Modern agricultural machinery plays a crucial role in ensuring efficient and effective farming operations. For those who rely on such equipment, understanding the different elements that contribute to its functionality is essential for maintenance and troubleshooting. In this guide, we will explore the key components that make up crucial planting systems, focusing on their design and interaction within the machinery.

Each piece of equipment consists of various parts that work together to deliver optimal performance in the field. From mechanical assemblies to precision-engineered tools, knowing the role of each section can significantly improve the overall efficiency and longevity of the machinery. This detailed breakdown will help users gain a better grasp of how these elements fit together and function.

Maintaining agricultural tools is a complex process, but with a clear understanding of the structural layout, it’s possible to perform repairs and replacements more effectively. The following sections will highlight some of the most important features, providing insights into how they contribute to the overall operation of the machine.

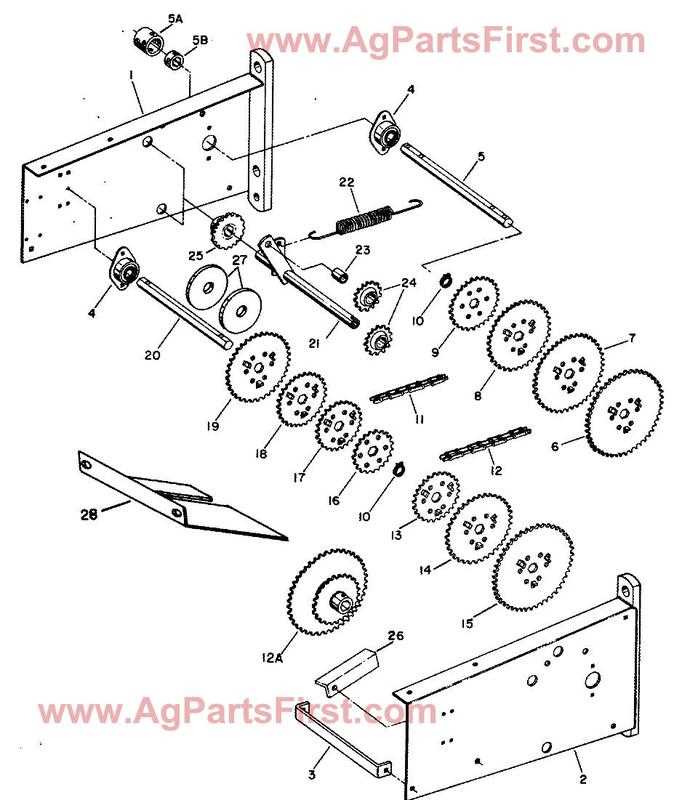

Overview of White 6100 Planter Components

The machinery in question is composed of several intricate elements designed to work in harmony for efficient performance. Understanding the primary sections of this equipment is essential for proper use and maintenance. Each part plays a vital role in ensuring smooth operation during planting processes.

Seed Delivery System: This mechanism ensures that seeds are accurately placed into the soil. It is engineered for precise control over seed depth and spacing, which is crucial for optimal crop growth.

Row Units: These are responsible for handling the soil preparation and seed placement. Each unit works independently, allowing for flexibility across different terrains and conditions.

Drive Mechanism: This part powers the operation, ensuring that all components function in sync. The drive ensures the accurate distribution of seeds by controlling the overall pace and consistency.

Hoppers: These containers hold seeds and fertilizers, ready to be distributed. Proper management of these sections ensures continuous planting without interruptions.

Frame Structure: The robust framework supports all other components, providing the necessary stability during use. Its durability is key to withstanding various envir

Main Elements and Their Functions

In any agricultural equipment, understanding the essential components and their specific roles is crucial for ensuring optimal performance. Each element plays a vital part in the overall operation, contributing to the precision and efficiency of the machine.

The framework provides structural support, allowing all other components to function in harmony. This solid foundation ensures durability and stability during use, especially in challenging field conditions.

The distribution mechanism ensures even and consistent dispersal of resources across the designated area. This precise control helps achieve uniform results, which is key for successful planting operations.

The adjustable units allow for fine-tuning according to specific field conditions. These adaptable parts ensure that the equipment can be optimized for different soil types, weather conditions, and planting requirements.

Finally, the drive system powers the entire machine, converting energy into motion. This system ensures that all parts work together seamlessly, maintaining consistency and reliability during operation.

Breakdown of Key Mechanical Parts

The section provides an in-depth look at the primary mechanical components responsible for the overall functionality of agricultural equipment. Each element plays a crucial role in ensuring efficiency and precision during operation, contributing to both reliability and performance in the field.

- Frame Assembly: The core structure that supports the entire system, ensuring stability and even weight distribution during use.

- Seed Dispenser: A critical unit that controls the flow and spacing of seeds, contributing to optimal planting patterns and minimizing waste.

- Drive Mechanism: This system powers various movements, such as rotation and forward motion, coordinating actions to maintain consistent performance.

- Row Units: These sections are designed to manage individual planting rows, adapting to different soil conditions and maintaining uniformity.

- Depth Control: Ensures seeds are placed at the correct depth, which is essential for maximizing germination rates and crop success.

- Gauge Wheels: These components regulate the depth of operation, offering consistent results across dif

Understanding the Essential Moving Parts

The core functionality of any mechanical system relies on the interplay between various dynamic components. These elements, responsible for movement and coordination, ensure smooth operation, enhancing performance and reliability in fieldwork. Understanding how these crucial components work together can help in maintaining and optimizing the system for efficient use.

Key Components to Consider

- Drive Mechanism: This component transfers energy to various parts of the system, powering key movements. Its maintenance is critical for ensuring smooth operations.

- Adjustment Assemblies: These assemblies enable fine-tuning of the equipment’s functionality, allowing for greater precision and adaptability to different conditions.

- Support Bearings: These provide stability, reducing friction and wear on moving elements, thus extending the lifespan of the entire system.

Maintenance Tips for Moving Components

- Regular

Hydraulic System in Agricultural Equipment

The hydraulic system plays a vital role in ensuring the proper functionality of agricultural machinery. It operates essential mechanisms, allowing seamless adjustment of key components and providing the necessary power for various operations. This system relies on hydraulic fluid and pressurized circuits to maintain smooth and efficient performance during fieldwork.

Key Components of the Hydraulic System

A typical hydraulic setup includes several core elements that work together to control fluid movement and apply force. These components include pumps, valves, hoses, and cylinders, each serving a distinct purpose in delivering power to different areas. Understanding how these elements interact can help in diagnosing issues and ensuring optimal performance in the field.

Hydraulic Maintenance Tips

Regular inspection and upkeep of the hydraulic system are essential for preventing downtime and ensuring long-term reliability. This includes checking for leaks, monitoring fluid levels, and replacing worn-out hoses or seals. Proper maintenance extends the equipment’s life and ensures its readiness for intensive agricultural tasks.

Component Details of Hydraulic Components

The hydraulic system plays a crucial role in ensuring the efficient operation of agricultural machinery. Understanding its various components is essential for maintenance and troubleshooting. This section delves into the key elements of hydraulic systems, highlighting their functions and importance in agricultural equipment.

Key Hydraulic Elements

- Hydraulic Pump: This device converts mechanical energy into hydraulic energy, providing the necessary fluid pressure to operate the system.

- Hydraulic Cylinders: Actuators that convert hydraulic energy back into mechanical energy, enabling various movements and actions within the machinery.

- Hoses and Fittings: Essential for transporting hydraulic fluid between components, ensuring a seamless connection and preventing leaks.

- Reservoir: Stores hydraulic fluid, maintaining adequate levels for system functionality and heat dissipation.

- Valves: Control the flow and direction of hydraulic fluid, enabling precise operation of the system.

Common Issues and Solutions

- Fluid Leaks: Regularly check hoses and connections for signs of wear. Replace any damaged components promptly.

- Pressure Drops: Inspect the pump and filters to ensure they are functioning correctly and not clogged.

- Slow Response: Check for air trapped in the system and bleed the lines to restore optimal performance.

Exploring the Seed Distribution Mechanism

The effective dispersion of seeds is crucial for ensuring optimal crop yields. Understanding the intricate mechanisms that facilitate this process can greatly enhance planting efficiency and overall agricultural productivity. This section delves into the components and functionalities involved in seed distribution, highlighting their significance in modern farming practices.

Key Components of the Distribution System

- Seed Hoppers: These containers hold seeds before they are released into the soil, ensuring a steady supply during operation.

- Distribution Plates: These plates regulate the flow of seeds, allowing for precise spacing and placement in the soil.

- Drive Mechanism: This component powers the distribution system, controlling the speed and timing of seed release.

Operational Principles

The operation of the seed distribution mechanism relies on various principles to achieve optimal results:

- Gravity Feed: Seeds fall from the hopper due to gravitational pull, ensuring a consistent flow.

- Mechanical Agitation: Movement within the hopper helps to break up clumps and promote even distribution.

- Timing Adjustments: Operators can adjust release timings to accommodate different seed types and soil conditions.

By comprehensively understanding these elements and principles, farmers can enhance their planting techniques and ensure healthier crops.

Parts Involved in Seed Placement

The process of ensuring optimal seed positioning during planting relies on various components that work together harmoniously. Each element plays a crucial role in facilitating accurate placement, which is essential for achieving successful crop establishment.

Seed Furs are instrumental in creating the appropriate trench for seed placement. They ensure the seed is buried to the correct depth, promoting germination and root development.

Closing Wheels play a significant role in covering the seeds after they have been placed. By effectively compacting the soil above the seed, they help retain moisture and protect the seeds from environmental stressors.

Seed Distributors are critical for delivering seeds to the furrows. These mechanisms ensure a consistent flow of seeds, which is vital for maintaining proper spacing and density.

Depth Control Mechanisms are essential for adjusting the planting depth according to soil conditions. They help maintain uniformity across the field, allowing for more predictable growth patterns.

By understanding the functions of these components, operators can ensure precise and efficient planting, ultimately leading to healthier crops and improved yields.

Maintenance Tips for Planter Components

Regular upkeep of agricultural machinery is essential for ensuring optimal performance and longevity. Proper care not only enhances functionality but also reduces the risk of unexpected breakdowns. Here are some key practices to consider for maintaining your equipment effectively.

1. Regular Inspections: Conduct frequent checks on all components to identify any signs of wear or damage. Look for cracks, rust, or loose connections that could hinder operation. Early detection can prevent costly repairs.

2. Lubrication: Ensure that all moving parts are adequately lubricated. This reduces friction and helps in maintaining smooth operation. Use the appropriate lubricant recommended by the manufacturer for best results.

3. Cleaning: Keep all surfaces free from dirt, debris, and residue. Regular cleaning not only improves the efficiency of the machinery but also prevents the buildup of harmful materials that can lead to corrosion and wear.

4. Calibration: Periodically check the alignment and calibration of various components. Proper alignment ensures uniform operation, which is crucial for achieving desired results during planting.

5. Seasonal Maintenance: Before and after the planting season, perform thorough maintenance checks. This includes tightening bolts, replacing worn parts, and ensuring all systems are functioning optimally.

6. Store Properly: When not in use, store equipment in a dry, sheltered environment to protect it from the elements. Consider using covers to further safeguard against dust and moisture.

Implementing these maintenance strategies will help ensure that your agricultural machinery operates efficiently, reducing downtime and enhancing productivity.

How to Keep Parts in Optimal Condition

Maintaining equipment components in peak form is essential for ensuring efficient operation and longevity. Regular attention to these elements can prevent wear and tear, reduce the likelihood of malfunctions, and ultimately save time and money on repairs.

Routine Inspections: Conduct frequent checks to identify any signs of damage or wear. Early detection of issues can prevent further deterioration and costly replacements.

Cleaning: Keeping elements free from dirt and debris is crucial. Accumulation of soil and residue can lead to corrosion and malfunction. Use appropriate cleaning solutions and tools to ensure thorough maintenance.

Proper Lubrication: Regularly applying the correct lubricant helps to reduce friction and prevent overheating. Ensure that you follow the manufacturer’s recommendations for specific lubricants and intervals.

Storage Conditions: Store components in a clean, dry environment to protect them from moisture and extreme temperatures. Using covers or protective cases can further enhance their longevity.

Timely Replacements: Be proactive about replacing worn or damaged items. Keeping spare components on hand can minimize downtime and enhance productivity during critical periods.

By following these practices, operators can ensure that their equipment functions smoothly and efficiently, enhancing overall performance and extending the service life of vital components.