When it comes to maintaining your garden, having a reliable cutting tool is essential. An efficient device not only enhances your gardening experience but also ensures precision and ease during use. Familiarity with its internal structure can significantly improve your ability to troubleshoot and perform maintenance tasks.

In this section, we will explore the various elements that make up this essential garden equipment. By delving into the intricate relationships between different components, you will gain insights that contribute to better upkeep and longevity of your tool. Recognizing how each piece works in harmony can lead to the ultimate performance of your device.

Whether you’re a seasoned gardener or a newcomer, understanding these mechanical elements will empower you. By grasping the functionality and purpose of each section, you’ll be well-equipped to handle repairs and enhancements, ensuring your equipment remains in top condition throughout its lifespan.

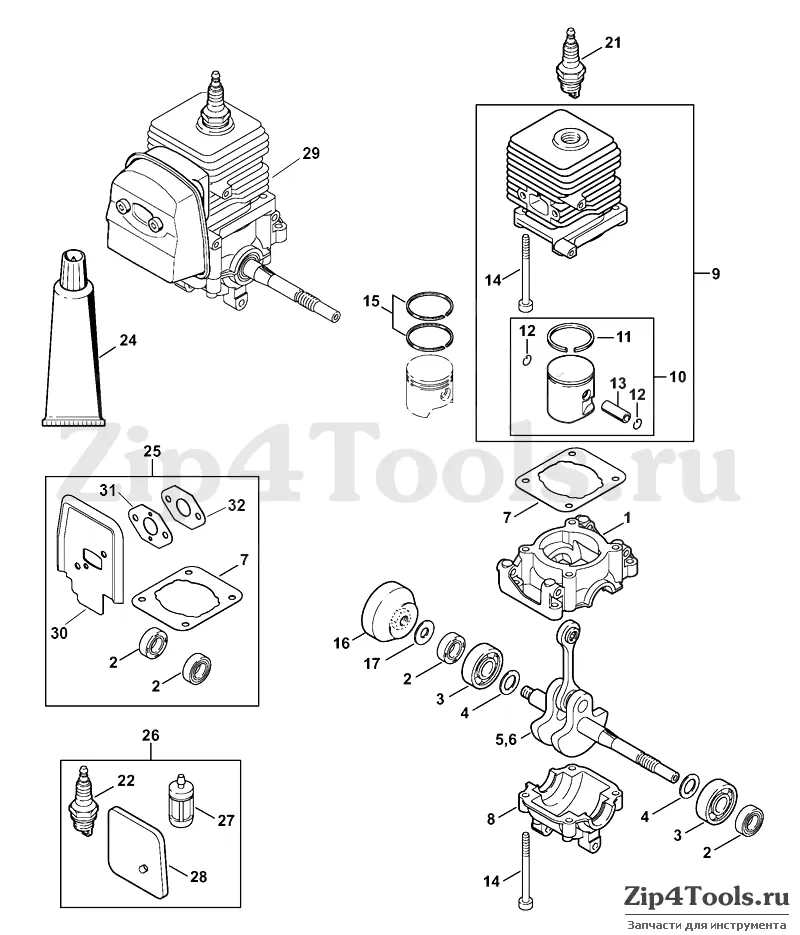

Understanding the Stihl HS 80 Model

The HS 80 model represents a noteworthy advancement in the realm of hedge trimming technology. This equipment combines power and precision, making it an essential tool for both professional landscapers and gardening enthusiasts. The design emphasizes user comfort and efficiency, ensuring that tasks can be completed swiftly and with minimal fatigue.

Key Features and Benefits

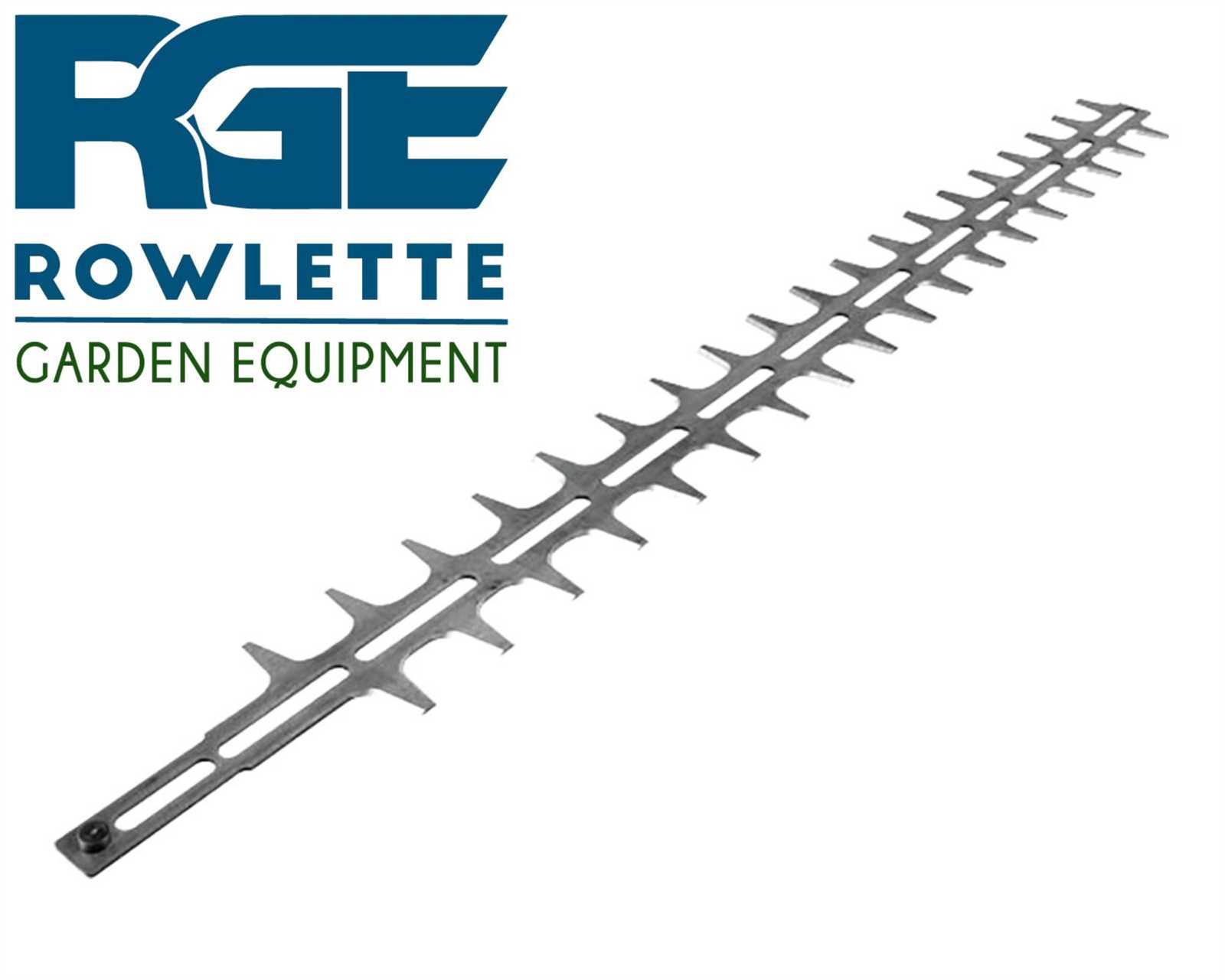

This model is equipped with a robust engine, which provides the necessary power to handle dense foliage effortlessly. The cutting blades are engineered for optimal sharpness and durability, allowing for clean cuts that promote healthy plant growth. Additionally, the ergonomic design facilitates prolonged use without discomfort, making it suitable for extensive trimming sessions.

Maintenance and Care

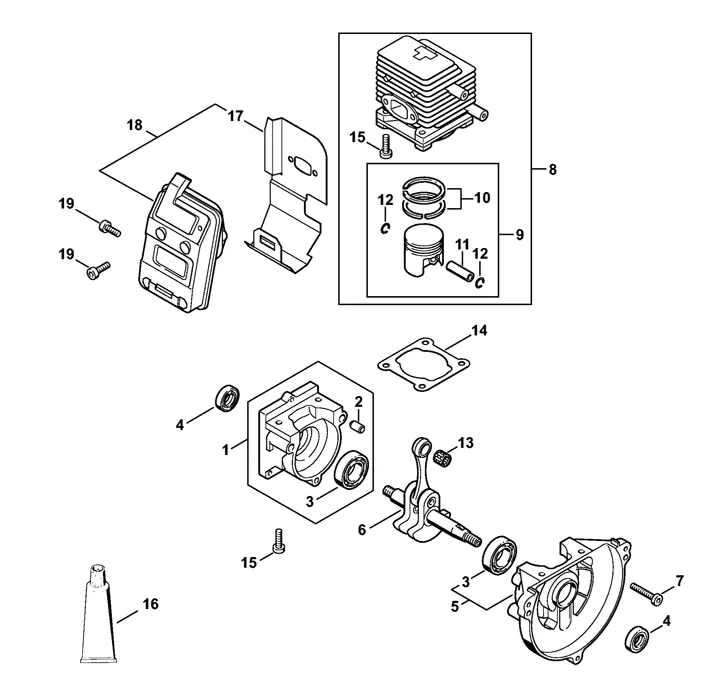

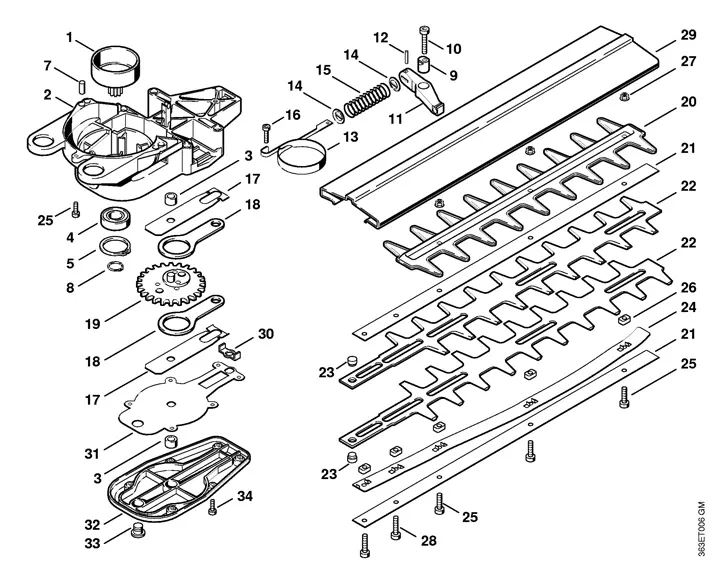

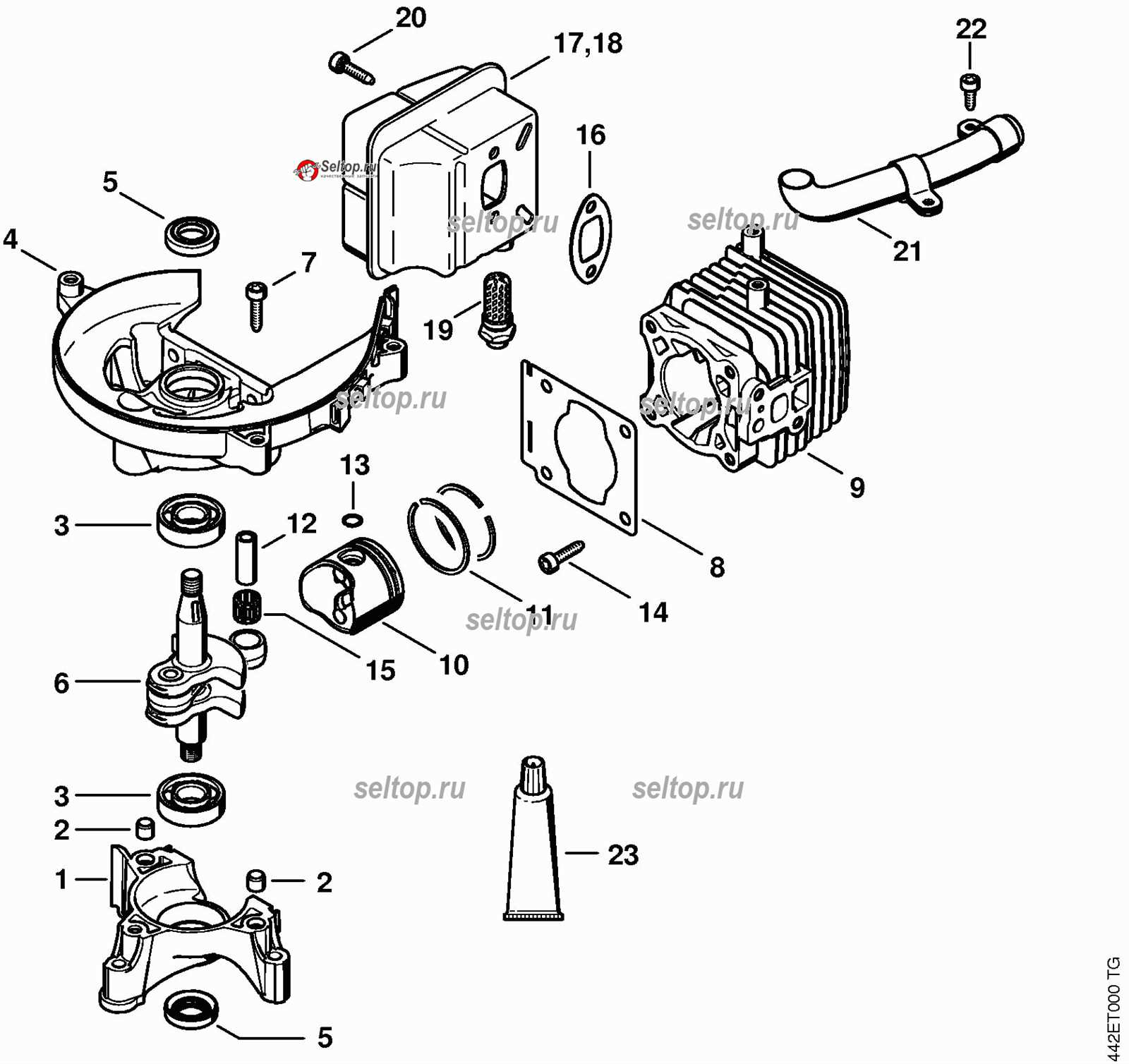

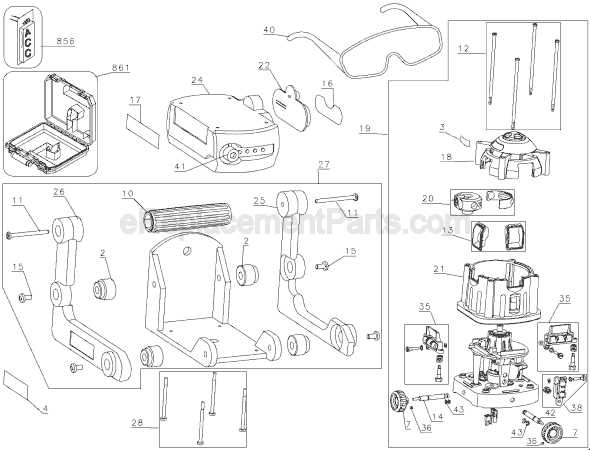

Key Components of the Trimmer

The efficient operation of a trimmer relies on several essential elements that work in harmony. Understanding these crucial components can enhance performance and ensure longevity, making maintenance easier and more effective.

Essential Parts Overview

Each element of the trimmer plays a specific role, contributing to its overall functionality. From the power source to the cutting mechanism, knowing how these parts interact can aid in troubleshooting and repairs.

Component Table

| Component | Description |

|---|---|

| Engine | Powers the device, converting fuel into mechanical energy. |

| Cutting Head | Contains the blade or string, responsible for trimming grass and vegetation. |

| Fuel Tank | Holds the fuel necessary for engine operation. |

| Throttle Control | Regulates engine speed, allowing for varied cutting intensity. |

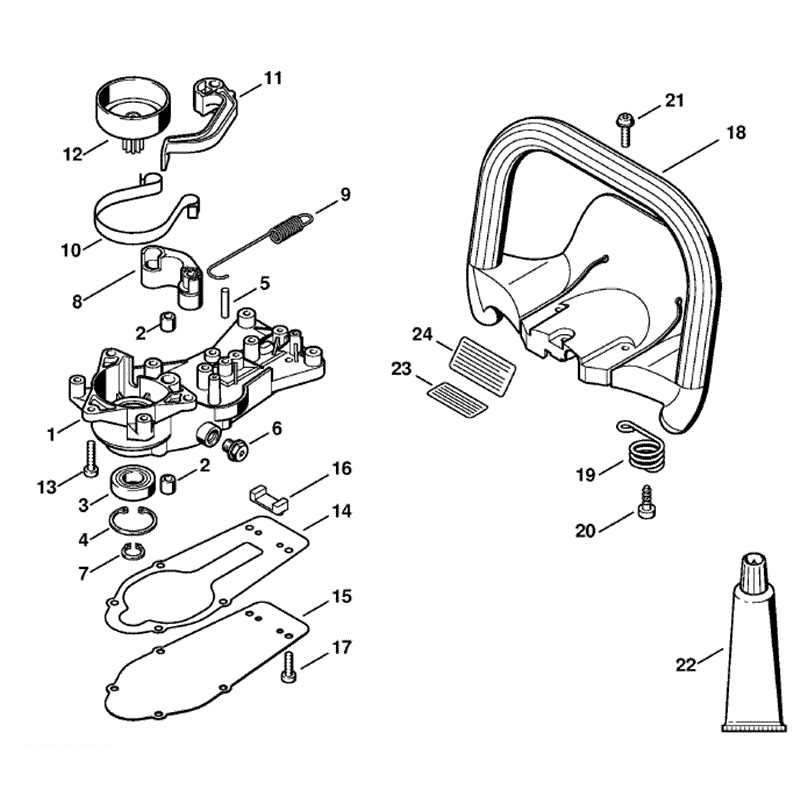

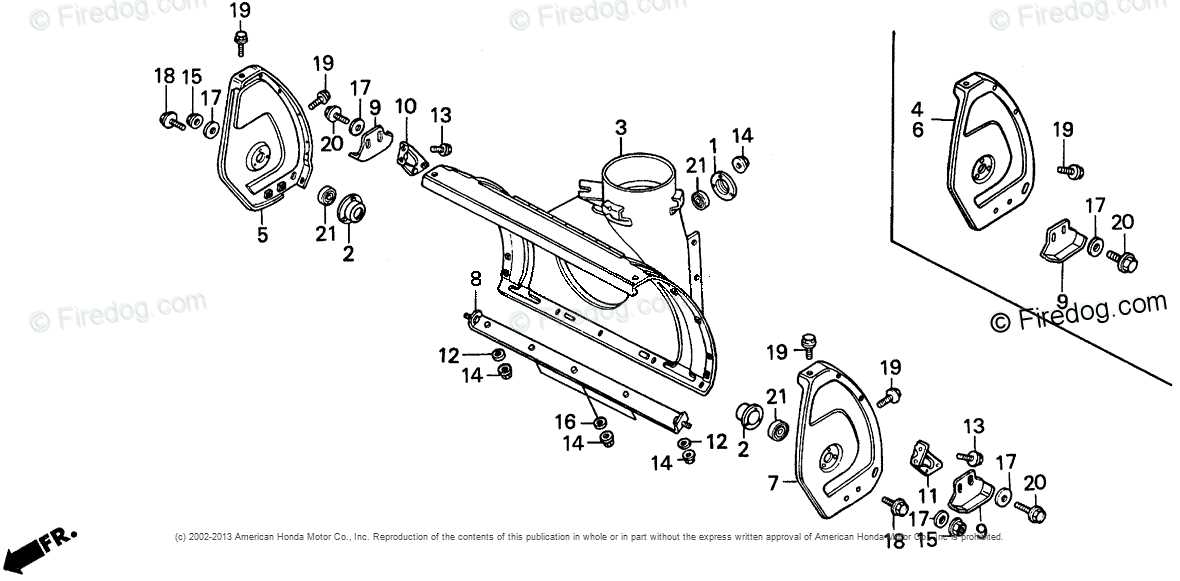

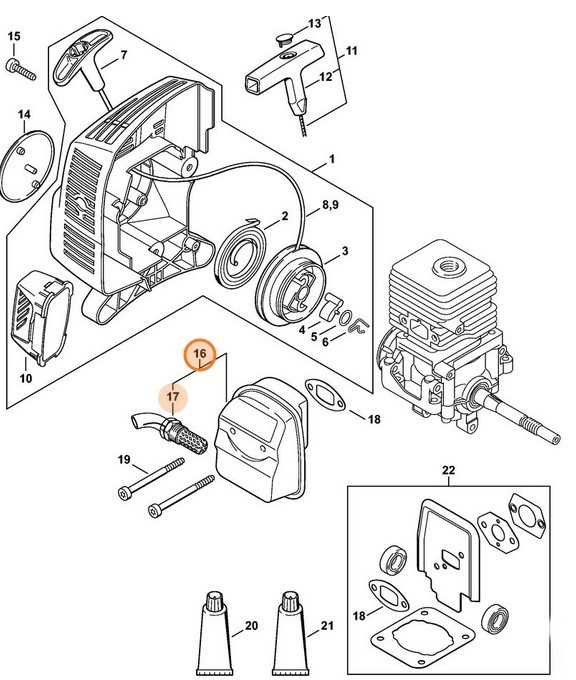

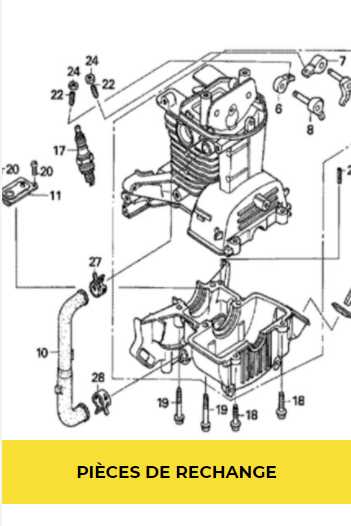

Parts Identification and Functionality

Understanding the components of a hedge trimmer is essential for effective maintenance and operation. Each element plays a crucial role in ensuring the tool performs optimally, allowing for precise cutting and trimming of hedges and shrubs. Familiarity with these components aids in troubleshooting and enhances overall efficiency.

Below are the key components and their functions:

- Engine: Powers the device, converting fuel into mechanical energy.

- Blade Assembly: The cutting mechanism that handles the foliage; sharp edges enable clean cuts.

- Gearbox: Transfers power from the engine to the blade, allowing for various cutting speeds.

- Handle: Provides grip and control, enabling the user to maneuver the trimmer easily.

- Safety Guard: Protects the operator from debris and potential injuries while in use.

- Throttle Trigger: Regulates the engine speed, allowing for more control during operation.

Regular inspection and understanding of these components not only prolong the lifespan of the tool but also improve safety and performance during trimming tasks.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires a proactive approach to care and upkeep. Regular maintenance not only enhances performance but also extends the lifespan of your tools, allowing you to enjoy their benefits for years to come.

Regular Cleaning

- Remove debris after each use to prevent corrosion and buildup.

- Use a soft brush or cloth to clean sensitive areas without causing damage.

- Inspect and clear air filters to maintain optimal airflow.

Routine Inspections

- Check all fasteners and components for wear and tightness regularly.

- Examine cutting edges and sharpen them as needed to ensure efficient operation.

- Monitor fuel and oil levels, replacing them according to the manufacturer’s guidelines.

By following these simple yet effective maintenance practices, you can ensure your equipment remains in excellent condition, ready to tackle any task you set before it.

Common Issues and Solutions

In the world of outdoor equipment, certain challenges can frequently arise, impacting performance and efficiency. Understanding these common problems and their solutions can significantly enhance the user experience and extend the lifespan of your tool.

Frequent Problems

- Engine not starting

- Overheating during operation

- Uneven cutting performance

- Vibrations during use

Possible Solutions

-

Engine not starting:

- Check the fuel level and ensure it’s fresh.

- Inspect the spark plug for wear or damage.

- Examine the ignition system for any faults.

-

Overheating during operation:

- Ensure proper lubrication is applied.

- Clean the air filter to promote airflow.

- Allow the engine to cool down periodically.

-

Uneven cutting performance:

- Sharpen or replace the cutting blades as needed.

- Adjust the height settings for even cuts.

- Check for any obstructions in the cutting area.

-

Vibrations during use:

- Tighten all bolts and screws securely.

- Inspect for worn or damaged components.

- Use vibration-dampening equipment where applicable.

How to Replace Parts Effectively

Replacing components in any machinery requires careful attention to detail and a systematic approach. Understanding the right techniques can ensure a smoother process, minimize errors, and extend the lifespan of your equipment. This guide will walk you through essential steps to make the replacement process efficient and effective.

Preparation is Key

Before starting the replacement, gather all necessary tools and materials. Organizing your workspace will help you avoid distractions and keep track of small items. Ensure you have a clean area where you can lay out the components and tools. Additionally, review the user manual or relevant guides to familiarize yourself with the specific steps involved.

Step-by-Step Replacement

When you are ready to begin, follow a clear, methodical approach. Start by removing the old component carefully, noting how it is attached. Taking pictures during disassembly can provide valuable references for reassembly. Once the old part is out, compare it with the new one to ensure compatibility before installation. Finally, secure the new component in place, following the reverse order of removal, and double-check that everything is tightened correctly to avoid future issues.

Where to Find Genuine Parts

Finding authentic components for your equipment is crucial for maintaining its performance and longevity. Whether you are a professional user or a hobbyist, sourcing reliable items can enhance your experience and ensure safety during operation.

A great starting point is visiting authorized dealers who specialize in quality machinery. These retailers often have a comprehensive selection of original items and can provide expert advice tailored to your specific model.

Additionally, exploring official websites dedicated to the manufacturer can yield useful resources. Many sites offer catalogs and guides that help identify the correct components needed for repairs or upgrades.

Online marketplaces can also be a viable option, but it’s essential to verify the authenticity of sellers to avoid counterfeit alternatives. Look for trusted platforms that guarantee the quality and reliability of their offerings.

Finally, engaging with local repair shops or service centers can be beneficial. These professionals not only stock genuine items but also possess the expertise to assist you in finding what you need.

Comparing HS 80 with Other Models

When selecting a hedge trimmer, understanding the differences between various models is essential for making the right choice. Several options on the market offer unique features, capabilities, and advantages that cater to specific needs, whether it’s for professional use or casual maintenance.

Performance and Power

In terms of power and efficiency, this model stands out for its reliable cutting performance. However, when compared to other alternatives, differences in engine size, blade length, and overall durability become apparent. These variations often influence user experience, especially in challenging conditions.

- Longer blade models provide more extensive coverage, reducing trimming time.

- Some alternatives feature improved fuel efficiency, making them more suitable for prolonged use.

- Heavier models may offer more power but can be less comfortable for extended tasks.

Ease of Use and Comfort

Another key factor to consider is ease of handling. While some hedge trimmers are known for their ergonomic design, others prioritize raw cutting ability. The weight and balance

DIY Repairs: Step-by-Step Guide

Undertaking maintenance on your own can be both cost-effective and rewarding. With a bit of patience and the right approach, you can fix issues without professional help, ensuring your equipment continues to perform well. This guide walks you through the essential steps to troubleshoot and repair common problems, offering a structured approach for easy navigation.

- Prepare Your Workspace

- Ensure you have a clean, well-lit area.

- Gather all necessary tools in advance.

- Use protective gear, such as gloves and safety glasses.

- Identify the Issue

- Inspect the equipment for visible signs of wear or damage.

- Listen for unusual sounds or vibrations during operation.

- Refer to the manual for potential troubleshooting tips.

- Disassemble Carefully

- Take note of how parts are arranged before removing them.

- Use appropriate tools to avoid damaging components.

- Keep screws and small