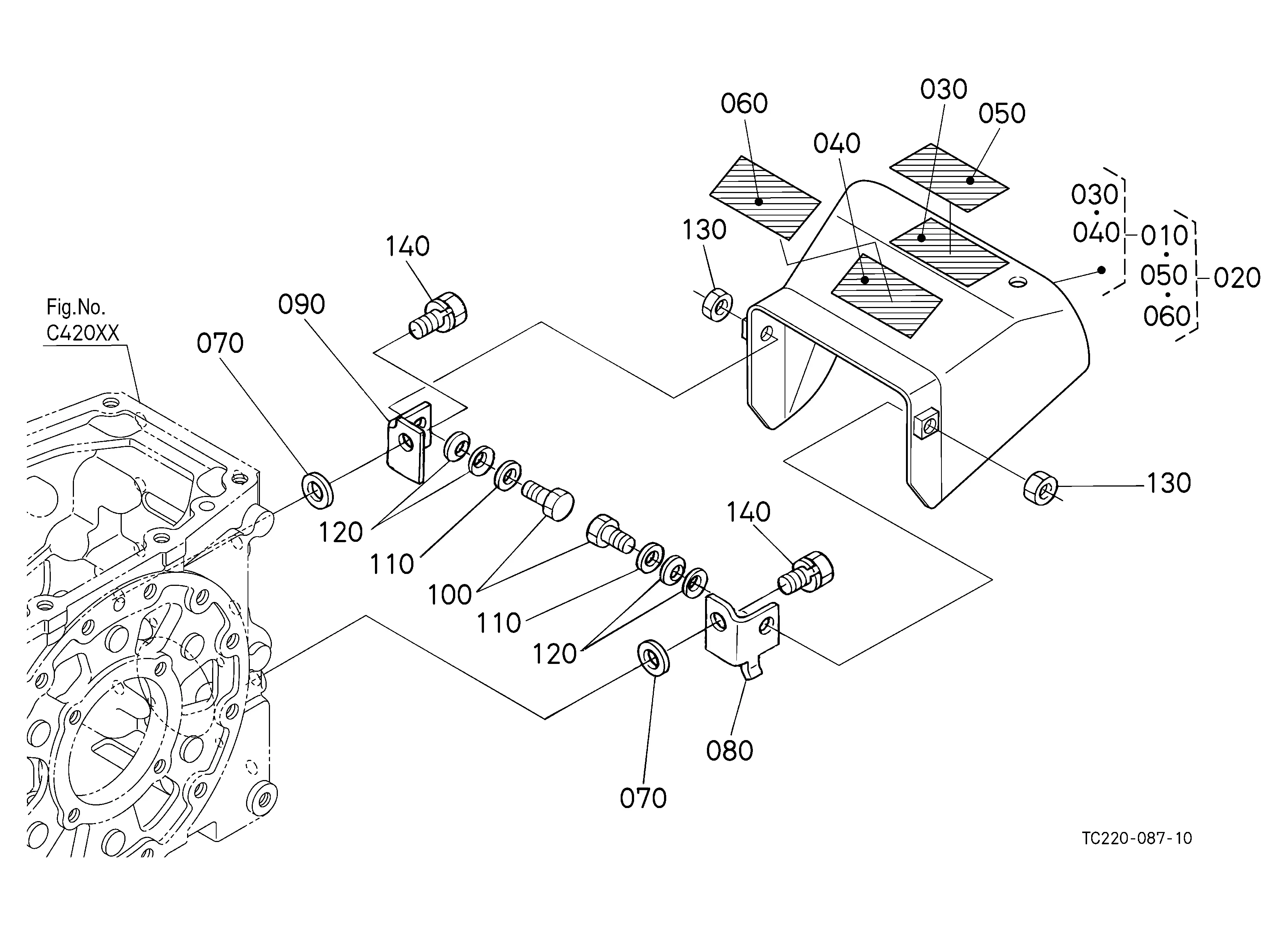

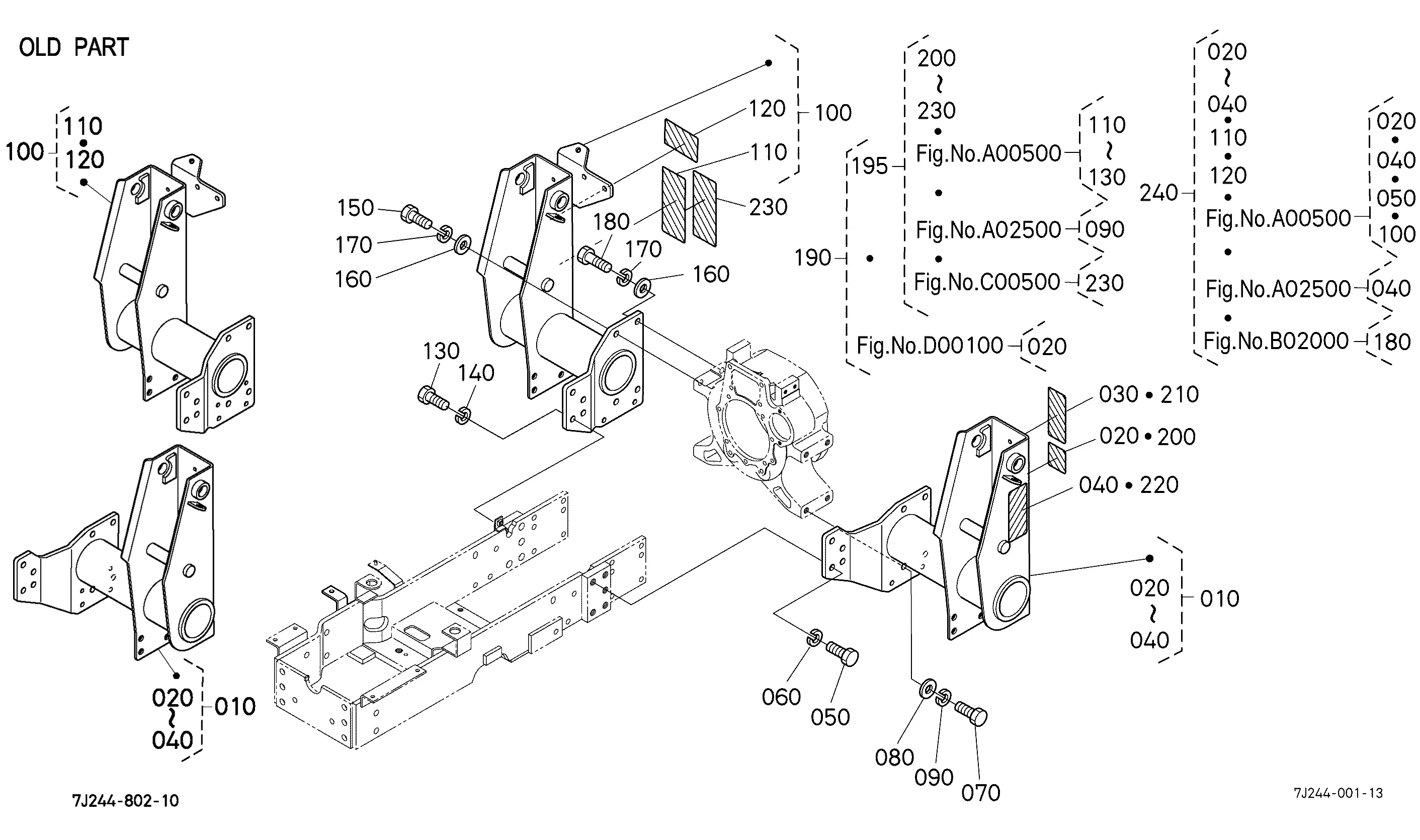

When it comes to the functionality of heavy equipment, having a clear view of its internal structure is essential. Knowing how different elements fit together not only aids in maintenance but also enhances overall performance. A comprehensive visual representation of these components serves as a valuable resource for operators and technicians alike.

Many users often find themselves searching for detailed illustrations that depict the various sections of their machinery. These visual aids can help identify specific parts, ensuring that repairs and replacements are executed with precision. Understanding the layout of these intricate systems is crucial for anyone looking to optimize their equipment’s efficiency.

In this discussion, we will explore the significance of having access to well-structured visuals that clarify the relationships between different machine elements. By delving into this topic, readers will gain insights into how to effectively interpret these diagrams, ultimately leading to improved knowledge and skills in equipment management.

Understanding the Kubota L3400

This section explores the essential components and functionalities of a specific agricultural machine, highlighting its significance in enhancing productivity and efficiency in farming tasks. A deep dive into the operational aspects can provide valuable insights for both new and experienced users.

Key Features

Among its many attributes, this machine boasts a robust engine and user-friendly controls, making it suitable for various agricultural applications. Its design emphasizes durability and reliability, ensuring that it can withstand demanding work conditions.

Maintenance Tips

Regular upkeep is crucial for optimal performance. Users should focus on routine checks, including fluid levels and wear components, to extend the lifespan of the equipment. Understanding the machine’s workings ultimately helps in making informed maintenance decisions.

Key Features of the L3400 Model

This model stands out due to its robust engineering and versatile capabilities, making it suitable for a variety of tasks. Its design emphasizes reliability and user-friendliness, appealing to both professionals and hobbyists.

Power and Performance

- Impressive horsepower allows for efficient operation.

- High torque output ensures optimal performance even in challenging conditions.

- Compact size enhances maneuverability in tight spaces.

Versatility and Adaptability

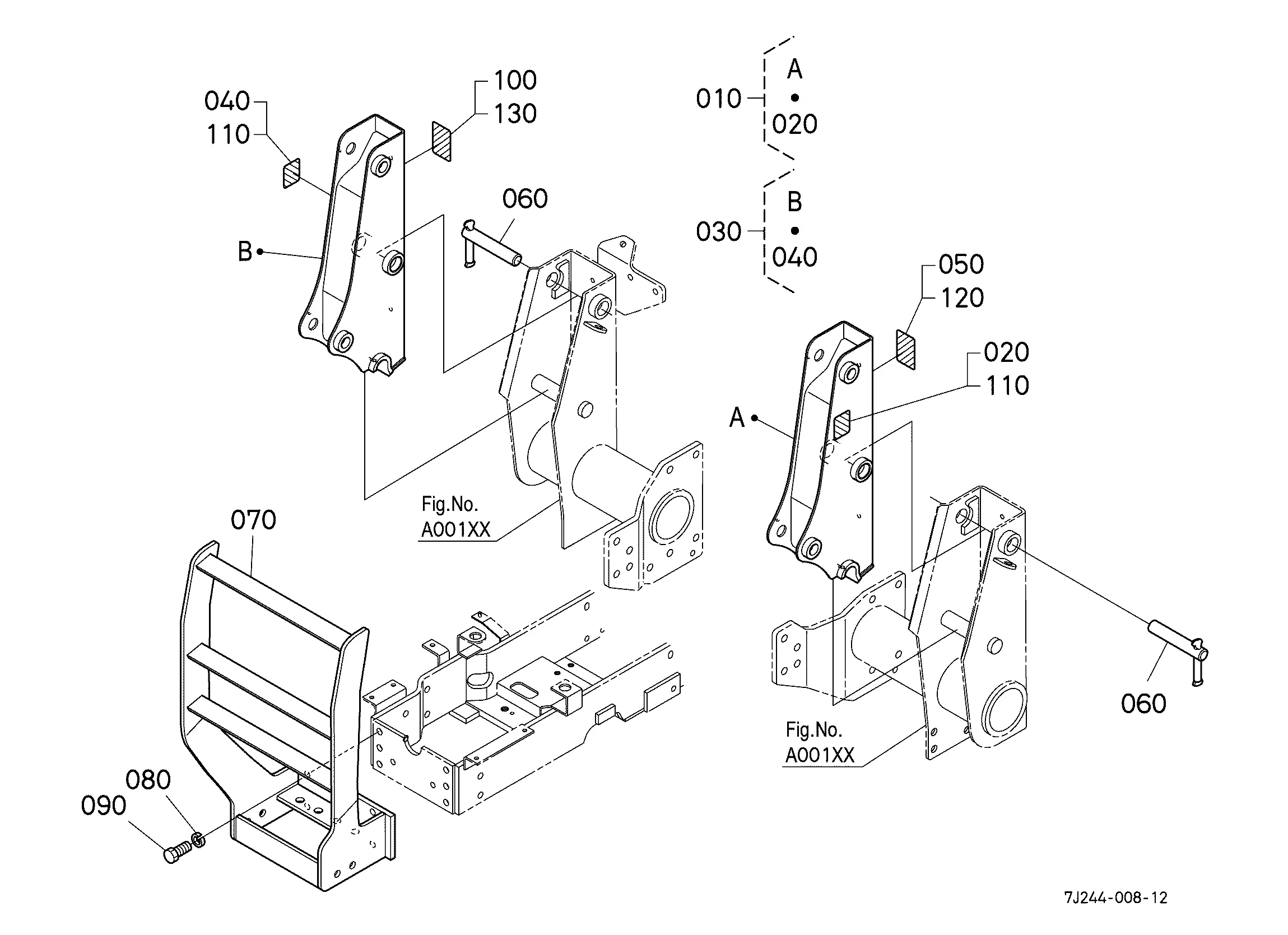

- Compatible with a wide range of attachments for different applications.

- Easy to switch implements, maximizing productivity.

- Durable construction suitable for agricultural and landscaping tasks.

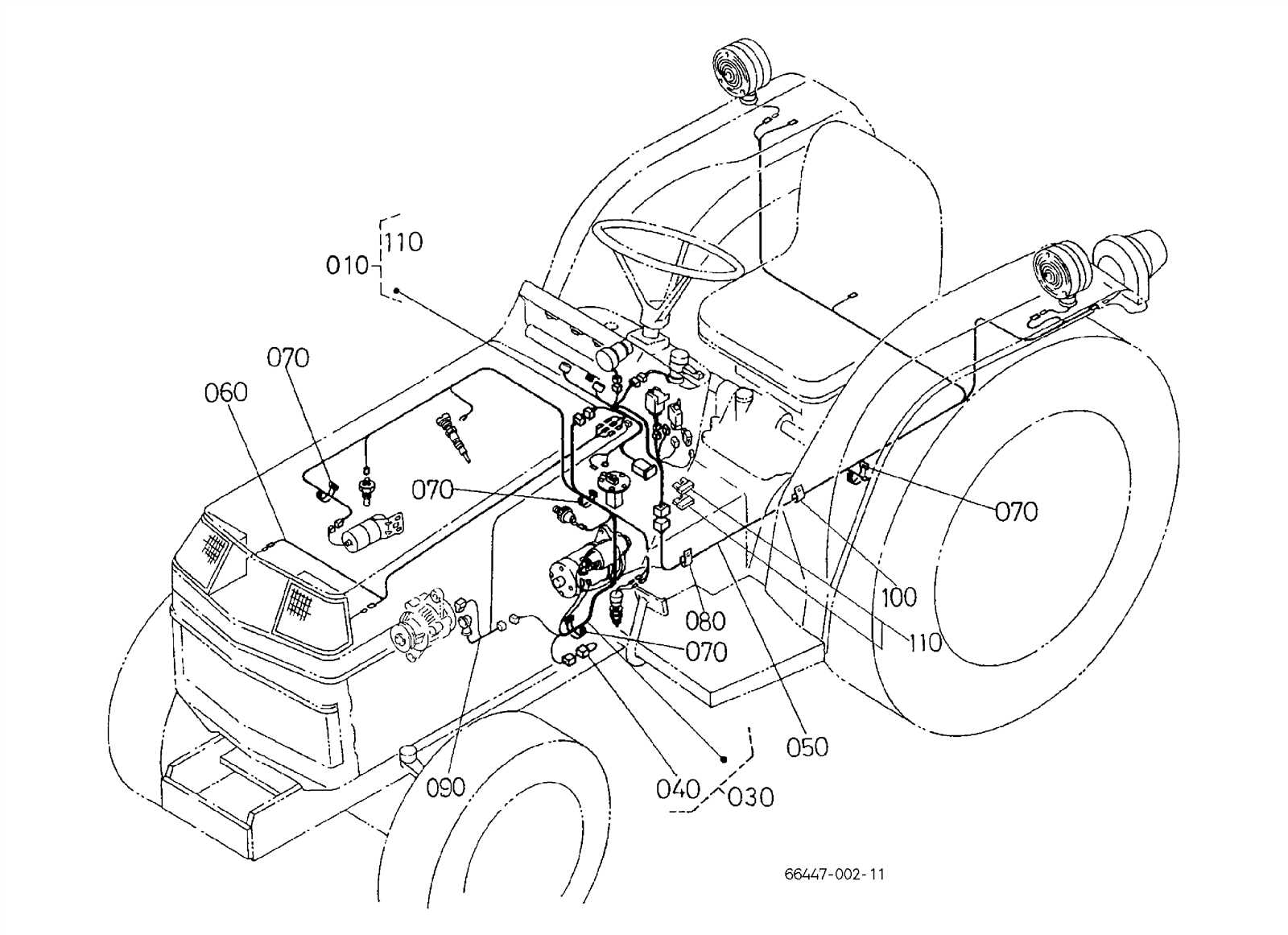

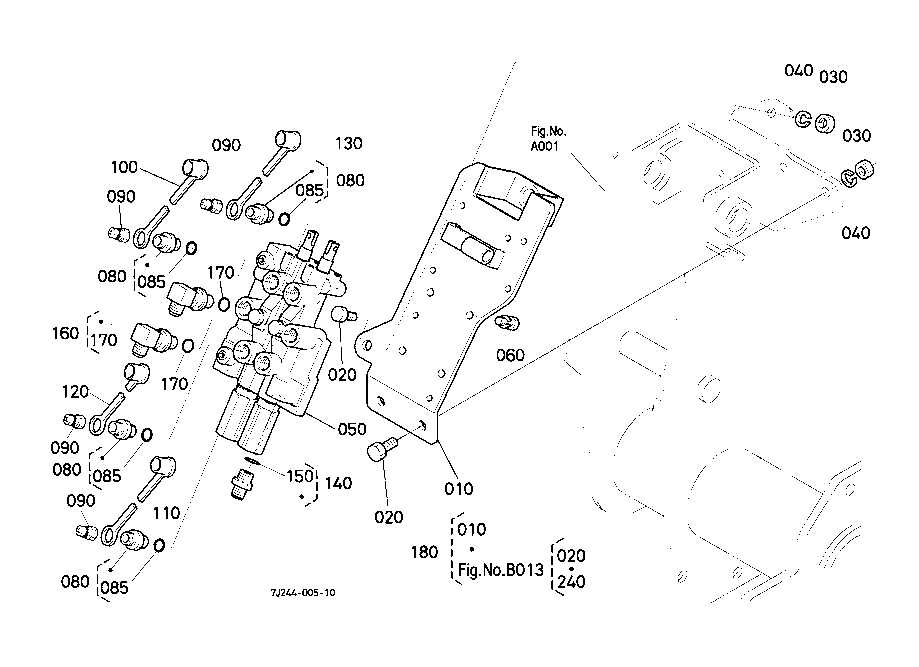

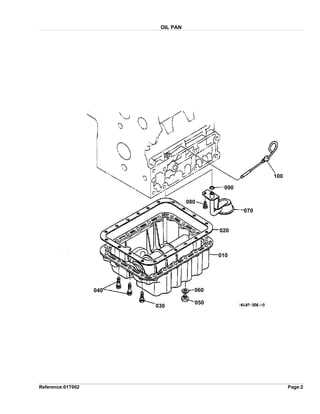

Importance of Parts Diagrams

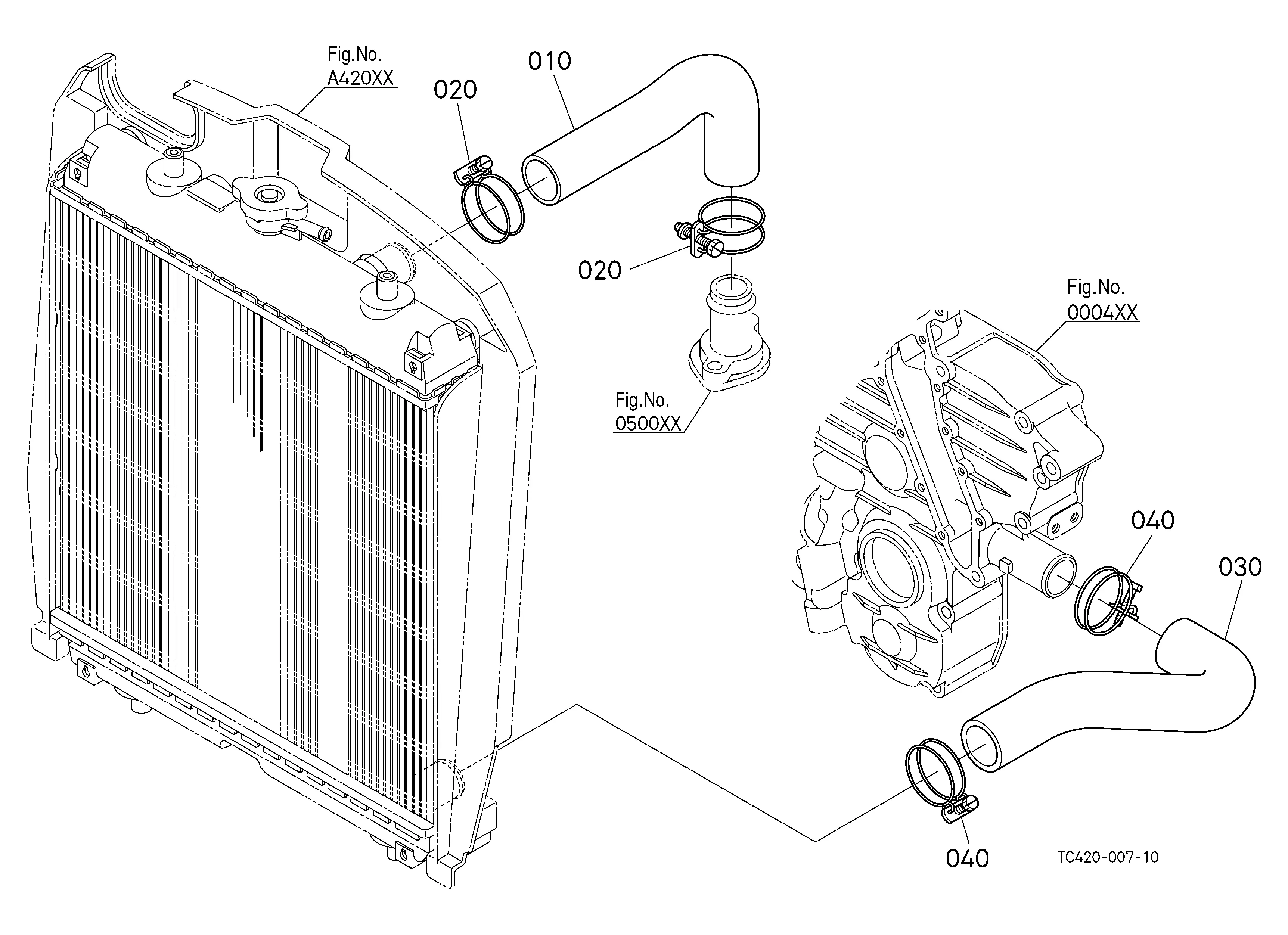

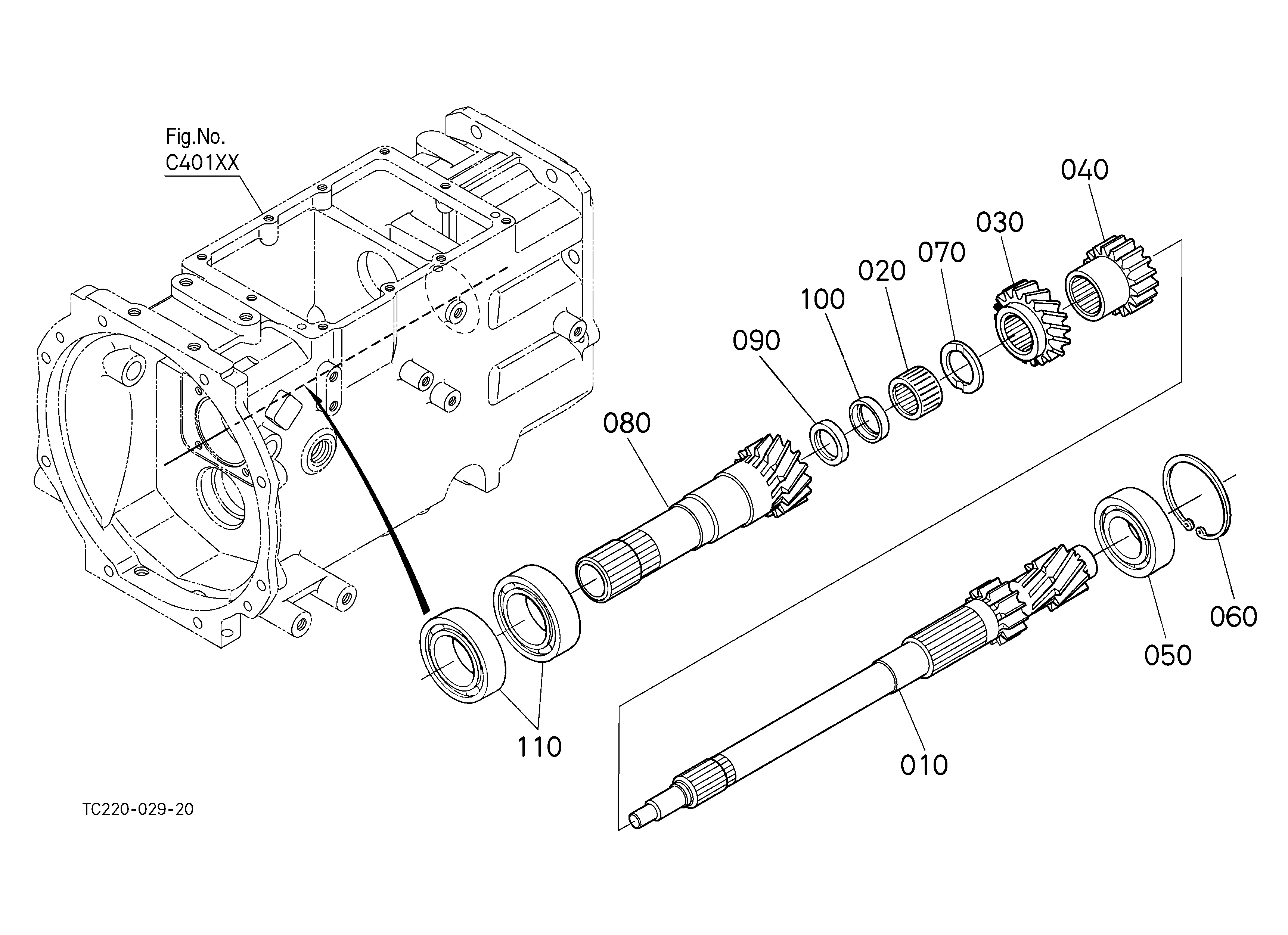

Visual representations of components play a crucial role in the maintenance and repair of machinery. They provide a clear view of how individual elements fit together, making it easier for technicians and operators to understand complex systems. By having a detailed illustration, users can quickly identify the required pieces for replacement or servicing, ensuring efficiency in their work.

Such illustrations not only assist in troubleshooting but also enhance the learning process for new users. By studying these visuals, individuals gain a deeper understanding of the machine’s functionality and interrelationships among its various elements. This knowledge empowers them to perform repairs confidently and correctly, minimizing downtime.

| Benefit | Description |

|---|---|

| Enhanced Clarity | Provides a clear overview of the assembly and arrangement of components. |

| Efficient Troubleshooting | Facilitates quick identification of faulty elements and their replacements. |

| Training Aid | Serves as a valuable resource for educating new personnel on machine operations. |

| Improved Maintenance | Streamlines the process of regular upkeep and ensures proper care of the equipment. |

In conclusion, these visual guides are indispensable tools that enhance understanding, improve repair efficiency, and foster a culture of maintenance awareness among users.

Common Issues with Kubota L3400

Every machine has its quirks, and this particular model is no exception. Understanding the frequent challenges can help owners maintain optimal performance and longevity. Below are some prevalent concerns that users may encounter.

Engine Performance: One common issue is a decrease in power output, which can be caused by fuel quality or air filter blockages. Regular checks and maintenance can mitigate these problems.

Hydraulic System: Leaks in the hydraulic system are frequently reported. These can stem from worn seals or damaged hoses, requiring immediate attention to prevent further damage.

Electrical Components: Owners often face electrical malfunctions, such as faulty starters or battery issues. Keeping connections clean and batteries charged can help avoid these complications.

Transmission Troubles: Difficulty in shifting gears may occur, often due to low fluid levels or contamination. Routine inspections of the transmission fluid can prevent this hassle.

Overall Maintenance: Regular upkeep is crucial to prevent the aforementioned issues. Developing a consistent maintenance schedule can ensure smoother operation and enhance the machine’s lifespan.

Where to Find Parts Diagrams

Locating visual references for machinery components is essential for effective maintenance and repairs. Understanding where to find these resources can streamline the process and ensure you have the correct information at your fingertips.

- Manufacturer Websites: Official sites often provide comprehensive resources, including manuals and visual guides.

- Online Retailers: Many parts suppliers feature detailed illustrations alongside their products to aid in identification.

- Forums and Community Groups: Engaging with fellow enthusiasts can lead to shared resources and insights on specific models.

- Technical Manuals: Printed or downloadable guides often include detailed visual aids for assembly and disassembly.

By exploring these avenues, you can effectively delve into the details needed for your equipment maintenance, ensuring you achieve the ultimate results.

Benefits of Using Original Parts

When it comes to machinery maintenance, the choice of components plays a crucial role in ensuring optimal performance and longevity. Utilizing authentic components guarantees compatibility and reliability, ultimately enhancing the overall efficiency of the equipment.

Quality Assurance: Genuine components are manufactured to meet the highest standards, providing durability that aftermarket alternatives often lack. This ensures that your machinery operates smoothly without unexpected failures.

Perfect Fit: Original components are designed specifically for your equipment, allowing for seamless installation and operation. This precise fit minimizes wear and tear, extending the lifespan of both the component and the machine.

Enhanced Performance: By using authentic parts, you maintain the original specifications and performance levels of your machinery. This helps to achieve the ultimate efficiency, ensuring that the equipment performs as intended.

Warranty Protection: Many manufacturers offer warranties on their genuine components. Utilizing these parts often keeps your warranty intact, protecting your investment in the long run.

Resale Value: Equipment maintained with original components typically retains a higher resale value. Potential buyers are often more inclined to invest in machinery that has been properly cared for with authentic parts.

Maintenance Tips for L3400 Owners

Proper upkeep is essential for maximizing the lifespan and performance of your machinery. Regular checks and timely interventions can prevent major issues and ensure smooth operation.

1. Regular Oil Changes: Make it a habit to replace the oil at recommended intervals. Clean oil is vital for optimal engine performance and longevity.

2. Inspect Filters: Regularly check air and fuel filters for clogs. Replacing them can improve efficiency and prevent engine problems.

3. Battery Care: Keep terminals clean and ensure a secure connection. Monitor fluid levels in lead-acid batteries to avoid corrosion.

4. Tire Maintenance: Check tire pressure frequently to ensure proper handling and fuel efficiency. Rotate tires as needed to promote even wear.

5. Clean the Exterior: Regularly wash the exterior to remove dirt and debris. This helps prevent rust and allows for easy inspection of potential issues.

6. Monitor Fluid Levels: Regularly check coolant, hydraulic fluid, and transmission fluid levels. Keeping these topped off ensures efficient operation.

7. Consult the Manual: Always refer to the owner’s manual for specific maintenance schedules and recommendations tailored to your model.

Upgrading Your Kubota Equipment

Enhancing your agricultural machinery can significantly boost productivity and efficiency. By investing in the right improvements, you can ensure your equipment operates at its best, meeting the demands of modern farming practices.

Here are some key areas to focus on when considering upgrades:

- Engine Performance: Upgrading components such as filters and injectors can lead to better fuel efficiency and power output.

- Hydraulic Systems: Enhanced hydraulic pumps and hoses can improve lifting capacity and responsiveness, making tasks easier.

- Transmission Enhancements: Upgrading to a more efficient transmission can lead to smoother operation and increased torque.

- Cab Comfort: Adding features like ergonomic seats and climate control can enhance operator comfort, leading to better focus and productivity.

- Safety Features: Implementing modern safety systems, such as improved lighting and stability controls, can protect both the operator and the equipment.

Before starting any upgrade project, it’s essential to assess your current equipment and identify specific needs. Researching compatible enhancements and consulting with professionals can lead to informed decisions that align with your operational goals.

Investing in quality upgrades not only improves performance but can also extend the lifespan of your machinery, ensuring you get the most out of your investment.