In the realm of machinery maintenance, having a clear visual representation of individual elements is essential for effective repairs and upgrades. This guide will explore the intricacies involved in the arrangement and functionality of various segments within a specific model, helping users grasp the relationships between components.

By dissecting the configuration of these crucial elements, one can enhance their knowledge of operational efficiency and troubleshooting techniques. A well-structured overview not only facilitates repairs but also deepens one’s appreciation for the engineering behind the equipment.

Ultimately, this exploration aims to provide clarity and insight, ensuring that both novice and experienced users can navigate the complexities of assembly and maintenance with confidence. Engaging with these layouts will empower individuals to optimize performance and extend the lifespan of their machinery.

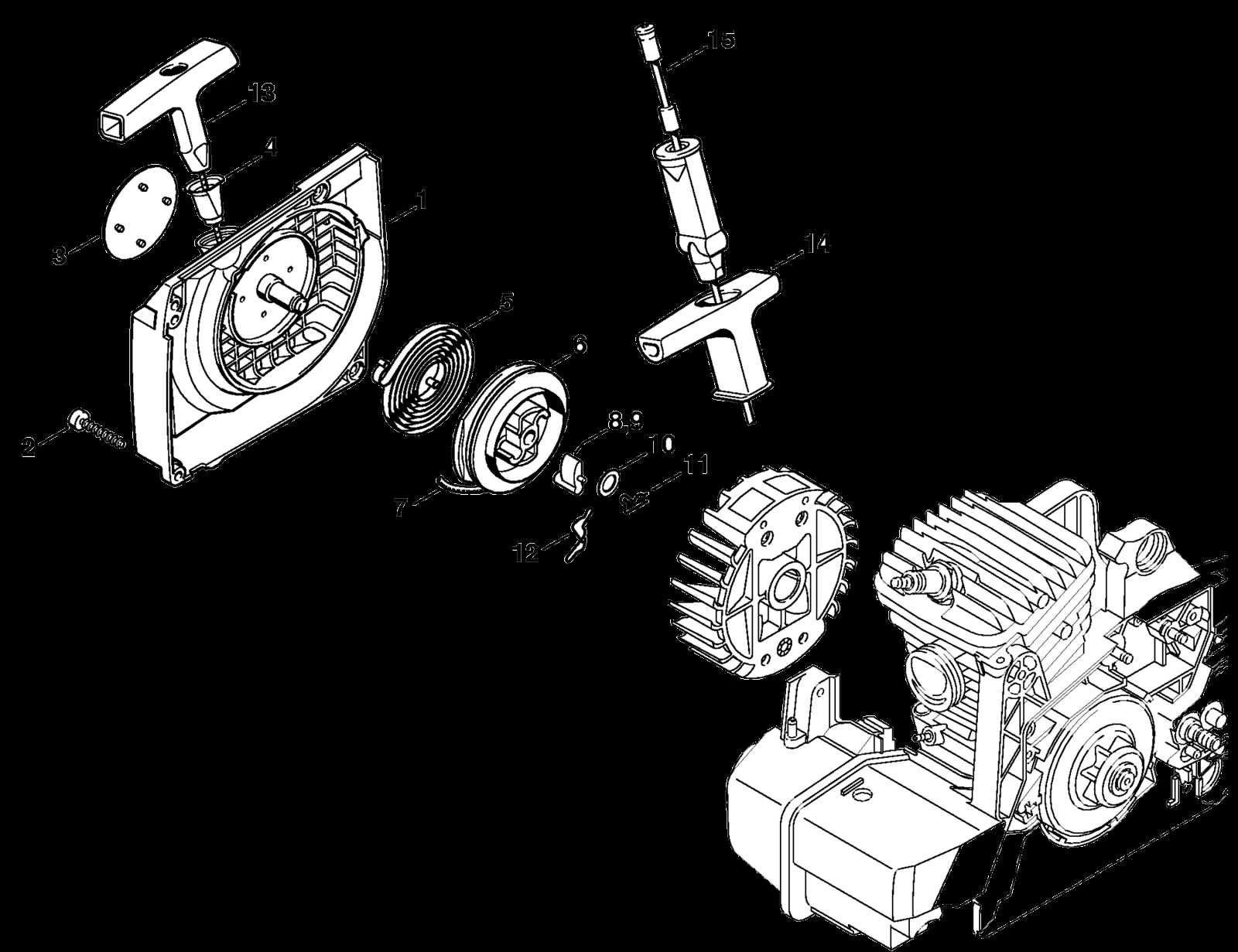

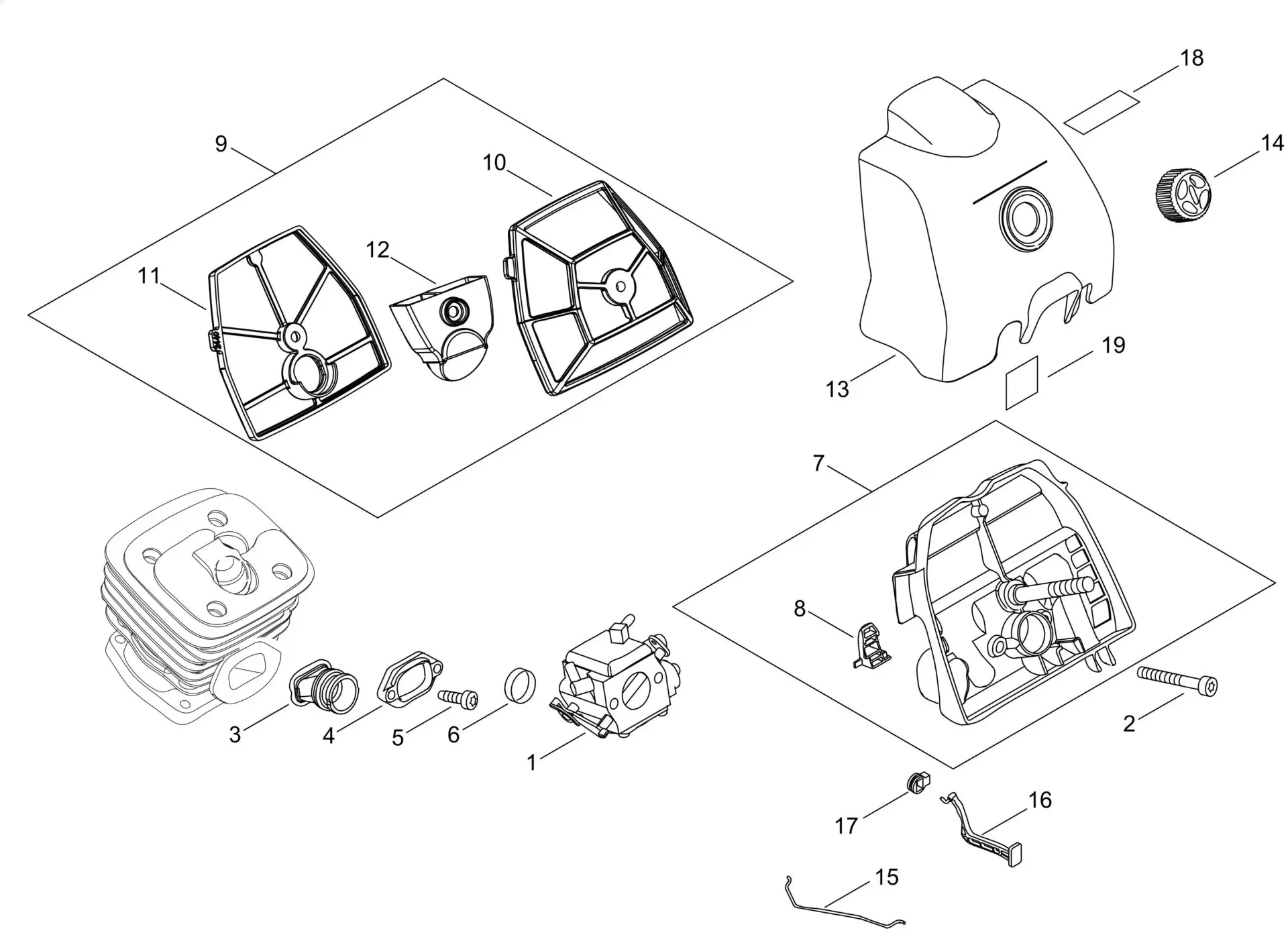

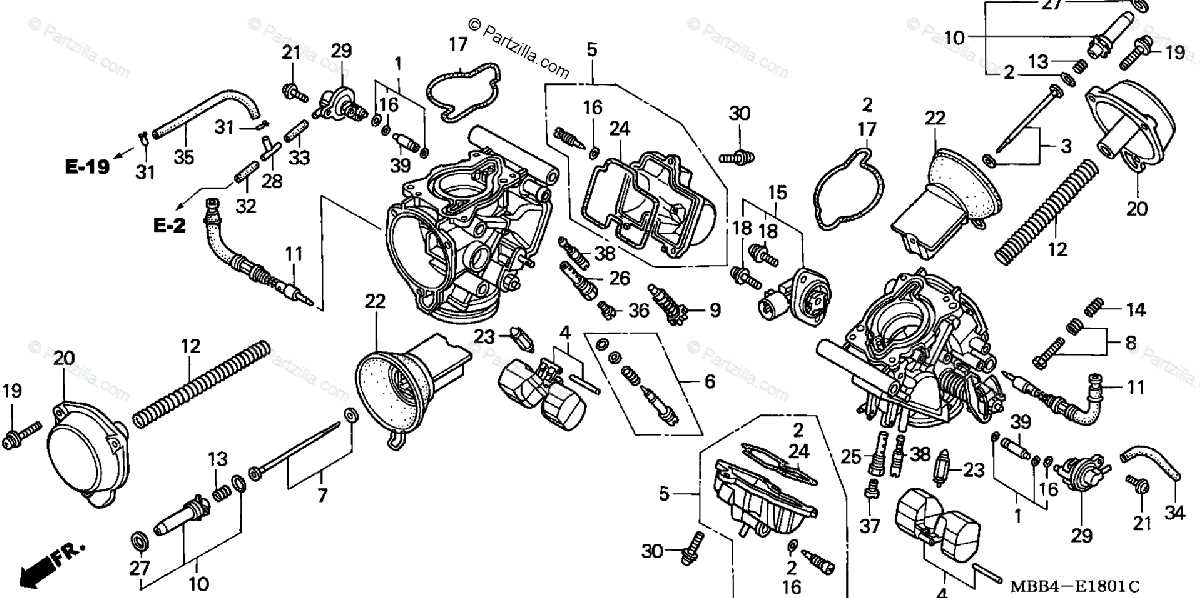

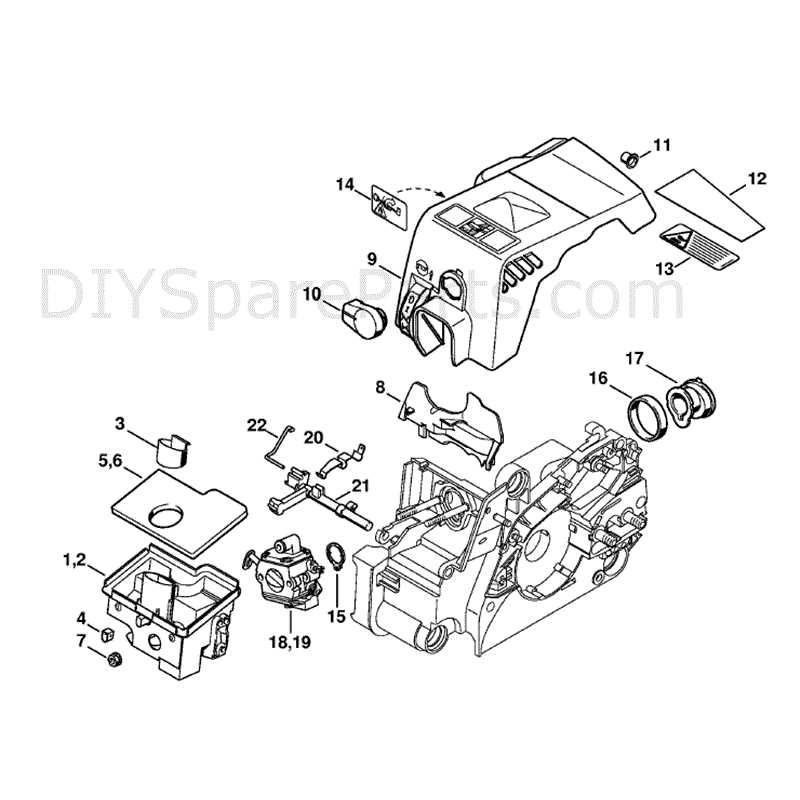

Understanding the Ms290 Parts Diagram

Grasping the intricacies of machinery components is essential for effective maintenance and repair. A detailed illustration showcasing the various elements of a specific model can significantly enhance comprehension and facilitate troubleshooting. By familiarizing yourself with each segment, you can improve your ability to identify issues and perform necessary adjustments.

To effectively interpret such a visual representation, consider the following aspects:

- Component Identification: Recognizing each element’s function is crucial for understanding how they interact within the system.

- Assembly Layout: The arrangement of parts provides insights into the overall design, allowing for better planning during repairs.

- Connection Points: Noting how components connect can help in diagnosing problems and ensuring proper assembly.

Moreover, exploring the accompanying legends and notes can reveal additional insights, aiding in a more thorough understanding. To master the intricacies of any mechanical setup, regular practice with these visual aids is recommended.

In summary, familiarizing oneself with the visual representation of machinery components not only streamlines the repair process but also enhances overall proficiency in handling equipment.

Key Components of the Ms290

Understanding the essential elements of a specific tool is crucial for optimal performance and maintenance. Each part plays a significant role in ensuring efficiency and longevity. This section will explore the main features that contribute to its functionality.

Engine: The heart of the machine, this component is responsible for generating the necessary power. Its efficiency directly impacts the overall performance.

Guide Bar: A vital element that directs the cutting process. The length and design of the bar determine the tool’s reach and precision.

Chain: The cutting mechanism that interacts with the guide bar. Its sharpness and durability are key for effective cutting tasks.

Air Filter: This component ensures clean airflow to the engine, preventing dust and debris from causing damage and maintaining optimal operation.

Fuel System: Comprising the tank and lines, this system is essential for delivering the right mix of fuel to the engine, ensuring smooth and reliable function.

Each of these components works in harmony, enhancing the tool’s performance and user experience, making maintenance and understanding of these elements paramount.

How to Read the Diagram Effectively

Understanding complex visual representations can greatly enhance your ability to navigate and assemble equipment. Familiarizing yourself with these illustrations allows you to identify components and their relationships, streamlining the process of maintenance or repair.

Identify Key Symbols

Begin by recognizing the various symbols used in the illustration. Each symbol represents a different element, and knowing their meanings is crucial for effective interpretation. Look for legends or keys that provide definitions for these symbols.

Follow the Flow of Connections

Trace the connections between different components. This will help you comprehend how each part interacts within the larger system. Pay attention to arrows and lines that indicate movement or relationships, ensuring you grasp the overall functionality.

Common Issues with Ms290 Parts

When dealing with machinery components, certain challenges frequently arise that can affect performance and longevity. Understanding these issues can help in maintaining equipment efficiently and ensuring optimal operation.

Wear and Tear

One of the most prevalent concerns is the natural degradation of components over time. Factors such as exposure to harsh conditions and heavy usage can lead to deterioration. This may manifest as decreased efficiency or even failure in critical functions. Regular inspections and timely replacements are essential to mitigate these risks.

Incorrect Assembly

Another common problem is improper installation, which can result in malfunction. If components are not assembled correctly, it can lead to misalignment or strain on various elements. Following manufacturer guidelines during assembly can significantly reduce the likelihood of such issues, ensuring that each part works harmoniously within the system.

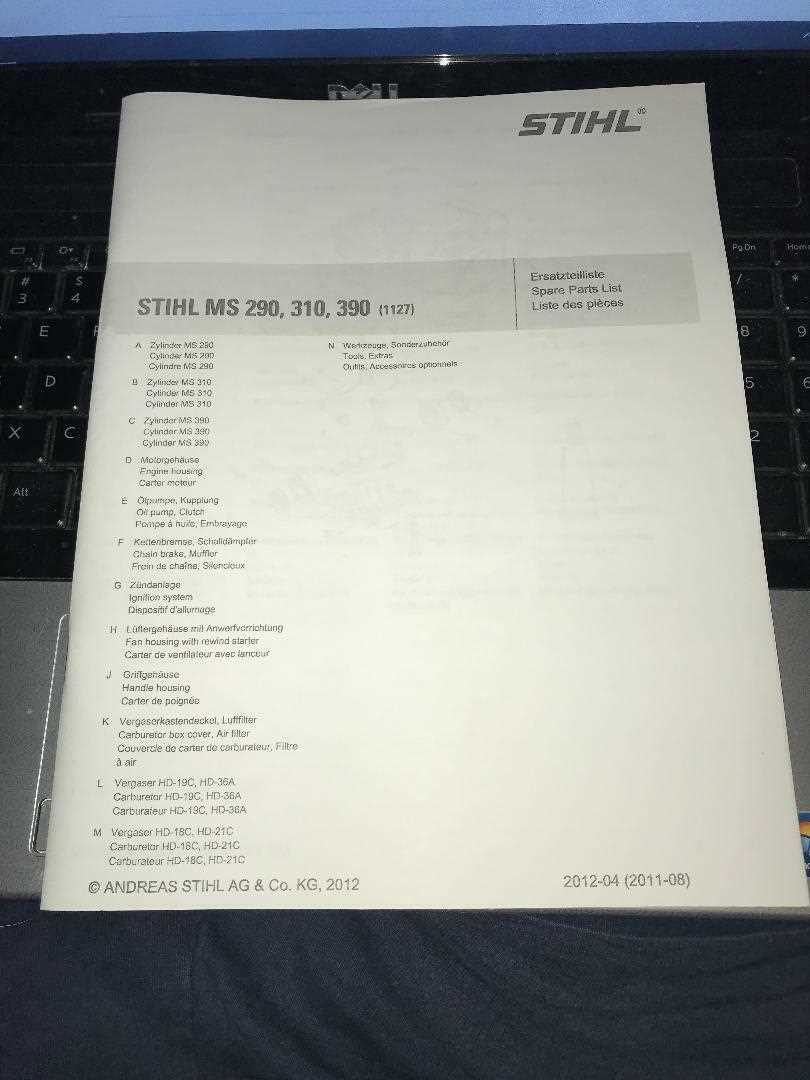

Replacement Parts Availability for Ms290

Access to essential components for maintenance and repair is crucial for ensuring optimal performance of equipment. Various sources offer a range of options, from original manufacturers to third-party suppliers, providing flexibility for users seeking replacements. Understanding where to find these items can streamline the process and enhance the longevity of the machinery.

Original manufacturers often provide a comprehensive selection, ensuring compatibility and reliability. Additionally, aftermarket suppliers can offer competitive pricing and alternative solutions, catering to diverse user needs. It’s advisable to compare availability across these sources to determine the best fit for specific requirements.

Online marketplaces and local retailers also play a significant role in accessibility. Customers can explore numerous listings, read reviews, and check stock levels, making informed choices more straightforward. Ultimately, a thorough search can yield various options to suit different budgets and preferences.

Maintenance Tips for Ms290 Components

Regular upkeep of your equipment is essential to ensure optimal performance and longevity. By focusing on key elements, you can enhance reliability and prevent unexpected failures.

- Inspect all elements regularly for wear and tear.

- Clean components to prevent debris buildup.

- Lubricate moving parts according to the manufacturer’s recommendations.

Additionally, consider the following suggestions:

- Replace worn-out items promptly to maintain efficiency.

- Store the machine in a dry, clean environment to prevent rust and corrosion.

- Follow the operational guidelines to minimize stress on individual parts.

Implementing these practices will ultimately contribute to the durability and effectiveness of your equipment.

Comparing Ms290 with Other Models

In the realm of power equipment, it is crucial to understand how various models stack up against each other. This comparison focuses on a specific unit and highlights its unique attributes, performance capabilities, and overall design in relation to similar machines. By examining these distinctions, users can make informed decisions based on their specific needs.

When evaluating different machines, factors such as engine efficiency, weight, and ergonomics play a vital role. For instance, one model might excel in power output, making it ideal for heavy-duty tasks, while another may offer a lighter design for ease of handling. Understanding these differences helps potential buyers choose the best fit for their intended applications.

Additionally, features like vibration control, noise reduction, and maintenance requirements can vary significantly. Some models may incorporate advanced technologies that enhance user comfort and extend the lifespan of the equipment. These innovations can set a machine apart in a competitive market, appealing to both novice and experienced users alike.

Ultimately, by comparing specifications and functionalities, consumers can identify which equipment aligns with their operational needs and preferences, ensuring optimal performance and satisfaction in their projects.

Tools Needed for Ms290 Repairs

When it comes to maintaining and fixing machinery, having the right tools is essential for ensuring effective and efficient repairs. A well-equipped toolkit not only facilitates the repair process but also helps prevent damage to components. Below is a list of essential instruments and their purposes for successful maintenance tasks.

- Screwdrivers: A set of both flathead and Phillips screwdrivers is necessary for loosening or tightening various screws.

- Wrenches: Adjustable and socket wrenches are crucial for removing and securing bolts and nuts.

- Pliers: Needle-nose and standard pliers are helpful for gripping, twisting, and cutting wires or other materials.

- Torque Wrench: This tool ensures that fasteners are tightened to the manufacturer’s specified torque settings, preventing over-tightening.

- File Set: A variety of files can assist in smoothing rough edges and ensuring proper fit of components.

In addition to the basic tools, having a few specialized items can enhance the repair experience:

- Chain Breaker: Essential for working with drive chains, allowing for easy removal and installation.

- Compression Gauge: Useful for testing engine performance by measuring compression levels.

- Multimeter: This device is crucial for diagnosing electrical issues by measuring voltage, current, and resistance.

- Oil Can: Ensures proper lubrication of moving parts, reducing wear and tear.

- Safety Gear: Gloves, goggles, and ear protection are vital for ensuring personal safety during repairs.

With the appropriate tools at your disposal, tackling repairs becomes a more manageable task, allowing for quick and effective solutions.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance is crucial to prevent accidents and injuries. A systematic approach helps create a secure environment, allowing for efficient and effective work. Adhering to safety protocols not only protects the individual but also prolongs the lifespan of the equipment being serviced.

Personal Protective Equipment

Wearing appropriate personal protective gear is essential. This includes gloves, goggles, and sturdy footwear to safeguard against potential hazards. Ensuring that all gear fits properly enhances safety and comfort during the repair process.

Work Area Organization

Maintaining a tidy and organized workspace is vital. Removing clutter reduces the risk of tripping or misplacing tools. Clearly marking hazardous areas and keeping emergency equipment accessible further enhances safety measures during maintenance tasks.