Maintaining a well-groomed lawn requires the right tools and knowledge. One essential aspect of lawn care machinery is understanding its components and how they function together. This knowledge not only ensures optimal performance but also extends the lifespan of your equipment.

In this section, we will explore the various elements that make up a specific model of lawn care machinery. By breaking down each component, we aim to provide clarity and insight, empowering you to make informed decisions when it comes to maintenance and repairs.

From the cutting mechanism to the supporting structures, comprehending how each piece contributes to the overall efficiency is crucial. Whether you are troubleshooting issues or planning upgrades, having a comprehensive overview will serve as your ultimate guide in effective lawn management.

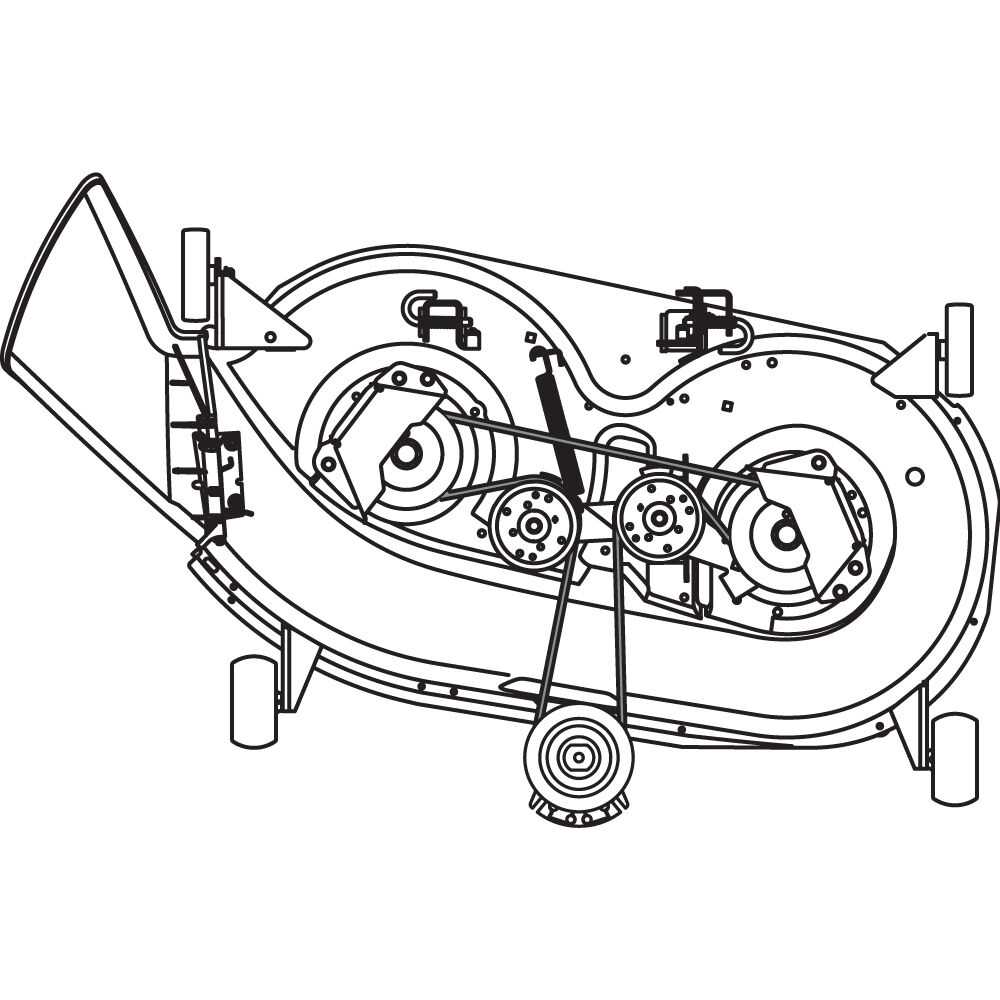

Understanding the Cub Cadet Mower Deck

Maintaining a lawn care machine involves understanding the core components responsible for its cutting and overall functionality. Each of these elements plays a critical role in achieving smooth operation, from the blades to the structural framework that supports them. By understanding how these parts interact and function together, users can ensure both optimal performance and longevity of the equipment.

The cutting unit is designed with precision to deliver a consistent and even result. It includes a series of sharpened blades, strategically positioned to achieve the desired grass height. The stability of this assembly is ensured by the surrounding framework, which keeps the components aligned and prevents wear during operation. Routine maintenance and part replacement are essential to preserve the quality of work and prevent potential damage.

Key components include the blade spindles, which allow the blades to rotate at high speed, and the tensioners that keep the blades properly tightened. Wear parts like belts, pulleys, and bearings are crucial for smooth movement and need regular inspection. Understanding the role of each part helps in troubleshooting and maintaining the machine efficiently, preventing costly repairs down the line.

Key Components of a Mower Deck

The effectiveness of any lawn cutting equipment relies heavily on the various integral elements that work together to ensure smooth operation and optimal performance. Understanding these components is essential for maintaining functionality, preventing damage, and achieving clean, even results during use. Each part plays a specific role, and even minor issues with any one of them can affect the overall outcome of the job.

These essential elements can be divided into categories based on their functions: rotation, adjustment, support, and safety. From the blades that perform the cutting task to the mechanisms that allow for height adjustments, all parts contribute to the overall efficiency and ease of use. Regular inspection and proper maintenance of these components will extend the life of the machine and enhance its performance over time.

| Component | Description |

|---|---|

| Blades | These are responsible for cutting the grass. Their sharpness and balance are crucial for achieving an even cut. |

| Spindles | These rotate the blades and are driven by the engine’s power. Regular lubrication ensures smooth operation. |

| Height Adjustment Mechanism | This part allows the operator to set the desired cutting height for different grass conditions. |

| Drive Belt | The drive belt transmits power from the engine to the blades and other components, enabling operation. |

| Chassis | The structural frame that supports all components and ensures stability during operation. |

| Safety Features | These include shields and safety switches that prevent accidental injury by stopping movement when necessary. |

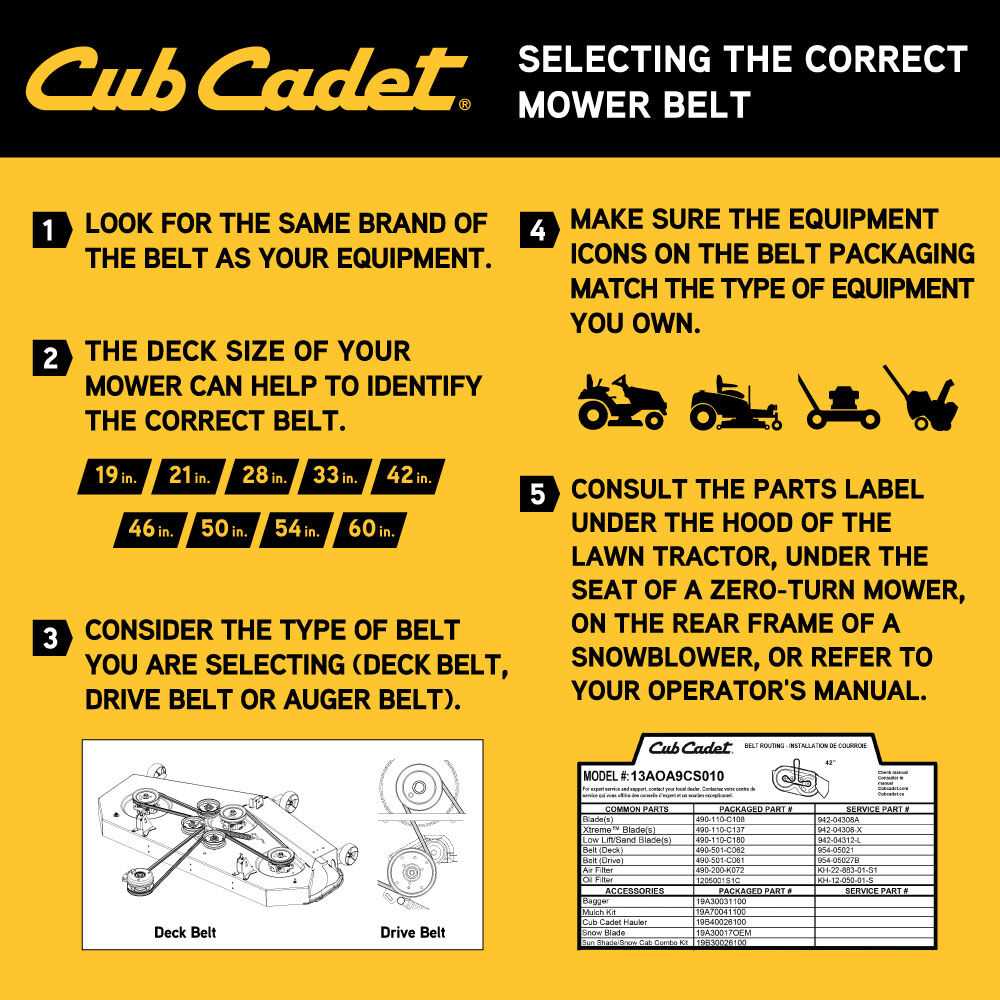

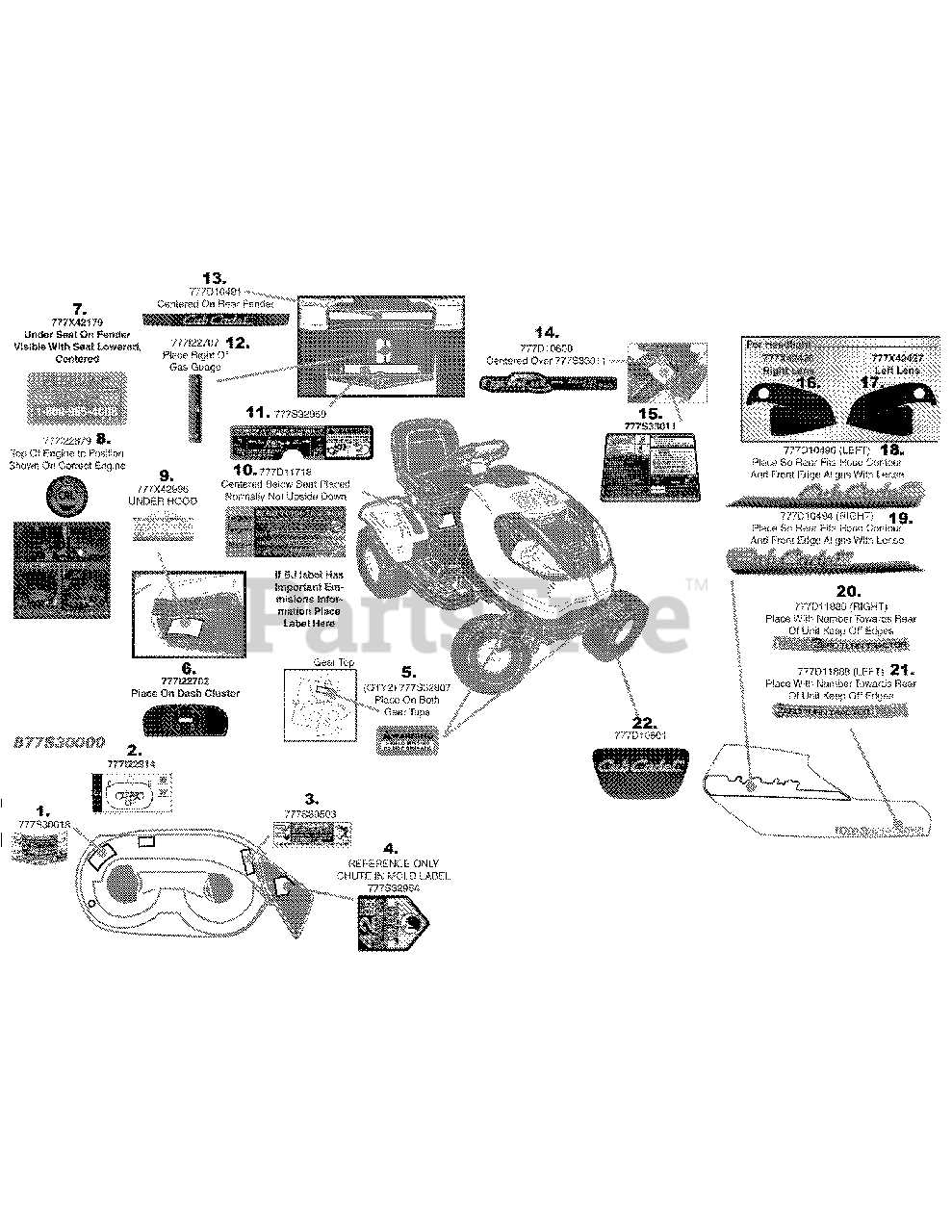

How to Identify Mower Deck Parts

Understanding the components of your machine is crucial for maintenance and repairs. Each element plays a specific role in ensuring the efficiency and performance of the equipment. Whether you’re replacing a worn-out item or performing regular checks, knowing how to identify these elements will save you time and effort. This guide will help you recognize and understand the function of each piece, so you can keep everything running smoothly.

Visual Inspection

The first step in identifying any component is to conduct a thorough visual inspection. Look for distinctive features such as shape, size, and mounting points. Wear and tear may also give you clues about the function of certain elements. For example, if a part shows significant damage or rust, it could indicate its exposure to high levels of stress. Some parts, like blades or pulleys, may have visible markings or numbers that can be referenced for easy identification.

Consulting the Manual

If you’re unsure, the best place to look is the user manual. Most equipment manuals come with an easy-to-read illustration or parts list. The parts list will help you correlate numbers with specific components, while illustrations provide a clearer view of each item’s placement and function. Keep in mind that this is essential when ordering replacements or making adjustments to your machine.

By using these methods, you will not only know what each piece does, but you will also ensure that your machine stays in top condition for years to come.

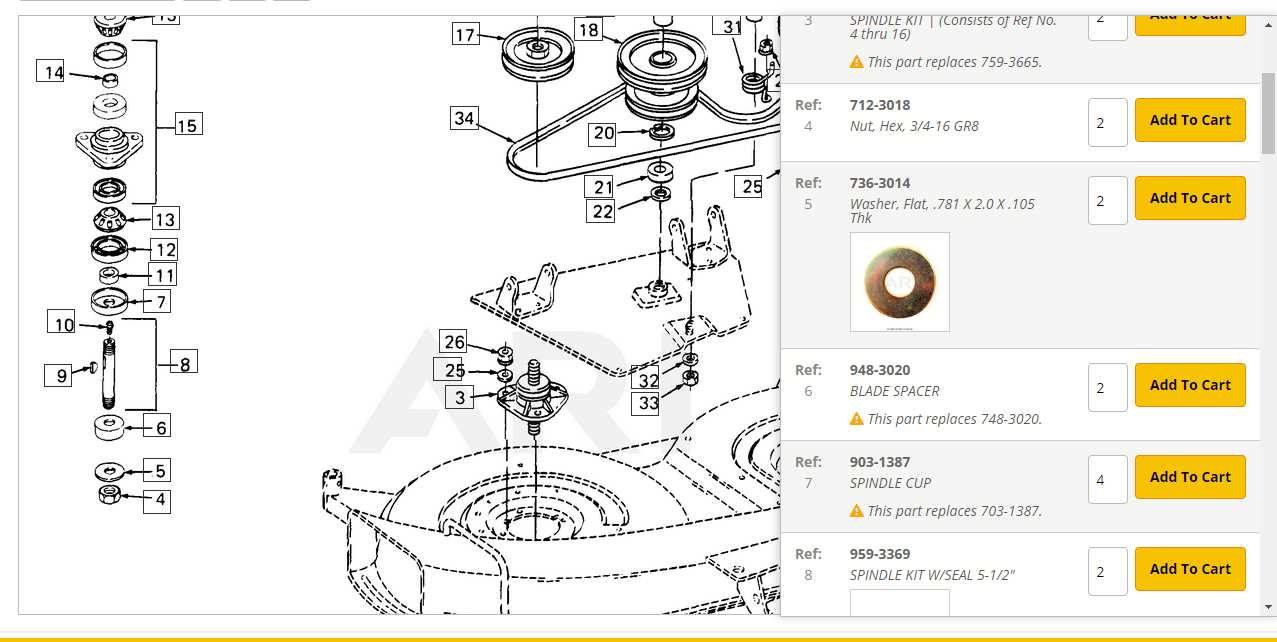

Importance of a Parts Diagram

When it comes to the maintenance and repair of complex machinery, having a clear visual representation of its components is crucial. A well-detailed guide showing how each element fits together allows users to understand the assembly and disassembly process more easily, saving both time and effort. Knowing the exact location and function of each individual part ensures that problems can be diagnosed and fixed with precision, reducing the likelihood of mistakes or additional damage.

Enhanced Troubleshooting

Having access to a visual guide can significantly simplify the process of identifying faulty or worn-out components. When something goes wrong, referencing such a guide can help users quickly pinpoint the source of the issue. This reduces the guesswork, making repairs faster and more efficient. Additionally, it helps prevent unnecessary replacements, as the exact problem can be identified, leading to targeted fixes rather than broad, costly changes.

Efficient Assembly and Repair

A clear, detailed map of the various elements of a machine allows for quicker and more accurate assembly, disassembly, and reassembly. It is especially beneficial when putting a device together after maintenance or repair, ensuring all parts are properly installed. This level of clarity also ensures that no parts are left out or incorrectly attached, improving the overall functionality and longevity of the equipment.

| Component | Function |

|---|---|

| Engine | Provides the power to drive the system |

| Blades | Perform the cutting operation |

| Wheels | Ensure mobility and stability |

| Drive Belt | Transmits power from the engine to the blades |

In conclusion, a visual representation of a machine’s components is more than just a reference–it is an essential tool for ensuring correct maintenance, efficient repairs, and proper functioning of the equipment. It empowers users with the knowledge to keep their machinery running smoothly, minimizing downtime and maximizing its lifespan.

Common Issues with Cub Cadet Decks

Many users encounter recurring challenges when maintaining their lawn care equipment. These problems can stem from a variety of factors, impacting performance and efficiency. Understanding these common issues is crucial for effective troubleshooting and ensuring optimal operation.

Uneven Cutting: One prevalent concern is uneven cutting. This can result from improper blade alignment or worn-out blades. Regularly checking and replacing blades can help maintain a consistent cut.

Clogging: Grass clippings and debris can build up, leading to clogging. Cleaning the underside frequently prevents blockages and enhances airflow, improving overall functionality.

Vibration: Excessive vibration during operation can indicate loose components or unbalanced blades. Inspecting and tightening all connections is essential to minimize this issue.

Noise Levels: Unusual sounds may signal mechanical problems. It’s important to investigate any odd noises early on to prevent further damage.

Wear and Tear: Over time, components can degrade. Regular inspections and timely replacements are necessary to prolong the lifespan of the equipment.

By being aware of these typical challenges, users can take proactive steps to maintain their equipment effectively.

How to Maintain Your Mower Deck

Proper upkeep of your cutting apparatus is essential for optimal performance and longevity. Regular maintenance ensures that the equipment operates efficiently, reducing wear and tear while enhancing the quality of your lawn care.

Regular Cleaning

- After each use, remove grass clippings and debris.

- Use a brush or scraper to clean the underside to prevent rust.

- Wash the exterior with water and mild detergent.

Inspection and Lubrication

- Check for any loose bolts or screws and tighten them as necessary.

- Inspect belts and cables for signs of wear or damage.

- Apply lubricant to moving parts to reduce friction and prevent rust.

Where to Find Replacement Parts

Finding the right components for your equipment can significantly enhance its performance and longevity. Whether you’re looking for a specific item or exploring options for maintenance, there are various avenues to explore.

Online Retailers

Many websites specialize in aftermarket and OEM components. These platforms offer a vast selection and often feature user-friendly search tools to help you locate the exact item you need. Always check customer reviews for reliability.

Local Dealers and Service Centers

Visiting nearby authorized dealerships or service centers can be beneficial. Not only can they provide genuine items, but their knowledgeable staff can assist you in identifying the ultimate solution for your requirements.

Tips for Installing New Components

When replacing elements on your outdoor equipment, it’s essential to ensure a smooth and efficient process. Proper installation not only enhances performance but also prolongs the lifespan of your machine.

Preparation Steps

- Gather all necessary tools before starting.

- Read the installation instructions thoroughly.

- Ensure you have the correct replacements for your model.

Installation Process

- Disconnect the power source to avoid accidents.

- Carefully remove the old components, noting their arrangement.

- Align the new pieces precisely as indicated in the guide.

- Tighten all fasteners securely but avoid overtightening.

- Reconnect the power source and test the equipment to ensure proper functionality.