In the realm of machinery, a comprehensive understanding of individual components is essential for effective operation and maintenance. Each element plays a vital role in ensuring the overall functionality and efficiency of the system. By familiarizing oneself with the various sections and their interconnections, operators can enhance performance and longevity.

Visual representations of these mechanical elements offer invaluable insights into their arrangement and interaction. Such illustrations serve as a guide, making it easier to identify specific sections and troubleshoot potential issues. Recognizing how each piece fits into the larger framework can empower users to make informed decisions regarding repairs and upgrades.

Additionally, a thorough exploration of these schematics can illuminate the intricacies of design and engineering behind the equipment. Understanding the purpose and function of each individual component fosters a deeper appreciation for the technology, ultimately leading to more effective usage and maintenance practices. The knowledge gained from these resources is indispensable for anyone involved in the operation of such machinery.

Understanding Wood-Mizer Equipment Components

Comprehending the various elements of cutting machinery is crucial for optimal performance and maintenance. Each component plays a specific role in ensuring the efficient operation of the equipment, contributing to the overall effectiveness of timber processing tasks.

Key components typically include:

- Engine: The powerhouse that drives the machinery, providing the necessary energy for operation.

- Blades: Essential for slicing through wood, these tools come in various shapes and sizes to accommodate different cutting requirements.

- Frame: The structural foundation that supports all other elements, ensuring stability during operation.

- Feed System: Mechanisms that facilitate the movement of timber through the cutting zone, enhancing efficiency.

- Controls: User interfaces that allow operators to adjust settings and monitor performance.

Understanding how these elements interact can lead to better troubleshooting and maintenance practices, ultimately improving the lifespan and effectiveness of the machinery.

Additionally, recognizing the significance of each component aids in identifying replacement needs and ensuring that the equipment runs smoothly. Regular checks and familiarity with the specific parts involved can greatly enhance operational success.

Key Features of Wood-Mizer Parts

The components of these innovative machines are designed to enhance efficiency and performance in wood processing. Each element plays a crucial role in ensuring optimal functionality, durability, and ease of maintenance. Understanding their unique characteristics helps users maximize productivity and minimize downtime.

| Feature | Description |

|---|---|

| Durability | Constructed from high-quality materials to withstand heavy use and harsh conditions. |

| Precision | Engineered for accurate cuts and consistent results, ensuring superior finish quality. |

| Modularity | Designed to be easily replaceable, allowing for quick repairs and upgrades. |

| Compatibility | Interchangeable with various models, enhancing flexibility in machine configuration. |

| Maintenance | Features that facilitate easy servicing and reduce overall maintenance time. |

Importance of Diagrams in Maintenance

Visual representations play a crucial role in the upkeep and servicing of machinery. They provide clear insights into the components and their interactions, ensuring that maintenance tasks are executed efficiently.

- Clarity: Illustrations simplify complex structures, making it easier for technicians to identify parts.

- Efficiency: With a visual guide, maintenance can be performed more quickly and accurately.

- Training: New personnel can grasp essential concepts faster through visual aids.

Incorporating these visual tools ultimately enhances the reliability and longevity of equipment, reducing downtime and improving overall productivity.

Common Issues with Wood-Mizer Machinery

In the realm of lumber processing, equipment reliability is paramount. However, even the most robust machinery can experience challenges that affect performance and productivity. Understanding these common issues can help operators maintain their equipment effectively and minimize downtime.

Mechanical Failures

One frequent problem involves mechanical breakdowns, which can arise from wear and tear or inadequate maintenance. Belts and bearings are often the first components to show signs of fatigue. Regular inspection and timely replacement are essential to prevent more significant failures that can halt operations.

Electrical Issues

Electrical malfunctions are another area of concern, often resulting from faulty wiring or component failure. Short circuits and power surges can lead to unexpected shutdowns, disrupting workflow. Ensuring that the electrical systems are regularly checked and updated can greatly reduce the likelihood of these issues.

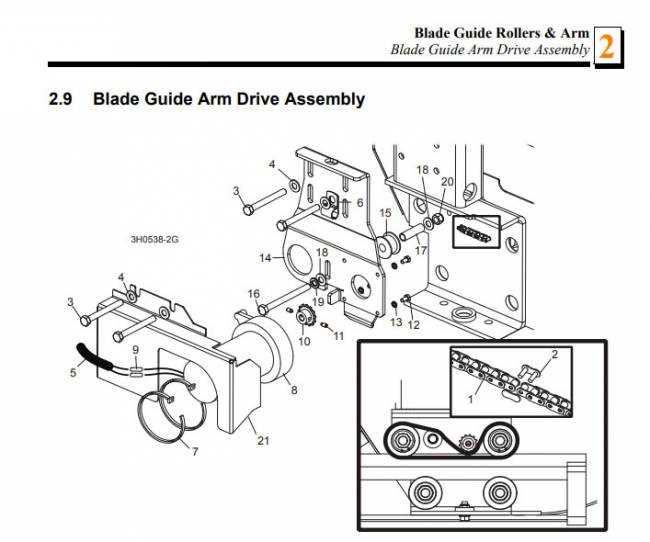

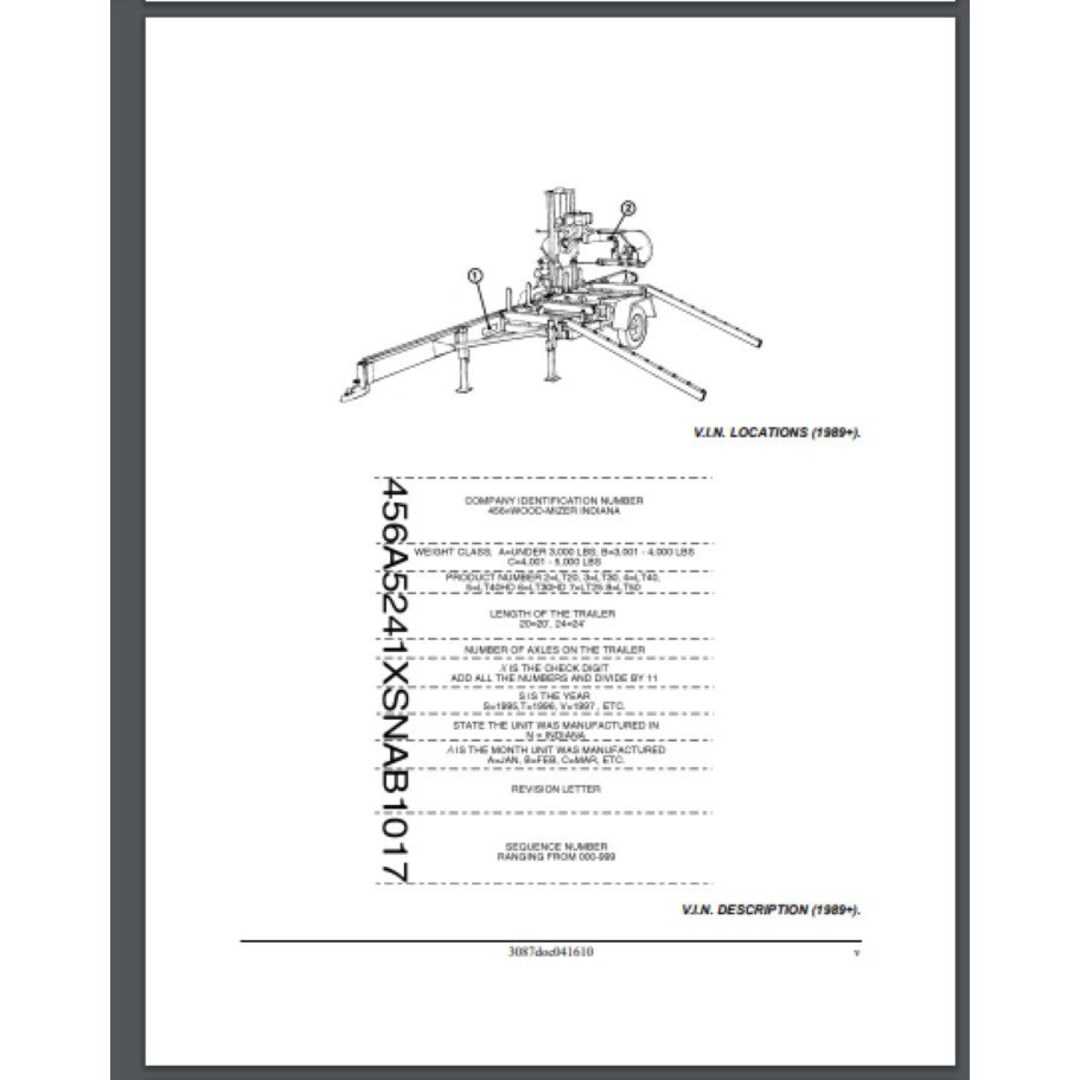

How to Read Parts Diagrams

Understanding visual representations of components can greatly enhance your ability to assemble or repair equipment. By familiarizing yourself with these illustrations, you can quickly identify each element and its function within the system. This knowledge is essential for effective maintenance and troubleshooting.

Identifying Components

Begin by locating the key parts, usually marked with numbers or letters. Each symbol corresponds to a specific item, allowing for easy reference. Pay attention to any accompanying legends or notes that clarify the function of each piece.

Understanding Relationships

Next, observe how the various elements interact. Arrows or lines often indicate connections, showing how parts fit together or function as a whole. Recognizing these relationships is crucial for successful assembly and repair.

Where to Find Replacement Parts

When it comes to maintaining and repairing machinery, locating the right components is essential for optimal performance. Many sources are available to help you track down the necessary items to keep your equipment running smoothly.

Official Distributors

Authorized vendors often provide a comprehensive selection of components, ensuring quality and compatibility. Checking their websites or contacting them directly can yield valuable information on availability and pricing.

Online Marketplaces

Web platforms that specialize in machinery can be a treasure trove for finding specific components. User reviews and ratings can guide you to reliable sellers, making your search efficient and effective.

Benefits of Using Original Components

Utilizing genuine components in machinery is essential for ensuring optimal performance and longevity. These authentic parts are designed specifically for compatibility and reliability, providing significant advantages over generic alternatives. When investing in equipment, choosing original components can lead to enhanced efficiency and reduced maintenance costs over time.

Quality Assurance

Original components undergo rigorous testing to meet high standards of quality and safety. This dedication to excellence means users can trust in their durability and functionality, ultimately leading to fewer breakdowns and a smoother operation.

Improved Performance

Genuine components are engineered to work harmoniously with the entire system, enhancing overall performance. This integration helps maintain the equipment’s intended specifications and operational efficiency, contributing to better productivity and lower energy consumption.

| Benefit | Description |

|---|---|

| Durability | Manufactured from high-quality materials to withstand wear and tear. |

| Compatibility | Designed to fit seamlessly with existing systems, ensuring optimal functionality. |

| Warranty Support | Original components often come with warranties, providing peace of mind. |

| Resale Value | Equipment with original components typically retains higher resale value. |

Upgrading Your Wood-Mizer Equipment

Enhancing your milling machinery can significantly improve efficiency and output quality. By investing in modern upgrades, you can boost performance, increase reliability, and extend the lifespan of your equipment. Whether it’s through the integration of advanced technology or the addition of new components, each modification can contribute to a more productive workflow.

Benefits of Modern Enhancements

Implementing new features can lead to improved accuracy in cuts, reduced operational downtime, and greater energy efficiency. Upgrades such as automated controls and enhanced safety mechanisms not only streamline processes but also protect the operator. Additionally, regular improvements ensure that your equipment remains competitive in a fast-evolving industry.

Selecting the Right Modifications

When considering enhancements, it’s essential to evaluate the specific needs of your operation. Assess current limitations and identify which areas would benefit the most from upgrades. Consulting with industry professionals can provide valuable insights into the most effective solutions tailored to your setup, ensuring you make informed decisions that align with your goals.