When it comes to maintaining machinery, having a clear visual representation of its elements can be invaluable. A comprehensive overview allows users to identify each component’s role, ensuring efficient repairs and upkeep. Such resources facilitate a deeper understanding of how each part interacts within the system.

Accessing detailed illustrations not only aids in troubleshooting but also enhances the overall experience of operating the equipment. By familiarizing oneself with the intricate layout of the machinery, operators can optimize performance and extend the lifespan of their investment.

In this section, we will delve into the essential elements that make up your machinery, providing insights that are crucial for both novices and seasoned users. The ultimate goal is to empower you with the knowledge needed to navigate maintenance tasks confidently.

Understanding the Kubota ZD326S

This section aims to explore the key features and functionalities of a prominent machine in the lawn care sector, known for its efficiency and durability. By delving into its design and operational capabilities, users can gain insights into why it stands out among its peers.

Key Features: This model boasts a powerful engine, ensuring robust performance during operation. Its ergonomic design enhances user comfort, allowing for extended usage without fatigue.

Maintenance: Regular upkeep is crucial for longevity. Familiarity with the internal components can help users perform basic maintenance and repairs, ensuring optimal performance over time.

Applications: Ideal for both residential and commercial settings, this machine is versatile enough to handle various landscaping tasks, making it a valuable asset for users.

Key Features of the ZD326S

This model stands out in its category due to a combination of innovative design and advanced technology, tailored for optimal performance in various mowing tasks. The machine is engineered to deliver efficiency and ease of use, making it a top choice for both professionals and homeowners.

- Powerful Engine: Equipped with a high-performance engine that provides excellent torque and speed, ensuring effective operation in diverse conditions.

- Precision Cutting: Features a cutting deck designed for precision, allowing for a clean and even cut while minimizing lawn damage.

- Hydrostatic Transmission: This system offers smooth acceleration and effortless speed control, enhancing maneuverability and operator comfort.

- Compact Size: Its compact design enables easy navigation in tight spaces, making it ideal for residential lawns and intricate landscapes.

- User-Friendly Controls: Intuitive control layout simplifies operation, allowing users of all skill levels to handle the equipment with confidence.

Overall, this model integrates these features to provide a reliable and efficient solution for lawn care, making it a valuable addition to any equipment fleet.

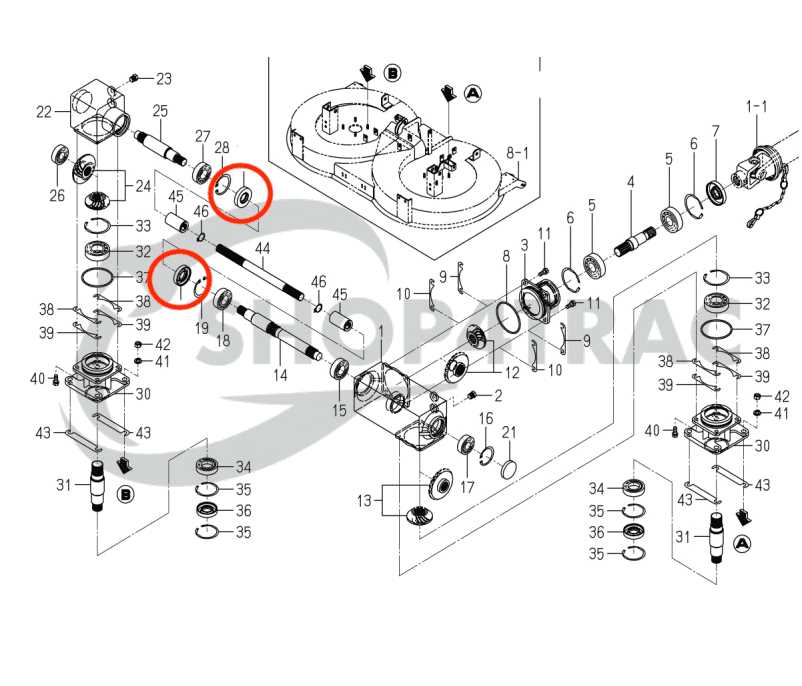

Importance of Parts Diagrams

Visual representations of components are essential for understanding the assembly and functionality of machinery. They serve as valuable tools for both maintenance and repair, ensuring that users can accurately identify and replace elements as needed. This clarity not only streamlines processes but also enhances the overall efficiency of operations.

Facilitating Maintenance

Having access to clear illustrations aids technicians in diagnosing issues effectively. By providing a comprehensive view of how parts interconnect, these visuals simplify the troubleshooting process, reducing downtime and improving productivity.

Enhancing User Knowledge

Studying these representations deepens one’s comprehension of the equipment’s structure and operation. Users can delve into the mechanics, gaining insights that empower them to perform basic repairs and maintenance tasks confidently.

Navigating the Parts Diagram

Understanding the layout of components is essential for efficient maintenance and repairs. By familiarizing yourself with the structure, you can easily identify each element and its function within the overall system. This knowledge will ultimately enhance your troubleshooting skills and prolong the lifespan of the equipment.

Identifying Key Components

Start by locating the main sections, which typically include the engine, transmission, and hydraulic systems. Each segment houses various elements that contribute to the machine’s performance. Recognizing these parts will help streamline your repair process.

Utilizing the Visual Guide

The visual representation serves as a valuable tool for quick reference. Pay attention to the labels and numbering, which are designed to assist you in locating specific items efficiently. This approach not only saves time but also ensures accuracy during replacements.

Common Replacement Parts for ZD326S

Regular maintenance of machinery is crucial for optimal performance and longevity. Certain components are frequently replaced due to wear and tear, ensuring that the equipment remains efficient and reliable. Understanding these components helps users stay proactive in their upkeep efforts.

Frequently Changed Components

- Blades: Essential for cutting, these parts require periodic replacement to maintain effectiveness.

- Filters: Oil and air filters must be changed regularly to ensure clean operation and prevent engine damage.

- Batteries: Over time, batteries can lose their charge capacity and may need replacement to avoid starting issues.

- Belts: Drive belts can wear out, affecting power transmission and requiring timely swaps.

Other Important Elements

- Seals and Gaskets: These components prevent leaks and should be inspected and replaced as needed.

- Wheels and Tires: Regular checks and replacements ensure stability and traction on various terrains.

- Lights and Indicators: Maintaining visibility and safety often requires the replacement of these electrical components.

- Hydraulic Hoses: Inspecting for wear and tear can prevent hydraulic failures, making timely replacements essential.

Where to Find Quality Parts

When searching for high-quality components for your machinery, it’s essential to know where to look. The right resources can make a significant difference in ensuring optimal performance and longevity of your equipment.

Authorized Dealers: One of the most reliable sources is authorized dealers. These suppliers often provide genuine components that meet the manufacturer’s specifications, ensuring compatibility and durability.

Online Marketplaces: Reputable online platforms also offer a vast selection of components. It’s important to check reviews and ratings to ensure you are purchasing from trustworthy sellers. Look for listings that provide detailed descriptions and clear images.

Local Repair Shops: Consider visiting local repair shops or service centers. They can often order specific components directly from manufacturers, giving you access to quality items without long wait times.

Forums and Community Groups: Engaging in forums or community groups can be beneficial. Members frequently share their experiences and recommendations for quality sources. Networking within these communities can lead you to hidden gems.

Trade Shows: Attending trade shows related to your industry can provide direct access to various suppliers and manufacturers. This environment allows for in-person discussions and evaluations of products.

By exploring these avenues, you can ensure that you acquire reliable and durable components for your machinery needs.

Maintenance Tips for Longevity

Proper upkeep is essential for extending the life of your machinery. Regular maintenance not only ensures optimal performance but also prevents costly repairs down the line.

- Regular Inspections: Frequently check for wear and tear, including belts, filters, and fluids.

- Cleanliness: Keep components free from dirt and debris to avoid overheating and inefficiencies.

- Fluid Changes: Replace oils and lubricants according to the manufacturer’s recommendations to ensure smooth operation.

- Tire Care: Monitor tire pressure and tread wear to enhance traction and prevent accidents.

- Battery Maintenance: Inspect connections and clean terminals to ensure reliable starting and operation.

By adopting these practices, you can delve deeper into the mechanics of your equipment and enhance its ultimate performance.

DIY Repairs Using the Diagram

Understanding the layout and components of your equipment can empower you to tackle repairs confidently. With a clear representation of each part, you can identify issues more efficiently and execute fixes without relying on external help. This approach not only saves time but also enhances your knowledge of how your machinery operates.

Identifying Issues

Before diving into repairs, it’s essential to pinpoint the problem accurately. Referencing a detailed schematic allows you to locate specific elements that may require attention. Whether it’s a worn-out component or a malfunctioning mechanism, having a visual guide makes the troubleshooting process straightforward.

Executing Repairs

Once you’ve diagnosed the issue, the next step is to perform the necessary maintenance. Use the visual guide to gather the right tools and replacement parts. This organized approach minimizes frustration and streamlines the repair process. Always remember to follow safety protocols to ensure a secure working environment.

By taking advantage of a well-structured representation, you can enhance your repair skills and maintain your equipment in optimal condition.