Having a thorough comprehension of the various elements of your gardening instrument is essential for effective maintenance and operation. Recognizing how each segment functions together contributes to the longevity and performance of the device, ensuring it meets your landscaping needs efficiently. This knowledge empowers users to tackle repairs and adjustments with confidence.

In this section, we will explore the intricate layout of the machine’s components, highlighting their roles and interconnections. By familiarizing yourself with these integral sections, you can enhance your understanding of how the device operates and how to troubleshoot potential issues effectively. Whether you are a seasoned professional or a gardening enthusiast, this information will prove valuable in optimizing the functionality of your tool.

Furthermore, grasping the arrangement of the various parts allows for better decision-making when it comes to purchasing replacements or upgrades. A well-informed user can easily identify the necessary components and ensure they select the right ones for their specific model, leading to improved performance and satisfaction.

Understanding the Pruner Anatomy

Familiarizing oneself with the components of a pruning device is essential for effective maintenance and efficient use. Each segment plays a pivotal role in ensuring that the equipment operates smoothly and meets performance expectations. A thorough grasp of the structure can lead to better care and a longer lifespan for the machinery.

Key Components of the Device

The device comprises various crucial elements, including the motor, blade assembly, and handle. Each of these parts must be well-understood, as they contribute significantly to the overall functionality. The motor powers the tool, while the blade assembly is responsible for cutting through branches and foliage. The handle provides the user with control and comfort during operation.

Maintenance Tips for Longevity

Regular upkeep is vital to prevent wear and tear. Users should routinely check the sharpness of the blades, ensure the motor is in good working condition, and inspect the handles for any signs of damage. Proper cleaning after use also plays a crucial role in maintaining the efficiency and durability of the tool.

Key Components of Trimming Tools

The effective operation of cutting devices relies on several essential elements that work in harmony. Understanding these fundamental components not only aids in maintenance but also enhances the overall performance of the equipment. By familiarizing oneself with these parts, users can ensure optimal functionality and longevity of their cutting tools.

Essential Elements

Each cutting instrument is composed of various crucial sections, each serving a distinct purpose. The following table outlines the primary components, their functions, and their importance in ensuring the tool operates efficiently.

| Component | Function | Importance |

|---|---|---|

| Motor | Drives the cutting mechanism | Provides the necessary power for efficient operation |

| Blade | Performs the cutting action | Determines the effectiveness and precision of cuts |

| Handle | Allows for user control and maneuverability | Ensures comfort and reduces fatigue during use |

| Guard | Protects the user from debris | Enhances safety during operation |

Maintenance Tips

Regular upkeep of these essential components is crucial for maintaining efficiency. Checking the sharpness of the blade, ensuring the motor is functioning properly, and keeping the handle clean can significantly extend the life of the tool. Users are encouraged to consult the manufacturer’s guidelines for specific maintenance practices.

Importance of Maintenance and Components

Proper upkeep of garden tools is essential for ensuring their longevity and optimal performance. Regular maintenance not only enhances the efficiency of the equipment but also prevents costly repairs and replacements. Understanding the significance of each element within the machinery aids users in making informed decisions regarding care and replacements.

Regular Inspections

Conducting routine checks allows for early detection of wear and tear. Identifying issues before they escalate helps in maintaining the functionality of the equipment. Keeping an eye on key components ensures that any necessary adjustments or replacements are addressed promptly.

Optimal Performance

Well-maintained tools operate more effectively, reducing the time and effort needed for tasks. Proper care extends the life of individual components, ensuring that users can rely on their equipment for years. This not only enhances productivity but also improves the overall experience when using the machinery.

Identifying Common Wear and Tear

Understanding the typical signs of deterioration in garden tools is crucial for maintaining their efficiency and longevity. Regular inspections can help users identify issues early, ensuring optimal performance during operation. Recognizing these indicators allows for timely maintenance or replacement, preventing further complications.

Several common signs of wear can manifest over time, including:

- Blunt Edges: Cutting implements may become dull, leading to decreased cutting efficiency.

- Cracks or Chips: Visible damage on blades or components can impair functionality and safety.

- Loose Fastenings: Screws and bolts may loosen, resulting in unstable operation.

- Corrosion: Rust or other signs of oxidation can weaken metal parts, affecting durability.

- Worn Handles: Handles may become slippery or damaged, impacting user control and comfort.

Regularly examining tools for these signs can help maintain their effectiveness and ensure safe usage. Implementing a routine check-up schedule is recommended to prevent unexpected breakdowns and enhance overall performance.

Tools Needed for Repair Work

When undertaking maintenance or restoration of gardening equipment, having the right tools is essential for ensuring efficiency and effectiveness. A well-equipped toolbox allows for smoother operations, minimizing the risk of damage and promoting safety during the repair process.

Essential instruments include screwdrivers of various sizes to accommodate different screws, wrenches for tightening or loosening nuts, and pliers for gripping and manipulating components. Additionally, a socket set can be invaluable for accessing hard-to-reach fasteners, while hex keys are often necessary for specialized bolts.

Don’t overlook the importance of a workbench for stability during repairs, as well as protective gear like gloves and goggles to ensure safety. Proper lighting and a magnifying glass can also assist in examining small parts and intricate mechanisms, making the repair process more manageable.

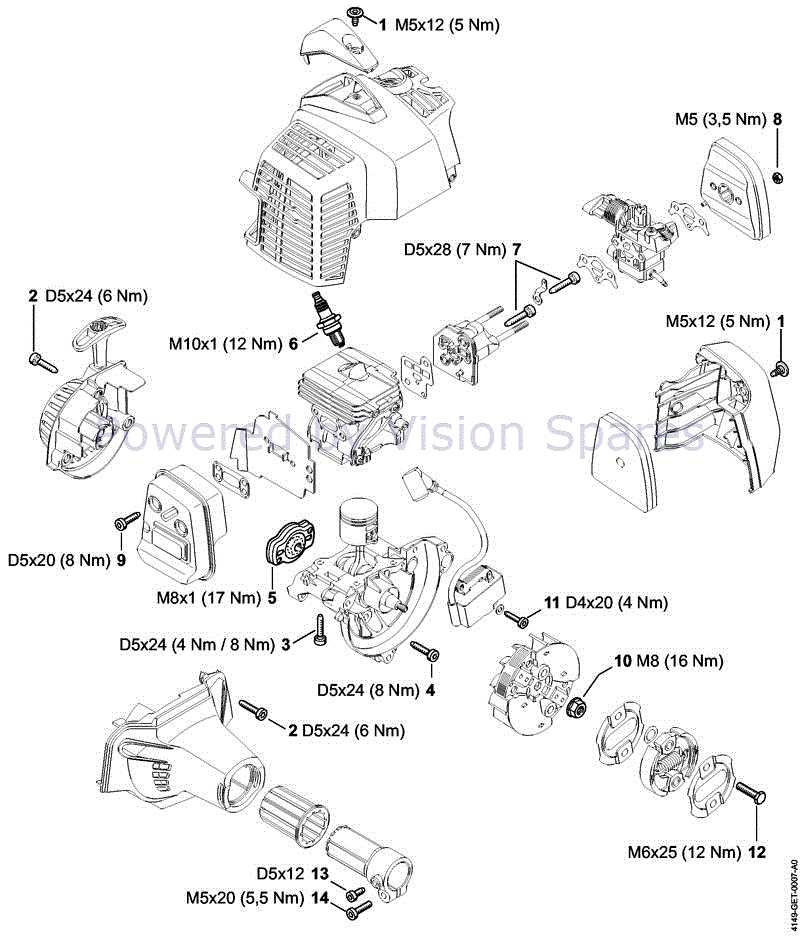

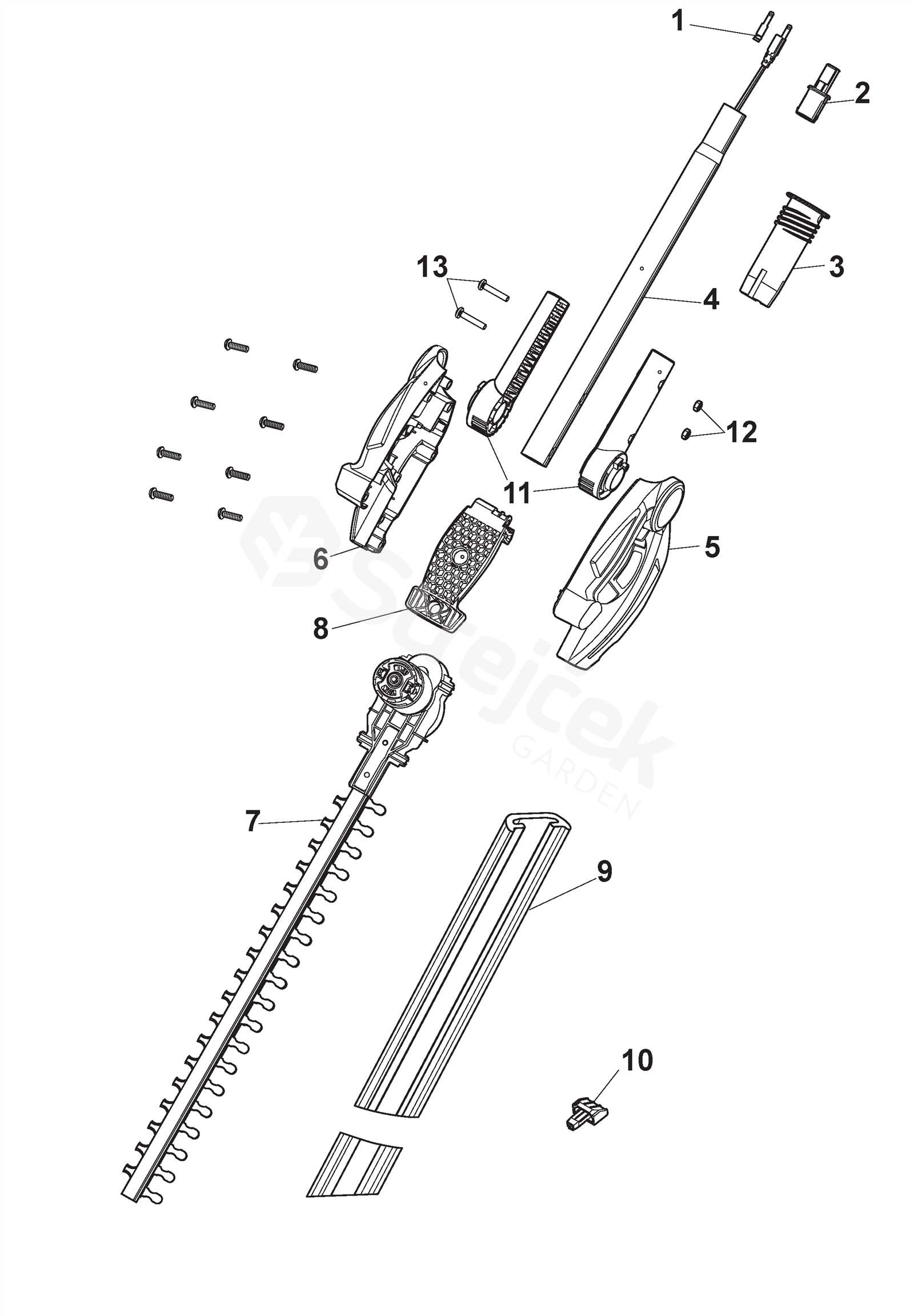

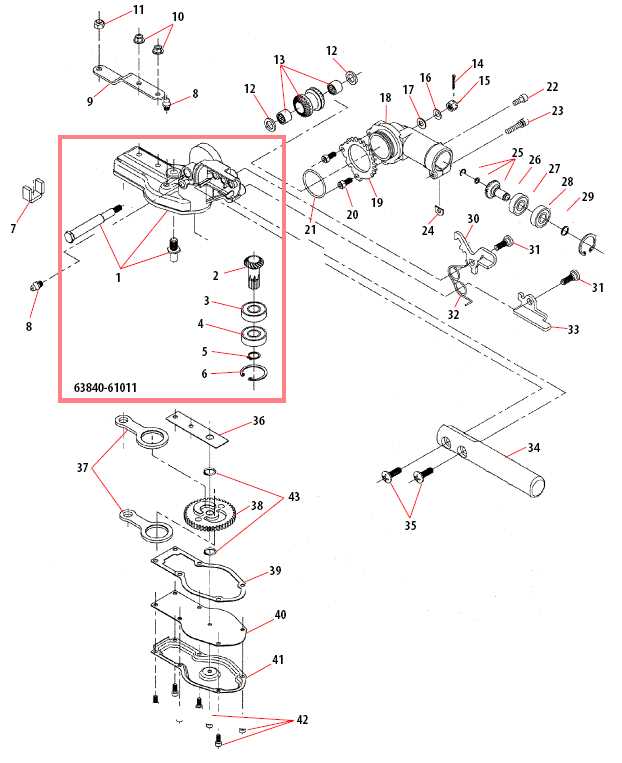

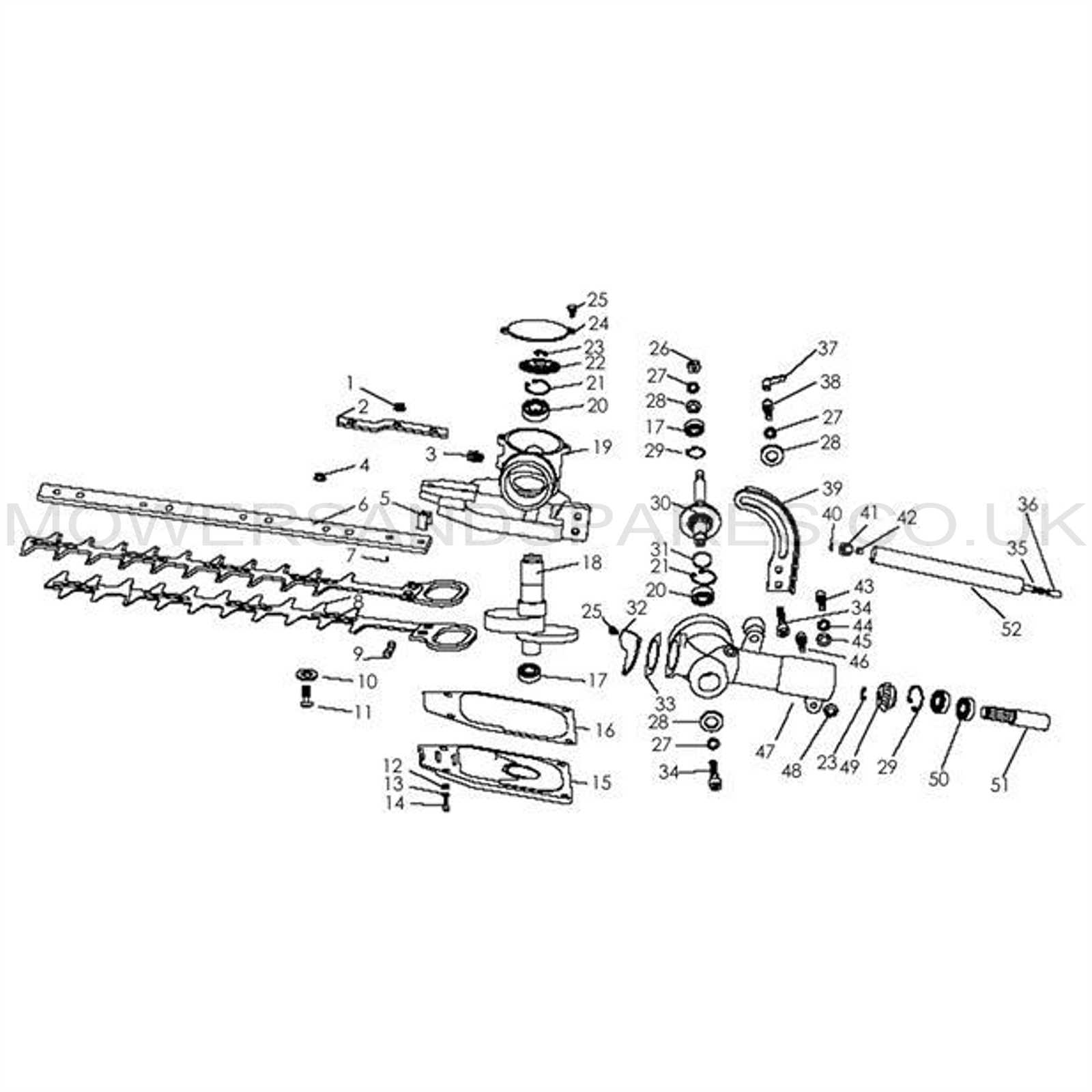

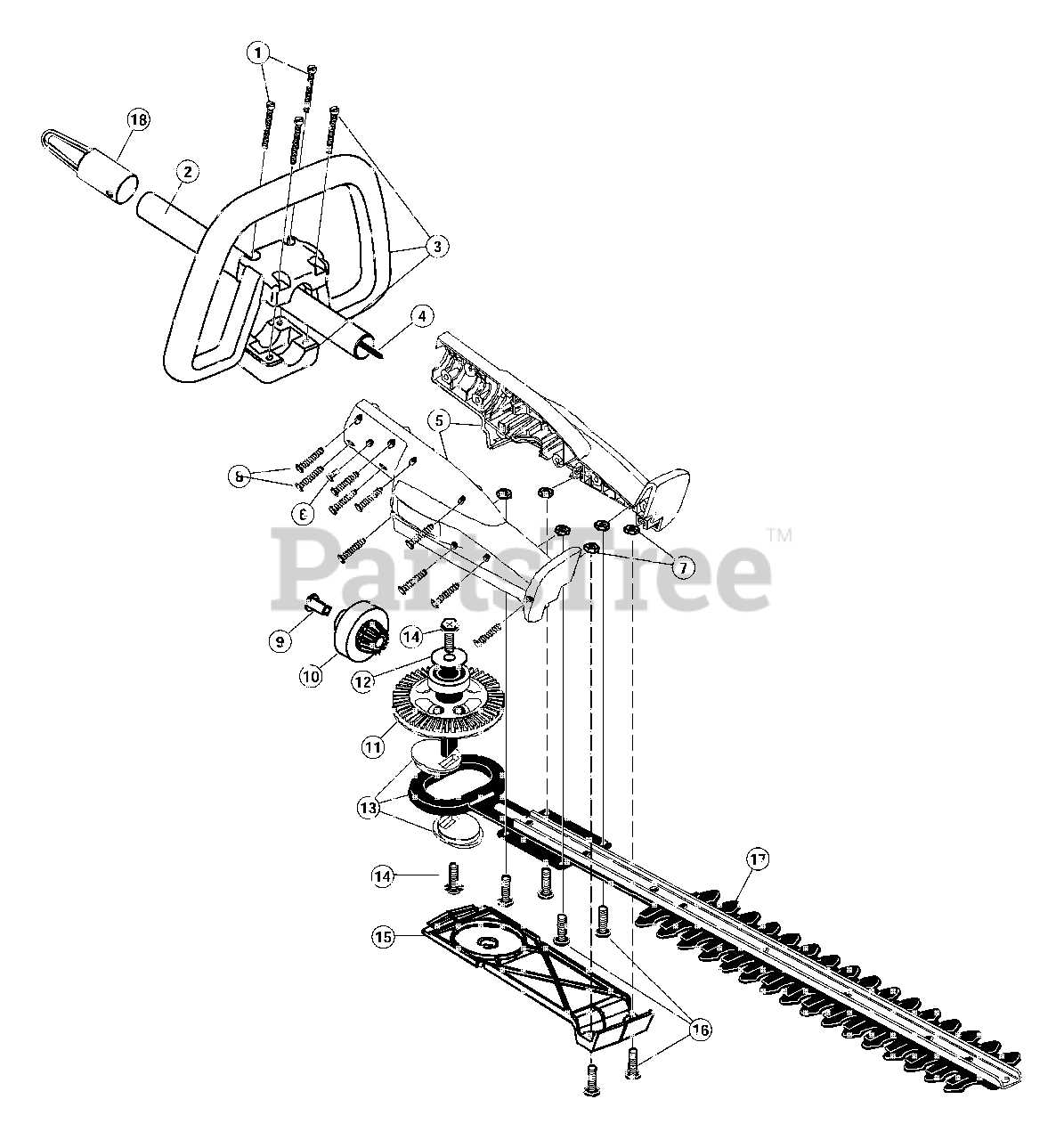

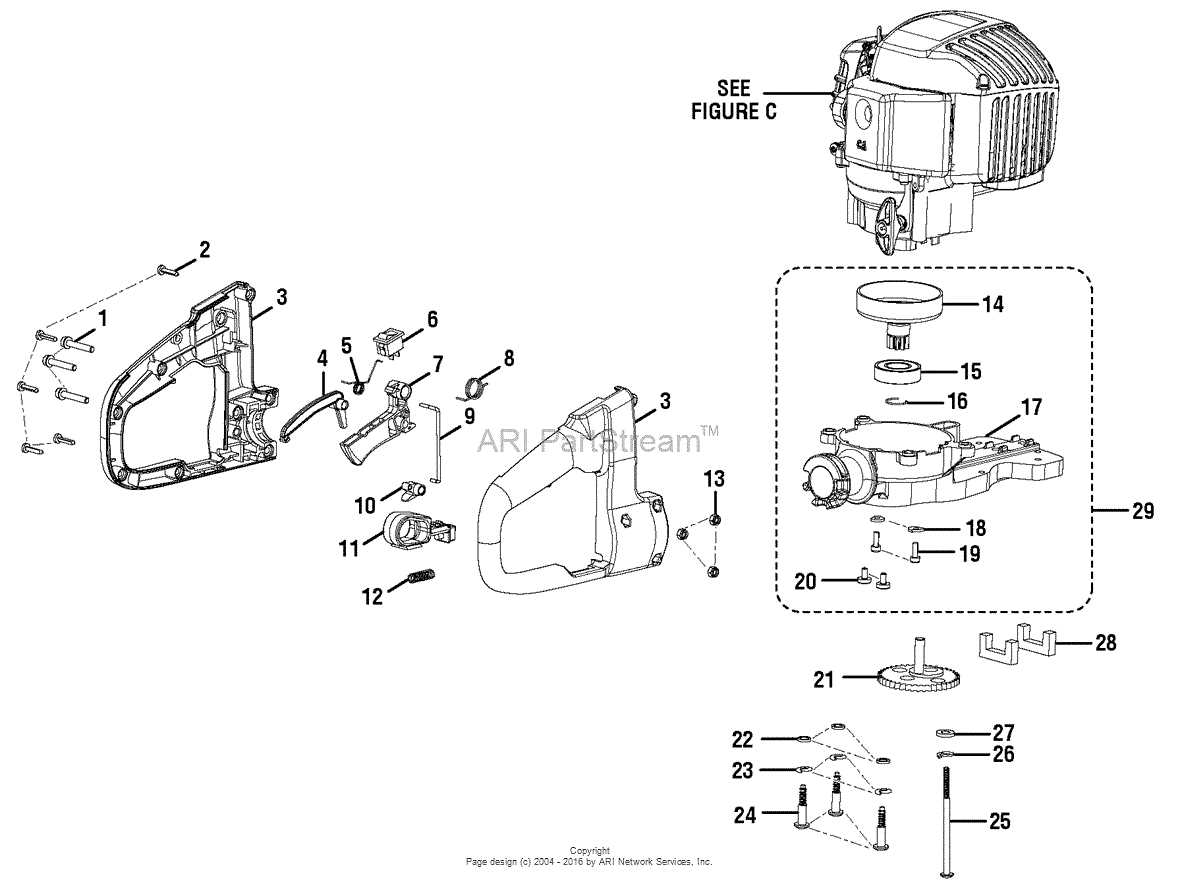

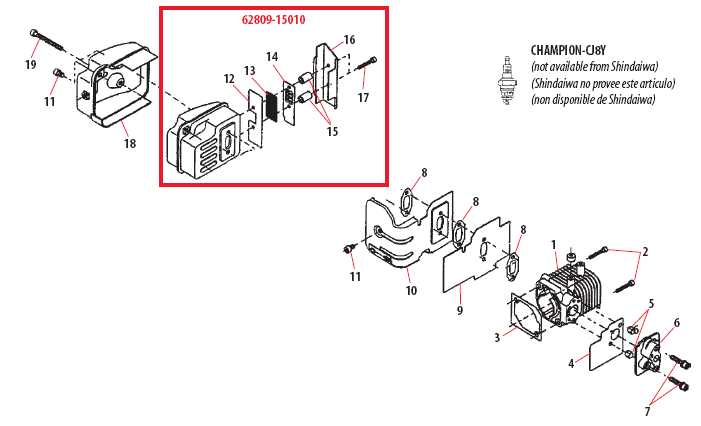

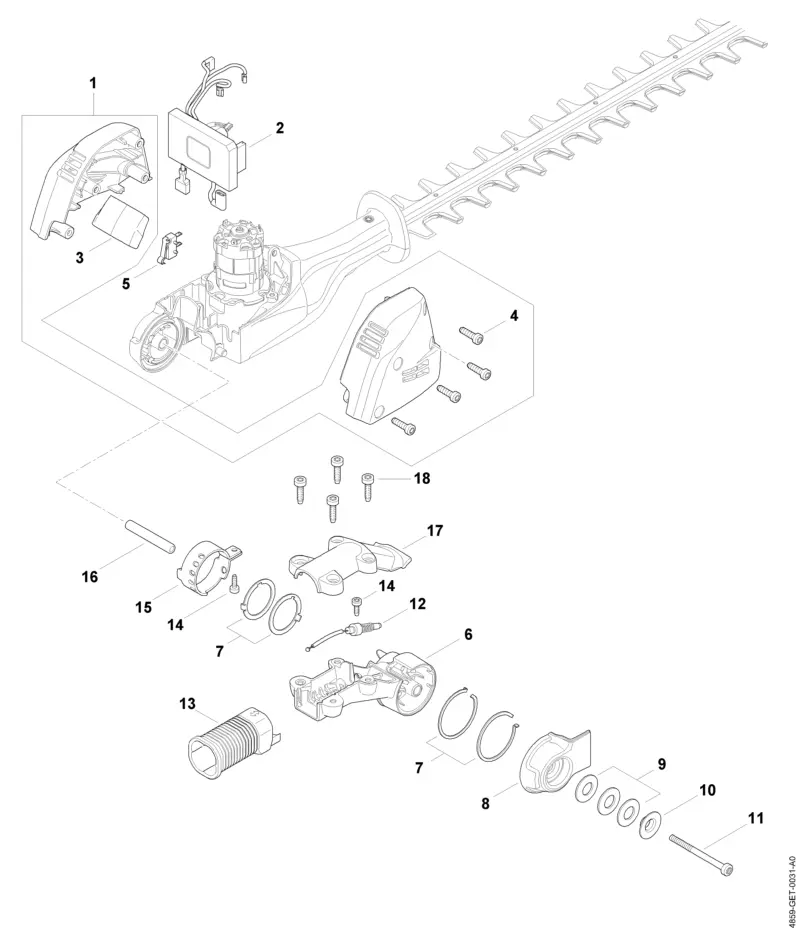

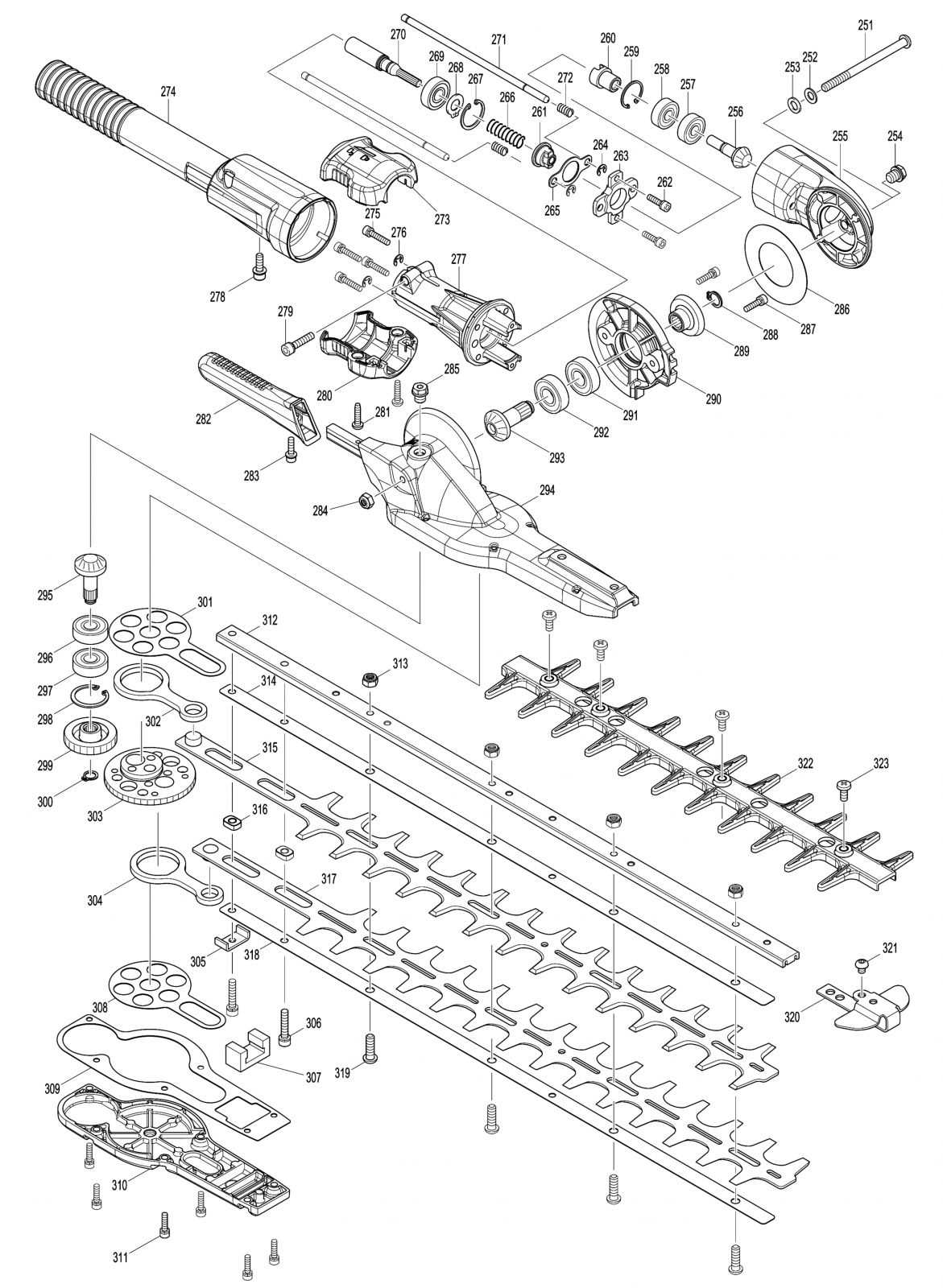

How to Read Parts Diagrams

Understanding technical illustrations is essential for effective maintenance and repair of machinery. These visuals provide crucial insights into the components of a device, showcasing their arrangement and function. Familiarizing yourself with these representations can enhance your ability to identify and troubleshoot issues efficiently.

Key Elements of Technical Illustrations

When analyzing these visuals, it is important to pay attention to specific features. Look for labeled components, which indicate their names and numbers. This information is vital for ordering replacements or understanding the assembly process. Additionally, note any accompanying annotations that explain the purpose or characteristics of certain elements.

Interpreting Component Relationships

Recognizing how different elements interact with one another is crucial. Observe how various parts connect and contribute to the overall functionality of the device. This understanding can aid in diagnosing problems and making informed decisions during repairs.

| Symbol | Description |

|---|---|

| ◉ | Indicates a specific component |

| ➔ | Shows connection points |

| ▼ | Denotes a replacement part |

Ordering Replacement Parts Online

In today’s digital age, acquiring components for your outdoor equipment has become more accessible than ever. Online platforms offer a wide range of options, enabling users to find the necessary elements quickly and efficiently. Whether you require a specific item or just browsing for replacements, the internet provides numerous resources to facilitate your search.

Benefits of Online Shopping

Purchasing components online presents several advantages. Firstly, it allows for easy comparison of prices and specifications across various vendors. Additionally, many websites provide detailed descriptions and customer reviews, which can assist in making informed decisions. Convenience is another key factor; shopping can be done from the comfort of your home without the need to visit multiple physical stores.

How to Ensure Quality

When ordering, it is crucial to verify the reliability of the website. Look for established retailers with positive feedback and clear return policies. Additionally, confirm that the items you are considering are compatible with your equipment. If you are unsure, consulting the manufacturer’s specifications or seeking advice from knowledgeable professionals can help ensure you receive quality components.

Tips for DIY Repairs and Upgrades

Taking on repairs and enhancements for your outdoor equipment can be both satisfying and cost-effective. Understanding the essential components and their functions allows you to tackle minor issues and implement improvements with confidence. Whether you are looking to restore performance or increase efficiency, knowing how to manage these tasks can lead to better results and prolonged equipment life.

Identifying Common Issues

Start by familiarizing yourself with frequent problems that may arise during use. Look for signs such as unusual noises, reduced power, or difficulty in operation. These indicators can often point to specific components that may require attention. Regular maintenance, including cleaning and lubrication, can prevent many issues from developing into significant repairs.

Essential Tools for Maintenance

Having the right tools on hand is crucial for effective repairs. Invest in a quality set of screwdrivers, wrenches, and pliers to handle various tasks. Additionally, consider a multimeter for electrical diagnostics and a torque wrench to ensure fasteners are secure. Proper tools not only make the job easier but also enhance your safety during the process.