In the realm of industrial machinery, a comprehensive understanding of the essential elements that drive performance is crucial. This section delves into the intricate arrangements and functionalities of various components that contribute to efficient air handling. Grasping the layout and interaction of these elements can significantly enhance maintenance practices and operational efficiency.

Identifying the specific roles each segment plays within the overall structure is paramount for troubleshooting and optimization. A detailed exploration of the layout not only aids in recognizing potential issues but also equips users with the knowledge necessary for effective upgrades and repairs. Through this understanding, operators can ensure that their systems function smoothly and reliably over time.

Moreover, having access to a visual representation of these critical elements allows for quicker learning and reference, fostering a more intuitive grasp of the machinery’s inner workings. This knowledge empowers users to make informed decisions, ultimately leading to improved performance and longevity of the equipment.

Understanding Quincy Compressor Components

Gaining insight into the various elements of air delivery systems is crucial for efficient operation and maintenance. Each component plays a significant role in ensuring optimal performance and longevity, making it essential to familiarize oneself with their functions and interconnections.

The primary elements that contribute to the effectiveness of these systems include:

- Power Source: This initiates the entire process, providing the necessary energy to operate.

- Intake Mechanism: Responsible for drawing in ambient air, this part ensures a continuous supply.

- Compression Chamber: Here, the air is compacted to increase pressure, facilitating efficient delivery.

- Cooling System: This element regulates temperature, preventing overheating and maintaining performance.

- Discharge Outlet: The point at which pressurized air is released for use in various applications.

Understanding the function of each component is vital for troubleshooting and enhancing efficiency. Regular maintenance of these elements can lead to improved reliability and performance in the long run.

Key aspects to consider include:

- Regular inspections to identify wear and tear.

- Timely replacement of any degraded components.

- Monitoring performance metrics to ensure optimal operation.

By mastering these elements, users can achieve a higher level of proficiency and ensure the effective operation of their air delivery systems.

Importance of Compressor Parts Diagram

A detailed representation of machinery components plays a crucial role in understanding their functionality and maintenance. Such illustrations provide insights that facilitate repairs, troubleshooting, and overall efficiency in operations.

Benefits of Visual Representations

- Enhances comprehension of complex systems.

- Assists in identifying specific elements during maintenance.

- Reduces the risk of errors in assembly or disassembly.

Impact on Operational Efficiency

- Streamlines the diagnostic process.

- Promotes quicker training for new technicians.

- Ensures proper reassembly, prolonging equipment lifespan.

Common Quincy Compressor Models Explained

This section explores the various models offered by a well-known manufacturer in the field of air systems. Each design serves specific applications and operational requirements, making it essential to understand their unique features and capabilities.

Popular Models Overview

- Model A

This model is designed for small-scale operations, providing reliable performance in limited spaces. It is favored for its energy efficiency and quiet operation.

- Model B

With enhanced capacity, this unit is suitable for medium-sized tasks. Its robust build ensures durability while maintaining consistent output levels.

- Model C

A high-capacity option, ideal for larger industrial environments. It boasts advanced technology for improved efficiency and reduced maintenance needs.

Key Features to Consider

- Energy Efficiency: Look for models that minimize power consumption while delivering optimal performance.

- Noise Levels: Evaluate the sound output, especially if the unit will be used in a sensitive environment.

- Durability: Consider materials and construction quality that enhance longevity and reliability.

- Maintenance Requirements: Some units are designed for easy servicing, reducing downtime and costs.

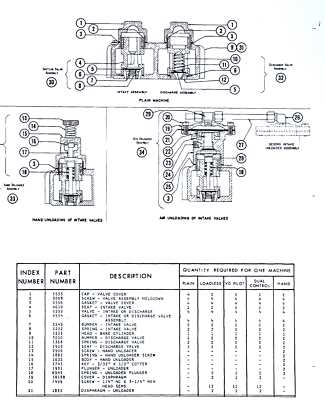

How to Read the Parts Diagram

Understanding a technical illustration that displays components and their relationships is essential for effective maintenance and repair tasks. This guide will help you navigate the visual representation, ensuring you can identify and locate each element accurately.

Start by familiarizing yourself with the overall layout. Typically, the illustration is divided into sections that categorize the elements based on functionality or location within the assembly. Look for a legend or key that clarifies the symbols or notations used throughout the visual. This will enhance your comprehension and facilitate easier referencing.

| Symbol | Description |

|---|---|

| A | Power Supply Unit |

| B | Control Mechanism |

| C | Pressure Sensor |

| D | Cooling Fan |

| E | Air Filter |

When examining the illustration, trace the flow or pathway indicated, as this can reveal how each part interacts within the system. Pay attention to any annotations that provide additional insights or specifications regarding size and compatibility. Familiarizing yourself with these aspects will empower you to effectively troubleshoot and replace components as necessary.

Identifying Key Components in Diagrams

Understanding the visual representation of mechanical systems is essential for efficient maintenance and troubleshooting. Recognizing crucial elements within these illustrations can greatly enhance operational knowledge and facilitate repairs. This section aims to outline the significance of identifying specific features and how they contribute to the overall functionality.

Key elements in any technical illustration often include:

- Power Source: The origin of energy that drives the entire mechanism.

- Control Mechanism: Components responsible for regulating the operation and performance.

- Output Element: Parts that perform the intended function of the system.

- Interconnecting Links: Features that ensure the proper flow of energy and communication between components.

- Safety Devices: Elements designed to prevent malfunctions or hazards during operation.

By familiarizing oneself with these critical features, individuals can improve their understanding of mechanical functionality and enhance their ability to diagnose issues. This knowledge is not only beneficial for repairs but also for implementing upgrades and ensuring long-term reliability.

Maintenance Tips for Quincy Compressors

Regular upkeep is essential for ensuring the longevity and efficiency of your equipment. By adhering to a consistent maintenance schedule, you can prevent breakdowns and optimize performance.

- Check the oil level regularly and change it according to the manufacturer’s recommendations.

- Inspect air filters frequently and replace them when they become dirty.

- Examine belts and hoses for signs of wear and replace as needed.

- Ensure all connections are secure to prevent leaks.

- Keep the surrounding area clean and free of debris to facilitate airflow.

Implementing these practices will help maintain operational efficiency and reduce the likelihood of costly repairs.

Common Issues and Troubleshooting Guide

This section addresses typical challenges encountered in the operation of air pressure systems and offers practical solutions. Understanding these frequent problems can aid in maintaining optimal performance and extending the lifespan of the equipment.

One prevalent issue is inadequate airflow, which can stem from clogged filters or blocked hoses. Regularly inspecting and cleaning these components can often resolve this problem effectively.

Another common concern is unusual noises during operation. This may indicate loose components or insufficient lubrication. Ensuring all fittings are secure and applying the appropriate lubricant can help mitigate these sounds.

Additionally, frequent cycling may signal an underlying fault, such as incorrect pressure settings or an air leak. Checking the pressure gauges and inspecting for leaks are crucial steps in troubleshooting this issue.

Finally, overheating can be a serious problem. It is essential to monitor temperature levels and verify that cooling systems are functioning properly to prevent damage.

Where to Find Replacement Parts

Finding suitable components for machinery maintenance is essential for optimal performance. Several avenues can be explored to ensure you source quality items effectively.

- Manufacturer’s Website: Check the official site for direct access to authentic components.

- Authorized Dealers: Partner with recognized retailers who offer genuine items and support.

- Online Marketplaces: Websites like eBay or Amazon can provide a variety of options, often at competitive prices.

- Local Repair Shops: Visiting nearby service centers may yield immediate availability and expert advice.

- Forums and Community Groups: Engaging with online communities can help locate rare components through shared resources.

Each option has its unique benefits, allowing you to make informed decisions based on your specific needs.