In any efficient watering system, it’s crucial to have a clear view of how various elements work together. These systems are designed to distribute water over a large area with minimal effort. To achieve optimal functionality, every element needs to be properly aligned and functioning in harmony. This ensures that the water flow remains consistent and the coverage is uniform across the designated zone.

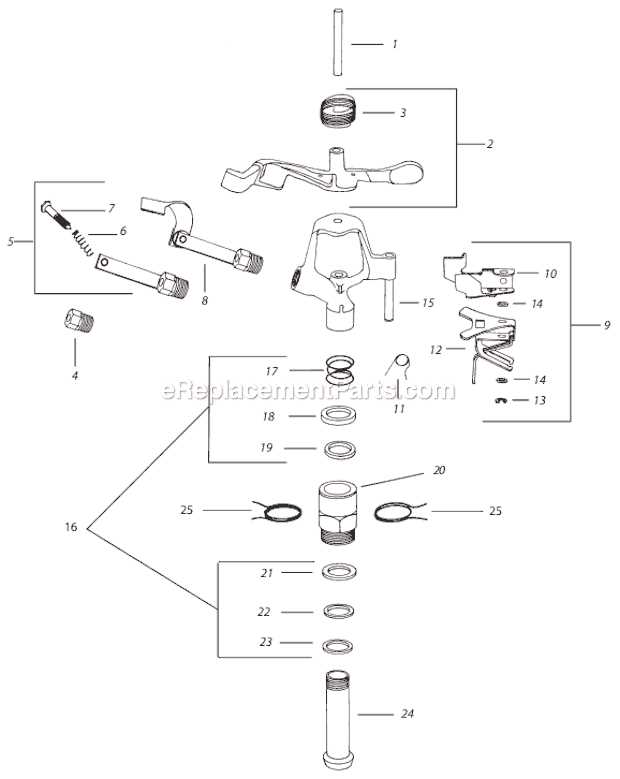

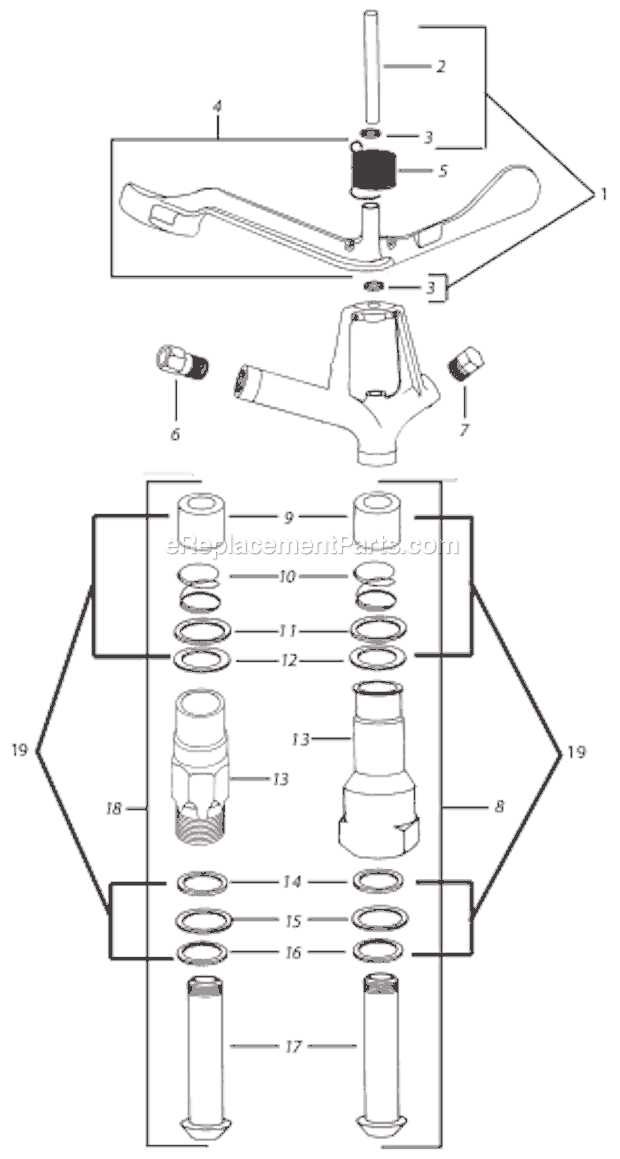

By breaking down the structure into individual elements, you can easily identify the key components that contribute to the performance. From the rotating mechanism to the nozzle, each part plays a vital role in directing the water. Understanding how these elements interact will help in troubleshooting and maintaining the system to ensure it operates at peak efficiency.

Whether you’re setting up a new system or maintaining an existing one, being familiar with each element allows for better adjustments and smoother operation. Knowing the details of each section ensures that you can make informed decisions about repairs or upgrades, keeping everything running smoothly.

Overview of Key Sprinkler Components

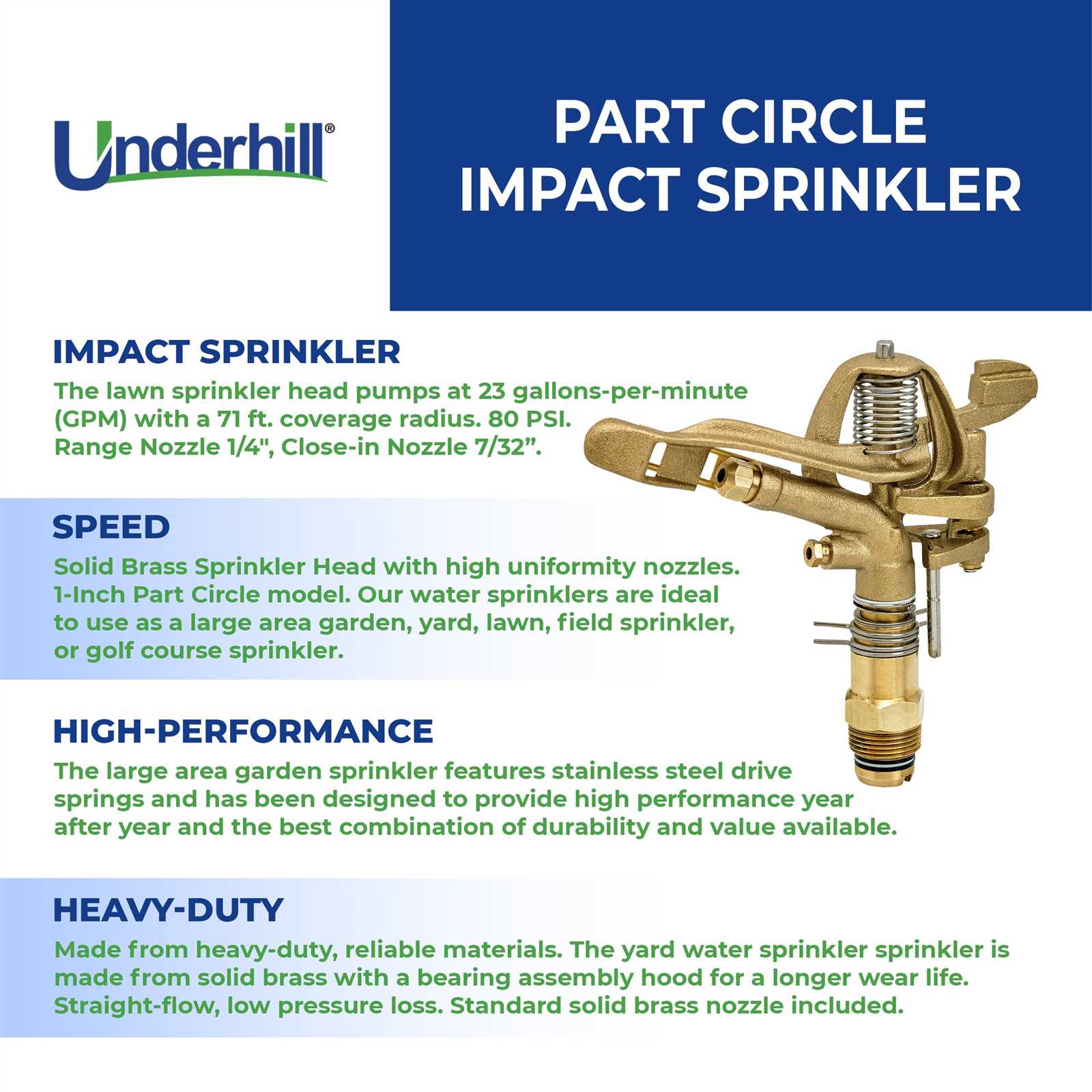

The efficient functioning of any watering system relies on a combination of various crucial elements. Each part plays a specific role in ensuring that water is distributed evenly and reaches the designated areas effectively. Understanding the purpose and function of these components is essential for maintaining and optimizing the system’s performance.

At the core of the system is the rotating mechanism, which is responsible for guiding water in a controlled pattern across the area. This mechanism works in tandem with the nozzle, a critical element that regulates water flow and pressure, helping to achieve the desired coverage. The base structure provides stability, ensuring that the system remains firmly in place during operation.

Other important components include the adjustable settings, which allow for customization of water distribution, and the seals, which prevent leaks and ensure smooth operation. By familiarizing oneself with these key elements, users can easily identify and troubleshoot potential issues, ensuring the system continues to function effectively over time.

Water Flow Mechanism and Functionality

The system responsible for distributing water evenly across a designated area operates through a series of carefully aligned components. These elements work together to regulate water pressure, control the direction of flow, and ensure efficient coverage. Understanding how water moves through the structure helps in optimizing performance and preventing issues.

Key Elements of Water Flow Control

The core mechanism begins with the intake, where water enters the system at a certain pressure. From there, it passes through channels designed to maintain a consistent flow. Each channel is crafted to reduce water loss and guide the flow toward the distribution point. This ensures that water is evenly dispersed over the target area, regardless of variations in pressure.

Flow Regulation and Pressure Balance

Maintaining balance in water pressure is essential for the system’s functionality. Internal valves and nozzles play a crucial role in adjusting the pressure, ensuring that water is neither wasted nor misdirected. These adjustments help maintain the right amount of water flow while distributing it evenly.

| Component | Function | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Intake Valve | Controls the amount of water entering the system. | ||||||||||||||||||

| Pressure Regulator | Maintains a balanced pressure throughout the

Rotational Movement and Control SystemsUnderstanding how rotational movement is guided and regulated is crucial for the effective functioning of various mechanical systems. The dynamic interaction between rotational components allows for efficient direction of force and precise control, ensuring optimal performance in multiple environments. Mechanics of RotationRotational mechanisms are typically driven by the interplay of gears, axles, and motorized elements. These components work together to initiate and maintain consistent movement, transferring energy from one part to another with minimal resistance. The speed and range of motion are often adjustable, depending on the system’s design and purpose. Control MechanismsControl systems play a significant role in regulating the motion. Automated or manual systems can adjust parameters such as rotational speed, angle, and timing, allowing for precise control. Sensors, timers, and feedback loops are commonly used to monitor and fine-tune the system, ensuring smooth and reliable operation.

Nozzle Types and Water DistributionEfficient water dispersion relies heavily on the correct choice of nozzles, each designed to control the flow and direction of the liquid. The selection of nozzles affects not only the range but also the uniformity of coverage, ensuring that the liquid is distributed evenly across the designated area. Types of NozzlesNozzles come in various shapes and sizes, each tailored for specific tasks. Some are designed to emit a concentrated stream, while others create a wider spray pattern for broader coverage. Choosing the appropriate type is key to optimizing performance, reducing waste, and adapting to different terrains. Water Distribution PatternsThe pattern of water distribution is determined by the nozzle’s design. Some nozzles distribute water in a circular or semicircular pattern, while others deliver it in straight lines or arcs. By adjusting the nozzle, you can modify the range and shape of the distribution, ensuring adequate coverage for different areas.

Regular maintenance and timely replacement of worn-out elements will help ensure that your system operates at its best, preventing unnecessary damage and saving on costly repairs. |