In the world of heavy machinery, comprehending the intricate layout and functionality of various components is essential for efficient operation and maintenance. This section delves into the essential elements that contribute to the performance of these versatile machines, providing a visual representation that enhances understanding.

Effective maintenance hinges on the ability to identify and manage individual elements within the machinery. By familiarizing oneself with the arrangement and interconnections of these crucial parts, operators can ensure longevity and optimal performance. A clear representation serves as a valuable tool for both seasoned professionals and newcomers alike.

Furthermore, grasping the structure of these machines can significantly reduce downtime and improve troubleshooting capabilities. This knowledge empowers users to perform repairs and replacements with confidence, ultimately leading to greater productivity and efficiency in various tasks.

Understanding Cat Skid Steer Components

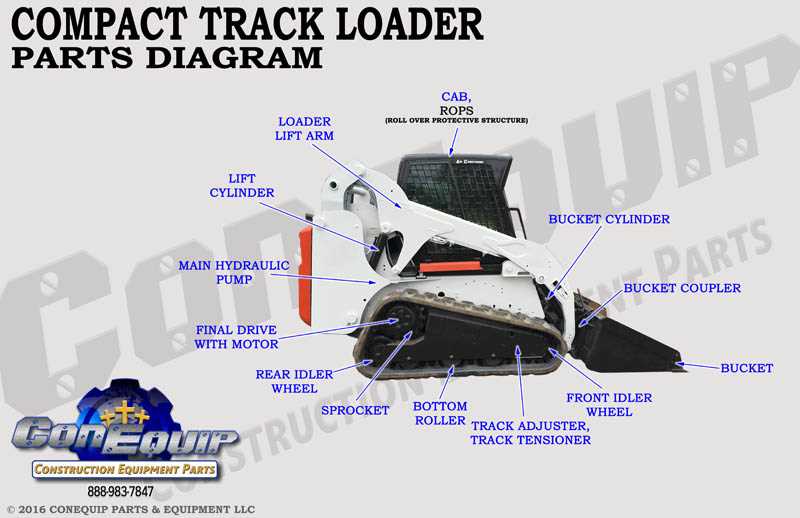

Familiarity with the various elements that comprise compact machinery is essential for effective operation and maintenance. Each component plays a pivotal role in ensuring optimal functionality, enabling users to tackle diverse tasks with precision. This knowledge not only aids in troubleshooting but also enhances overall efficiency during use.

Main Functional Elements

The primary components of this machinery include the hydraulic system, engine, and drive mechanism. The hydraulic system is crucial for powering attachments and performing heavy lifting, while the engine provides the necessary power to drive the machine. Additionally, the drive mechanism ensures smooth mobility and maneuverability, making it easier to navigate various terrains.

Maintenance and Care

Regular upkeep of these essential components is vital to prolonging the lifespan of the equipment. Routine inspections and maintenance practices help identify potential issues before they escalate, ensuring that each part functions as intended. Understanding the role of each element not only fosters better maintenance practices but also empowers operators to make informed decisions about repairs and replacements.

Key Features of Cat Skid Steers

These compact and versatile machines have gained popularity in various industries due to their remarkable design and functionality. Their unique characteristics make them indispensable for tasks ranging from construction to landscaping.

Robust Performance: Engineered to deliver exceptional power, these machines can handle heavy loads and challenging terrains with ease. Their high torque and efficient engines ensure optimal productivity.

Compact Design: The small footprint allows for maneuverability in tight spaces, making them ideal for urban construction sites and residential areas. Their agile nature enhances operational efficiency.

Versatile Attachments: A wide range of attachments can be used, allowing for diverse applications. From buckets to augers, these tools enable users to tackle various tasks without the need for multiple machines.

Operator Comfort: Designed with the user in mind, the ergonomic cab provides excellent visibility and comfort. Features such as adjustable seating and intuitive controls enhance the overall operating experience.

Durability: Built with high-quality materials, these machines are designed to withstand the rigors of heavy-duty use. Their robust construction ensures longevity and reliability in demanding environments.

Importance of Maintenance for Longevity

Regular upkeep is crucial for ensuring the durability and efficiency of any machinery. Proper maintenance not only extends the lifespan of the equipment but also enhances its performance, minimizing the risk of unexpected failures. Understanding the significance of consistent care can lead to better operational reliability and cost savings over time.

Benefits of Regular Upkeep

Engaging in routine servicing provides numerous advantages. Timely inspections can identify potential issues before they escalate, allowing for proactive measures. Additionally, adhering to a maintenance schedule can significantly improve the overall functionality, ensuring that the machinery operates at peak performance. This approach not only preserves the investment but also contributes to smoother operations in various tasks.

Consequences of Neglect

Failing to maintain equipment can result in serious repercussions. Neglected machinery is prone to wear and tear, leading to costly repairs and downtime. Over time, this neglect can diminish productivity and increase operational risks, creating a cycle of inefficiency. Prioritizing maintenance is essential to avoid these pitfalls and to ensure a reliable and long-lasting performance.

Identifying Common Replacement Parts

Understanding the essential components of heavy machinery is crucial for effective maintenance and operation. Recognizing frequently needed elements can streamline repairs and enhance productivity.

Key Components to Monitor

Regular inspections should focus on a few vital elements that often require attention. These components play a significant role in overall functionality and efficiency.

| Component | Function | Signs of Wear |

|---|---|---|

| Hydraulic Cylinder | Facilitates lifting and moving | Leaking fluid, decreased performance |

| Transmission Filter | Ensures clean fluid for gear operation | Reduced responsiveness, unusual noises |

| Drive Belts | Transfers power to various systems | Cracks, fraying, squeaking sounds |

Replacement Guidelines

When replacing any component, it’s vital to consult the manufacturer’s recommendations. This ensures compatibility and optimal performance for the equipment.

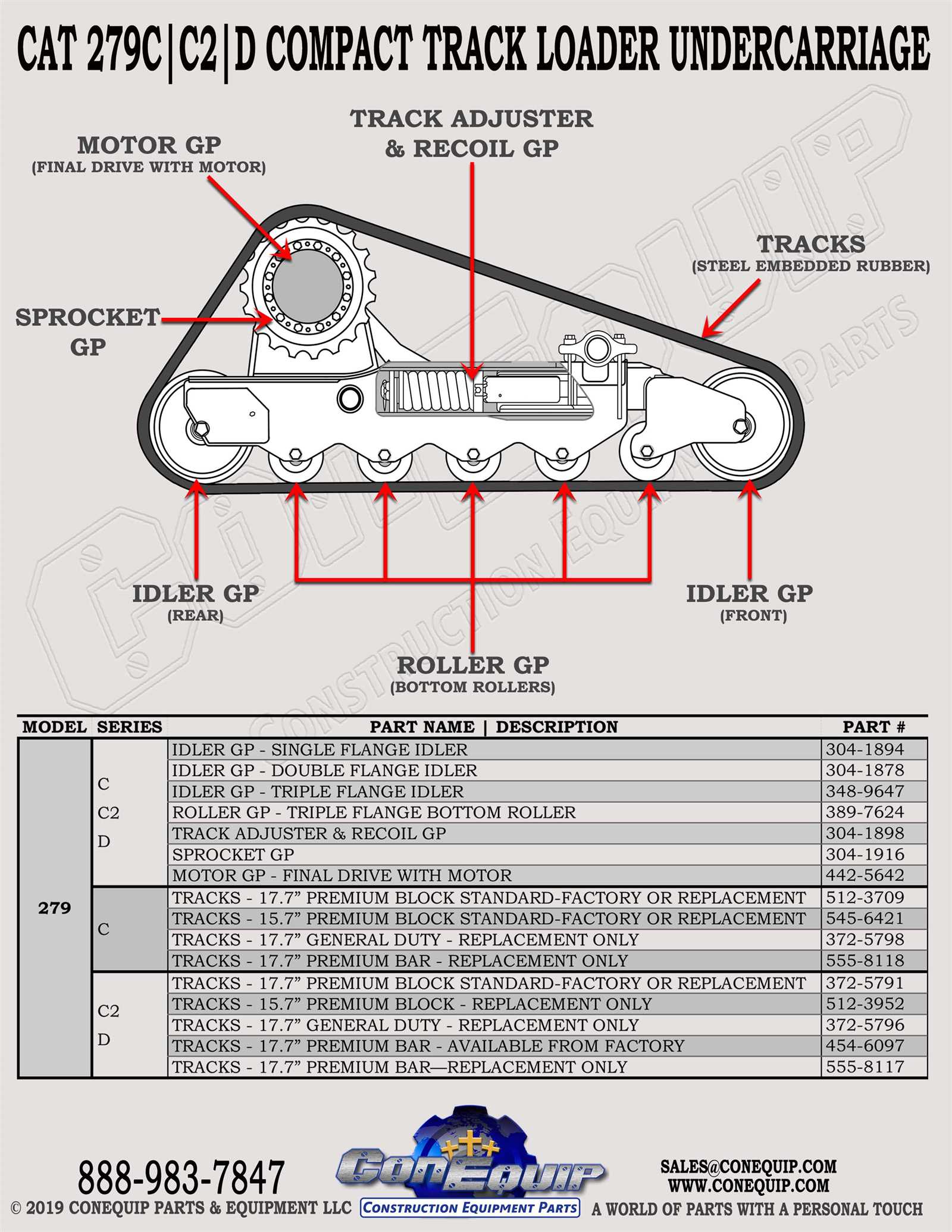

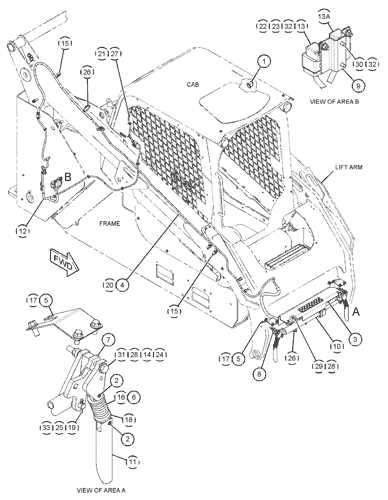

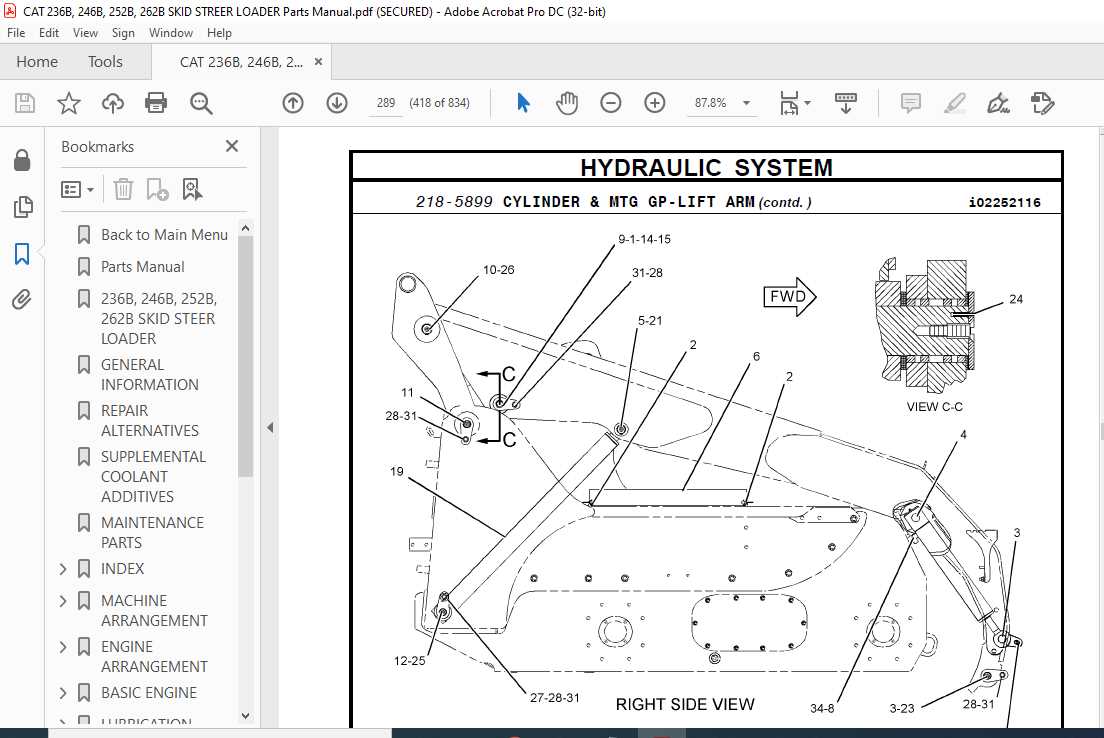

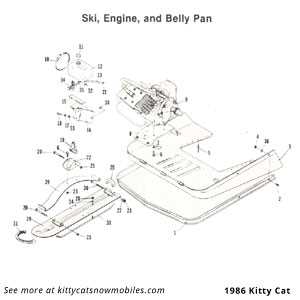

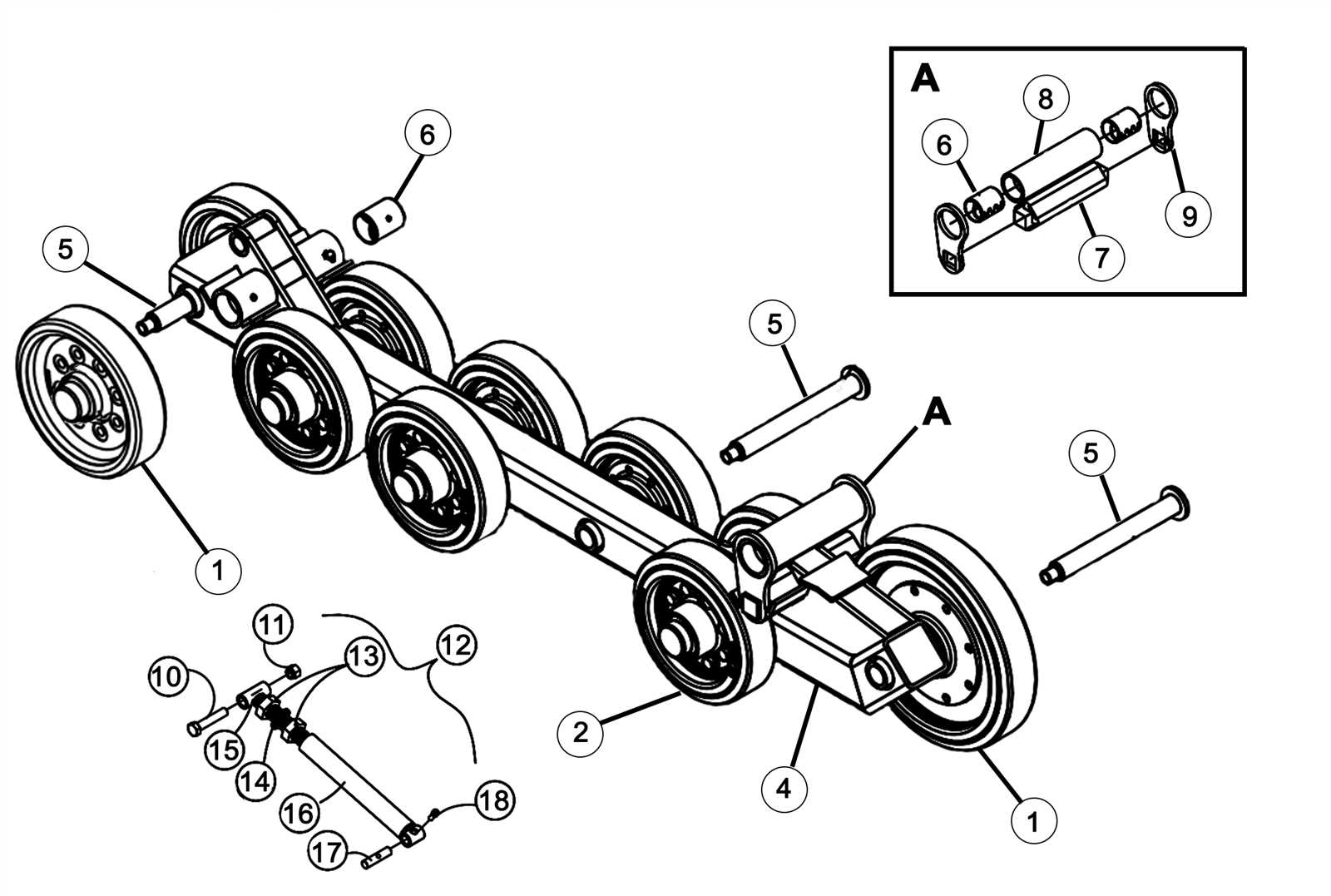

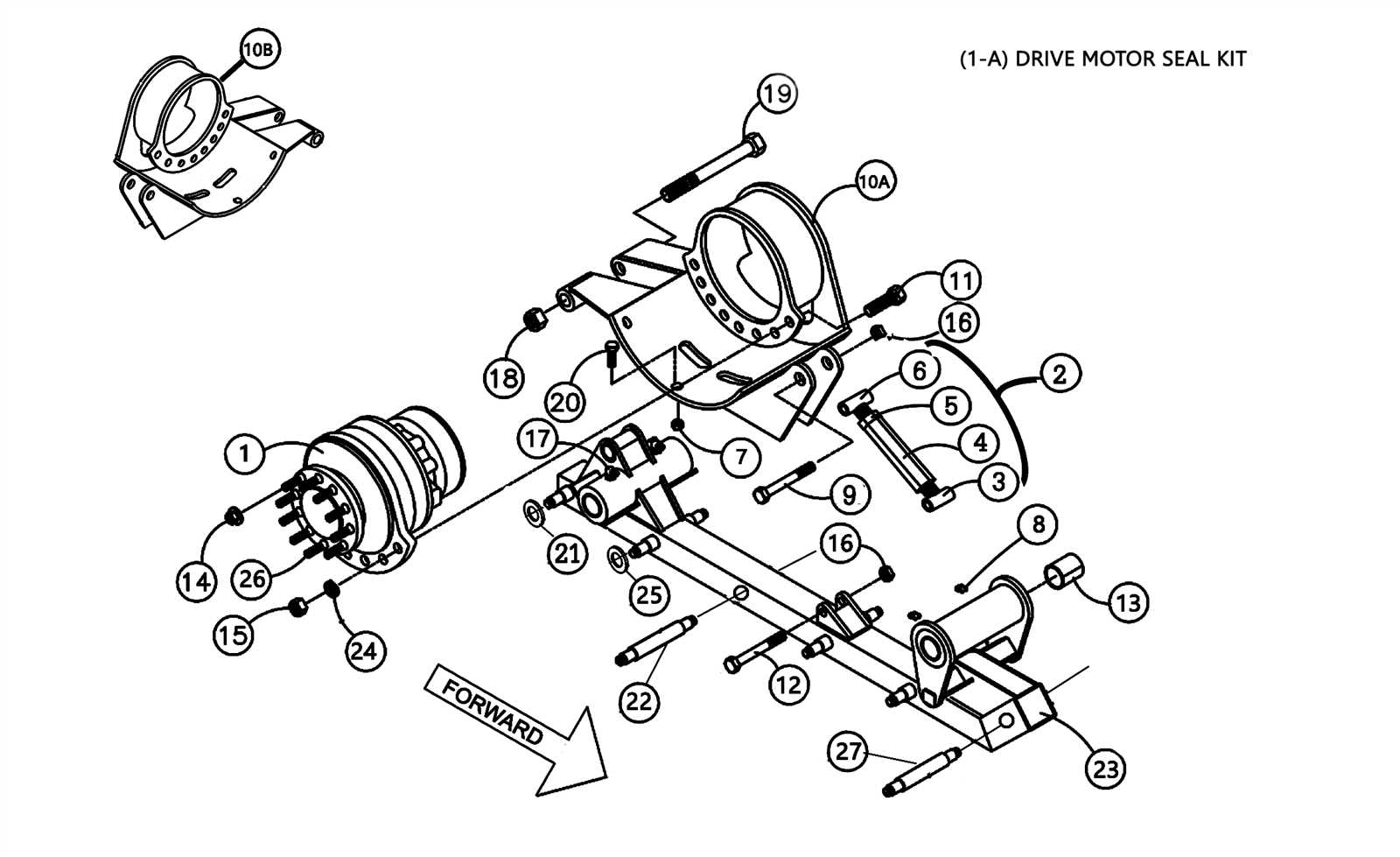

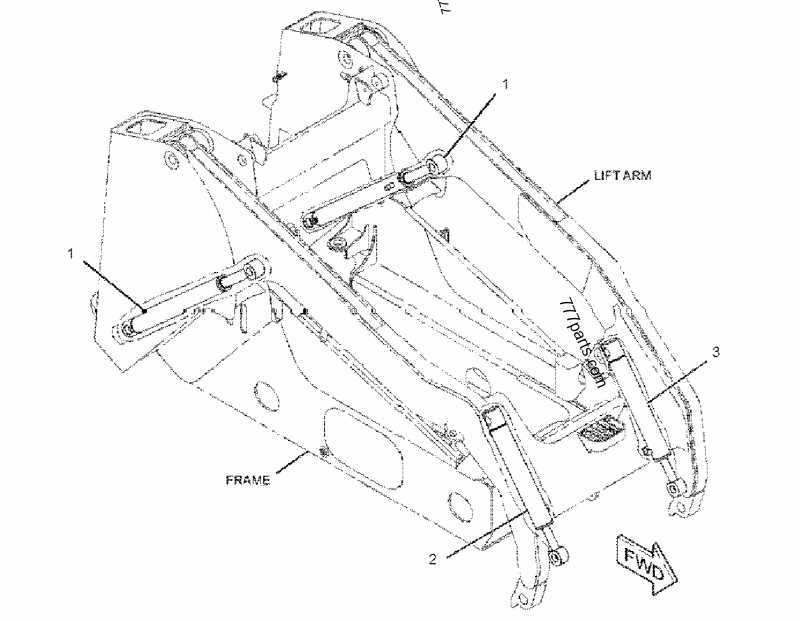

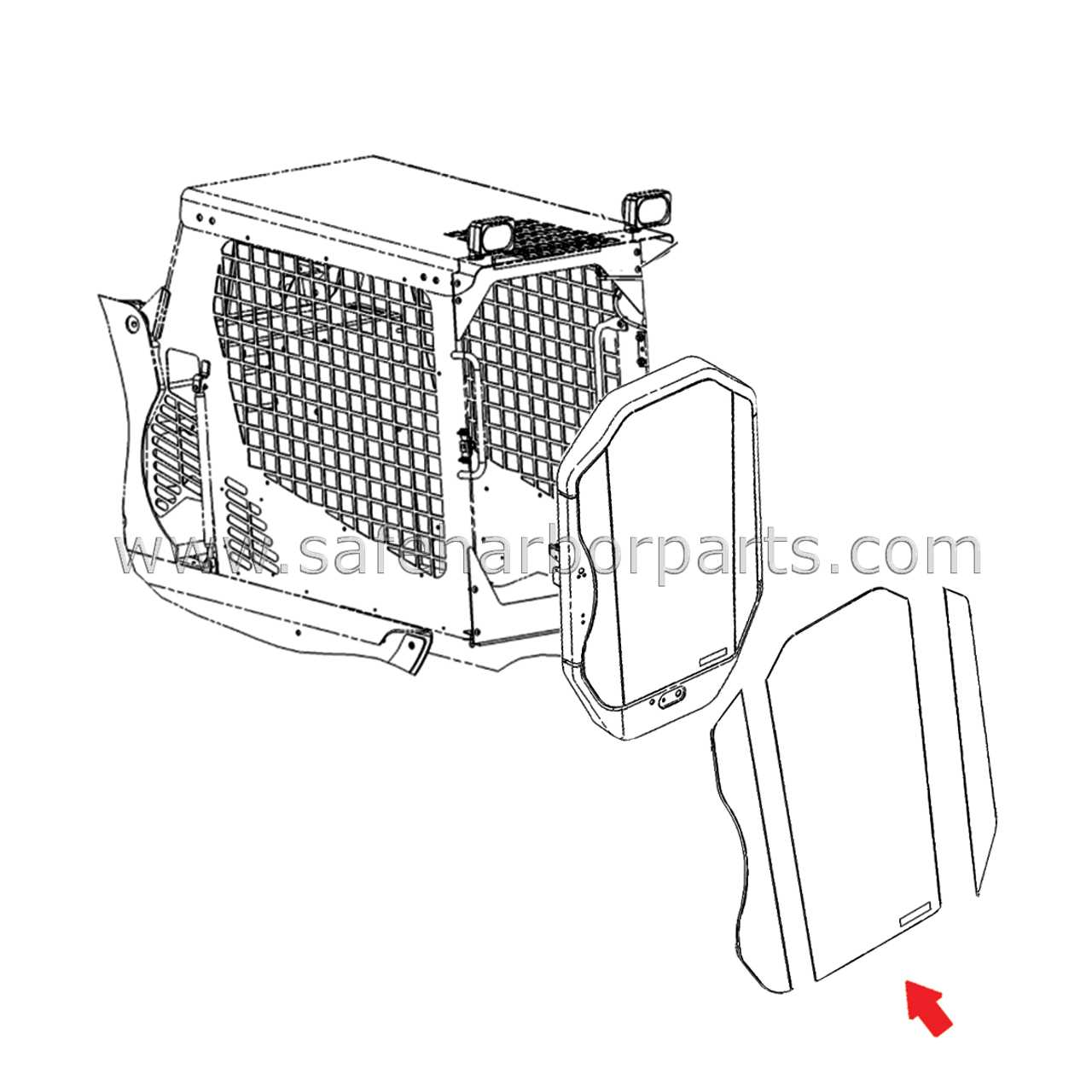

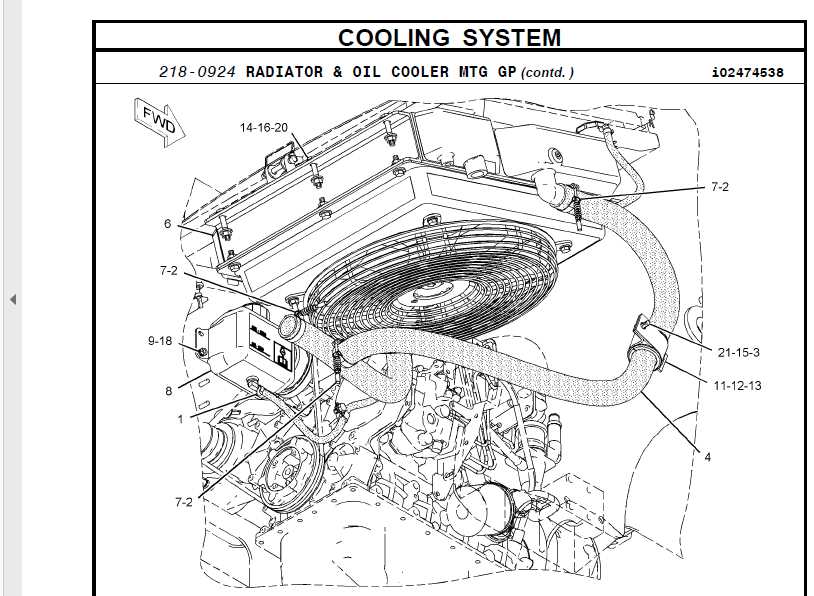

How to Read a Parts Diagram

Understanding a component illustration is essential for effective maintenance and repair. These visual aids provide a detailed representation of various elements, allowing users to identify and locate specific items quickly. Familiarity with such diagrams can streamline the troubleshooting process and ensure accurate reassembly after servicing.

Familiarizing with Symbols and Labels

Each illustration typically includes a variety of symbols and labels that denote different components. Take time to study these elements, as they serve as a key to deciphering the overall layout. Commonly, numbers or letters are used to reference parts, which can be cross-referenced with a parts list for clarity. Recognizing these markers will enhance your ability to navigate the illustration effectively.

Understanding Assembly and Orientation

In addition to identifying individual elements, it’s crucial to grasp how these pieces fit together within the larger system. Pay attention to the orientation and relationships between components. Visualizing how each part interacts will aid in both disassembly and reassembly, minimizing the risk of errors. Always refer back to the illustration throughout your maintenance tasks to ensure accuracy and efficiency.

Where to Find Genuine Cat Parts

Finding authentic components for your machinery is essential for maintaining performance and longevity. Many options are available to ensure you acquire quality replacements that fit your equipment seamlessly.

Authorized Dealers: Visiting certified distributors is one of the most reliable methods. These locations offer a selection of genuine items and can provide expert advice on compatibility.

Official Websites: Manufacturer websites often feature online catalogs where you can search for the exact components you need. This ensures you have access to the latest products and specifications.

Online Marketplaces: Reputable platforms can also be a resourceful avenue. Look for sellers with high ratings and positive reviews to guarantee authenticity.

Local Repair Shops: Many local service centers specialize in machinery repairs and can source genuine components for you. Establishing a relationship with these shops can lead to trustworthy recommendations.

Tips for Ordering Replacement Parts

When it comes to acquiring necessary components for machinery, understanding the process can significantly enhance efficiency and reduce downtime. Proper preparation and knowledge are key to ensuring that you obtain the correct items swiftly.

1. Know Your Model: Always have the model number and specifications handy. This information is crucial for identifying the right components.

2. Use Reliable Sources: Choose reputable suppliers or manufacturers to ensure quality and authenticity of the items.

3. Double-Check Compatibility: Before finalizing your order, verify that the items are compatible with your equipment to avoid unnecessary returns.

4. Consider Bulk Orders: If you frequently require specific components, ordering in bulk can save time and costs in the long run.

5. Keep a Maintenance Log: Maintaining a record of replacements and repairs can help you anticipate future needs and streamline the ordering process.

Common Issues and Troubleshooting Guide

Understanding potential challenges and their solutions is essential for maintaining equipment efficiency. This guide provides insights into frequently encountered problems, enabling operators to diagnose and resolve issues swiftly. Recognizing symptoms early can prevent more significant malfunctions and ensure smooth operation.

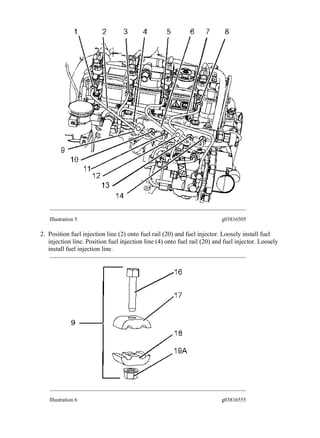

Engine Performance Problems

One of the most prevalent issues involves engine performance. Symptoms such as stalling, rough idling, or decreased power output may indicate fuel delivery problems or air filter obstructions. Regular inspection of fuel lines and replacing clogged filters can significantly enhance engine performance and reliability.

Hydraulic System Failures

Hydraulic system failures can manifest as slow or unresponsive controls. Common causes include fluid leaks, low hydraulic fluid levels, or worn-out seals. Checking fluid levels regularly and ensuring all connections are secure can prevent costly repairs and extend the lifespan of hydraulic components.