In the realm of gardening, efficient soil cultivation is essential for achieving optimal growth. To facilitate this, various mechanical devices are employed, each consisting of multiple elements that work together harmoniously. A comprehensive understanding of these individual components can greatly enhance maintenance and repair efforts, ensuring the longevity and effectiveness of the equipment.

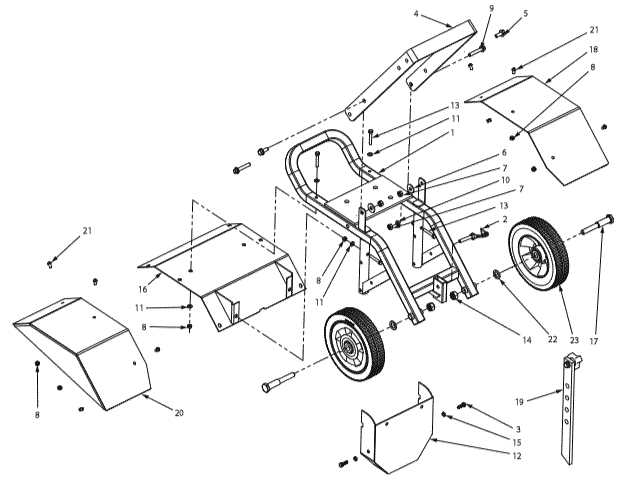

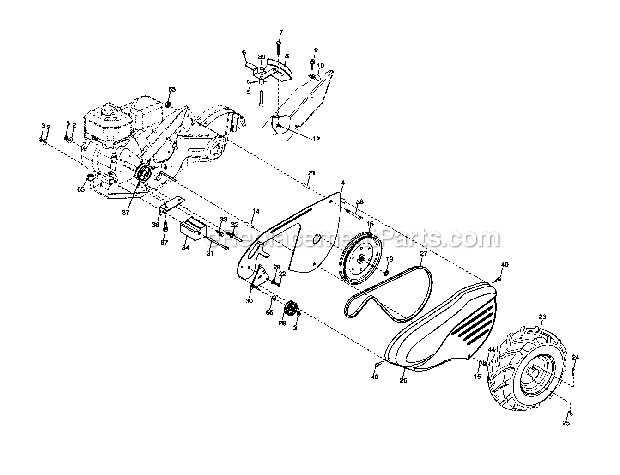

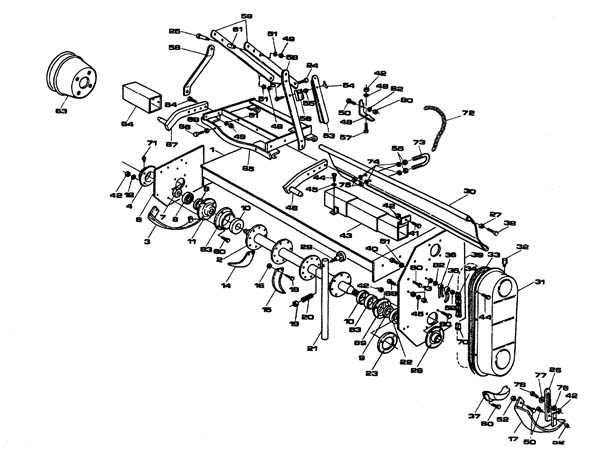

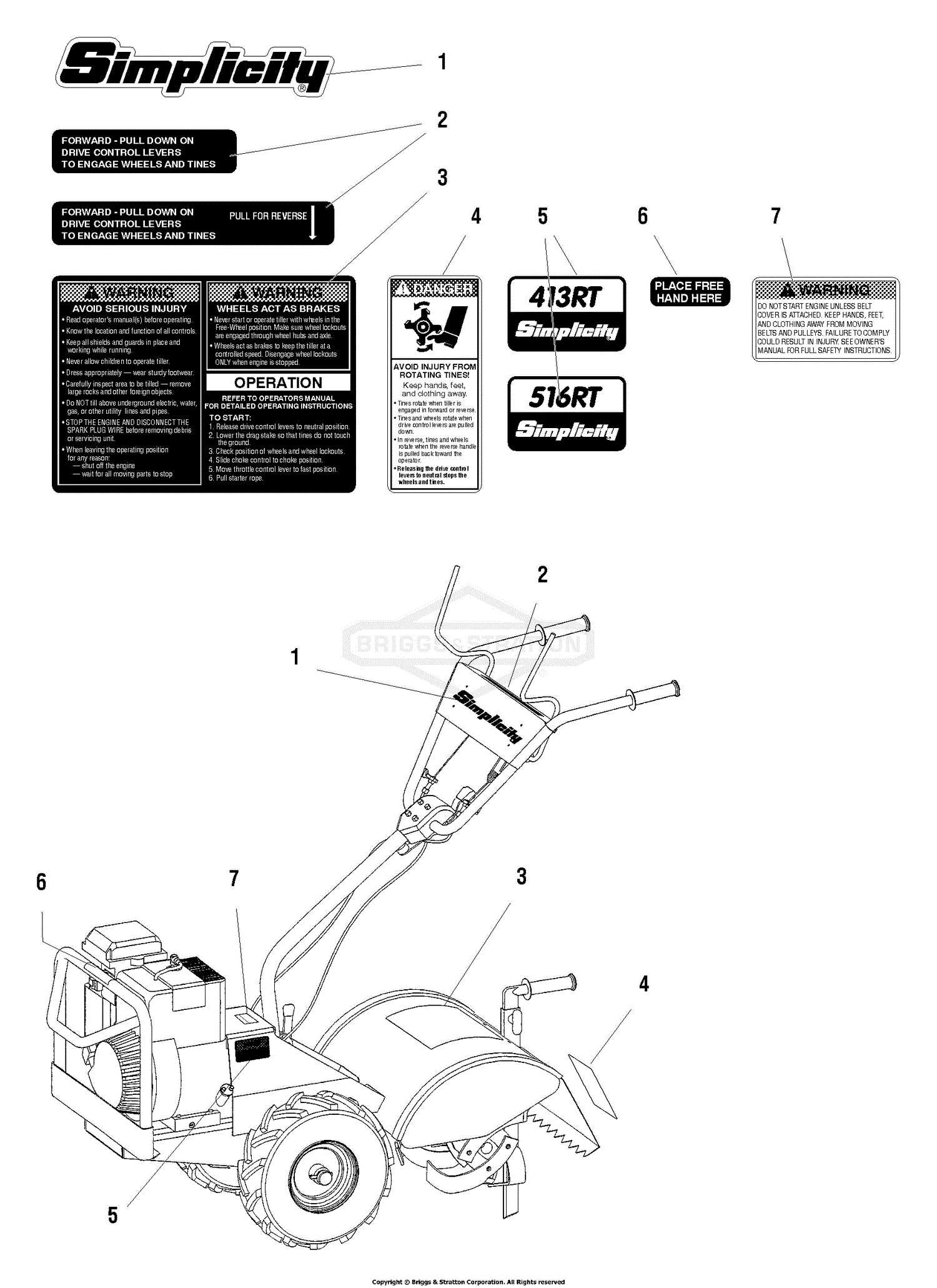

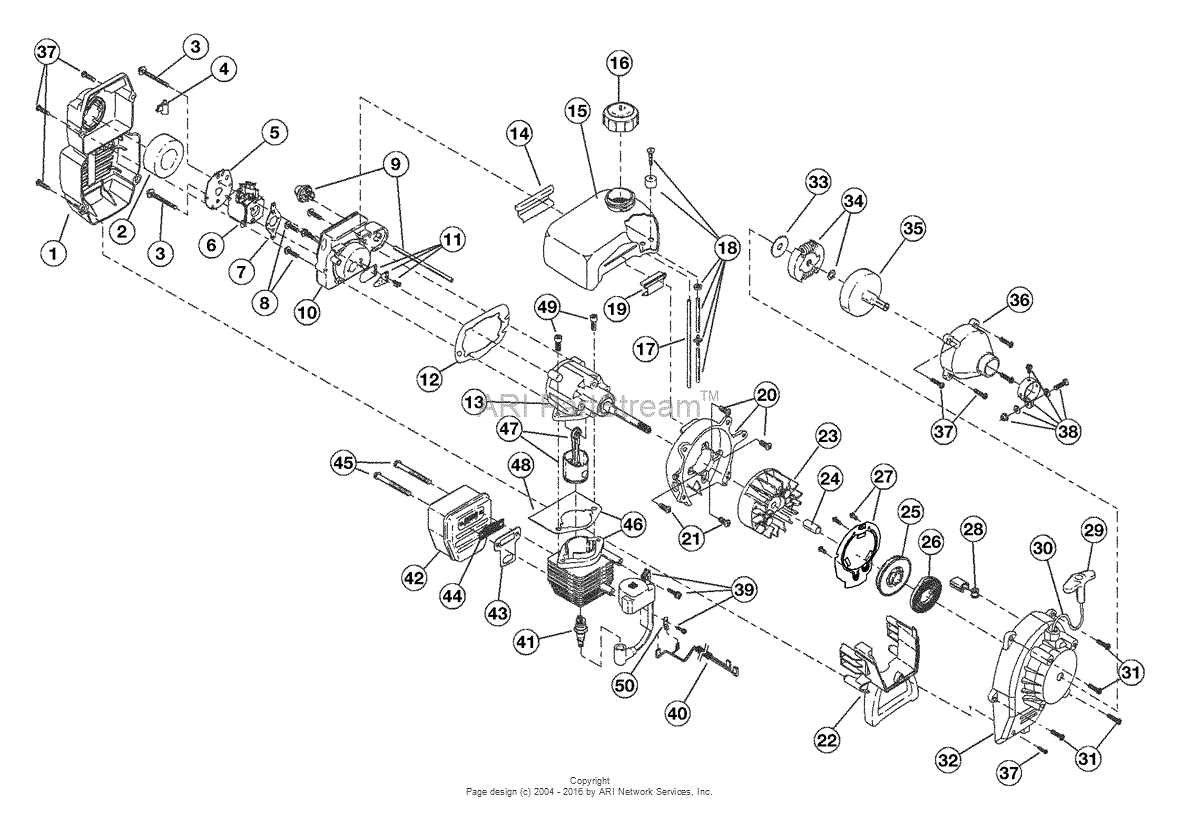

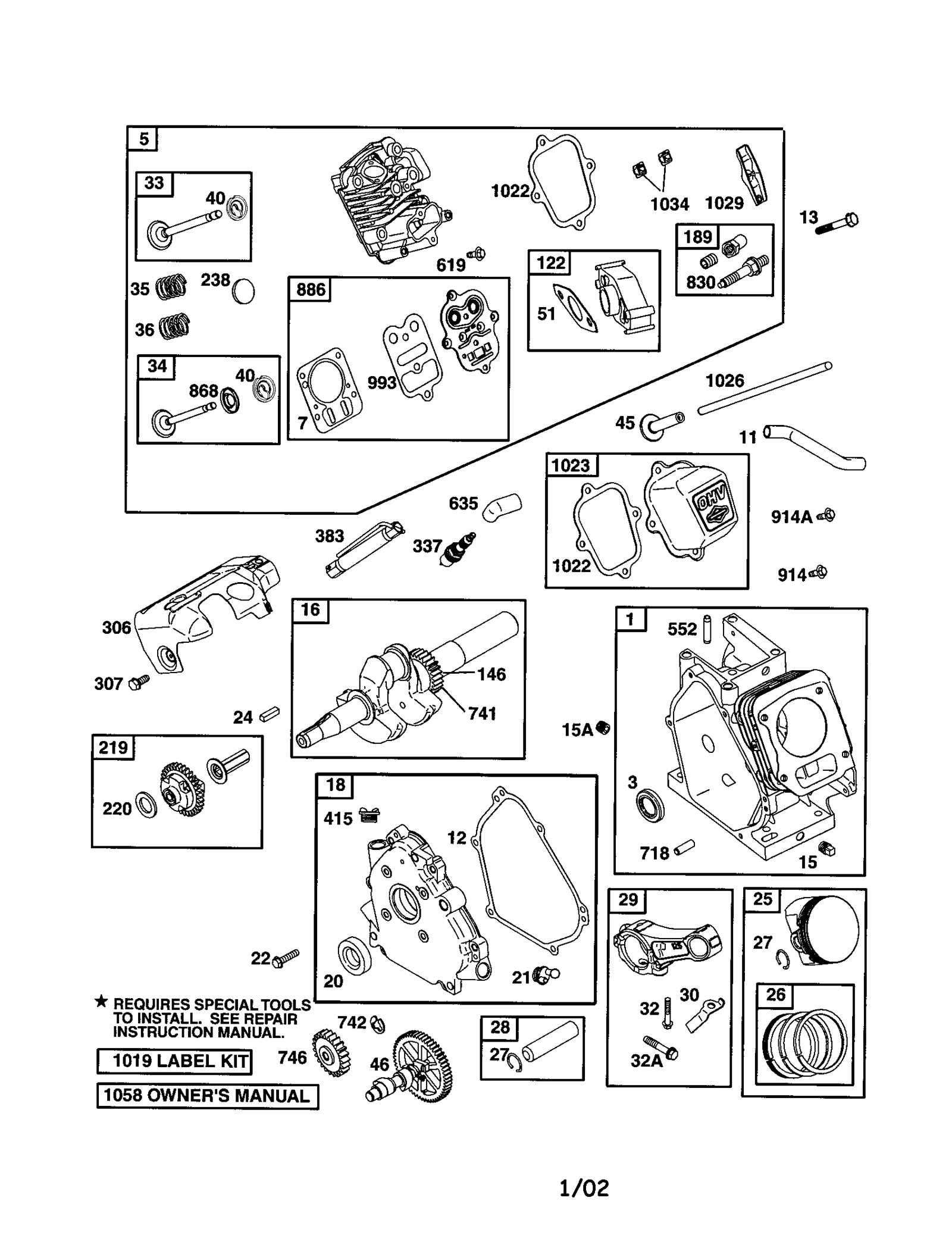

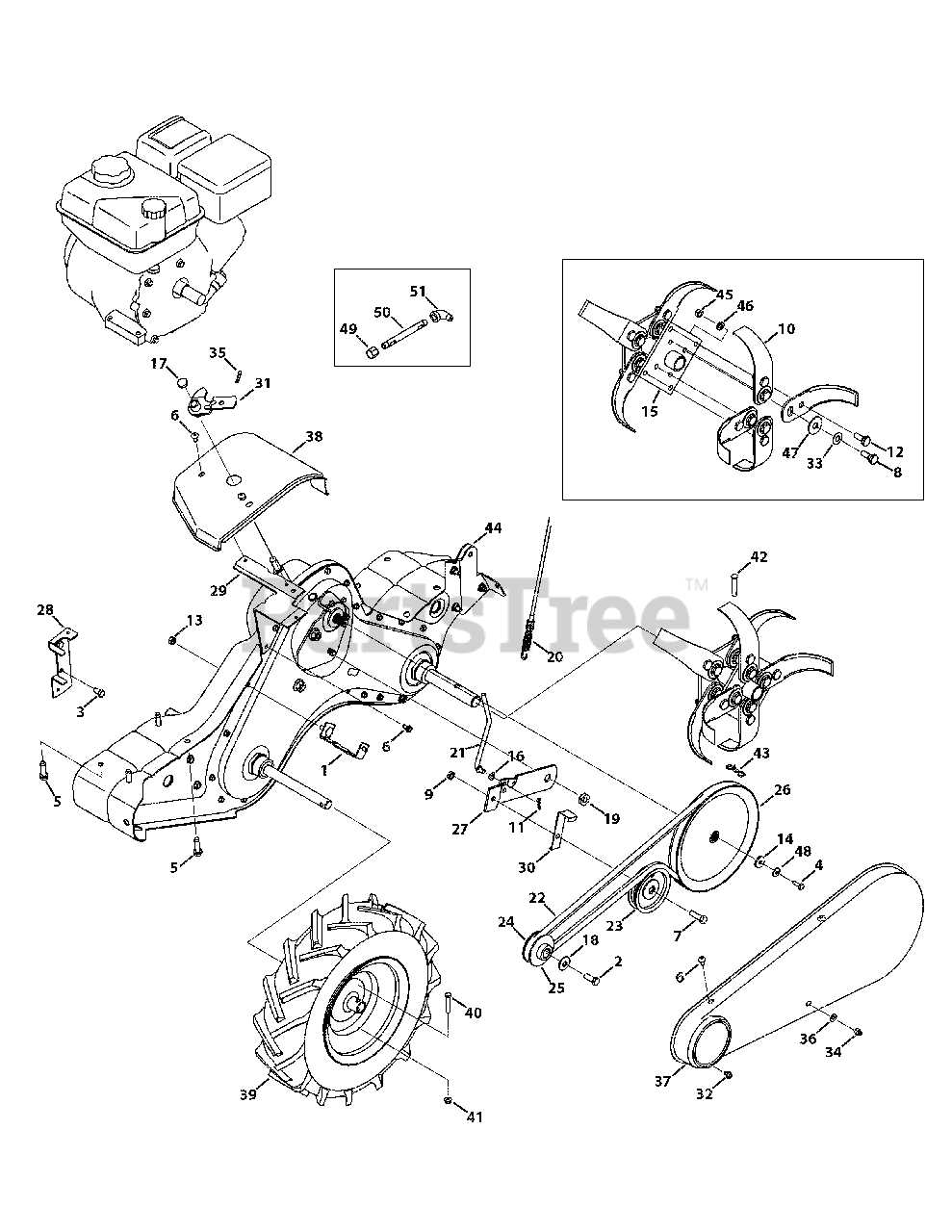

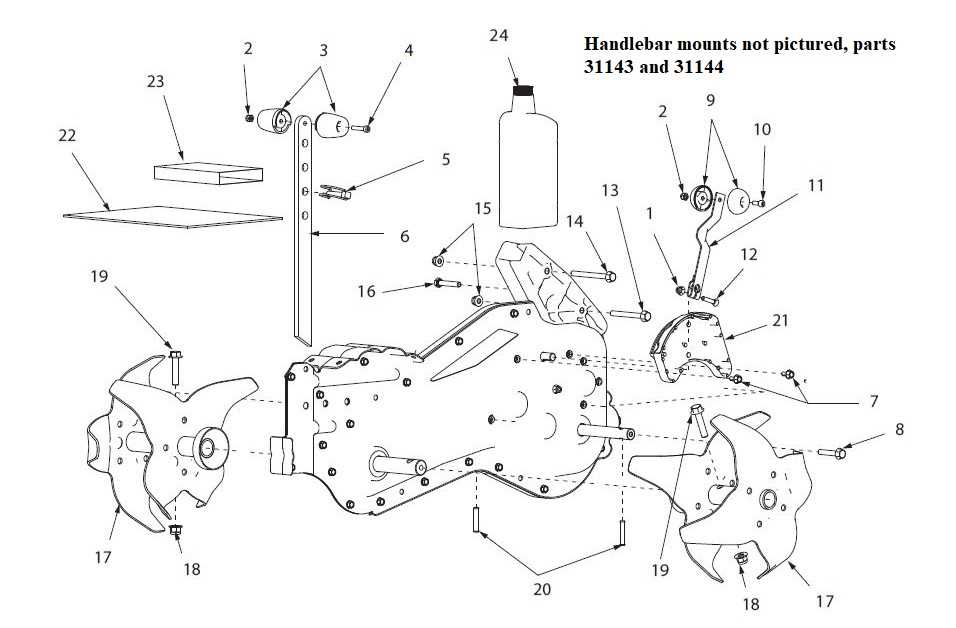

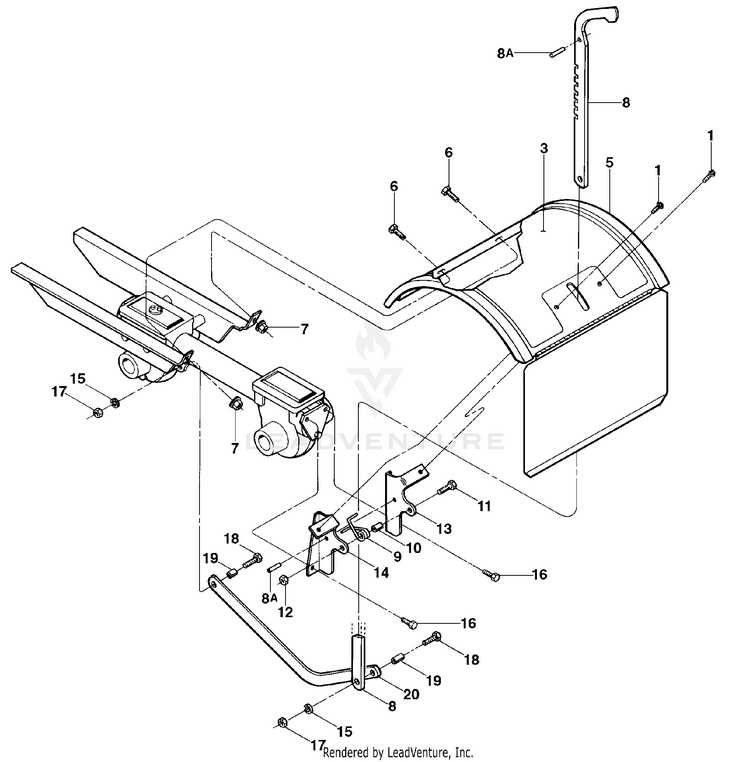

Within this context, visual representations play a crucial role in grasping the intricate relationships between different sections. Such illustrations not only clarify the assembly but also aid in identifying specific issues that may arise during operation. By familiarizing oneself with the layout and function of each segment, users can effectively troubleshoot problems and perform necessary adjustments.

Moreover, having a clear view of the various mechanisms involved allows for informed decision-making when sourcing replacements or upgrades. Whether you are a seasoned gardener or a novice, understanding these foundational elements can significantly improve your gardening experience, making it more efficient and enjoyable.

Understanding Craftsman Rototiller Components

When engaging in garden preparation, comprehending the essential elements of tilling machinery is crucial for optimal performance. Each component plays a significant role in ensuring efficient soil cultivation and facilitating plant growth. By familiarizing oneself with these key features, users can enhance their gardening experience and maintain their equipment effectively.

Main Elements of Tilling Equipment

The primary aspects include the engine, which powers the machine, and the tilling blades, responsible for breaking up the soil. Other vital components are the transmission system and various controls that enable ease of use. Understanding how these parts interact is essential for troubleshooting and regular maintenance.

Importance of Regular Maintenance

Routine care for each component not only extends the lifespan of the equipment but also guarantees its efficiency. Identifying wear and tear early on allows for timely replacements, ensuring that the machine performs at its best. Proper knowledge of these elements ultimately leads to more productive gardening efforts.

How to Identify Key Parts

Understanding the main components of your gardening equipment is essential for effective maintenance and optimal performance. Familiarizing yourself with these elements can enhance your ability to troubleshoot issues and perform necessary repairs. This guide will help you recognize the vital sections of your machinery and their functions.

Essential Components Overview

Each piece of equipment consists of various integral sections that contribute to its overall functionality. Recognizing these sections allows users to diagnose problems and identify which areas require attention. Below are some of the key elements typically found in gardening machinery:

| Component | Description |

|---|---|

| Engine | Drives the machine, providing the necessary power for operation. |

| Transmission | Transmits power from the engine to the wheels or tines, affecting speed and torque. |

| Tines | Rotating blades that cultivate and aerate the soil, crucial for effective tilling. |

| Handlebar | Controls the direction and maneuverability of the equipment. |

| Wheels | Facilitate movement across different terrains, impacting stability and control. |

Tips for Identification

To accurately identify these components, refer to the user manual or online resources that detail specific models. Visual inspections can also be beneficial; look for distinguishing features and consider taking notes or photos for reference. Regular familiarity with these sections will streamline maintenance and ensure the longevity of your equipment.

Common Issues with Rototiller Parts

When maintaining garden machinery, users often encounter several recurring challenges that can impact performance and longevity. Understanding these typical problems is crucial for effective upkeep and ensuring efficient operation.

- Engine Difficulties:

- Hard starting or failure to start

- Unusual noises during operation

- Overheating issues

- Transmission Troubles:

- Slipping gears or loss of power

- Difficulty in changing speeds

- Tine Problems:

- Worn or damaged tines leading to inefficient soil turnover

- Loose tines causing vibrations and reduced effectiveness

- Fuel System Concerns:

- Clogged fuel lines or filters

- Fuel leaks affecting operation

- Electrical Issues:

- Faulty ignition systems resulting in failure to start

- Worn wiring leading to intermittent problems

Addressing these common challenges proactively can enhance the performance of the machinery and prolong its lifespan.

Maintenance Tips for Longevity

Ensuring the extended lifespan of your gardening equipment requires regular attention and care. By following a few essential practices, you can enhance performance and reliability, allowing your tools to function optimally for years to come.

Regular Cleaning

Keeping your equipment clean prevents dirt and debris buildup, which can lead to mechanical issues. After each use, wipe down surfaces and check for any signs of wear.

Periodic Inspections

Routine checks help identify potential problems before they escalate. Examine all components for signs of damage and ensure everything is securely fastened.

| Task | Frequency |

|---|---|

| Clean Equipment | After each use |

| Check Oil Levels | Every 10 hours of use |

| Inspect Belts and Cables | Monthly |

| Sharpen Blades | At the beginning of the season |

Finding Replacement Parts Online

Locating components for your gardening equipment has become increasingly convenient with the rise of online resources. Many platforms now offer detailed listings and descriptions, making it easier for you to find what you need without leaving your home. Whether you’re looking for specific components or general accessories, the internet provides a vast array of options.

When searching for the right items, it’s essential to consider a few key factors:

| Factor | Description |

|---|---|

| Compatibility | Ensure that the component matches the specifications of your equipment to avoid functionality issues. |

| Quality | Look for reputable sellers who provide high-quality goods, as this will impact the longevity and performance of your machine. |

| Price | Compare prices across different websites to find the best deal without compromising on quality. |

| Shipping | Check shipping costs and delivery times to ensure that you receive your items promptly and at a reasonable expense. |

Utilizing online marketplaces and specialty websites can significantly streamline your search, ensuring you have the necessary tools to keep your outdoor machinery operating efficiently.

Diagram Overview for Easy Repair

Understanding the layout of components is essential for efficient maintenance and repair tasks. A clear representation allows users to identify each segment easily, facilitating quick assessments and replacements. This approach not only saves time but also enhances the overall effectiveness of repair efforts.

Benefits of a Clear Layout

A well-organized visual guide significantly reduces the chances of mistakes during the repair process. By highlighting each section, users can swiftly locate necessary items, ensuring a smoother workflow. This clarity aids both novice and experienced individuals in achieving the desired results without unnecessary complications.

Tips for Effective Use

To maximize the advantages of the visual representation, familiarize yourself with the layout before beginning any repairs. Cross-reference with your toolset to ensure you have everything needed at hand. Additionally, consider taking notes on any specific observations while working, which can be valuable for future maintenance tasks.

Safety Precautions While Working

Ensuring safety during outdoor equipment operation is crucial to prevent accidents and injuries. Adhering to specific guidelines can significantly reduce risks and enhance overall efficiency. Below are essential practices to follow when handling such machinery.

Personal Protective Equipment (PPE)

- Always wear sturdy footwear to protect your feet from falling objects and sharp edges.

- Use gloves to shield your hands from cuts and abrasions.

- Wear eye protection to guard against flying debris.

- Consider hearing protection if operating noisy machinery for extended periods.

Operational Guidelines

- Inspect the equipment before use to identify any potential hazards.

- Keep the work area clear of obstacles and debris to avoid tripping.

- Never operate the machinery in wet conditions to prevent slips and electrical issues.

- Follow the manufacturer’s instructions for proper usage and maintenance.

- Be aware of your surroundings and avoid working alone whenever possible.

Upgrading Parts for Better Performance

Enhancing the functionality of your gardening machine can lead to improved efficiency and ease of use. By selecting higher-quality components, you can ensure that your equipment operates at its best, providing more power and reliability during tasks.

Benefits of Upgrading

- Increased Efficiency: Better components can lead to faster and more effective operation.

- Improved Durability: Quality materials withstand wear and tear, extending the lifespan of your machine.

- Enhanced Comfort: Upgrades can reduce vibrations and noise, making the user experience more pleasant.

Key Components to Consider

- Engine: A more powerful engine can significantly boost performance, allowing for tougher tasks.

- Blades: Sharper and more durable blades can improve cutting efficiency and reduce strain on the machine.

- Tires: Upgrading to high-traction tires ensures better maneuverability and stability on various terrains.

Frequently Asked Questions About Rototillers

This section addresses common inquiries related to soil cultivation machinery. It aims to provide clarity on usage, maintenance, and troubleshooting for users seeking efficient gardening solutions.

What should I consider when choosing a tilling machine?

When selecting a tilling machine, consider factors such as the size of your garden, soil type, and the machine’s power and features. Matching these aspects will ensure optimal performance and ease of use.

How often should I perform maintenance on my equipment?

Regular maintenance is essential for longevity. It’s recommended to check and service the machine at least once a season, focusing on the engine, tines, and belts for wear and tear.

Can I use my machine on rocky soil?

While some models can handle rocky conditions, it’s advisable to remove larger stones beforehand to prevent damage to the tines and ensure effective tilling.

What is the ideal depth for tilling?

The ideal depth generally ranges from 6 to 8 inches, depending on the crop and soil condition. Adjusting this can enhance soil aeration and nutrient mixing.

How do I troubleshoot issues with my machine?

For troubleshooting, start with the basics: check fuel levels, inspect the spark plug, and ensure that all components are securely fastened. Consulting the manual can also provide valuable insights.