppliers who may offer cheaper alternatives that do not meet the necessary standards.

To further assist in your search for authentic components, it’s helpful to familiarize yourself with product specifications and part numbers. This information can typically be found in the product manual or through the manufacturer’s online resources. Once identified, you can confidently purchase parts that are designed for your equipment model.

| Component Type | Key Features | Where to Find |

|---|---|---|

| Engine Components | Designed for specific model engines for optimal performance | Authorized retailers or official website |

| Transmission Parts | Durable and tested to withstand operational stress | Certified dealers or trusted suppliers |

| Blade Assemblies | Precision-engineered for safe and effective cutting | Manufacturer’s official parts catalog |

By focusing on authentic components, you can ensure that your machinery continues to perform at its best, providing reliable service and a longer lifespan. Always verify the source and part numbers before making any purchases to avoid counterfeit or substandard replacements.

Tips for Deck Upgrades

Enhancing the performance and durability of your lawn equipment is essential for achieving optimal results. Upgrading components can significantly improve efficiency and provide a smoother experience while maintaining your outdoor spaces. Here are some key considerations for making effective enhancements.

First, focus on selecting high-quality materials that offer greater resistance to wear and tear. Durable components can withstand harsh conditions and extend the lifespan of your machinery. Additionally, consider compatibility with existing mechanisms to ensure seamless integration.

Another important aspect is the maintenance of the upgraded components. Regular checks and timely replacements can prevent unforeseen issues and enhance overall performance. Keeping everything well-lubricated and free of debris can make a notable difference.

| Tip | Description |

|---|---|

| Quality Materials | Invest in robust components to increase longevity and reduce maintenance frequency. |

| Compatibility | Ensure new additions are compatible with existing systems for optimal performance. |

| Regular Maintenance | Implement a schedule for checks to enhance reliability and efficiency. |

| Consult Experts | Seek professional advice if unsure about the best upgrades for your specific needs. |

Frequently Asked Questions about L120

This section addresses common inquiries related to a specific model of lawn care equipment, providing clarity on its operation, maintenance, and components. Understanding these frequently asked questions can help users optimize their experience and ensure longevity.

What maintenance tasks should I perform regularly? Routine maintenance includes checking the oil levels, inspecting the blades, and cleaning the exterior. Regular upkeep ensures optimal performance and extends the lifespan of the machine.

How can I troubleshoot starting issues? If you experience difficulty starting, check the battery charge, ensure the fuel is fresh, and inspect the ignition system. These factors often play a crucial role in starting performance.

What should I do if the cutting quality is poor? Unsatisfactory cutting can be addressed by sharpening the blades and adjusting the cutting height. Regularly inspecting these components is vital for achieving a clean cut.

Are there any recommended accessories? Various accessories can enhance functionality, such as mulching kits and baggers. These attachments can improve efficiency and cater to specific lawn care needs.

How do I store the equipment during the off-season? Proper storage involves cleaning the machine, removing the battery, and storing it in a dry place. Protecting it from the elements helps prevent damage over time.