Understanding the detailed layout of essential elements in machinery is crucial for effective maintenance and repair. This guide provides a thorough breakdown of how different components are arranged and interconnected. It serves as a practical resource for identifying and locating various systems within the machine, ensuring that each part is accounted for and understood in context.

The structure of mechanical systems can sometimes appear complex. However, with a well-organized visualization of the connections and individual elements, it becomes significantly easier to comprehend how everything functions together. This guide aims to simplify that process, allowing for a more intuitive approach to troubleshooting and upkeep.

By examining the arrangement of the equipment’s internal elements, you’ll gain valuable insights into its operational dynamics. Each section is clearly labeled and explained, helping users navigate through the systems with confidence and precision. This resource is designed to aid both experienced technicians and those new to machine maintenance.

Understanding the Layout of John Deere LX255 Components

The efficient performance of any machine depends greatly on the organization and interaction of its various elements. To ensure optimal functionality, it is important to grasp how each component is arranged and how they work together as part of the overall system. By examining the structural layout, users can gain a deeper understanding of how different mechanisms are positioned and how to maintain or repair them more effectively.

Each section of the machine is carefully designed to maximize operational efficiency and ease of use. From the power source to the drive system, every piece is interconnected, ensuring smooth and reliable performance. Recognizing the role and position of each unit within this system is key to troubleshooting and extending the lifespan of the equipment.

Key Mechanical Sections of the LX255

This machine features several essential areas that ensure its smooth operation. These areas work together to deliver power, control, and maneuverability. Understanding each section will help users better maintain and troubleshoot the equipment, ensuring efficient performance over time.

Engine Compartment

At the heart of this model lies a powerful engine that provides the necessary energy for all its functions. The engine compartment houses not only the engine but also essential components like the fuel system, air filters, and cooling mechanisms. Regular maintenance of these elements is crucial for optimal performance and longevity.

Transmission and Drive System

The transmission and drive system are responsible for transferring power from the engine to the wheels, allowing for smooth movement and speed control. This section includes the gearbox, drive belts, and axle components. Proper care of the transmission ensures efficient power distribution and responsive handling.

| Section | Key Component | Function |

|---|---|---|

| Engine Compartment | Air Filters | Maintains clean air intake for engine efficiency |

| Transmission | Drive Belts | Transfers power from engine to wheels |

| Cooling System | Radiator | Prevents overheating during extended use |

How to Identify Essential Engine Parts

Understanding the key components of a machine’s motor is crucial for anyone looking to maintain or repair it effectively. Recognizing the most important elements can help ensure smooth operation and prevent breakdowns. In this guide, we will explore the primary components that drive the functionality of the motor, enabling you to identify them quickly and confidently.

The cylinder block is the core structure, housing crucial moving elements that produce power. This large metal casting supports the combustion process, and its design ensures stability and strength.

Another vital component is the crankshaft, which converts the reciprocating motion of pistons into rotational movement. This allows the motor to generate the torque necessary for driving other systems.

The camshaft plays a critical role in managing the opening and closing of valves, coordinating the intake and exhaust cycles. This precise timing mechanism ensures the efficient operation of the combustion process.

Additionally, the pistons move within the cylinder, driven by combustion pressure. These parts transfer force to the crankshaft, continuing the mechanical process that powers the machine.

Finally, the timing belt or chain is essential for synchronizing the camshaft and crankshaft, ensuring that valves and pistons move in harmony. Its correct installation and tension are vital for motor efficiency.

The Role of the Transmission System

The transmission system plays a crucial role in ensuring smooth power delivery and optimal performance. It functions as the intermediary between the engine and the wheels, adjusting power output to match varying speeds and conditions. By regulating the torque and speed ratios, the transmission enables efficient movement and control of the vehicle across different terrains and loads.

Power Regulation and Distribution

A well-functioning transmission ensures that the engine operates within its ideal power range while distributing energy effectively. This balance allows the machinery to handle diverse tasks without compromising on efficiency or overburdening the engine. It provides the flexibility needed to shift between low and high gears depending on the workload or driving conditions.

Ensuring Longevity and Performance

Proper maintenance of the transmission system is essential for long-term reliability. Ensuring that gears and components are functioning correctly prevents wear and tear, extending the lifespan of the entire vehicle. Regular checks and timely repairs not only optimize performance but also contribute to smoother operation and fuel efficiency.

Electrical System Breakdown for the LX255

The electrical system in this model is a crucial component that ensures reliable performance and smooth operation of the machinery. This section provides a comprehensive overview of the key elements involved in the electrical circuitry, helping users understand the connections and components that power various functions. Each part is connected to ensure efficient energy distribution, starting mechanisms, and safety features, making maintenance and troubleshooting easier.

| Component | Function | Location |

|---|---|---|

| Battery | Provides power to the entire electrical system | Mounted near the engine compartment |

| Starter Solenoid | Engages the starter motor to crank the engine | Located close to the battery |

| Ignition Switch | Controls the starting and stopping of the engine | Mounted on the control panel |

| Wiring Harness | Connects various electrical components for power and control signals | Runs throughout the frame |

| Fuses | Protects the system from electrical overloads | Located in a fuse box near the dashboard |

How Steering and Suspension Components Work

The steering and suspension systems play a crucial role in ensuring a vehicle’s stability and control. These components work in harmony to provide a smooth ride and accurate handling, allowing for efficient maneuverability on various terrains. Understanding their functionality is essential for effective maintenance and troubleshooting.

At the core of the steering system are elements that enable the driver to control the direction of the vehicle. This system typically includes a steering wheel, steering column, and various linkages that connect to the wheels. When the steering wheel is turned, it transfers motion through these linkages, pivoting the wheels in the desired direction. This responsiveness is vital for navigating curves and obstacles safely.

The suspension system, on the other hand, is designed to absorb shocks and maintain tire contact with the ground. It consists of springs, shock absorbers, and various linkages that support the vehicle’s weight while allowing for vertical movement. By cushioning impacts from uneven surfaces, the suspension system enhances ride quality and stability, significantly affecting overall driving performance.

Both systems are interconnected, with the suspension influencing steering precision and vehicle control. Regular inspection and maintenance of these components are essential to ensure optimal performance, contributing to the longevity and safety of the vehicle.

Fuel System Overview and Maintenance Tips

The fuel system is a critical component that ensures the efficient operation of small engines. It is responsible for delivering the necessary fuel to the engine, which is then mixed with air to facilitate combustion. Proper functioning of this system is essential for optimal performance, fuel efficiency, and longevity of the machinery.

Key Components of the Fuel System

This system typically consists of several essential elements, including the fuel tank, fuel pump, filter, and carburetor. Each component plays a vital role in the fuel delivery process:

- Fuel Tank: Stores the fuel required for operation.

- Fuel Pump: Moves the fuel from the tank to the engine.

- Filter: Removes impurities from the fuel before it reaches the engine.

- Carburetor: Mixes air and fuel in the correct proportions for efficient combustion.

Maintenance Recommendations

Regular maintenance is crucial to ensure the smooth operation of the fuel system. Here are some tips to keep it functioning optimally:

- Inspect and Replace Filters: Regularly check the fuel filter for clogs and replace it as needed to maintain proper fuel flow.

- Clean Fuel System Components: Periodically clean the carburetor and other components to prevent buildup that can affect performance.

- Check for Leaks: Inspect hoses and connections for any signs of fuel leaks, which can lead to performance issues and safety hazards.

- Use Fresh Fuel: Ensure that the fuel used is fresh and free of contaminants to avoid engine problems.

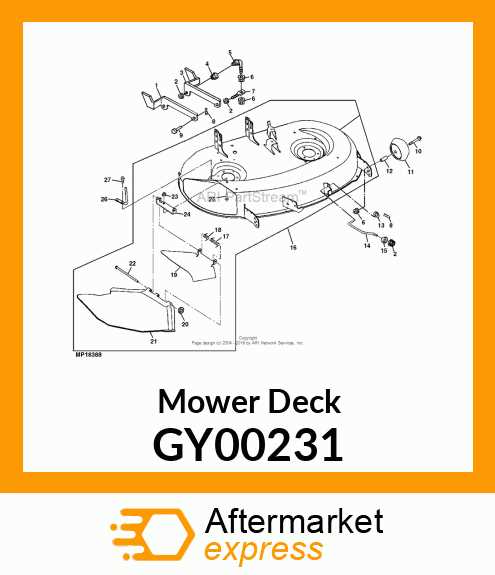

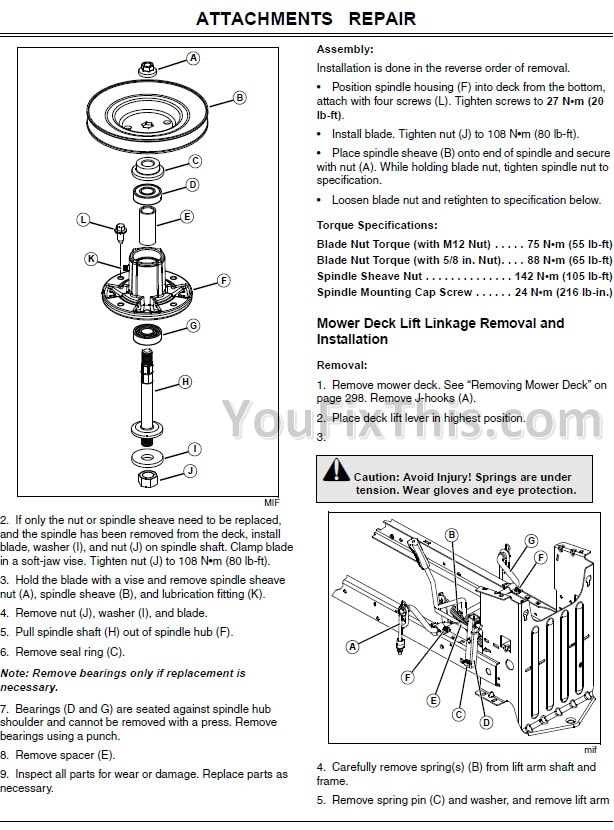

Common Issues with the Mower Deck

The mower deck is a crucial component that plays a significant role in the overall performance and efficiency of your cutting machine. Understanding the common challenges that may arise can help in maintaining optimal functionality and achieving a clean cut. Below are some frequent issues that users might encounter with this essential part.

| Issue | Description | Solution |

|---|---|---|

| Uneven Cutting | This problem often results in an uneven lawn appearance due to varying cutting heights. | Check the deck height settings and adjust as necessary. Inspect the blades for sharpness and wear. |

| Clumping of Grass | Grass clippings may accumulate under the deck, affecting performance and leaving clumps on the lawn. | Clean the underside of the deck regularly and ensure proper airflow for effective grass discharge. |

| Blade Dullness | Dull blades can lead to jagged cuts and increased strain on the engine. | Sharpen or replace blades as needed to maintain cutting efficiency. |

| Vibration Issues | Excessive vibration during operation can indicate imbalances or loose components. | Inspect the mounting hardware and blades for tightness and check for any bent or damaged parts. |

| Corrosion | Rust can develop on metal parts, compromising structural integrity and functionality. | Regularly clean and apply protective coatings to prevent rust and deterioration. |

Upgrading or Replacing Parts for Better Performance

Enhancing the efficiency and functionality of your equipment often involves the strategic selection of components. Whether you aim to boost power, improve fuel efficiency, or extend the lifespan of your machine, knowing which elements to upgrade can make a significant difference. This section explores the advantages of enhancing or substituting various components to achieve optimal performance.

Benefits of Component Upgrades

- Increased Efficiency: Upgrading certain elements can lead to improved fuel efficiency and reduced operating costs.

- Enhanced Performance: High-quality replacements can enhance the overall power and speed of the machinery.

- Improved Longevity: Selecting durable and high-performance parts can extend the lifespan of your equipment.

- Better Compatibility: Modern components may offer better compatibility with advanced technologies, providing smoother operation.

Common Components to Consider for Replacement

- Engine Components: Upgrading the engine for better power output and efficiency.

- Transmission Parts: Replacing parts can enhance shifting performance and reliability.

- Hydraulic Systems: Enhancing hydraulic components improves lifting capacity and operational speed.

- Electrical Systems: Modernizing electrical components ensures better connectivity and responsiveness.