In the realm of power tools, the intricacies of a chainsaw’s construction play a crucial role in its performance and reliability. A well-organized representation of these elements can aid users in comprehending how each component contributes to the overall functionality of the device. Grasping this information not only enhances the user’s ability to maintain the tool effectively but also ensures that any necessary repairs can be undertaken with confidence.

When examining the various sections of the equipment, one can observe how the interplay of different components leads to optimal operation. Recognizing the arrangement and purpose of each part empowers individuals to troubleshoot issues and make informed decisions regarding upgrades or replacements. This knowledge ultimately fosters a deeper appreciation for the craftsmanship involved in these powerful machines.

Delving into the structure of the chainsaw unveils a world of engineering designed for efficiency and safety. Each element, from the cutting mechanism to the power source, is meticulously crafted to work in harmony. Understanding these relationships can transform the way users approach their tool, enabling them to maximize its potential while ensuring longevity through proper care and handling.

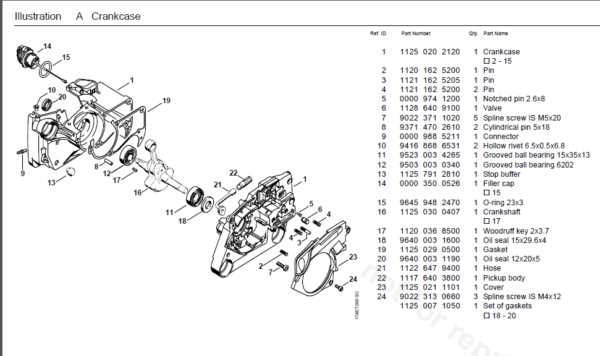

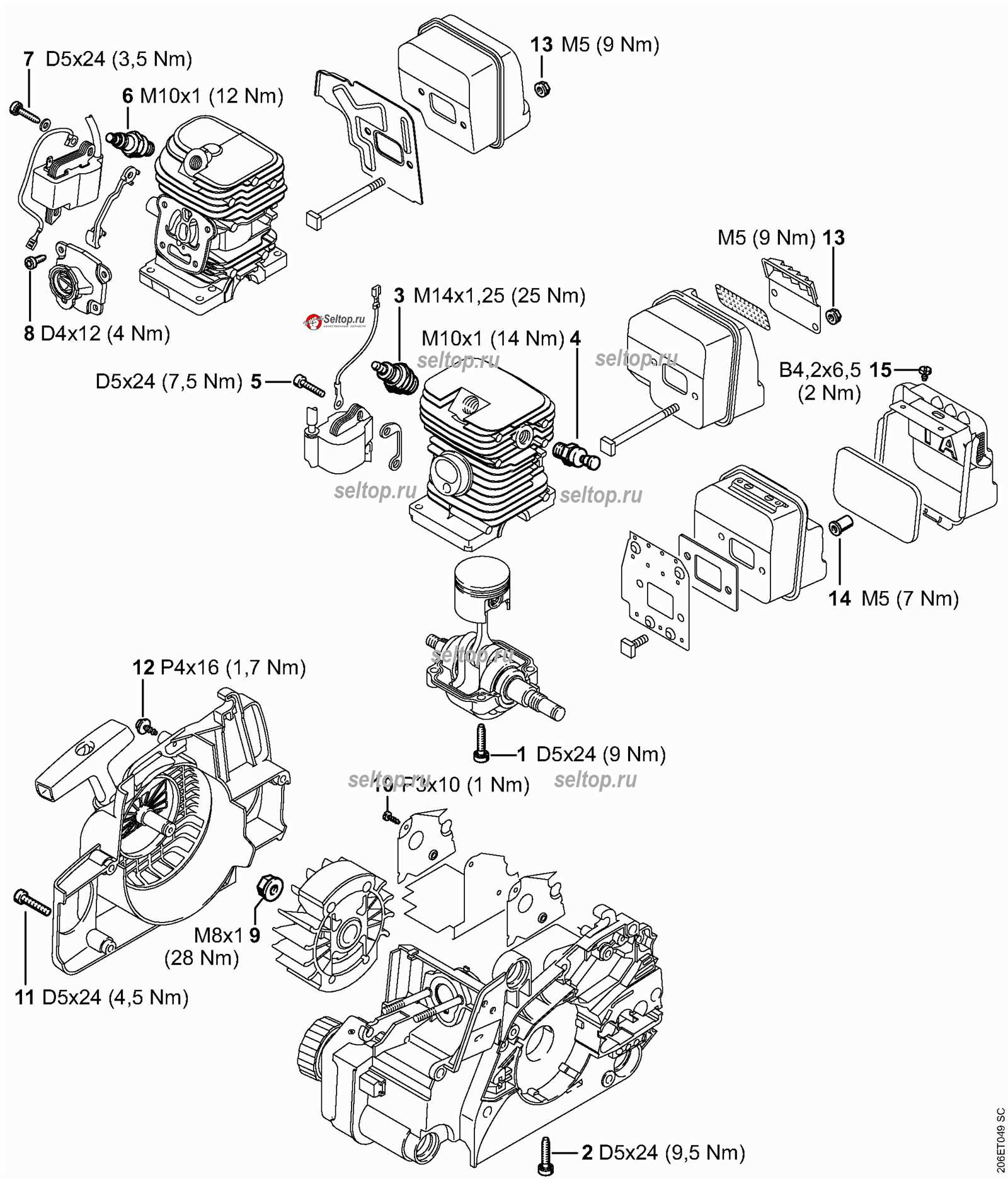

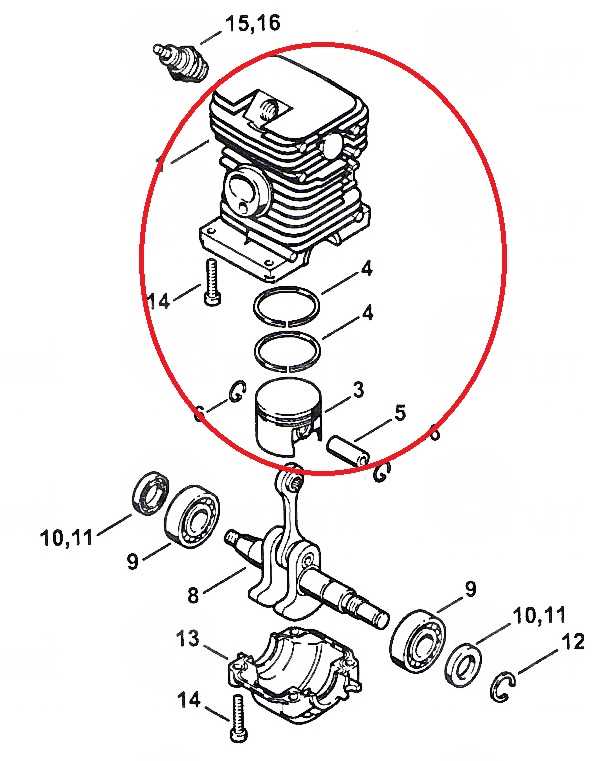

This section provides a comprehensive look at the various elements that make up a particular model of a chainsaw. Understanding these components is essential for proper maintenance and troubleshooting. Each part plays a vital role in ensuring the device operates smoothly and efficiently.

Key Elements of the Device

The main features of the chainsaw include essential components that contribute to its performance. Familiarity with these elements aids users in identifying parts that may require attention or replacement.

| Component | Function |

|---|---|

| Engine | Powers the chainsaw and enables cutting through various materials. |

| Chain | Moves around the bar to cut through wood and other substances. |

| Guide Bar | Supports the chain and guides its movement during operation. |

| Fuel Tank | Holds the fuel needed for engine operation. |

| Air Filter | Prevents debris from entering the engine, maintaining its performance. |

Understanding Maintenance Needs

Regular upkeep of each component is crucial for optimal functionality. Users should familiarize themselves with the signs of wear and know when to seek replacements to extend the lifespan of their equipment.

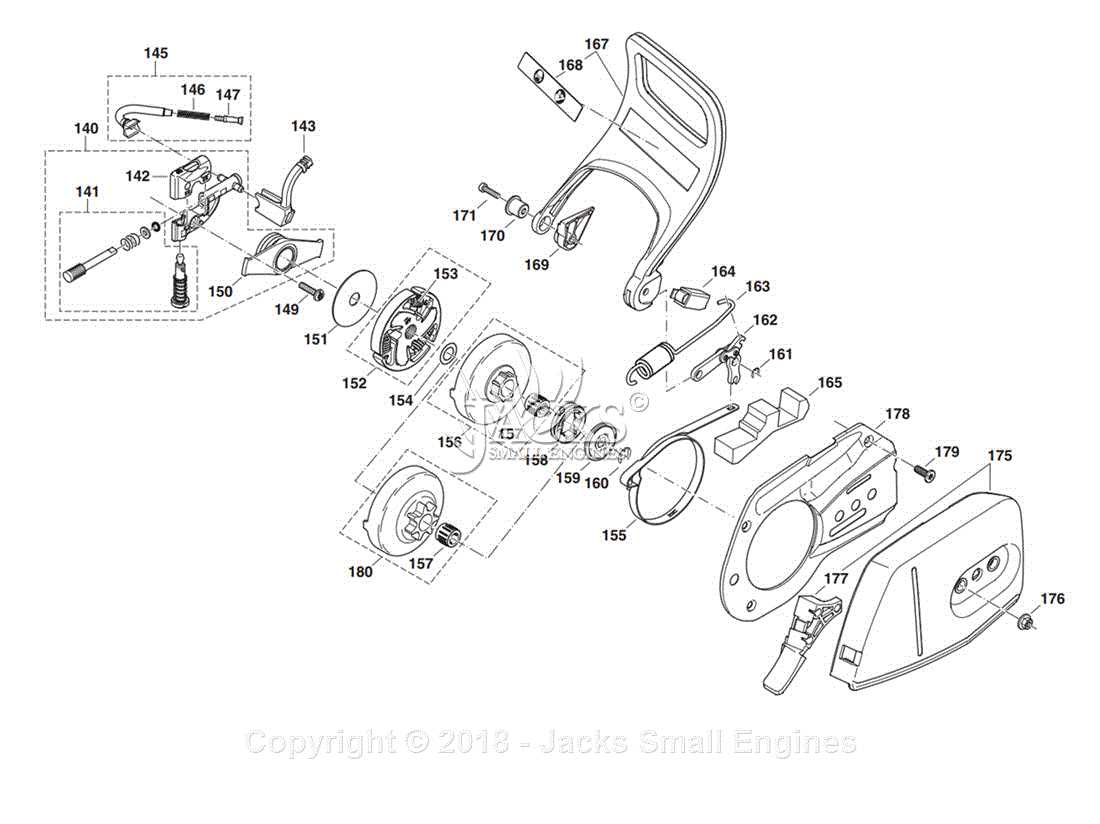

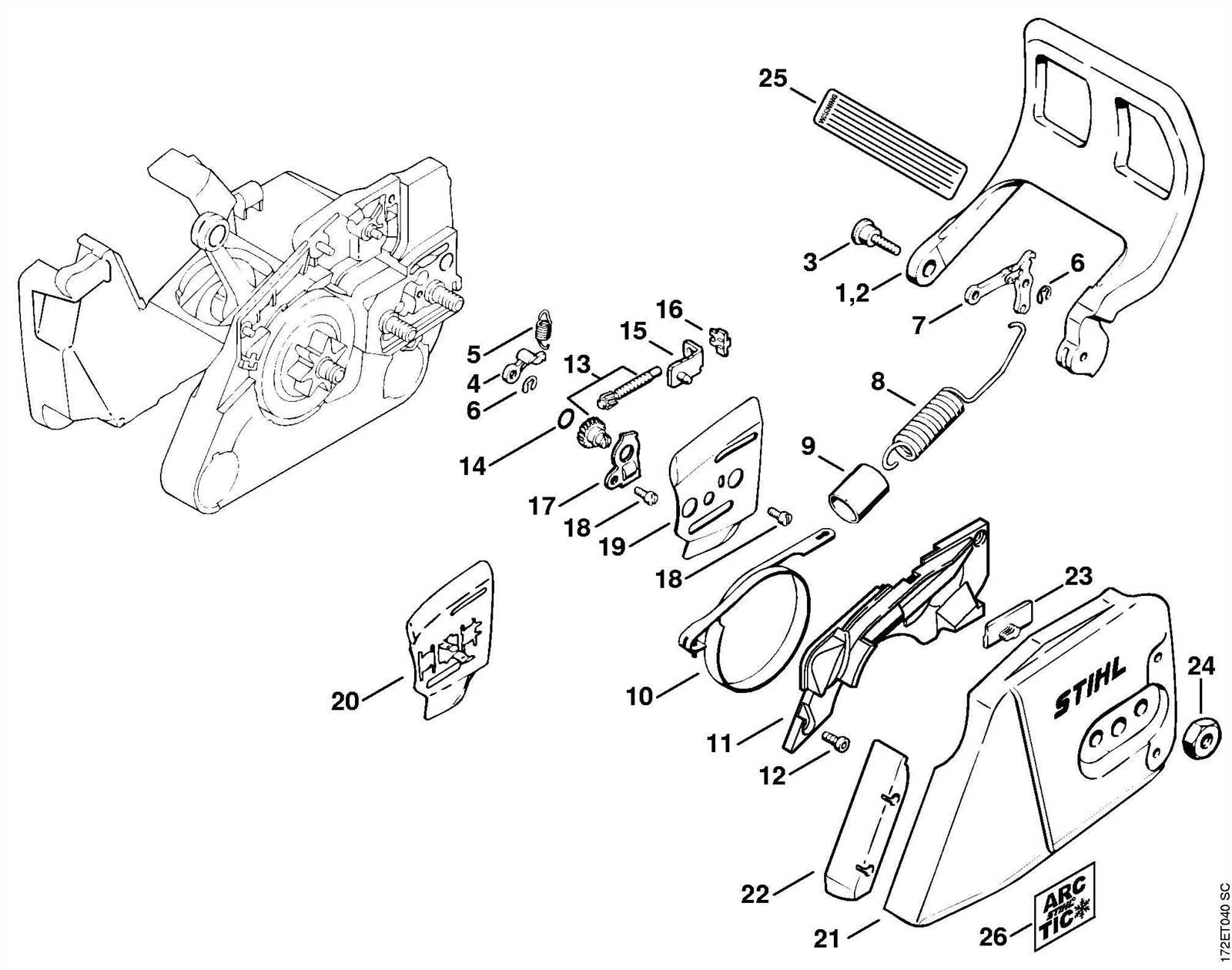

Understanding the Parts Layout

Grasping the arrangement of components in a mechanical device is crucial for effective maintenance and operation. A well-structured layout aids users in identifying individual elements and their functions, facilitating smoother repairs and enhancements. This section will explore the significance of a clear component organization.

Key Benefits of a Structured Component Arrangement

- Enhanced Identification: A coherent layout makes it easier to locate specific elements, reducing confusion during repairs.

- Improved Maintenance: Understanding where each component is situated aids in performing routine checks and servicing.

- Streamlined Repairs: Quick access to individual parts can expedite troubleshooting and restoration processes.

Common Components and Their Functions

- Engine Assembly: The powerhouse of the machine, responsible for providing the necessary energy.

- Cutting Unit: This section contains the tools responsible for executing the primary cutting tasks.

- Control Mechanism: This area includes various levers and switches that allow users to operate the device effectively.

Common Replacement Parts Explained

In the realm of outdoor power equipment, understanding the various components that may require substitution over time is essential for maintaining optimal performance. Equipment is composed of several integral elements that, when worn or damaged, can hinder functionality. Identifying and addressing these common items can significantly extend the life of your machinery and enhance its efficiency.

Essential Components

Among the key elements that often need replacement are filters, chains, and bars. Filters are crucial for ensuring clean air and fuel flow, which directly impacts engine performance. Over time, these can become clogged with debris, leading to reduced efficiency. Chains and bars, on the other hand, experience wear due to regular use and may require frequent monitoring to prevent operational issues.

Maintenance and Care

Regular maintenance can help in identifying components that show signs of wear. For instance, spark plugs are vital for ignition and can degrade over time, affecting starting efficiency. Keeping an eye on these components and replacing them as necessary can prevent larger issues and maintain the reliability of your equipment.

How to Interpret the Diagram

Understanding a visual representation of components is essential for effective maintenance and repair of equipment. These illustrations provide a clear overview of various elements, their relationships, and how they interact within the machine. By familiarizing yourself with the layout and symbols used, you can efficiently navigate through the parts and identify specific areas requiring attention.

Key Symbols and Labels

Most visual guides will include specific symbols and labels that denote different parts and functions. Recognizing these elements is crucial for accurate interpretation. Each symbol typically corresponds to a particular component, while labels may provide additional information about specifications or compatibility.

Reading the Layout

The arrangement of components within the illustration usually follows a logical structure. Begin by identifying the main sections, which may include the engine, handle, and safety features. From there, trace the connections between parts, paying attention to any arrows or lines that indicate movement or assembly direction. This methodical approach will enhance your understanding of how everything fits together.

| Symbol | Description |

|---|---|

| A | Engine Assembly |

| B | Fuel Tank |

| C | Handle Grip |

| D | Chain Brake |

Maintenance Tips for Key Parts

Proper care and upkeep of essential components in your equipment are crucial for ensuring optimal performance and longevity. Regular maintenance not only enhances efficiency but also prevents potential issues that could arise from wear and tear. Here are some practical suggestions to keep your machinery in top condition.

Regular Cleaning

Cleaning is vital to maintain the functionality of various elements. Dirt and debris can accumulate, leading to decreased performance. Make it a habit to clean parts thoroughly after each use, focusing on areas where buildup is common. Using a soft brush or compressed air can effectively remove stubborn particles.

Lubrication and Inspections

Lubrication is essential for reducing friction and preventing premature wear. Regularly check all moving parts and apply the appropriate lubricant as needed. Additionally, conduct periodic inspections to identify any signs of damage or looseness. Addressing minor issues promptly can save time and costs in the long run.

Identifying Compatibility with Other Models

When working with chainsaw components, understanding the interchangeability of parts among different models is crucial for ensuring optimal performance and functionality. Each model may have unique specifications, but many share similarities that allow for compatibility. This knowledge can save time and resources, particularly when seeking replacements or upgrades.

Compatibility often hinges on several factors, including design features, size, and functionality. It is essential to examine component specifications closely, as even minor differences can affect how parts fit and perform. For instance, while certain chainsaw models may use the same engine size or bar length, the attachment mechanisms or housing designs may vary, influencing whether a part can be seamlessly integrated.

Additionally, consulting with manuals and manufacturer resources can provide insights into which components are interchangeable. Some manufacturers offer cross-reference charts that highlight compatible parts across various models. This approach not only aids in identifying suitable replacements but also enhances the overall efficiency of the equipment.

In summary, recognizing the compatibility of components with other models involves thorough research and careful consideration of specifications. This understanding can facilitate better maintenance practices and prolong the life of the equipment.

Where to Find Genuine Parts

When seeking authentic components for your equipment, it is essential to ensure quality and compatibility. Reliable sources not only guarantee that you receive the correct items but also provide peace of mind regarding performance and durability.

Here are some recommended avenues to explore:

- Authorized Dealers: These establishments often carry a comprehensive range of original components. Visiting a nearby dealer can provide access to the latest products and expert advice.

- Official Online Stores: Many manufacturers have dedicated online platforms where you can browse and purchase genuine items directly. This option often includes detailed specifications and compatibility information.

- Specialty Retailers: Certain retailers specialize in equipment parts, offering a selection of authentic components. Check for those with a strong reputation and positive customer feedback.

- Trade Shows and Expos: Attending industry events can connect you with manufacturers and suppliers. These venues often showcase new products and may offer exclusive deals.

- Manufacturer’s Support Services: Most brands provide customer support channels, including hotlines and online chat options. They can assist you in locating specific components and guide you on proper installation.

Assembly Instructions for Major Components

Proper assembly of key elements in a power tool is crucial for optimal performance and longevity. Understanding how these components fit together can enhance functionality and reduce the risk of operational issues. The following instructions provide guidance on assembling the main parts effectively, ensuring a reliable and efficient tool.

Step-by-Step Assembly Process

Begin by organizing all necessary components in a clean workspace. Ensure that each part is free from debris and damage. Start with the housing, securing it with the appropriate screws and fasteners. Follow this by attaching the engine unit, making sure that all connections are aligned correctly. Pay close attention to the alignment of the drive system and ensure it moves smoothly.

Final Assembly Checks

Once the major components are assembled, conduct a thorough inspection to confirm that everything is securely fastened. Check for any signs of misalignment or looseness. It’s also essential to verify that all safety mechanisms are correctly positioned and functioning. Completing these final checks will help guarantee that the tool operates safely and effectively.

Troubleshooting Common Issues

When operating a chain saw, users may encounter various challenges that can hinder performance. Understanding these common issues and their potential solutions can enhance the overall efficiency of the equipment. This section aims to provide guidance on identifying and resolving frequent problems that may arise during use.

-

Engine Won’t Start:

If the engine fails to start, check the fuel levels and ensure the mixture is correct. Additionally, examine the spark plug for wear and replace it if necessary.

-

Chain Stopping:

If the cutting chain stops unexpectedly, inspect the tension settings. An overly tight chain can cause binding, while a loose chain may slip off.

-

Excessive Vibration:

Vibration during operation can indicate improper assembly or worn components. Verify that all parts are securely attached and check for any damage.

-

Oil Leaks:

Leaks from the oil reservoir can lead to inadequate lubrication. Check seals and gaskets for wear and replace them as needed to maintain proper function.

-

Poor Cutting Performance:

If the cutting efficiency decreases, examine the sharpness of the chain. Dull blades can result in increased effort and reduced cutting ability.

By systematically addressing these common challenges, users can maintain optimal performance and extend the lifespan of their equipment.