When it comes to maintaining machinery, a clear understanding of its individual elements is crucial for optimal performance and longevity. Each segment plays a vital role, contributing to the overall functionality and efficiency. Familiarizing yourself with these parts enables informed decisions during repairs and upgrades.

Exploring the intricacies of these components not only enhances your technical knowledge but also empowers you to troubleshoot issues more effectively. A well-structured overview can serve as a valuable reference, guiding you through the various elements and their interrelations.

In this guide, we will delve into the essential aspects of your machinery’s layout, offering insights that will lead to the ultimate understanding of how each piece fits together to ensure seamless operation. This foundational knowledge will be beneficial for both novice and seasoned users alike.

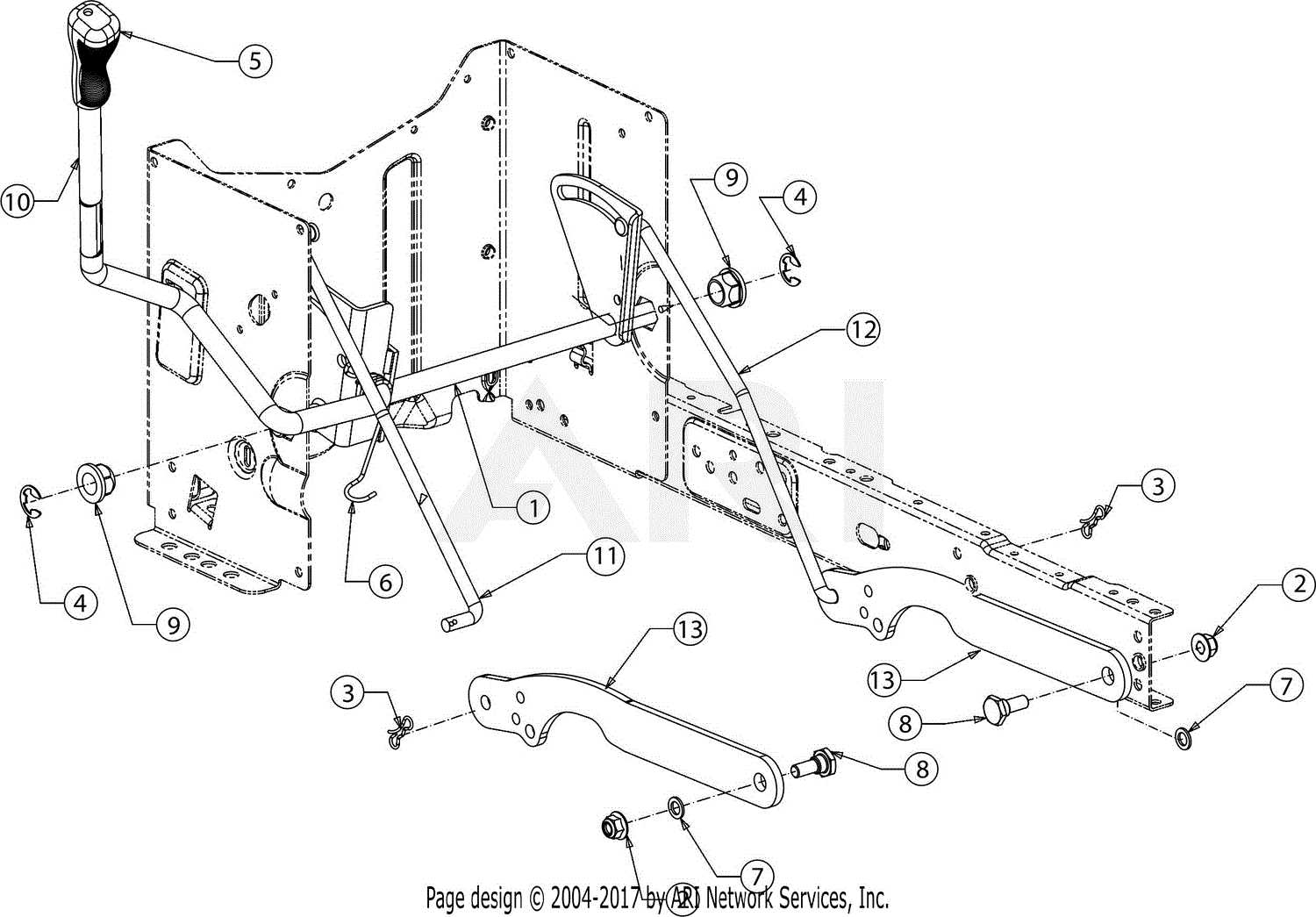

Understanding the 13wm77ks011 Parts Diagram

This section delves into the essential elements of a complex assembly, providing clarity on how various components interact and function together. Grasping the layout and relationships among these elements is crucial for effective maintenance and troubleshooting. A well-structured visual representation allows users to identify parts quickly and understand their roles within the entire system.

Key Components and Their Functions

Each element depicted plays a significant role in the overall operation. Recognizing each piece’s purpose enables users to anticipate potential issues and perform necessary repairs or replacements. Familiarity with these components not only enhances efficiency but also ensures the longevity of the equipment.

Utilizing Visual References for Maintenance

Visual aids serve as valuable tools for both novice and experienced technicians. By consulting these resources, users can follow step-by-step procedures for assembly or disassembly. This approach minimizes errors and streamlines the process, making it easier to maintain optimal performance.

Key Components of the 13wm77ks011

This section delves into the essential elements that make up the assembly in question. Understanding these components is crucial for comprehending how the system operates effectively and efficiently.

1. Core Structure: The fundamental framework serves as the backbone, providing stability and support for all other elements. Its design ensures durability and resilience under varying conditions.

2. Operational Mechanism: This component is responsible for driving the functionality of the entire unit. It converts input into desired output, allowing the system to perform its intended tasks seamlessly.

3. Control Interface: The interface enables user interaction, facilitating easy management of the system’s features. It typically includes buttons, displays, or touchscreens that enhance user experience.

4. Power Supply: An efficient power source is vital for the operation of the assembly. This element converts electrical energy into the necessary form to energize the various components effectively.

5. Safety Mechanisms: These features are designed to protect both the equipment and users from potential hazards. They include sensors, alarms, and automatic shut-off systems that ensure safe operation.

6. Connectivity Options: Various ports and wireless technologies enable integration with other devices. This allows for enhanced functionality and data exchange, expanding the system’s capabilities.

In summary, recognizing the significance of each of these crucial elements provides insight into the overall efficiency and performance of the assembly. Understanding how they interact is key to maximizing their potential and ensuring reliable operation.

How to Read Parts Diagrams

Understanding visual representations of components is essential for efficient assembly and maintenance. These illustrations provide a detailed view of individual pieces and their relationships within a system, allowing for easier identification and troubleshooting.

First, familiarize yourself with the symbols and notations used in the visual guide. Each component is usually represented by a specific shape or icon, accompanied by labels that indicate their names or functions. Pay attention to any color coding, as it often signifies different categories or statuses of the elements.

Next, observe the layout. Components are typically organized in a manner that reflects their actual arrangement in the assembly. This spatial relationship helps in comprehending how parts fit together and interact. Take note of any directional arrows or lines that indicate movement or connections, as these are crucial for understanding operational flow.

Finally, cross-reference the visual with any accompanying documentation. Detailed descriptions or lists of components can provide additional insights, ensuring that you have a complete understanding of the system. This comprehensive approach will enhance your ability to work with these illustrations effectively.

Common Issues with 13wm77ks011 Parts

When dealing with specific components in machinery, several recurring problems can arise, impacting performance and reliability. Identifying these issues early can help in preventing extensive damage and ensuring smooth operation.

One frequent concern is wear and tear, which can lead to decreased efficiency. Components may also suffer from improper alignment, causing strain and potential malfunction. Additionally, contaminants can accumulate, affecting the overall function. Below is a table summarizing these common challenges and their potential solutions.

| Issue | Description | Solution |

|---|---|---|

| Wear and Tear | Components degrade over time due to friction and stress. | Regular maintenance and timely replacements are essential. |

| Improper Alignment | Misalignment can lead to excess strain and premature failure. | Ensure correct installation and periodic checks for alignment. |

| Contamination | Dust and debris can hinder functionality and cause overheating. | Implement effective cleaning procedures and use protective covers. |

Maintenance Tips for Optimal Performance

Ensuring top-notch functionality requires regular upkeep and attention to detail. By following specific guidelines, you can enhance longevity and efficiency while minimizing potential issues.

Regular Inspection

- Conduct routine checks for wear and tear.

- Look for signs of corrosion or damage.

- Ensure all components are securely fastened.

Lubrication and Cleaning

- Apply appropriate lubricants to moving parts.

- Clean surfaces to prevent buildup of debris.

- Replace any worn or inefficient materials promptly.

By incorporating these practices into your maintenance routine, you will ultimately achieve better performance and reliability.

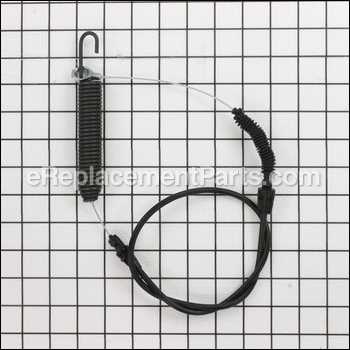

Where to Find Replacement Parts

Finding suitable components for your equipment can sometimes feel like a daunting task. However, with the right resources and a bit of guidance, you can easily locate the necessary items to keep your machinery running smoothly.

Online Retailers

Many online platforms specialize in providing a wide range of components. Here are some tips for effective searching:

- Use specific keywords related to the item you need.

- Check customer reviews for quality assurance.

- Compare prices across different websites to ensure the best deal.

Local Supply Stores

Visiting nearby stores can also be beneficial. Consider the following options:

- Search for dedicated hardware shops that may carry what you need.

- Ask for recommendations from professionals in your area.

- Inquire if they can order specific items if they are not currently in stock.

By utilizing both online and local resources, you can streamline the process of finding the components necessary for your projects. Always remember to verify the compatibility of items before making a purchase.

Comparing Diagrams of Similar Models

When examining the schematics of various machinery, it’s essential to understand the similarities and differences that can arise among models. These illustrations provide valuable insights into how components interact and highlight design variations that may affect functionality and maintenance. By analyzing comparable layouts, one can identify critical aspects that influence performance and compatibility.

In the following table, we summarize key features of different versions, allowing for an efficient comparison:

| Model | Main Features | Common Components | Differences |

|---|---|---|---|

| Model A | High efficiency, compact design | Motor, gearbox, sensors | Enhanced cooling system |

| Model B | Robust construction, user-friendly interface | Motor, gearbox, sensors | Advanced control options |

| Model C | Lightweight, portable | Motor, gearbox, sensors | Battery-powered operation |

This comparison highlights how different models can share fundamental elements while catering to various operational needs and preferences. Such insights are crucial for users looking to make informed decisions regarding their equipment choices.

Tools Needed for Assembly and Repair

Having the right instruments at your disposal is crucial for efficient assembly and maintenance tasks. These essential implements not only enhance precision but also ensure safety during the process. Selecting appropriate tools can significantly reduce the time and effort required to complete repairs or put components together.

Essential Hand Tools: Basic hand tools such as wrenches, screwdrivers, and pliers are fundamental for any assembly task. They allow for easy manipulation of parts and fasteners, making the process smoother.

Power Tools: Incorporating power tools like drills and impact drivers can expedite assembly. These devices are designed to handle tougher materials and complex jobs with ease.

Measuring Instruments: Accurate measurements are vital. Tools like calipers and tape measures help ensure that every piece fits perfectly, reducing the likelihood of errors.

Safety Equipment: Always prioritize safety by using protective gear such as goggles and gloves. This equipment safeguards against potential injuries while working with various components.

By having a well-rounded toolkit, you can confidently tackle assembly and repair challenges, ultimately enhancing your efficiency and effectiveness.

Frequently Asked Questions About the Diagram

This section addresses common inquiries related to the visual representation of components and their interrelations. Understanding these illustrations can be crucial for effective assembly, maintenance, or troubleshooting.

- What information can I find in these illustrations?

- Detailed layout of all elements.

- Identification of each piece and its function.

- Connections and interactions between components.

- How do I read these visual aids?

- Start by identifying the main sections.

- Follow the labeled arrows to understand flow and connections.

- Refer to accompanying notes for specific details.

- Are there any symbols I should know?

- Yes, common symbols include circles for connections and squares for components.

- Check the legend for unique markings that indicate special functions.

- Where can I find additional resources?

- Manufacturer’s website for user manuals.

- Online forums dedicated to specific products.

- Technical support from customer service.

- What if I can’t find the information I need?

- Contact the manufacturer directly for assistance.

- Consult with professionals who have experience with similar models.

- Utilize community forums for shared knowledge and tips.