When it comes to maintaining your outdoor machinery, understanding its various components is essential. Having a comprehensive overview of the different elements that work together can greatly enhance your ability to troubleshoot issues and perform necessary repairs. This section provides valuable insights into the intricate assembly of your lawn maintenance tool, ensuring you are well-informed about each piece and its function.

Delving into the specifics, you will discover how each segment contributes to the overall performance and efficiency of the machine. Familiarizing yourself with these elements not only helps in identifying potential problems but also empowers you to make informed decisions regarding upgrades or replacements. Embracing this knowledge will enable you to maximize the longevity and functionality of your equipment.

As you navigate through the information presented, you will gain a clearer perspective on how to effectively care for and manage your lawn machinery. By recognizing the significance of each component, you are better equipped to maintain your equipment in optimal condition, allowing for a more enjoyable and productive experience in your outdoor endeavors.

This model is equipped with advanced capabilities designed to simplify lawn care. The machine offers reliable performance, making it suitable for maintaining a variety of outdoor spaces. With a focus on efficiency and ease of use, it ensures a smooth mowing experience for users of all levels.

Engine Performance

- Powerful motor that delivers consistent output

- Efficient fuel consumption for extended runtime

- Durable components designed to handle tough terrain

Comfort and Control

- Ergonomically designed seating for extended use

- Intuitive control system for easy operation

- Adjustable speed settings to match various mowing conditions

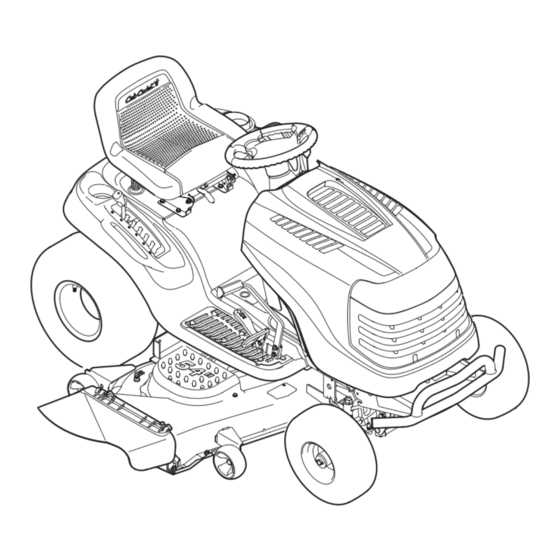

Understanding the Parts Breakdown

When maintaining or repairing outdoor equipment, it’s essential to grasp how various components work together. By knowing the key elements and their functions, you can troubleshoot issues more efficiently and ensure proper replacements when necessary. A clear overview of the internal workings helps to keep everything running smoothly, minimizing downtime and extending the machine’s lifespan.

Let’s dive into the essential elements that keep your equipment operating effectively. Below is a breakdown of crucial systems that are integral to its performance:

- Engine Assembly: This is the heart of the machine, powering all movements and ensuring continuous operation.

- Transmission System: Responsible for transferring power to the wheels, this system allows for smooth speed changes and reliable movement over various terrains.

- Identifying Major Components

Understanding the key elements of your lawn tractor is essential for efficient operation and maintenance. By recognizing the main features and their roles, you can ensure the smooth functioning of the machine and address any potential issues with ease. These components work together to provide optimal performance, making it important to familiarize yourself with each one.

The engine, often considered the heart of the machine, is responsible for powering the entire system. Connected to it are the transmission and drive mechanisms, which allow the vehicle to move forward and backward with ease. Proper attention to these areas will help maintain consistent movement and control.

Another crucial element is the cutting deck, which houses the blades used for trimming. This section is directly involved in the primary function of the machine, requiring regular checks to ensure sharpness and balance. Additionally, the control panel, where all operational commands are made, plays a vital role in

How to Access the Parts Diagram

When maintaining or repairing your machine, it’s essential to have a clear overview of all the components and their placement. This guide will help you locate the visual layout of various elements, ensuring that you’re well-prepared to make any necessary replacements or adjustments.

- Visit the manufacturer’s official website.

- Navigate to the support or product section.

- Enter your equipment’s model information in the search field.

- Find the relevant section for component layouts and related documents.

- Select the assembly view you’re interested in to download or view online.

By following these steps, you will gain easy access to the necessary technical documents for efficient and accurate repairs.

Maintenance Tips for Longevity

Proper care and routine upkeep play a key role in extending the life of your outdoor equipment. By following essential practices, you can ensure optimal performance and prevent unnecessary wear over time. The following tips will help maintain the functionality of your machine for years to come.

- Regularly inspect belts, filters, and other moving parts for signs of wear or damage.

- Keep blades sharp to reduce strain on the engine and improve cutting efficiency.

- Clean the undercarriage after each use to prevent debris buildup that may cause rust or block essential components.

- Lubricate key joints and bearings to ensure smooth operation and prevent friction-related issues.

- Change oil and filters according to the manufacturer’s recommendations to keep the engine running smoothly.

- Check tire pressure regularly to ensure even distribution of weight and avoid unnecessary strain on

Common Replacement Parts Guide

Maintaining your outdoor equipment requires regular attention, and knowing which components are prone to wear over time can help keep everything running smoothly. In this guide, we’ll cover frequently replaced items that are essential for keeping your machine in top condition.

Belts are crucial for the operation of your equipment, as they are responsible for transferring power to different parts of the machine. Over time, these can become worn or cracked, which may lead to reduced efficiency or even malfunction.

Another key element to monitor is the blades. Dull or damaged blades can impact performance, making cutting less effective. Replacing these ensures precise and efficient operation, especially during heavy use.

Regular replacement of filters, such as air or fuel types, is necessary to prevent blockages and maintain a smooth-running engine. These components keep debris and contaminants from affecting

Where to Purchase Genuine Parts

Ensuring the longevity and optimal performance of your equipment depends heavily on sourcing the right components. Authentic replacements are key to maintaining durability and reliability, but finding the right suppliers can sometimes be a challenge. Here, we’ll explore the best options to acquire genuine replacements for your machine, ensuring that your investment is well-protected.

Authorized Dealers

One of the most reliable ways to get original components is through certified retailers. These providers guarantee that what you are buying is made to exact specifications, designed to fit and work seamlessly with your machine.

- Local certified shops often carry a wide range of original replacements.

- Online platforms from official distributors offer convenience and easy browsing.

Online Marketplaces

For those who prefer the convenience of online shopping, several trusted platforms specialize in selling original components. While it’s essential to verify the authenticity of