In the realm of outdoor maintenance, the efficiency of cleaning equipment relies heavily on its internal mechanisms. A thorough grasp of these components not only enhances performance but also extends the lifespan of the machine. This exploration delves into the intricacies of these vital elements, offering insights into their arrangement and functionality.

Visual representation of the various elements involved can significantly aid users in identifying and resolving issues. By comprehending how each segment interacts within the assembly, one can optimize operations and ensure effective performance. Understanding these connections fosters a deeper appreciation for the engineering behind these powerful tools.

Whether you are a seasoned user or a novice, familiarizing yourself with the structural layout and function of each component is crucial. This knowledge empowers you to maintain your equipment better, troubleshoot efficiently, and make informed decisions when repairs or replacements are necessary.

Understanding Simpson Pressure Washers

This section aims to explore the functionality and components of high-performance cleaning machines, which are essential for achieving optimal cleanliness in various settings. These devices harness the power of water at elevated forces to tackle tough dirt and grime efficiently.

Key Components: Each cleaning machine consists of several critical elements that work in harmony to deliver effective results. Familiarity with these components can enhance your understanding and maintenance capabilities.

Efficiency and Versatility: These machines are designed for a multitude of tasks, from residential upkeep to industrial applications. Recognizing their adaptability allows users to maximize their investment.

Ultimately, comprehending the mechanics behind these cleaning tools not only aids in proper usage but also ensures longevity and performance consistency.

Key Components of Pressure Washer Pumps

Understanding the essential elements that drive a high-efficiency cleaning device is crucial for optimal performance. Each component plays a significant role in ensuring effective operation and longevity. Familiarity with these key elements allows users to troubleshoot issues, perform maintenance, and maximize the functionality of their equipment.

1. Motor

The motor serves as the powerhouse of the system, converting electrical energy into mechanical energy. This transformation is vital for generating the force needed to propel water through the system. A well-functioning motor ensures that the equipment operates smoothly and consistently, providing the necessary pressure for effective cleaning tasks.

2. Water Intake and Outlet

The water intake and outlet mechanisms are critical for the flow of liquid through the device. The intake draws in water from a source, while the outlet directs the flow towards the nozzle. Proper sealing and connection are essential to prevent leaks and maintain the desired pressure. Over time, wear and tear may necessitate the replacement of these components to ensure optimal performance.

Understanding these foundational elements enhances user knowledge, leading to better maintenance practices and improved overall efficiency of the cleaning device.

Importance of Pump Maintenance

Regular upkeep of fluid-moving devices is crucial for ensuring optimal performance and longevity. Neglecting these essential tasks can lead to inefficiencies, breakdowns, and costly repairs. Maintaining these systems not only preserves functionality but also enhances safety during operation.

Key reasons for consistent maintenance include:

- Efficiency: Well-maintained equipment operates more effectively, reducing energy consumption.

- Longevity: Routine checks can extend the lifespan of machinery, saving money in the long run.

- Safety: Regular inspections help identify potential hazards, protecting users from accidents.

- Performance: Keeping components in good condition ensures they work at their best, providing reliable results.

- Cost Savings: Preventive maintenance can minimize unexpected breakdowns and repairs, leading to lower operational costs.

By prioritizing these practices, users can maintain functionality and reliability, ensuring the equipment serves its purpose effectively over time.

Common Issues with Pressure Washer Pumps

When using cleaning equipment, several common challenges can arise, impacting performance and efficiency. Understanding these issues can help users troubleshoot effectively and maintain their devices for optimal operation.

Frequent Problems

- Loss of Pressure: A drop in water force can result from various factors, including worn seals or clogged filters.

- Overheating: Insufficient water flow or prolonged use can lead to excessive heat, causing components to fail.

- Strange Noises: Unusual sounds during operation may indicate internal damage or the need for lubrication.

- Leaks: Fluid escaping from connections or seals often points to wear and tear that requires immediate attention.

Troubleshooting Tips

- Regularly inspect seals and hoses for signs of wear.

- Ensure the water supply is consistent and free of debris.

- Check for any blockages in filters and clean them as needed.

- Monitor operating temperature and allow for cool-down periods during extended use.

How to Identify Pump Parts

Understanding the components of your machine is essential for effective maintenance and troubleshooting. Each element plays a crucial role in the overall functionality, and recognizing them can help in identifying issues and ensuring proper operation. This guide will assist you in pinpointing the various elements, enhancing your familiarity with your equipment.

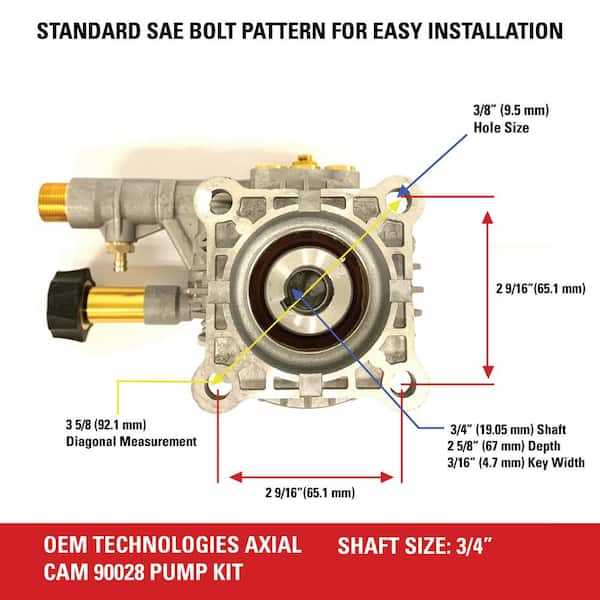

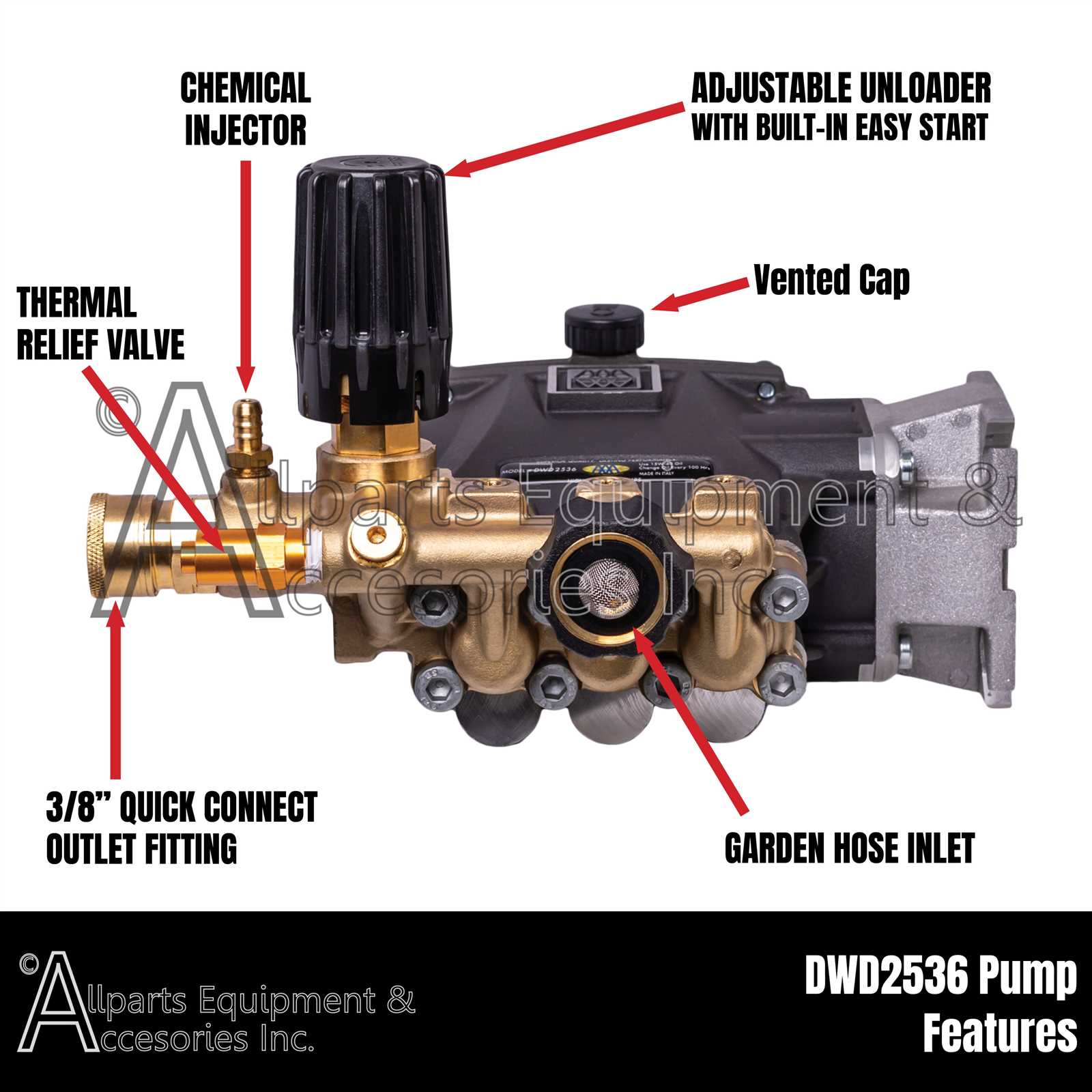

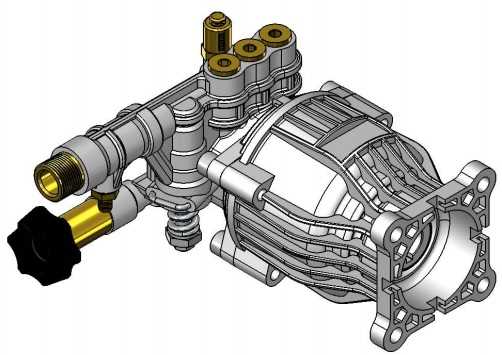

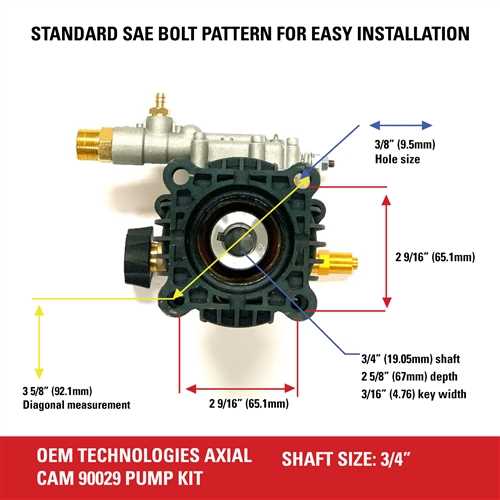

Begin with the Housing: The outer casing serves as the first layer of protection and support. Inspect it for any signs of wear or damage, as this can impact performance.

Examine the Inlet and Outlet: These openings are vital for the flow of liquid. Check for blockages or leaks, as they can severely affect efficiency. The inlet often has a filter that should be kept clean to prevent debris from entering.

Identify the Impeller: This rotating component is responsible for moving the liquid through the system. Look for any cracks or signs of wear that may hinder its function.

Check the Seals and O-Rings: These small yet essential components prevent leaks at various junctions. Inspect them regularly for signs of degradation, as worn seals can lead to significant issues.

Consider the Drive Mechanism: This is the system that powers the movement of the impeller. Ensure that belts or gears are intact and free from excessive wear.

By familiarizing yourself with these components, you can effectively diagnose issues and maintain optimal performance, ensuring your equipment operates smoothly and efficiently.

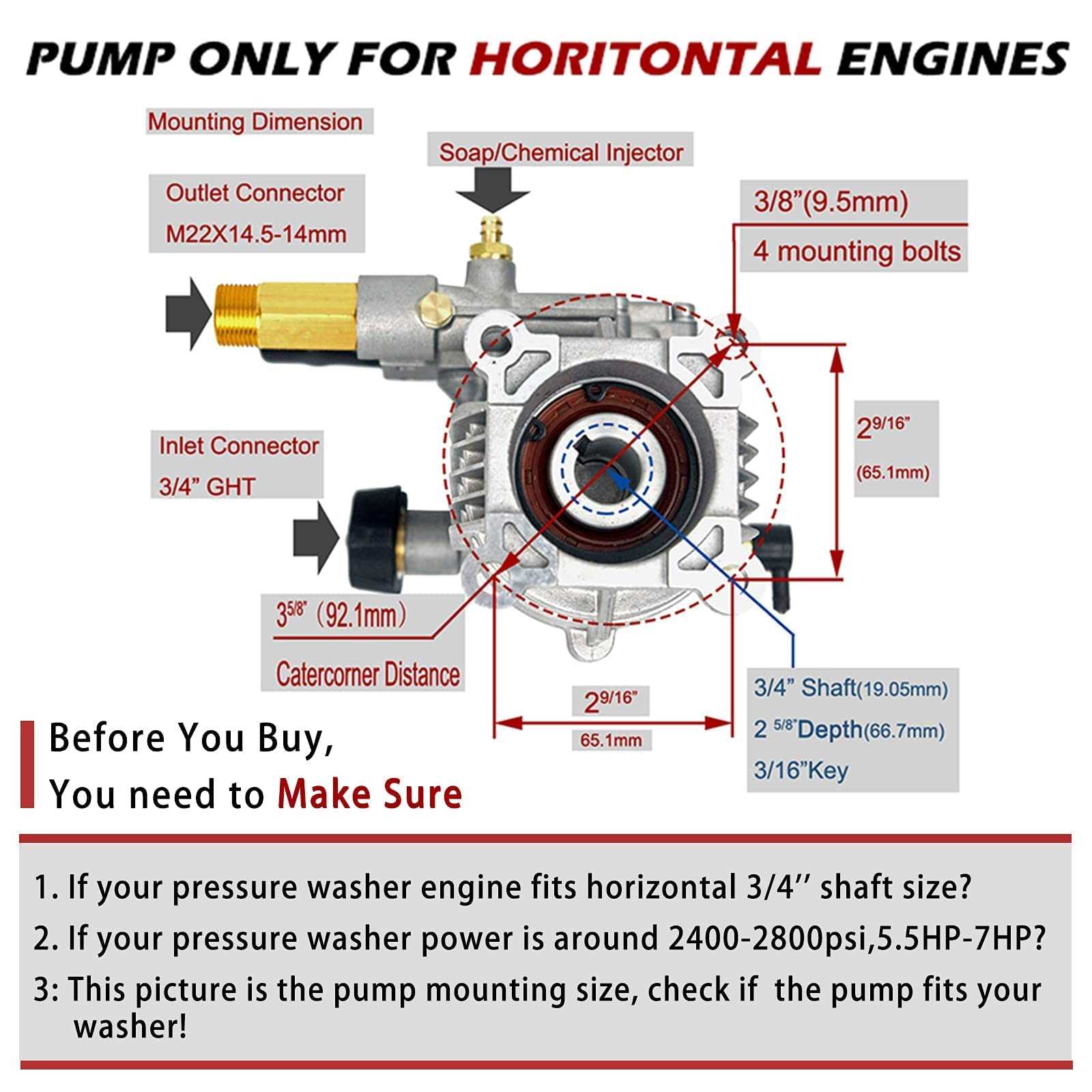

Reading Pump Diagrams Effectively

Understanding visual representations of machinery can greatly enhance your ability to troubleshoot and maintain equipment. By familiarizing yourself with the symbols and layouts typically used, you can navigate these illustrations with confidence, allowing for more efficient repairs and modifications.

Begin by identifying the key components illustrated in the schematic. Each element plays a critical role, and recognizing their functions will aid in grasping the overall operation. Take note of how these elements are interconnected, as this can reveal potential points of failure.

Next, follow the flow of operations depicted in the graphic. Understanding the sequence can help you anticipate issues that may arise during use. Look for arrows or indicators that show the direction of movement or the flow of fluids, as these are crucial for identifying how the system works as a whole.

Finally, practice cross-referencing the visual guide with the actual equipment. This hands-on approach reinforces your understanding and allows you to spot discrepancies or wear that may not be immediately apparent from the illustration alone.

Replacing Simpson Pump Components

Maintaining optimal functionality of your cleaning equipment often involves the replacement of worn or damaged elements. Understanding the key components and their roles is crucial for effective upkeep. This process not only enhances performance but also extends the lifespan of your machine.

Before initiating the replacement, it’s important to gather the necessary tools and ensure you have the correct substitutes for the components you intend to change. A well-organized workspace can significantly streamline the task. Additionally, consulting the user manual can provide valuable insights into specific requirements and procedures.

When removing old elements, take care to note the arrangement and connections, as this will simplify the installation of new parts. If any seals or gaskets are included, be sure to replace them to prevent leaks and ensure efficiency. Once the new components are in place, double-check all connections and secure any fasteners properly.

After assembly, perform a thorough inspection and run a test cycle to ensure everything is functioning correctly. Regular maintenance checks will help identify potential issues early, allowing you to address them before they escalate. Following these steps will not only improve the effectiveness of your cleaning device but also save you time and resources in the long run.

Tools Required for Pump Repairs

When it comes to maintaining and fixing your cleaning equipment, having the right tools is essential. Proper instruments not only streamline the repair process but also enhance the quality of the work performed. Understanding which tools to use can save time and prevent potential damage to components.

1. Wrenches: A set of adjustable and socket wrenches is crucial for loosening and tightening various fasteners. They provide the necessary leverage for a secure fit.

2. Screwdrivers: Both flathead and Phillips screwdrivers are needed to access different screws and secure parts. A magnetic tip can be particularly useful in retrieving dropped screws.

3. Pliers: Needle-nose and standard pliers can assist in gripping and twisting components that are hard to reach, making them invaluable during repairs.

4. Cleaning Supplies: Brushes, rags, and solvent cleaners are necessary to keep surfaces free from debris and buildup, ensuring that the equipment functions optimally.

5. Safety Gear: Always wear gloves and goggles to protect yourself from any hazardous materials or sharp edges that may be encountered during the repair process.

By equipping yourself with these essential tools, you can confidently tackle any maintenance or repair task that arises, ensuring longevity and efficiency in your equipment.