The functionality of any clamping mechanism relies on a variety of essential elements that work together seamlessly. A thorough understanding of these components is crucial for effective maintenance and operation. This guide aims to illuminate the intricate relationships between the different sections of these devices, helping users appreciate their design and utility.

By examining the layout of each piece, users can gain insights into how to enhance performance and longevity. Identifying the specific functions of every component enables better troubleshooting and repairs, making it easier to address issues as they arise. Whether you’re a seasoned professional or a novice, this exploration will equip you with valuable knowledge.

Moreover, recognizing the importance of each individual element contributes to safer and more efficient usage. Proper assembly and disassembly are paramount, and understanding the connections between these elements can prevent potential mishaps. This detailed analysis serves as a valuable resource for anyone looking to maximize the effectiveness of their clamping apparatus.

Understanding Wilton Vise Components

Grasping the intricacies of tool mechanisms is essential for effective usage and maintenance. Each element plays a vital role in ensuring that the assembly operates smoothly and efficiently. By familiarizing oneself with these components, users can enhance their experience and prolong the lifespan of their equipment.

Key Elements

Several fundamental elements contribute to the overall functionality of these tools. Each component has a specific role that supports the device’s operational capacity.

| Component | Description |

|---|---|

| Body | The main structure providing stability and support. |

| Jaws | Parts that grip and hold the materials securely. |

| Screw Mechanism | Allows for the adjustment and movement of the jaws. |

| Base | Offers a sturdy foundation, ensuring the tool remains stationary during use. |

Importance of Understanding Components

Recognizing the significance of each part leads to better maintenance practices and more effective usage. This knowledge empowers users to troubleshoot issues and make informed decisions about repairs and upgrades.

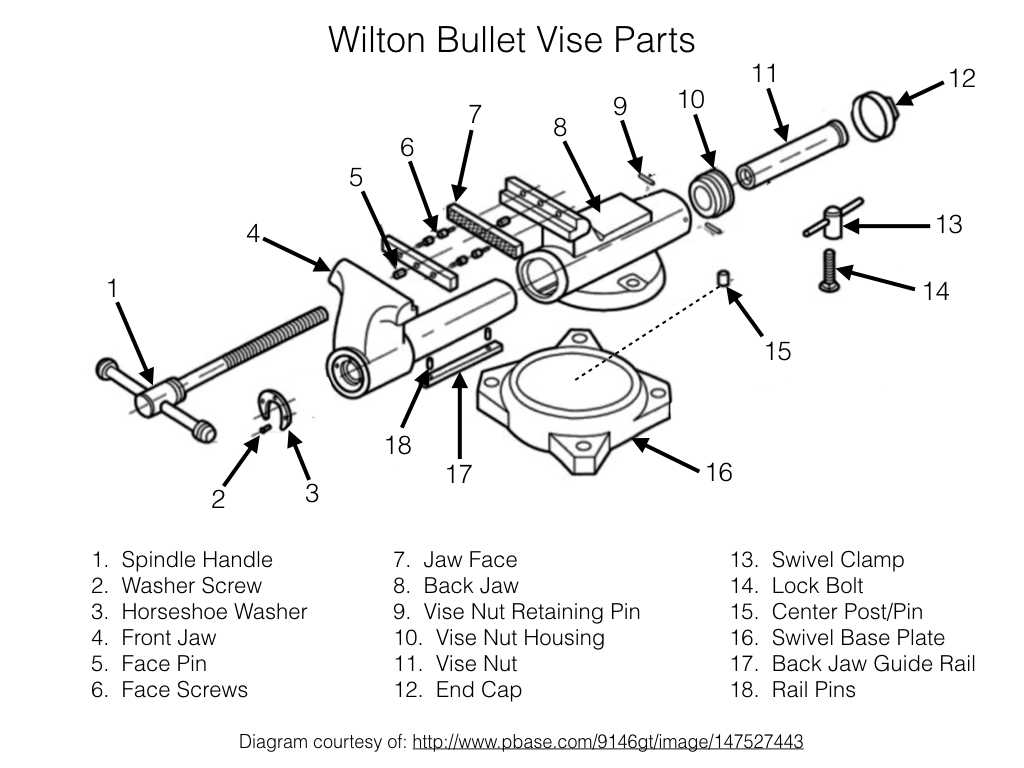

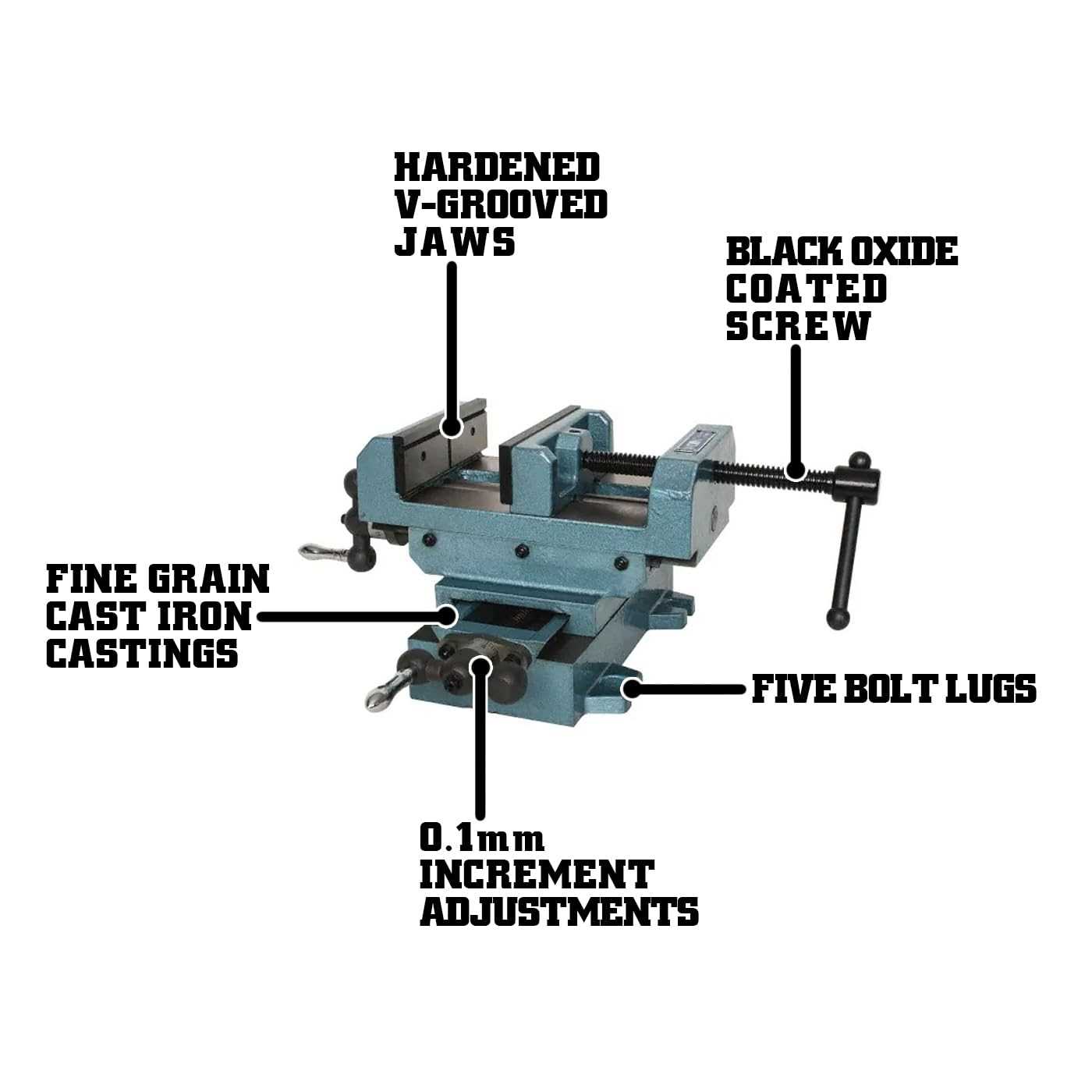

Essential Parts of a Wilton Vise

Understanding the critical components of a sturdy clamping tool is vital for effective operation and maintenance. Each element plays a unique role in ensuring precision and durability, allowing users to achieve optimal performance during various tasks. This section highlights the fundamental elements that contribute to the functionality of this indispensable workshop accessory.

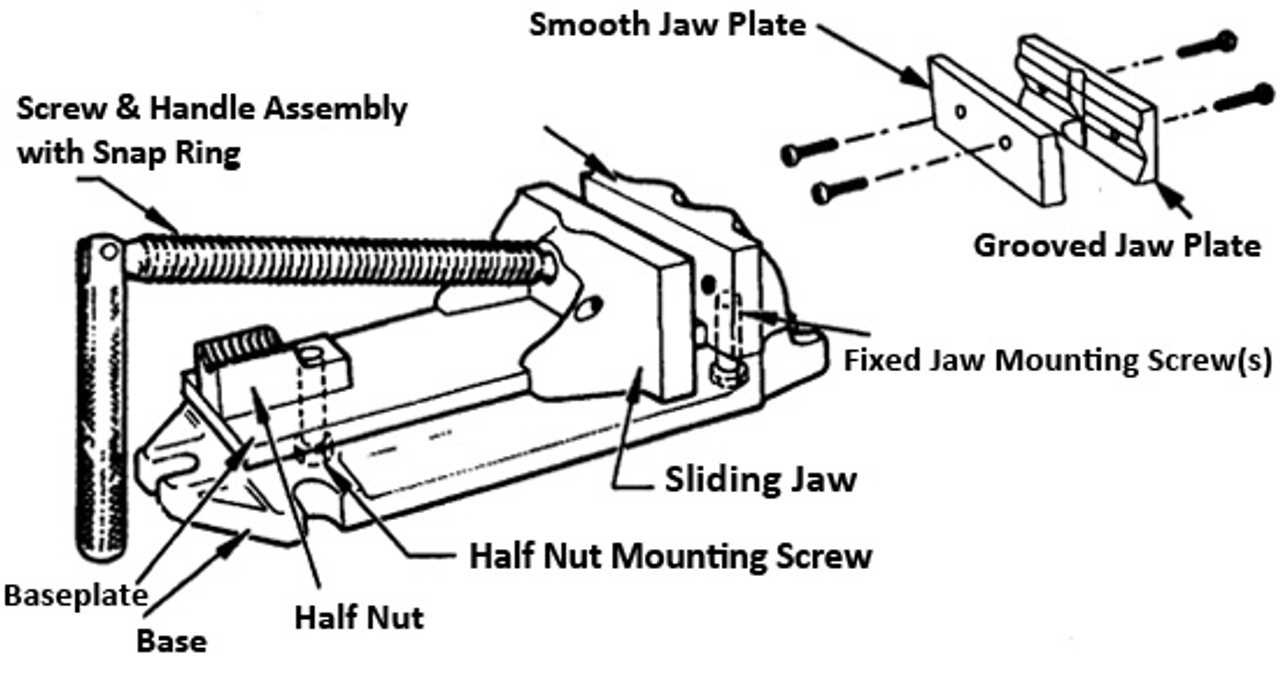

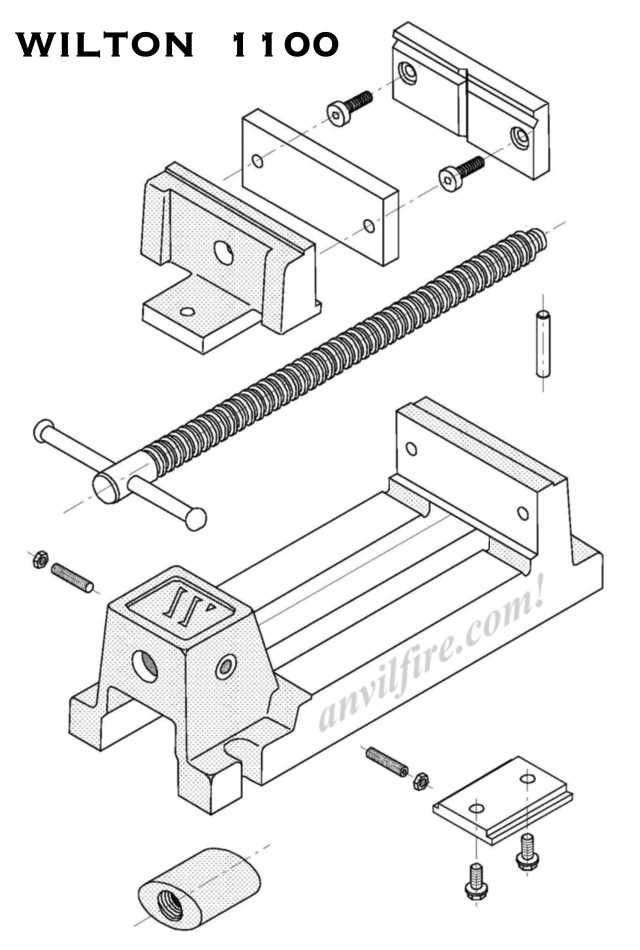

Main Components

The primary structure includes a robust frame designed to withstand heavy pressure and frequent use. This framework is complemented by movable jaws that provide secure gripping capabilities. The alignment of these jaws is crucial for achieving uniform clamping, and they often come with a textured surface to enhance grip.

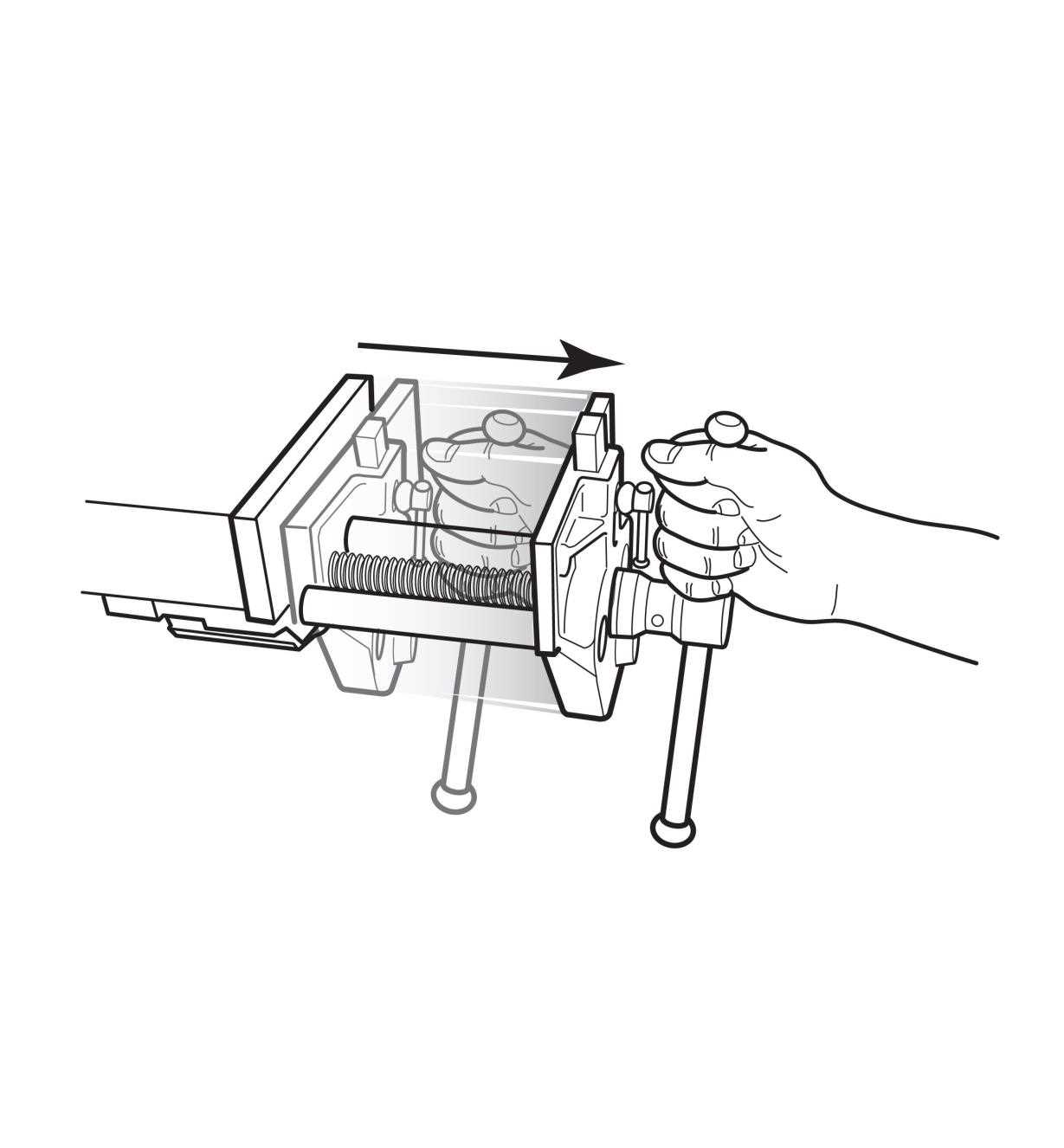

Efficient adjustment systems facilitate easy manipulation of the movable sections. A reliable screw mechanism allows for smooth operation, enabling users to quickly tighten or loosen the jaws as needed. Additionally, a locking feature is essential for maintaining stability during tasks, preventing any unwanted movement.

In summary, familiarity with these essential components ensures not only the effective use of the tool but also enhances longevity and reliability in various applications.

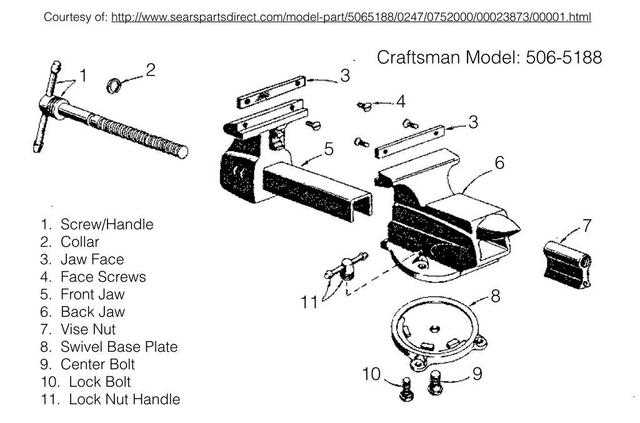

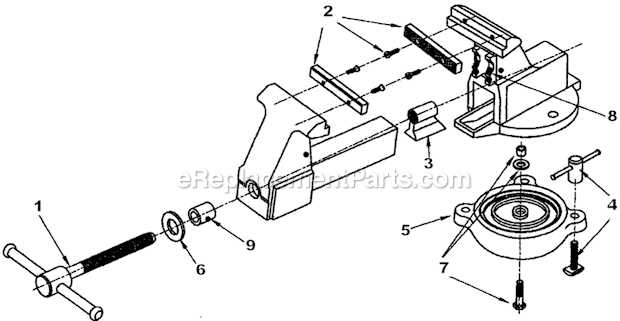

How to Read a Vise Diagram

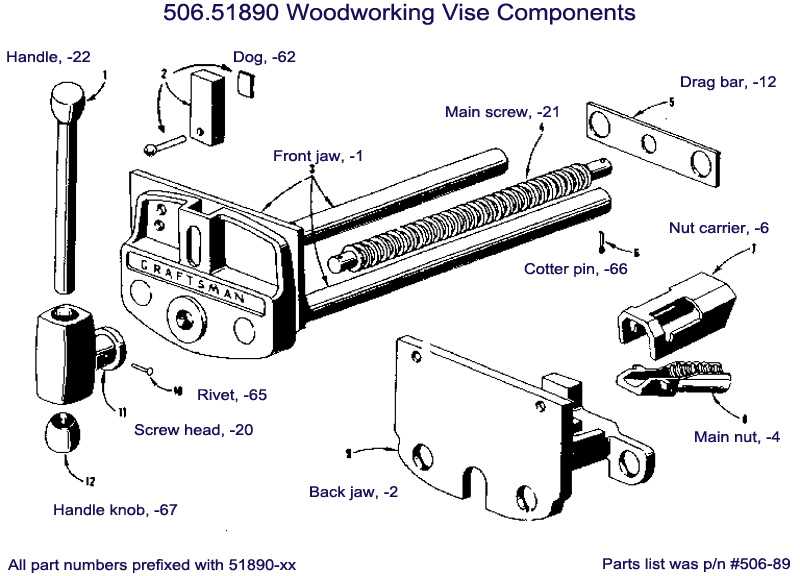

Understanding a visual representation of tools and their components is essential for effective maintenance and repair. Familiarizing yourself with the layout and labels within such illustrations allows for more efficient problem-solving and assembly.

Here are key steps to effectively interpret these visuals:

- Identify Main Elements: Start by locating the primary components. These are typically marked clearly and may include essential features of the tool.

- Examine Labels: Pay attention to the text or numbers associated with each section. These designations often correspond to specific components or functions.

- Look for Relationships: Observe how different parts connect or interact. This understanding is crucial for proper assembly or disassembly.

- Refer to a Legend: Many illustrations include a key or legend that explains symbols or abbreviations used. Always consult this for clarity.

- Follow Instructions Sequentially: If the visual is part of a guide, follow the steps in the order presented. This ensures that you don’t miss any critical actions.

By mastering these techniques, you will enhance your ability to navigate and utilize these useful representations effectively.

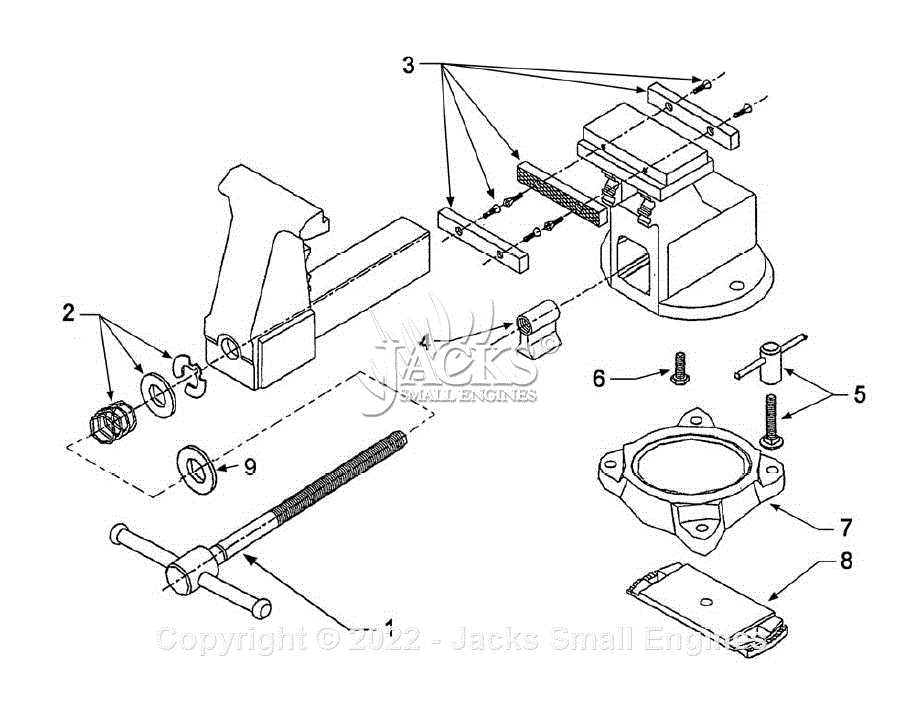

Common Issues with Vise Parts

Every tool can encounter challenges that affect its functionality and longevity. Understanding these common complications can significantly enhance your experience and ensure efficient operation. Identifying symptoms early allows for prompt resolution and maintenance.

Frequent Problems

Several recurring issues often arise, impacting usability and performance:

| Issue | Description |

|---|---|

| Worn Threads | Stripped or damaged threads can hinder smooth adjustments and secure gripping. |

| Rust Formation | Corrosion can impede movement and compromise structural integrity, requiring careful cleaning. |

| Misalignment | Components that are not properly aligned can lead to ineffective clamping and uneven pressure. |

Preventive Measures

Regular maintenance, including lubrication and inspection, can mitigate many of these issues. Addressing problems proactively ensures optimal performance and extends the tool’s lifespan.

Replacing Wilton Vise Components

Maintaining and refreshing your clamping tool is essential for optimal performance. Over time, certain elements may wear down, affecting functionality and precision. This section will guide you through the process of swapping out these crucial components, ensuring your equipment operates at its best.

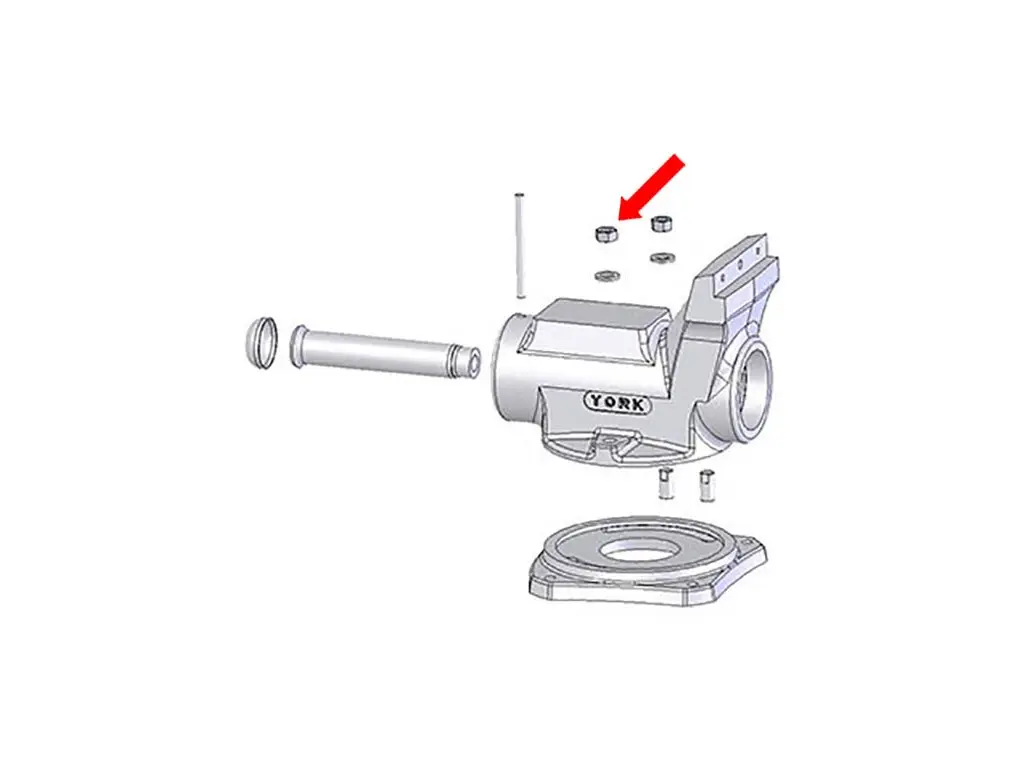

Identifying the Necessary Components is the first step. Inspect the tool for any signs of damage or excessive wear, focusing on the movable jaw, threaded rod, and base. Once identified, sourcing high-quality replacements will enhance durability and efficiency.

Disassembly and Reassembly requires attention to detail. Carefully remove the worn components, taking note of their arrangement. This will help streamline the installation of new pieces, ensuring a seamless fit and restoring your tool’s functionality.

Lastly, regular maintenance post-replacement is crucial. Lubricate moving parts and tighten all connections to prolong the lifespan of your tool. This proactive approach will lead to improved performance and reliability.

Maintenance Tips for Longevity

Ensuring the prolonged functionality of your tool requires regular care and attention. By implementing a few simple practices, you can significantly extend its lifespan, keeping it in optimal condition for years to come. The following tips will help maintain efficiency and prevent wear over time.

Regular Cleaning

Keeping the surface clean is essential. Accumulation of dust, debris, and grime can lead to rust and deterioration. Use a soft cloth and appropriate cleaning solutions to wipe down surfaces after each use. Pay special attention to hard-to-reach areas where dirt can accumulate unnoticed.

Lubrication and Inspection

Regularly lubricating moving parts minimizes friction and prevents damage. Use a high-quality lubricant and apply it according to the manufacturer’s recommendations. Additionally, inspect components frequently for signs of wear or damage. Early detection can save you from costly repairs down the line.

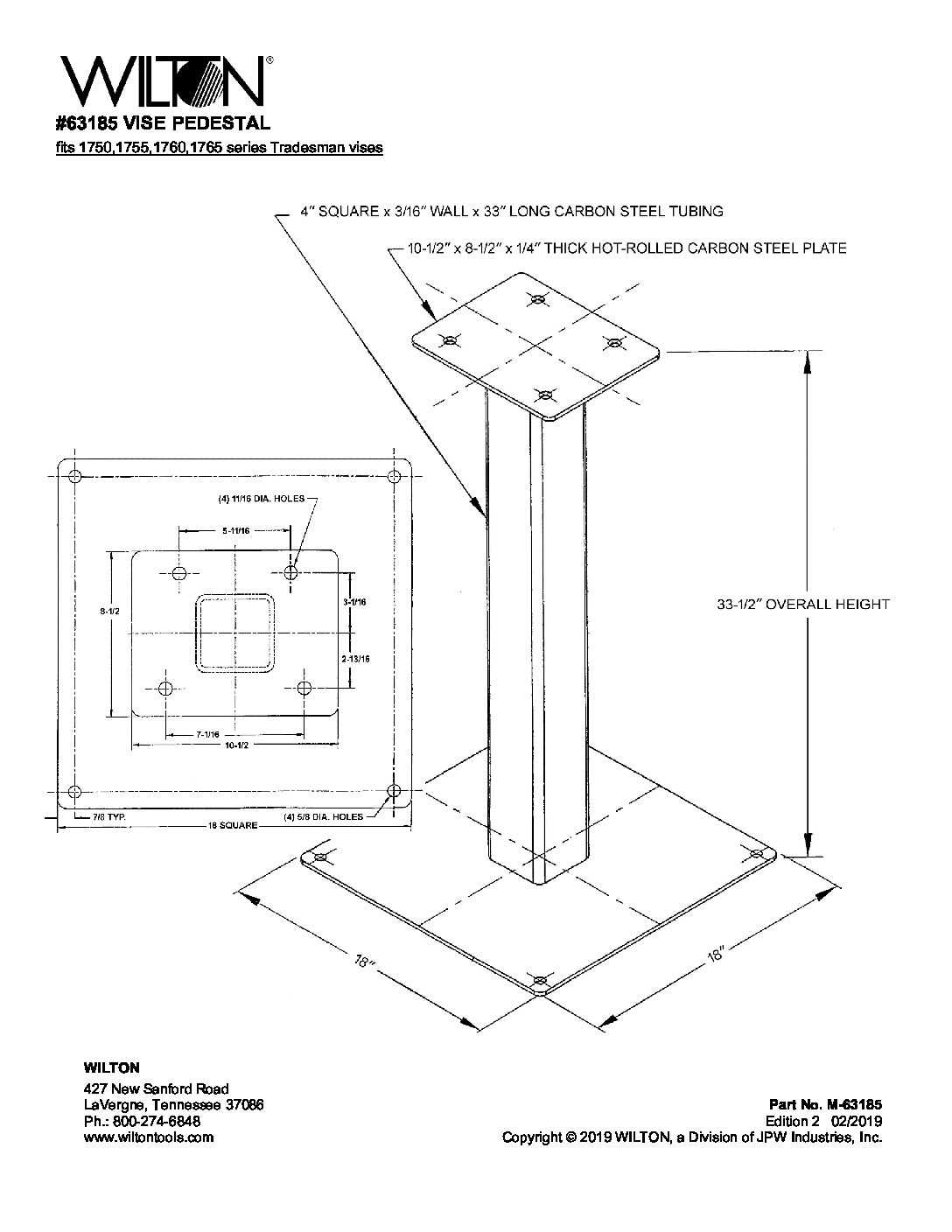

Choosing the Right Vise Model

Selecting the appropriate tool for your workspace can significantly enhance productivity and efficiency. Understanding your specific needs and the tasks you plan to undertake is crucial in making an informed decision. This section aims to guide you through the considerations necessary to find the ideal option for your projects.

First and foremost, assess the types of materials you will be working with. Different models are designed for various applications, and recognizing your primary materials will help narrow down your choices. Consider whether you require a robust grip for heavy-duty tasks or a more delicate approach for intricate work.

Another critical factor is the size and space available in your workshop. Ensure that the model you select fits comfortably within your workspace without sacrificing functionality. Evaluate the weight and portability if you plan to move the tool frequently.

Lastly, budget constraints will play a role in your selection. It’s essential to balance quality and cost to ensure you invest in a reliable option that meets your needs without exceeding your financial limits. Researching different brands and reading reviews can provide valuable insights into durability and performance.

Benefits of Using Quality Vises

Investing in high-quality clamping tools offers numerous advantages for both professionals and hobbyists. These durable implements enhance precision, stability, and overall efficiency during various projects, making them essential for anyone who values craftsmanship and reliability.

Improved Stability and Precision

High-grade models are designed to provide exceptional stability, allowing users to secure materials firmly in place. This feature minimizes movement, ensuring accurate cuts and alignments. As a result, the finished product exhibits a higher level of quality, reducing the likelihood of errors and rework.

Enhanced Durability and Longevity

Investing in superior models means enjoying long-lasting performance. Quality materials and construction methods resist wear and tear, ensuring that these tools remain functional for years. This durability not only saves money in the long run but also contributes to consistent performance across various applications.

Where to Find Replacement Parts

Locating suitable components for your tools can be a straightforward task with the right approach. Whether you need to repair an essential fixture or enhance its functionality, various resources are available to assist you in your search for the necessary items.

Online Retailers are often the first stop for many users. Numerous e-commerce platforms specialize in tool accessories and can provide a wide selection of items. A quick search can yield numerous options, often with customer reviews to help you make informed decisions.

Local Hardware Stores can also be a valuable resource. These establishments may carry a limited stock of accessories or be able to order specific components for you. Speaking directly with knowledgeable staff can provide insights into the best solutions for your needs.

Manufacturer Websites typically offer a comprehensive catalog of available items. By visiting the official site, you can find detailed information about compatible components, ensuring that you select the right match for your tool.

Specialized Forums and Community Groups often serve as platforms for enthusiasts and professionals alike to share experiences and recommendations. Engaging in these communities can lead you to rare finds or useful advice on where to source particular items.

By utilizing these resources, you can effectively track down the components necessary to keep your equipment in optimal condition.