Exploring the inner workings of your machinery can be both enlightening and essential for effective maintenance. Knowing how components interact not only enhances functionality but also extends the lifespan of your tools. A well-structured overview of these elements can empower users to troubleshoot issues with confidence.

In this section, we will delve into the intricate relationships between various components, highlighting their roles and how they contribute to overall performance. By grasping these connections, operators can ensure their devices operate at ultimate efficiency.

Additionally, visual aids can serve as invaluable resources, providing clarity and facilitating a deeper understanding of assembly and disassembly processes. With this knowledge, maintaining and optimizing your equipment becomes a straightforward task, ensuring reliability when you need it most.

Kobalt Air Compressor Overview

This section explores a popular tool designed to convert energy into potential energy, allowing users to perform various tasks efficiently. It serves multiple applications, making it an essential item in workshops and construction sites.

The equipment features a robust design that enhances durability and performance. Users can find various specifications tailored to meet different requirements, whether for light-duty or heavy-duty usage.

| Model | Power (HP) | Tank Size (Gallons) | Max PSI |

|---|---|---|---|

| Model A | 1.5 | 6 | 125 |

| Model B | 2.0 | 10 | 150 |

| Model C | 3.0 | 20 | 175 |

Understanding the functionalities and specifications allows users to select the most suitable variant for their needs, enhancing both efficiency and productivity.

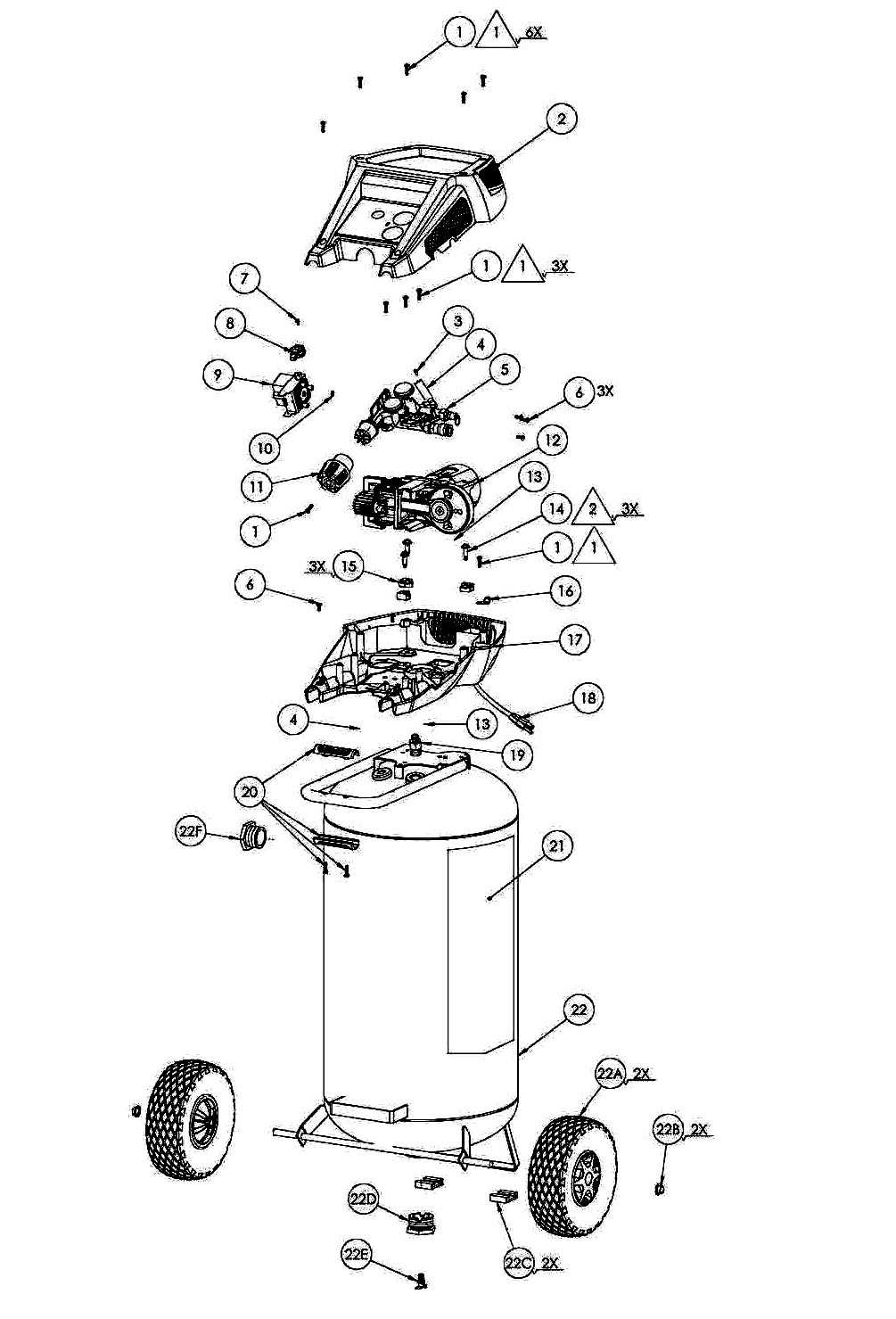

Understanding Compressor Components

Grasping the fundamental elements of a pressurizing system is essential for efficient operation and maintenance. Each component plays a critical role in the overall functionality, ensuring optimal performance and longevity. Familiarity with these individual parts can enhance troubleshooting skills and improve user experience.

Key components typically include:

- Piston: A vital piece that compresses the gas, converting it into a higher-pressure state.

- Motor: The driving force that powers the entire mechanism, providing the necessary energy for operation.

- Tank: A storage unit that holds the compressed gas, allowing for a steady supply during usage.

- Regulator: This component controls the output pressure, ensuring it remains within specified limits for safe operation.

- Valves: These parts direct the flow of gas and maintain proper pressure levels within the system.

- Filters: Essential for removing contaminants from the air before it enters the unit, protecting internal components.

Each of these elements interacts cohesively, contributing to the efficiency and reliability of the overall mechanism. Understanding their functions can empower users to make informed decisions regarding maintenance and repair.

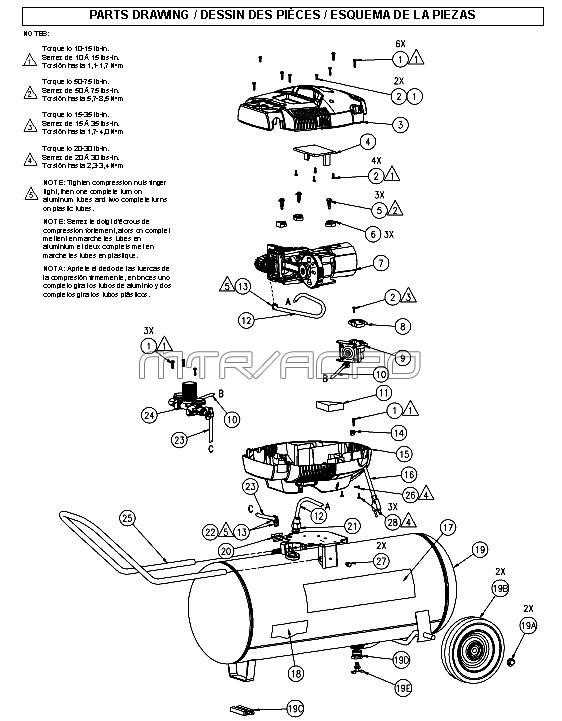

Importance of Parts Diagrams

Understanding the structure and components of any mechanical device is crucial for effective maintenance and repair. Visual representations play a significant role in helping users identify individual elements, their functions, and how they interact within the system.

Here are some key reasons why these visual guides are essential:

- Clarity: Illustrations provide a clear view of complex assemblies, making it easier to comprehend the overall design.

- Efficiency: Quick reference aids streamline the repair process, saving time and reducing frustration.

- Accuracy: Detailed visuals minimize the risk of errors during reassembly or part replacement.

- Education: These visuals serve as educational tools, helping users to learn about the equipment’s inner workings.

- Inventory Management: They assist in identifying required components for repairs or upgrades, ensuring the right items are procured.

In conclusion, visual representations are invaluable resources that enhance understanding, promote efficient repairs, and contribute to the longevity of mechanical systems.

Common Issues with Kobalt Compressors

Understanding the frequent challenges faced by users of these powerful tools is essential for maintaining their efficiency and longevity. Identifying these issues can prevent major breakdowns and enhance overall performance.

- Overheating: This can occur due to prolonged use or inadequate ventilation.

- Air Leaks: Common in hoses and fittings, leading to reduced efficiency.

- Low Pressure: Often a result of blockages or faulty components.

- Noisy Operation: Can indicate wear in mechanical parts or lack of lubrication.

- Starting Issues: Typically related to electrical connections or motor problems.

Regular maintenance and timely inspections can help mitigate these problems and ensure optimal functionality.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires regular care and attention. By adopting a systematic maintenance routine, you can significantly extend the lifespan of your machinery and enhance its performance. This section outlines essential practices to keep your device running smoothly.

Regular Inspections: Conduct frequent checks to identify any wear and tear. Look for signs of damage or unusual sounds during operation. Early detection can prevent larger issues and costly repairs.

Proper Lubrication: Keep moving components well-lubricated to reduce friction and prevent overheating. Use the manufacturer-recommended lubricant and apply it as per the guidelines to ensure optimal functioning.

Clean Filters: Clogged filters can lead to decreased efficiency and potential breakdowns. Regularly clean or replace filters to maintain airflow and enhance overall performance.

Monitor Operating Conditions: Be mindful of the environment where your equipment operates. Extreme temperatures, humidity, and dust can negatively impact performance. Ensure your setup is appropriate for the machine’s specifications.

Follow Usage Guidelines: Adhere to the manufacturer’s recommendations regarding operation and maintenance. Overworking the equipment can lead to premature failure, so understanding its limits is crucial.

By implementing these practices, you can safeguard your investment and ensure that it remains reliable for years to come.

Replacing Worn Parts Effectively

Maintaining the functionality of any machinery involves timely replacement of components that have experienced wear and tear. Addressing these issues proactively can significantly extend the lifespan of the equipment and enhance its performance. Understanding how to identify and replace these crucial elements is essential for any user.

First, it is important to regularly inspect the machinery for signs of deterioration. Look for unusual noises, leaks, or decreased efficiency, as these may indicate that specific components are no longer functioning optimally. Visual inspections can reveal cracks, discoloration, or corrosion, which are clear indicators that replacement is necessary.

Next, sourcing the right replacements is vital. Always refer to the manufacturer’s specifications to ensure compatibility and reliability. Choosing quality alternatives can lead to better performance and longevity, which can save time and resources in the long run.

Finally, proper installation techniques must be followed to ensure that new components fit correctly and function as intended. Familiarizing oneself with the assembly process can prevent future issues and ensure a seamless operation. Taking these steps not only enhances performance but also promotes safety, contributing to a more efficient working environment.

Choosing Quality Replacement Components

When it comes to maintaining and enhancing your equipment, selecting high-quality substitute components is crucial for ensuring optimal performance and longevity. The right choices can significantly impact efficiency, reliability, and overall functionality. Prioritizing durability and compatibility will help you avoid frequent replacements and costly repairs.

Researching Manufacturers is an essential step in the selection process. Opt for brands that have a reputation for excellence and a history of producing reliable items. Reading reviews and seeking recommendations from professionals can provide valuable insights into the best options available.

Another key factor is material quality. Components made from superior materials tend to withstand wear and tear better than their cheaper counterparts. Look for items that offer corrosion resistance and robust construction to enhance their lifespan and reliability.

Compatibility is also vital. Ensure that the substitutes you consider are designed to fit seamlessly with your existing setup. Mismatched components can lead to inefficient operation and potential damage. Always check specifications and compatibility before making a purchase.

Lastly, consider the warranty offered by the manufacturer. A solid warranty can provide peace of mind, indicating that the manufacturer stands behind the quality of their products. This assurance can be particularly valuable in the event of unexpected issues or failures.

Step-by-Step Repair Guide

This section provides a comprehensive approach to effectively troubleshoot and fix issues that may arise with your device. By following a systematic process, you can identify the problem and apply the necessary solutions to restore functionality.

Before starting the repair, ensure you have the required tools and a safe workspace. It’s crucial to disconnect the device from any power source to prevent accidents during the process.

| Step | Description |

|---|---|

| 1 | Inspect the device for visible signs of damage or wear. Check hoses and connections for leaks or cracks. |

| 2 | Remove any covers or enclosures to gain access to internal components. Keep track of screws and parts for reassembly. |

| 3 | Test the electrical components with a multimeter to ensure they are functioning correctly. Replace any faulty parts as necessary. |

| 4 | Examine seals and gaskets for wear. Replace them to prevent air leaks and maintain optimal performance. |

| 5 | Reassemble the device carefully, ensuring all components are securely fastened. Follow the reverse order of disassembly. |

| 6 | Reconnect the device to the power source and conduct a test run to ensure everything is functioning as intended. |

By following these steps, you can effectively address common issues and maintain the longevity of your equipment.

Where to Find Parts Diagrams

Locating technical illustrations for machinery components can be essential for effective maintenance and repair. Understanding where to access these resources ensures that you can efficiently identify and procure the necessary elements for your equipment. Numerous platforms and methods are available to assist in your search.

Online Resources

The internet hosts a variety of websites dedicated to equipment manuals and visual guides. Some reliable sources include manufacturer websites, online retailers, and community forums. Utilizing search engines with specific keywords can yield helpful results, leading to official documents and user-shared content.

Local Retailers and Service Centers

Physical stores often maintain catalogs or can provide direct assistance in locating the necessary illustrations. Contacting authorized dealers or service centers can yield not only diagrams but also insights from experienced technicians who are familiar with the equipment.

| Source Type | Description |

|---|---|

| Manufacturer Website | Official resources often include manuals and diagrams for all products. |

| Online Retailers | Many sellers provide links to manuals and product details for better understanding. |

| Community Forums | Platforms where users share experiences, solutions, and documentation. |

| Local Dealers | Authorized sellers may have physical copies of manuals and diagrams. |