Maintaining complex systems requires a thorough understanding of their internal structure. A detailed breakdown of the various elements involved in such equipment helps to identify potential areas of concern and ensures smooth operation over time. Familiarizing yourself with the layout and arrangement of these components allows for easier troubleshooting and repairs, making upkeep far more manageable.

When dealing with large and intricate devices, having a clear visual representation of their elements is essential. It enables technicians and operators to locate and assess the condition of different sections quickly. This approach not only speeds up the

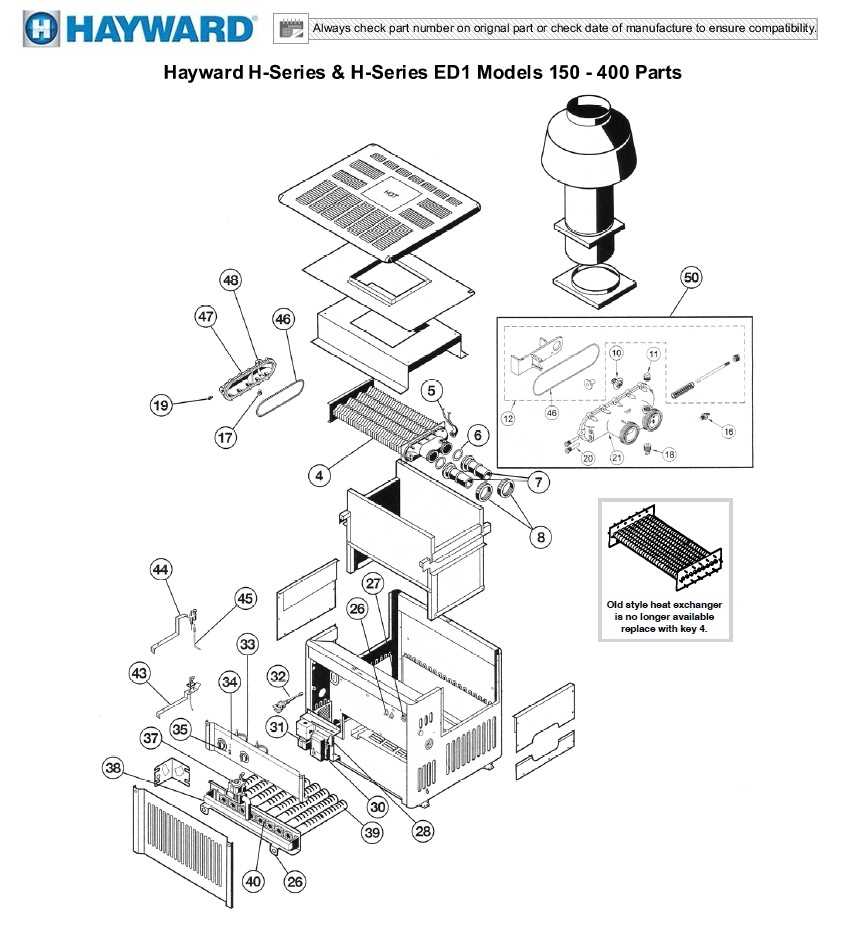

Understanding Key Components of the H400 Model

The system under consideration is composed of various elements that ensure efficient performance and reliability. Each section works together to provide optimal functionality, making it essential to understand the key features and their interactions within the device.

Core Mechanisms

At the heart of the unit lies a series of mechanisms responsible for controlling and regulating the overall operation. These include temperature regulation, safety measures, and essential operational controls. These components ensure smooth and safe functioning under different conditions.

Supporting Structures

In addition to the primary mechanisms, the model relies on several auxiliary parts that contribute to maintaining stability and durability. These components provide necessary support, aiding in heat management, fluid control, and structural integrity, enhancing the overall lifespan of the system.

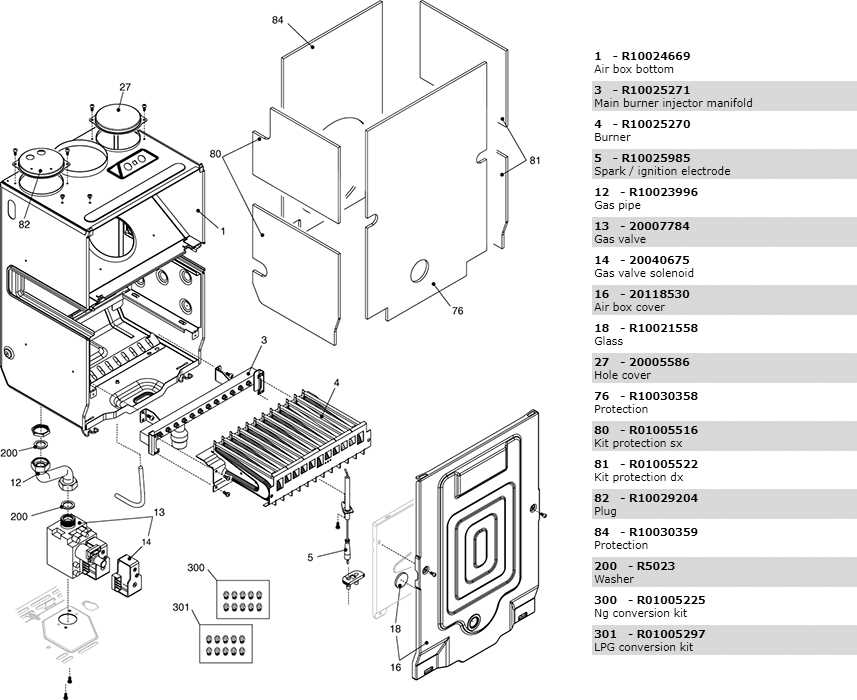

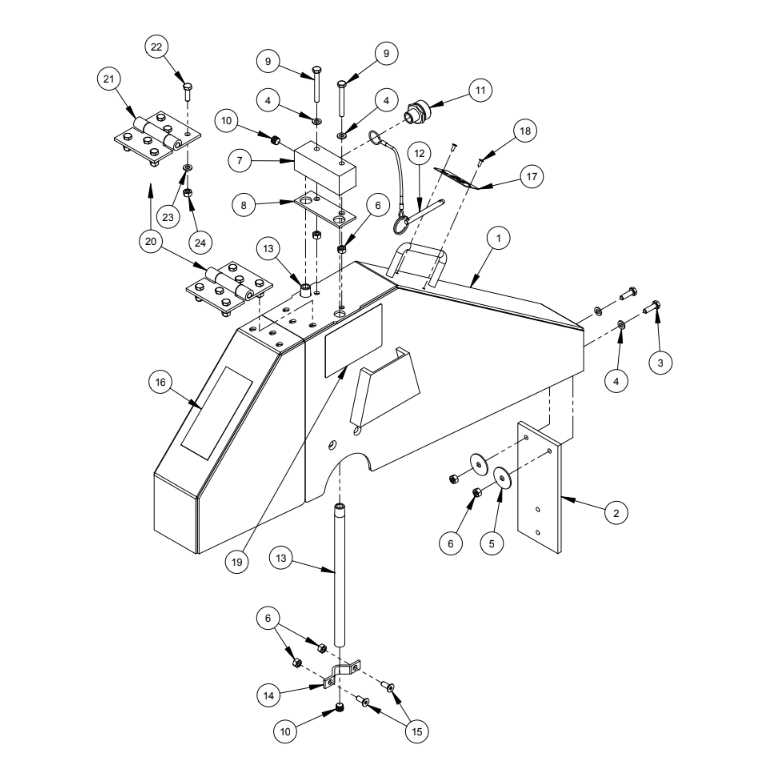

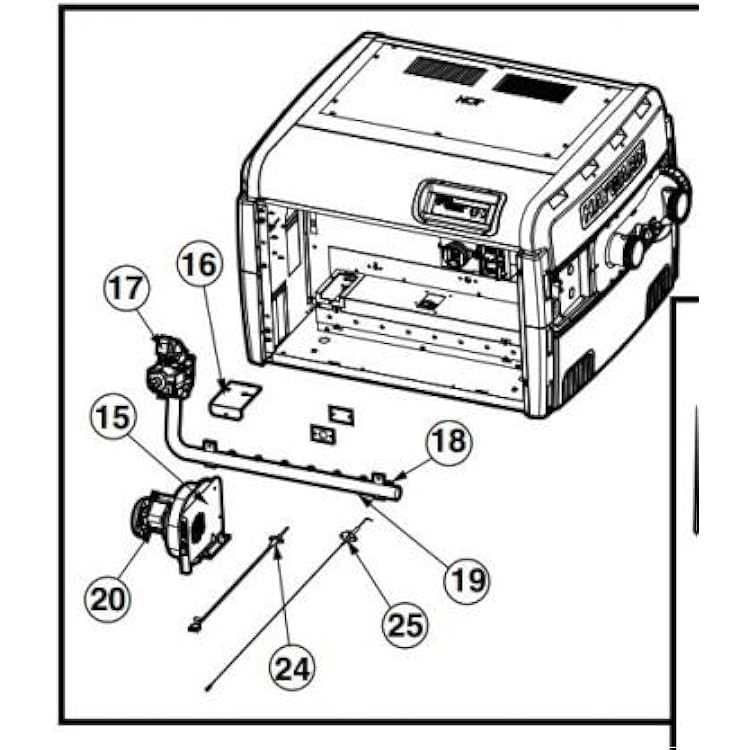

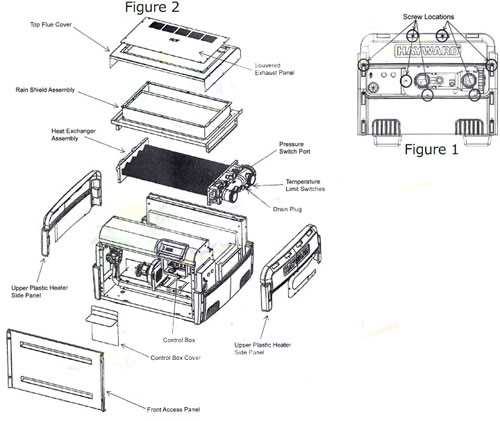

Internal Structure and Layout Overview

The internal arrangement of components in this system is designed with efficiency and durability in mind. Each element is strategically placed to optimize the overall performance, ensuring smooth operation and easy maintenance. This section provides a high-level understanding of how the various parts are organized and connected within the device.

- Core elements are situated centrally, allowing for balanced functionality.

- Auxiliary components are positioned around the main sections for better accessibility during servicing.

- Key connection points are organized logically to streamline the flow of energy and resources.

This thoughtful design not only simplifies troubleshooting but also extends the lifespan of the system by minimizing internal stress on critical areas.

Common Issues and Part Replacements

When maintaining any heating system, certain components may eventually wear out or malfunction over time. Proper upkeep is essential to ensure long-term performance and reliability. Below are some of the most frequently encountered problems and the components that often need to be changed to resolve them.

- Erratic Temperature Control: This issue often arises due to faulty sensors or wiring. Replacing these components usually restores proper function.

- System Won’t Ignite: Ignition failure is a common problem, typically caused by a malfunctioning ignition assembly or blocked valves. Inspecting and replacing these elements can resolve the issue.

- Leaking Unit: Leakage can result from worn seals or corroded connectors. It’s advisable to replace the affected parts to prevent further damage.

- Unusual Noises: Strange sounds coming from the

Guidelines for Proper Maintenance

Maintaining your equipment regularly ensures its longevity and optimal functionality. By following consistent upkeep routines, you can prevent common issues, improve performance, and extend the lifespan of the system. Addressing potential problems early will save time and resources in the long run.

Start by regularly inspecting all connections, fasteners, and seals. This will help you detect any wear or looseness before they lead to larger malfunctions. Cleaning key components and ensuring proper lubrication are also crucial steps in keeping the system running smoothly.

Additionally, monitoring the system’s operation under different conditions can help you identify unusual behavior or performance dips. Establishing a schedule for periodic checks and component replacements based on the manufacturer’s recommendations will reduce the chances of unexpected failures.

Critical Components Affecting Performance

The efficiency and reliability of any system depend heavily on a few essential elements. These elements not only contribute to optimal functionality but also play a significant role in preventing potential issues during operation. Understanding how these components interact with each other is key to maintaining high performance and longevity.

Heat Management Elements

Effective heat dissipation mechanisms are crucial to avoid overheating, which can lead to reduced efficiency or even damage. Components responsible for thermal control ensure that the system operates within safe temperature limits, protecting both internal parts and external equipment from wear and tear.

Flow Control Mechanisms

Another vital aspect is the control of fluid or air movement. Proper regulation of these flows ensures smooth operation and consistent output. When flow mechanisms are compromised, overall performance can suffer, leading to reduced effectiveness and possible malfunctions.

Safety Features and Precautions

When operating heating systems, it’s essential to be aware of various safety attributes and necessary precautions to ensure a secure environment. Understanding the built-in protective mechanisms can significantly reduce risks associated with malfunctions or improper use.

Overheat Protection: Many heating units incorporate sensors that automatically shut off the system when excessive temperatures are detected. This feature helps prevent damage to the equipment and mitigates fire hazards.

Water Flow Monitoring: A vital component of safe operation is the monitoring of water circulation. Units equipped with flow switches will disable operation if insufficient water is present, protecting against dry fire situations that can lead to significant damage.

Electrical Safety: It is crucial to ensure that all electrical connections are secure and adhere to local codes. Grounding systems and circuit breakers provide essential protection against electrical faults, preventing potential shocks or fires.

Regular Maintenance: Routine inspections and servicing are fundamental in identifying wear and tear. Keeping components clean and in good working condition is vital to maintain optimal safety standards and operational efficiency.

By adhering to these safety features and precautions, users can enhance the reliability of their heating systems and ensure a secure environment for operation.

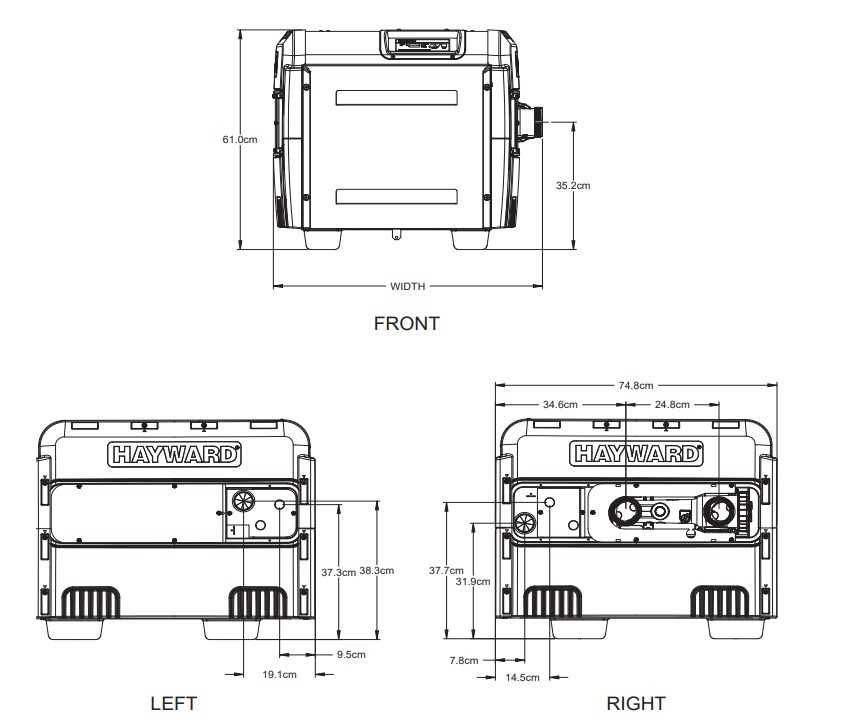

Compatibility with Other Models

This section explores the compatibility of various components with different models within the same brand. Understanding how parts interchange can enhance the maintenance and performance of your equipment, allowing users to make informed decisions when replacing or upgrading their systems.

Interchangeable Components

Several elements are designed to work seamlessly across multiple models, ensuring that users can find suitable replacements without compromising functionality. These interchangeable components not only simplify the repair process but also reduce costs, as parts from one unit may serve as a viable option for another.

Considerations for Compatibility

When assessing compatibility, it is essential to evaluate specifications such as size, capacity, and connection types. Additionally, consulting technical manuals or manufacturer guidelines can provide clarity on which components are best suited for specific applications, further ensuring optimal performance.

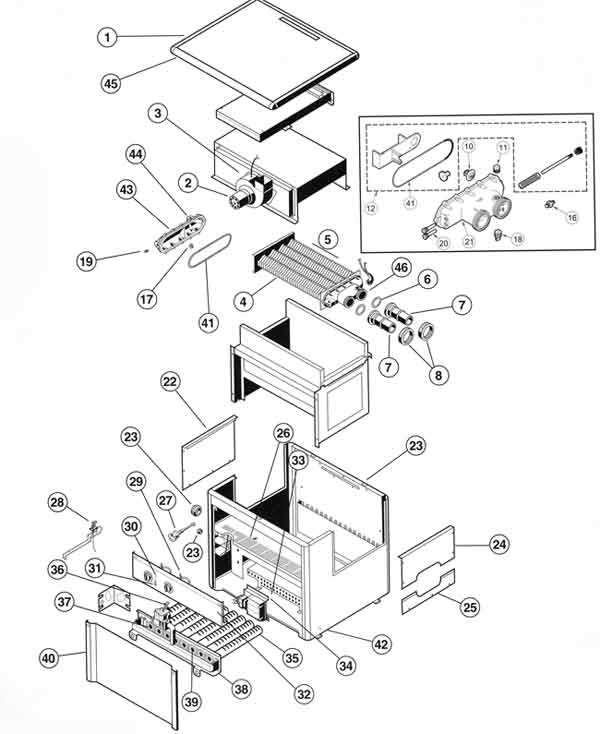

Steps for Efficient Part Installation

Ensuring a seamless assembly process is crucial for optimal functionality and longevity of equipment. This section outlines essential procedures to follow when integrating components into your system. Adhering to these guidelines will enhance the installation experience and minimize potential complications.

First, gather all necessary tools and materials before starting the installation. Having everything on hand will streamline the process and reduce interruptions. Next, carefully review the instruction manual to understand the requirements and specifications of each component. Familiarity with the assembly steps will provide clarity and prevent mistakes.

During the installation, ensure that each component is positioned correctly and secured firmly. Utilize appropriate fasteners and connectors to guarantee stability and performance. It is also advisable to check for any obstructions or potential interferences that may hinder the installation.

Finally, after completing the assembly, perform a thorough inspection of the setup. Verify that all connections are tight and that there are no loose elements. Running a test cycle can help confirm that everything operates as intended. Following these steps will lead to a successful integration and enhance the overall efficiency of the equipment.

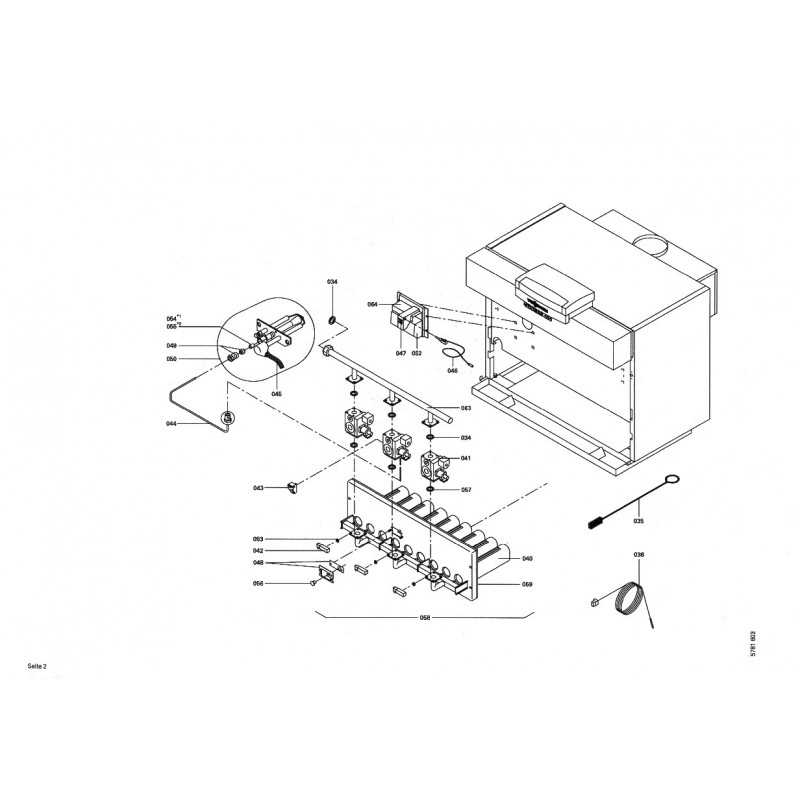

Diagnosing Malfunctions and Finding Solutions

Identifying issues and resolving them is crucial for maintaining efficient operation in any mechanical system. Regular assessments can prevent minor problems from escalating into significant failures. This section outlines effective strategies for troubleshooting common complications, along with potential remedies to enhance performance and longevity.

Common Issues and Their Symptoms

Several factors may lead to performance issues, including irregular operation, unusual noises, or inadequate functionality. Recognizing these signs early can facilitate swift intervention. Common symptoms include erratic temperature control, persistent leaks, or abnormal pressure readings. Keeping a detailed log of these occurrences aids in pinpointing underlying causes.

Effective Troubleshooting Techniques

Once symptoms are noted, a systematic approach to diagnosis is essential. Begin by inspecting all connections and ensuring they are secure. Next, test the components using appropriate tools to verify their functionality. If specific parts appear faulty, replacing them with compatible alternatives can restore optimal operation. Moreover, consulting user manuals or expert resources can provide invaluable insights into resolving persistent challenges.