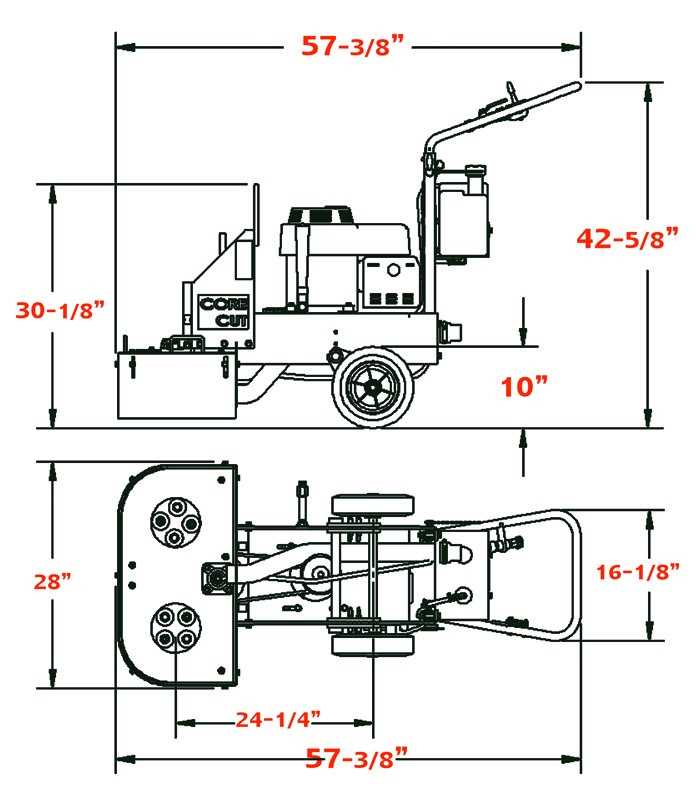

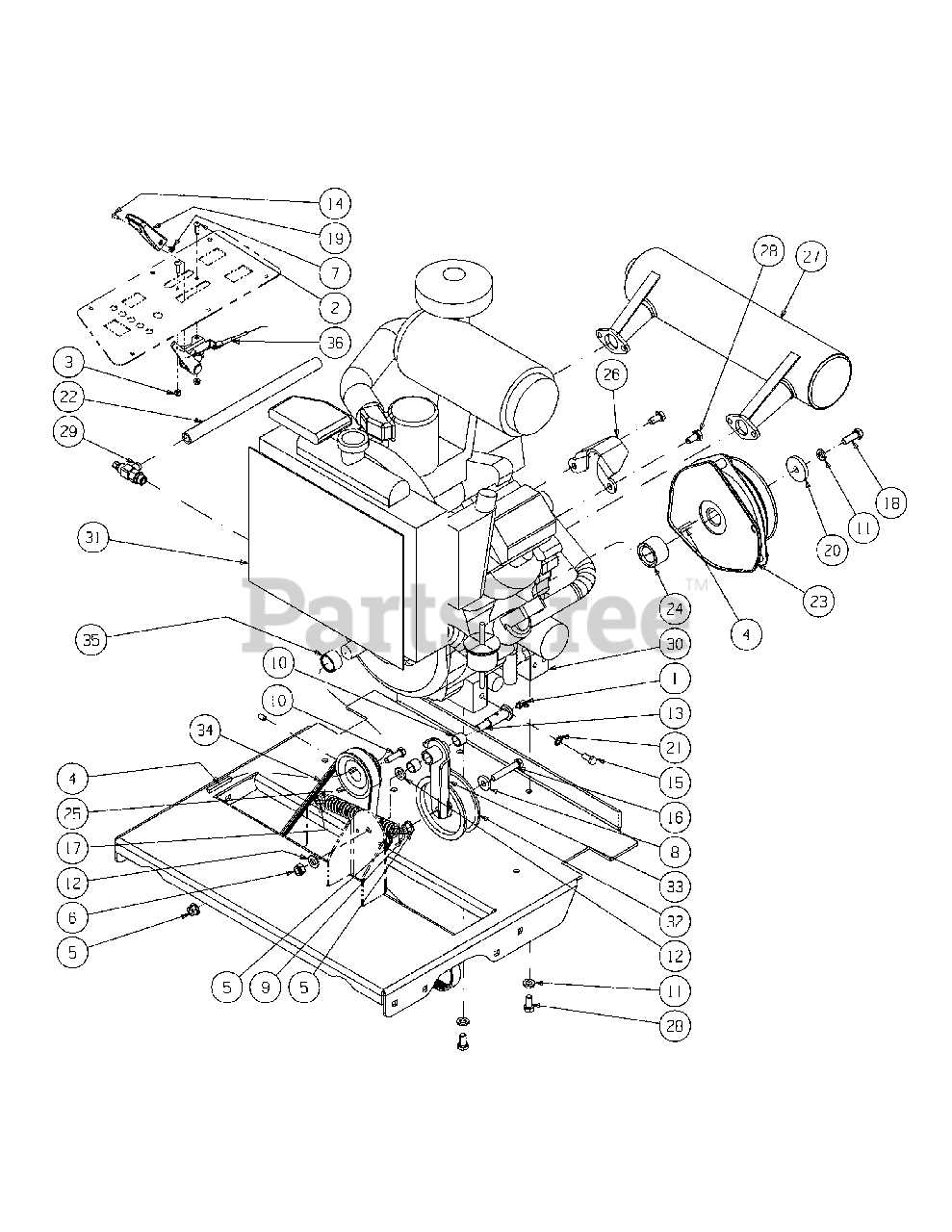

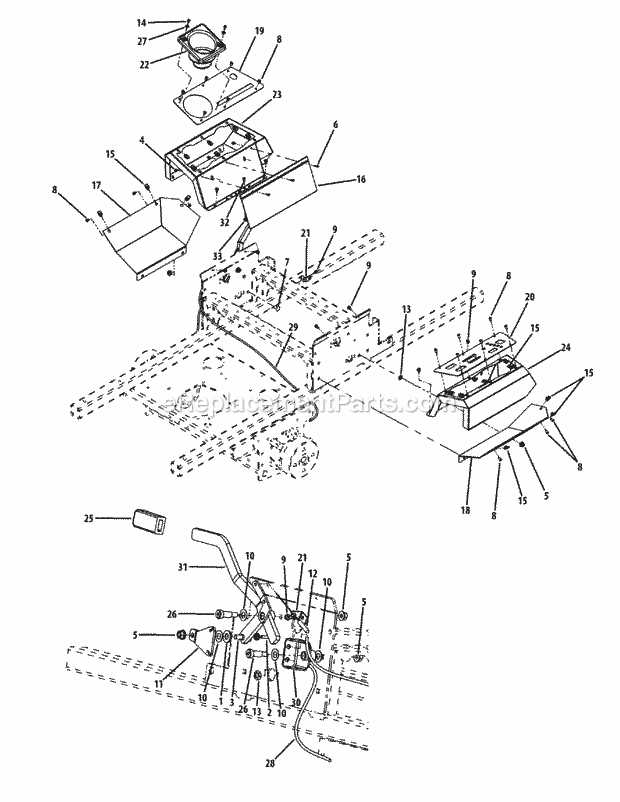

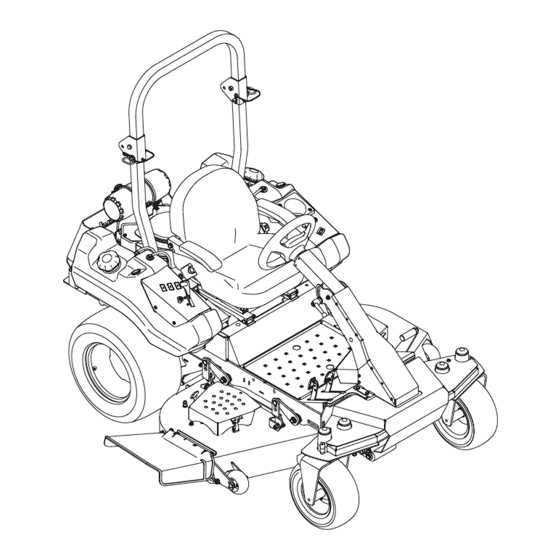

The intricate layout of machinery components is essential for the effective operation of any robust machine. A thorough grasp of the various elements involved is vital for both maintenance and repair tasks. By delving into the configuration of these components, users can enhance their familiarity with the equipment, leading to improved performance and longevity.

Exploring the arrangement and function of individual elements allows operators to identify potential issues before they escalate. This knowledge empowers users to take proactive measures, ensuring that their machinery remains in optimal working condition. Whether for routine checks or more complex repairs, a comprehensive understanding of the inner workings proves invaluable.

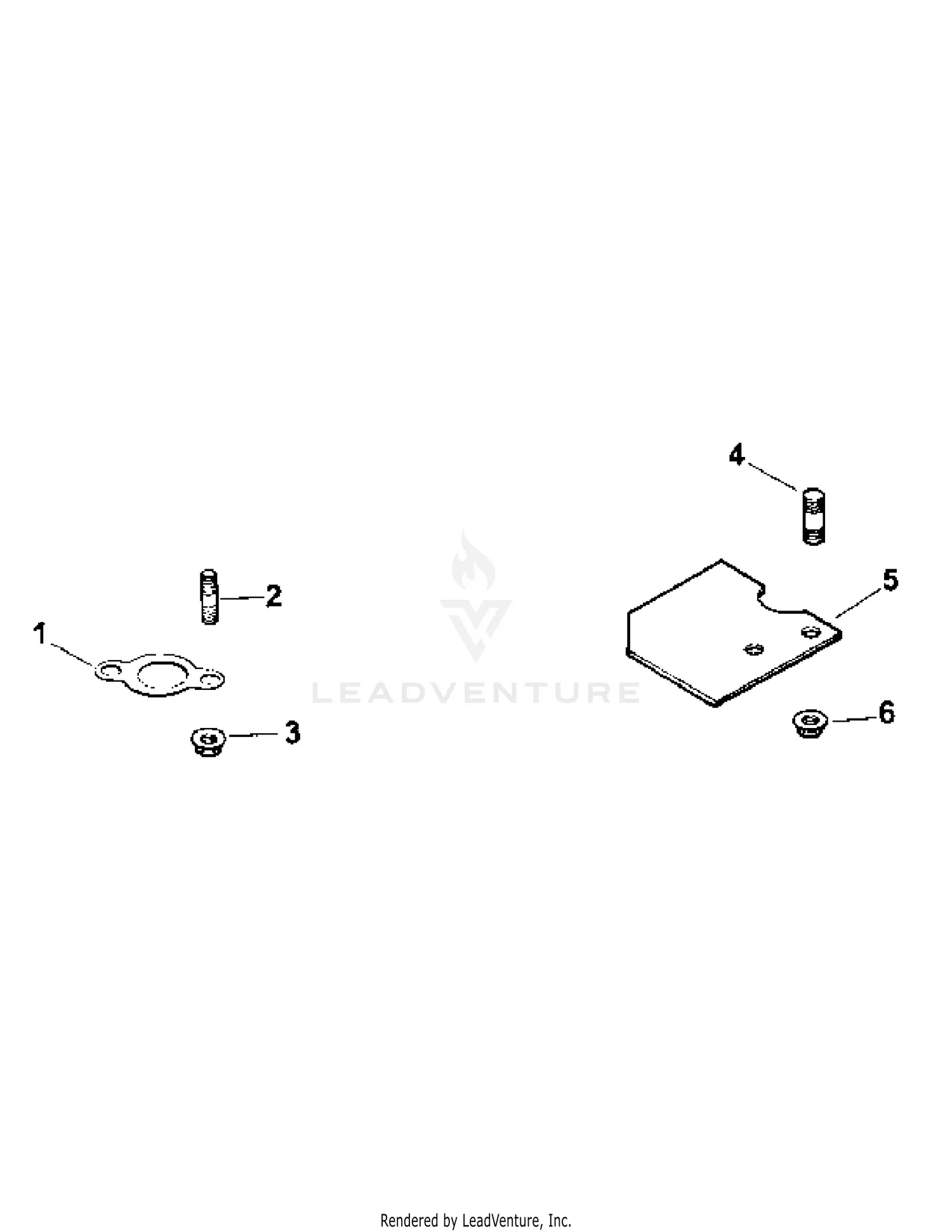

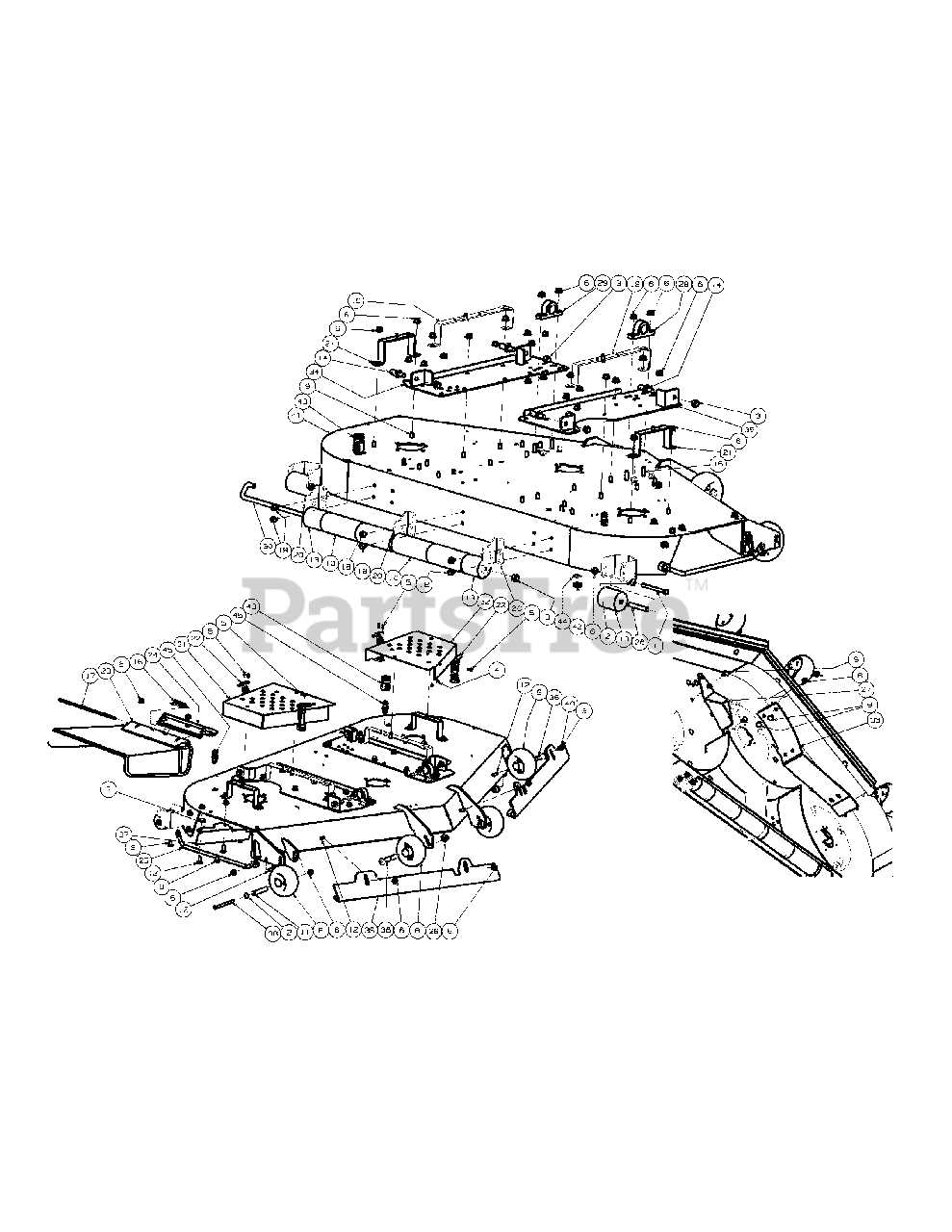

Utilizing a visual representation can simplify the process of recognizing where each component fits within the overall structure. Such illustrations serve as an excellent reference point for both novice and experienced users alike. By equipping oneself with the right information, operators can effectively navigate any challenges that arise during maintenance and operation.

Essential Components Overview

This section provides a detailed examination of the crucial elements that contribute to the functionality and performance of the machine. Understanding these components is vital for effective maintenance and repair, ensuring optimal operation in various conditions.

| Component Name | Description |

|---|---|

| Engine | Power unit that drives the system, converting fuel into mechanical energy. |

| Transmission | System responsible for transferring power from the engine to the wheels, allowing for speed adjustments. |

| Chassis | The frame that supports the entire structure, providing stability and strength. |

| Hydraulic System | Network of components that use fluid pressure to perform various functions, including lifting and steering. |

| Control Panel | Interface that allows the operator to manage settings and monitor the machine’s performance. |

| Wheels | Support the vehicle and enable movement across different terrains. |

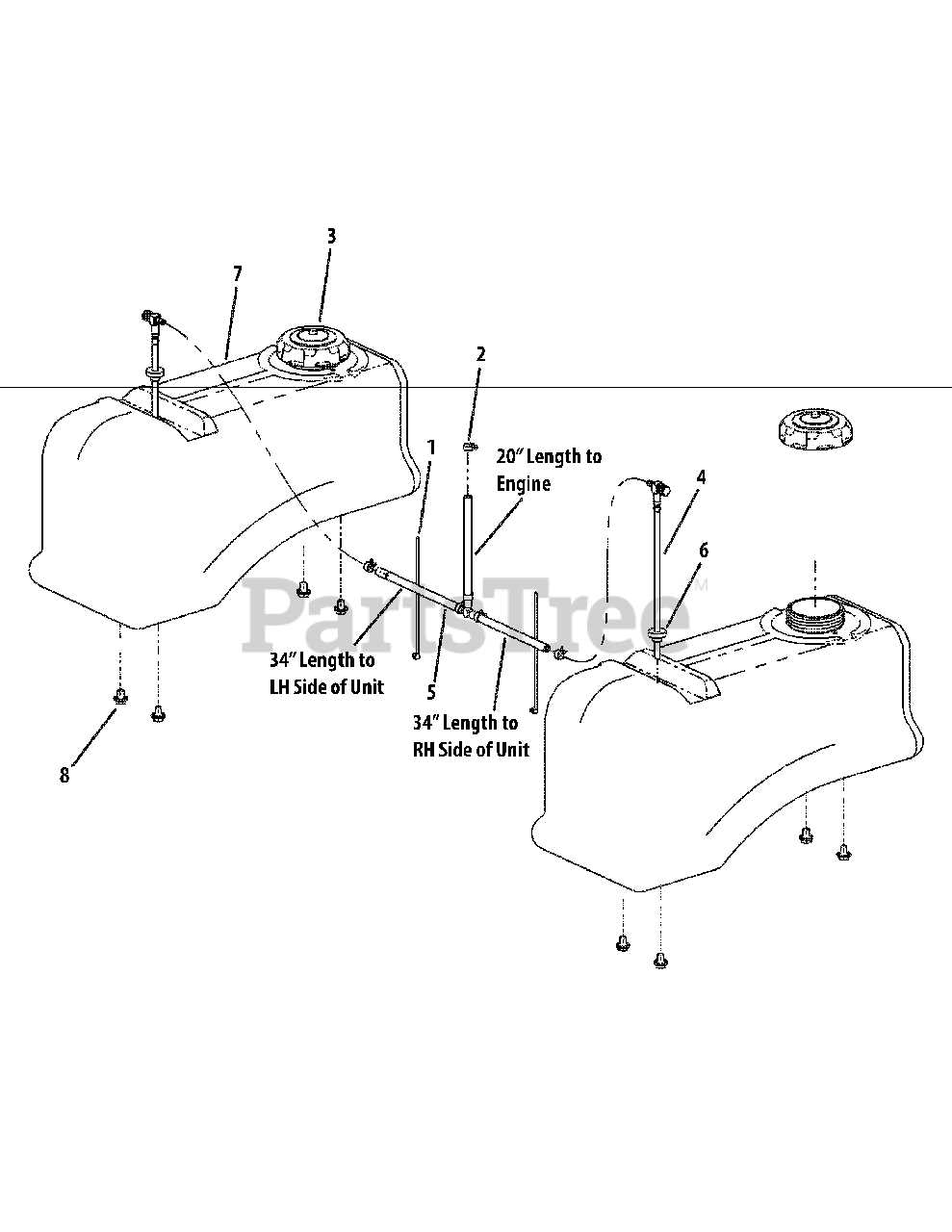

| Fuel System | Components that store and deliver fuel to the engine for combustion. |

Maintenance Tips for Smooth Operation

Regular upkeep is essential for ensuring optimal functionality and longevity of any outdoor equipment. Adhering to a structured maintenance routine can prevent unexpected breakdowns and enhance performance. This section provides key recommendations to facilitate seamless operation.

1. Regular Cleaning: Keep the exterior and internal components clean to prevent dirt and debris accumulation. Use a soft brush or cloth to remove dust and grime after each use.

2. Fluid Checks: Periodically inspect and replenish essential fluids such as oil, coolant, and hydraulic fluid. Maintaining proper fluid levels is crucial for preventing overheating and ensuring efficient operation.

3. Blade Maintenance: Sharpen and inspect blades frequently to ensure efficient cutting. Dull blades can strain the engine and lead to uneven results.

4. Tire Inspection: Check tire pressure regularly and look for any signs of wear. Properly inflated tires improve traction and maneuverability.

5. Battery Care: Monitor the battery’s condition and clean the terminals to prevent corrosion. Ensure the battery is charged and functioning correctly to avoid starting issues.

6. Seasonal Checks: Perform a comprehensive inspection at the beginning and end of each season. This includes checking belts, cables, and any other components for wear and tear.

By implementing these maintenance strategies, operators can enhance the reliability and efficiency of their equipment, ensuring it performs at its best for years to come.

Signs of Wear and Replacement Needs

Recognizing the indicators of deterioration is crucial for maintaining optimal performance and longevity of outdoor machinery. Regular inspection and timely intervention can prevent more significant issues down the line, ensuring smooth operation and efficiency.

Common Indicators of Wear

- Unusual Noises: Sounds such as grinding, rattling, or squeaking often signal that components are not functioning properly.

- Visual Damage: Cracks, rust, or deformities on exterior surfaces can indicate underlying issues that may affect functionality.

- Performance Degradation: A noticeable decline in efficiency, such as reduced power or sluggish operation, is often a sign that parts may need replacement.

Replacement Considerations

- Frequency of Use: Higher usage rates can accelerate wear, necessitating more frequent inspections and replacements.

- Environmental Factors: Exposure to harsh conditions, such as extreme temperatures or moisture, can lead to faster deterioration of components.

- Manufacturer Guidelines: Following the recommended service intervals provided by the manufacturer can help in timely identification of replacement needs.

How to Identify Compatible Parts

Ensuring that components fit correctly and function optimally is essential for any machinery. When seeking replacements or upgrades, it is important to understand how to select the right items that work seamlessly with your existing equipment. This process involves evaluating specifications, compatibility, and performance characteristics.

1. Understand Specifications: Start by reviewing the technical details of the original components. Key metrics such as size, weight, and material can significantly affect how well a new item will integrate with your machinery.

2. Cross-Reference Compatibility: Consult compatibility charts or databases that compare various components. Manufacturers often provide lists of items that are interchangeable or recommended for specific models, which can help you make informed decisions.

3. Seek Expert Guidance: When in doubt, reach out to professionals or experienced users. Forums, local retailers, and repair shops can offer valuable insights into the most reliable options available.

4. Verify Performance: Consider the performance ratings of potential replacements. Ensure that the new components meet or exceed the original specifications to maintain functionality and reliability.

5. Trial and Error: Sometimes, the best way to find a suitable fit is through experimentation. Keep an open mind and be willing to try different options while closely monitoring their performance.

By following these guidelines, you can enhance the longevity and efficiency of your equipment, ensuring that each component operates as intended.

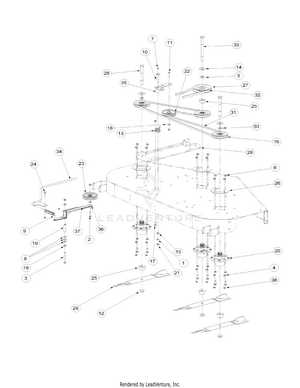

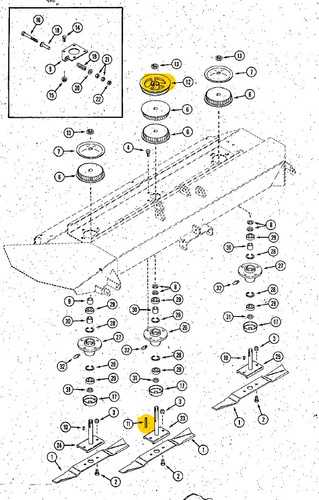

Understanding the Deck Assembly Structure

The deck assembly is a critical component of any mowing apparatus, playing a vital role in the overall functionality and performance of the equipment. This assembly is designed to house the cutting mechanisms, providing both stability and efficiency during operation. A comprehensive grasp of its structure can significantly enhance maintenance efforts and improve the longevity of the device.

Main Components of the Deck Assembly

Each element within the deck assembly is meticulously engineered to work in harmony with the others. Understanding these components is essential for troubleshooting and effective upkeep.

| Component | Description |

|---|---|

| Housing | Encases the cutting mechanism, providing protection and structural integrity. |

| Blades | Sharp instruments responsible for cutting the grass to the desired height. |

| Spindle Assembly | Supports the blades and allows for rotation, enabling effective cutting action. |

| Adjustment Mechanism | Facilitates changes in the cutting height, allowing for versatility in operation. |

| Deck Supports | Provide stability to the assembly, ensuring consistent contact with the ground. |

Importance of Regular Maintenance

Regular inspection and maintenance of the deck assembly are crucial for optimal performance. Addressing wear and tear on components, ensuring proper blade sharpness, and keeping the assembly free from debris can greatly enhance efficiency and effectiveness during mowing tasks.

Troubleshooting Electrical System Issues

Addressing electrical system malfunctions is essential for ensuring optimal performance and safety in machinery. Identifying the root causes of these issues requires a systematic approach, focusing on various components that may contribute to the problem. This section outlines common troubleshooting steps and considerations to effectively diagnose electrical problems.

Here are key areas to inspect when facing electrical system challenges:

- Battery Condition

- Check for loose or corroded connections.

- Ensure the battery is adequately charged.

- Inspect for any physical damage or leaks.

- Wiring Integrity

- Examine wires for signs of fraying or breaks.

- Ensure connections are secure and free from corrosion.

- Look for any signs of overheating in wiring harnesses.

- Fuses and Relays

- Inspect fuses for continuity and replace any that are blown.

- Test relays for proper operation using a multimeter.

- Check the relay connections for any corrosion or damage.

- Switch Functionality

- Test all switches to ensure they are functioning correctly.

- Look for signs of wear or internal failure in switches.

- Ensure that switches are receiving power as intended.

By systematically evaluating these components, you can effectively identify and resolve electrical issues, leading to improved functionality and reliability.

Upgrading for Enhanced Performance

Improving the efficiency and functionality of your equipment is essential for maximizing productivity and achieving optimal results. Upgrades can range from minor adjustments to significant enhancements, tailored to meet specific operational needs. By focusing on key components, you can ensure that your machinery performs at its best, providing a reliable and effective solution for your tasks.

One effective approach to boosting performance involves evaluating various elements that contribute to overall functionality. Consideration of both mechanical and technological components can lead to significant improvements. The following table outlines some common upgrades that can enhance operational efficiency:

| Component | Upgrade Options | Benefits |

|---|---|---|

| Engine | High-performance filters, enhanced fuel injectors | Increased power output, improved fuel efficiency |

| Transmission | Upgraded gears, advanced lubrication systems | Smoother operation, extended lifespan |

| Suspension | Reinforced springs, adjustable dampers | Improved stability, better handling |

| Electronics | Advanced control systems, upgraded sensors | Enhanced precision, improved responsiveness |

By carefully selecting and implementing these enhancements, operators can ensure their equipment remains competitive and capable of handling demanding tasks. Regular assessments and upgrades will not only prolong the life of the machinery but also elevate its overall performance, leading to increased satisfaction and better results in the field.

Where to Find Reliable Spare Parts

When it comes to maintaining your outdoor equipment, sourcing dependable replacement components is crucial for ensuring optimal performance and longevity. There are various avenues to explore when looking for quality items to keep your machinery in top shape.

Here are some effective strategies to consider:

- Authorized Dealers: Seek out certified distributors who specialize in your specific equipment brand. They often stock genuine components, providing assurance of compatibility and quality.

- Online Retailers: Numerous e-commerce platforms offer a wide selection of replacement items. Look for websites with customer reviews and ratings to gauge reliability.

- Local Hardware Stores: Many community hardware stores may carry essential components or can order them for you. Building a relationship with local suppliers can also be beneficial.

- Specialty Shops: Consider shops that focus on outdoor power equipment. These establishments are likely to have knowledgeable staff who can assist you in finding the right components.

- Salvage Yards: For cost-effective options, check out salvage yards that specialize in machinery. You might discover used items in good condition, which can be a budget-friendly alternative.

By exploring these options, you can ensure you find trustworthy replacement components that will help keep your machinery running smoothly for years to come.