In the world of agricultural machinery, the efficiency and functionality of equipment are paramount for successful operations. A comprehensive understanding of how various components fit together can significantly enhance maintenance and repair efforts. This knowledge is essential for farmers and technicians alike, enabling them to identify issues quickly and ensure optimal performance.

Visual aids play a crucial role in grasping the intricacies of machine assembly. By examining detailed illustrations that highlight each element, users can gain insights into the interconnectivity of components. These resources not only facilitate easier identification of parts but also streamline the troubleshooting process, ensuring that downtime is minimized and productivity is maximized.

Whether you are a seasoned professional or a newcomer in the agricultural field, familiarizing yourself with the schematics of your equipment can be a game changer. This foundational knowledge empowers users to make informed decisions about repairs and upgrades, ultimately leading to more effective farming practices. With the right resources, the maintenance of your machinery can become a straightforward and manageable task.

Overview of John Deere 660 Hay Rake

This section provides a comprehensive look at a specific model of agricultural equipment designed for the effective gathering of cut forage. The machine plays a crucial role in optimizing the harvesting process, ensuring efficiency and productivity on the farm.

Key features of this model include:

- Robust construction for durability

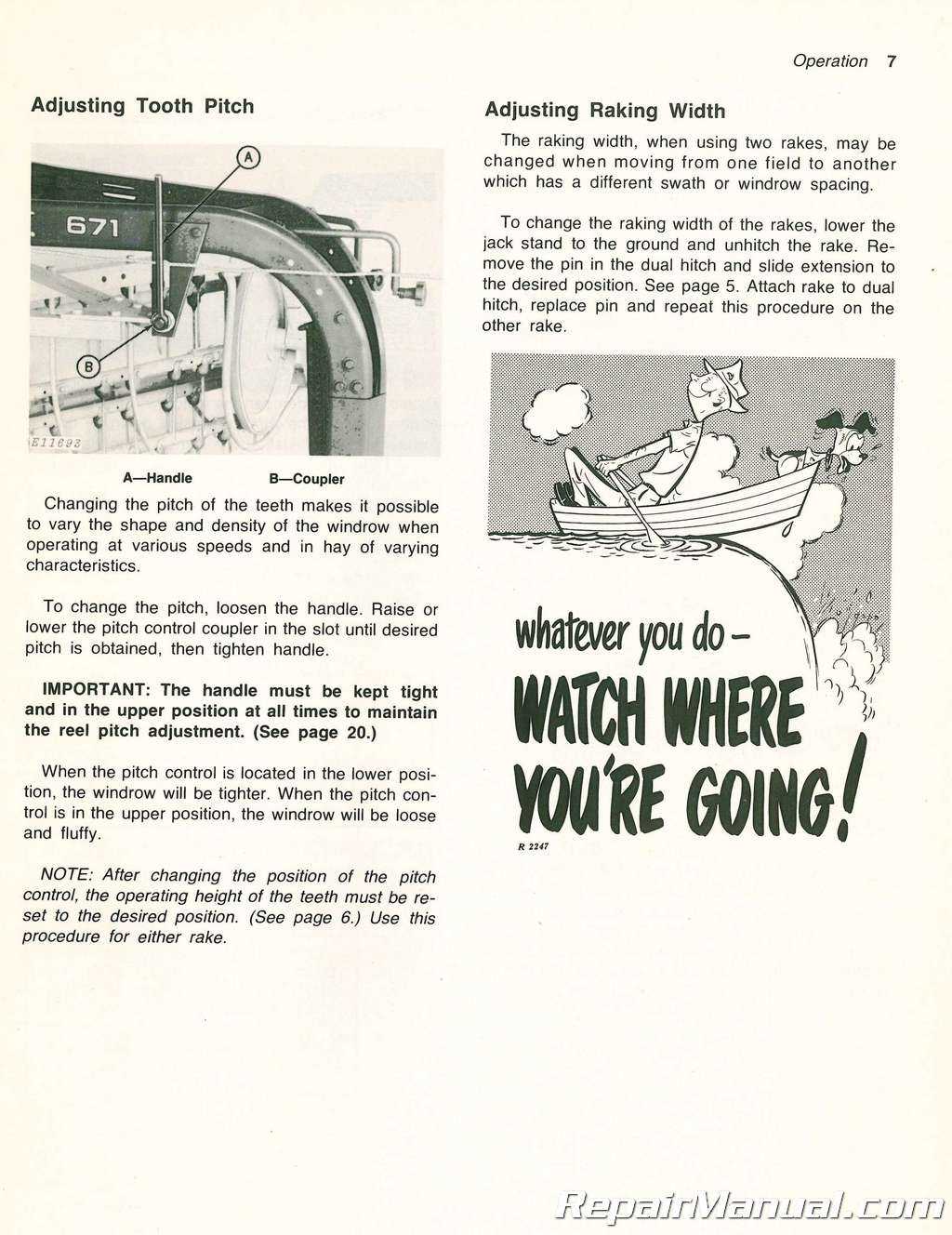

- Innovative design for ease of operation

- Adjustable settings to suit various field conditions

- Compatibility with a range of tractors

Understanding the components and functionality of this implement is essential for maintenance and troubleshooting. Familiarity with its mechanics can lead to improved performance and longevity.

Farmers can benefit from the following advantages:

- Increased efficiency in forage collection

- Reduced time spent on field operations

- Enhanced quality of collected materials

- Minimized wear and tear on other machinery

Overall, this agricultural tool serves as an indispensable asset for those looking to maximize their yield and streamline their workflow in the field.

Importance of Maintenance for Hay Rakes

Regular upkeep of agricultural implements is crucial for ensuring their longevity and optimal performance. Without proper attention, even the most robust machinery can suffer from wear and tear, leading to inefficiencies and costly repairs. Establishing a routine maintenance schedule not only enhances functionality but also prevents unexpected breakdowns during critical periods of operation.

Benefits of Regular Upkeep

Consistent maintenance provides several advantages. Firstly, it enhances productivity by ensuring that the equipment operates smoothly, thereby reducing downtime. Secondly, it helps identify potential issues before they escalate into significant problems. This proactive approach minimizes repair costs and prolongs the lifespan of the machinery. Furthermore, well-maintained equipment often contributes to higher quality outcomes in the field, ensuring that operations run seamlessly.

Key Maintenance Practices

To maintain peak performance, several practices should be implemented. Regular inspections of moving parts, lubricating mechanisms, and checking for wear are essential steps. Additionally, keeping machinery clean and free of debris can significantly improve efficiency. Finally, ensuring that all components are aligned and functioning correctly is vital to achieving the best results.

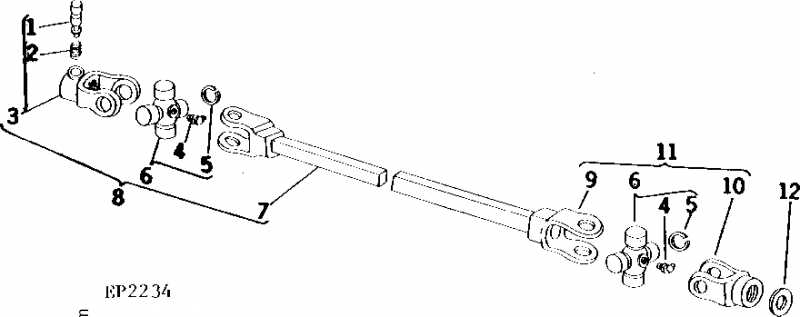

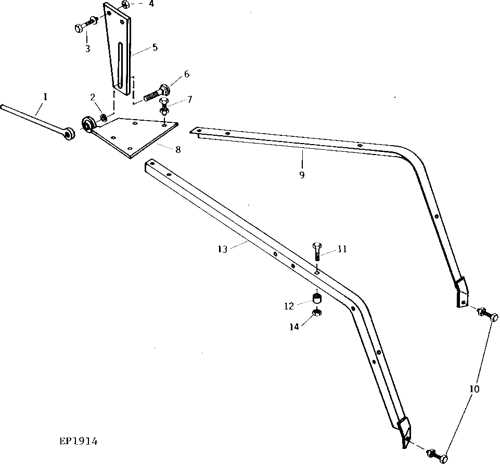

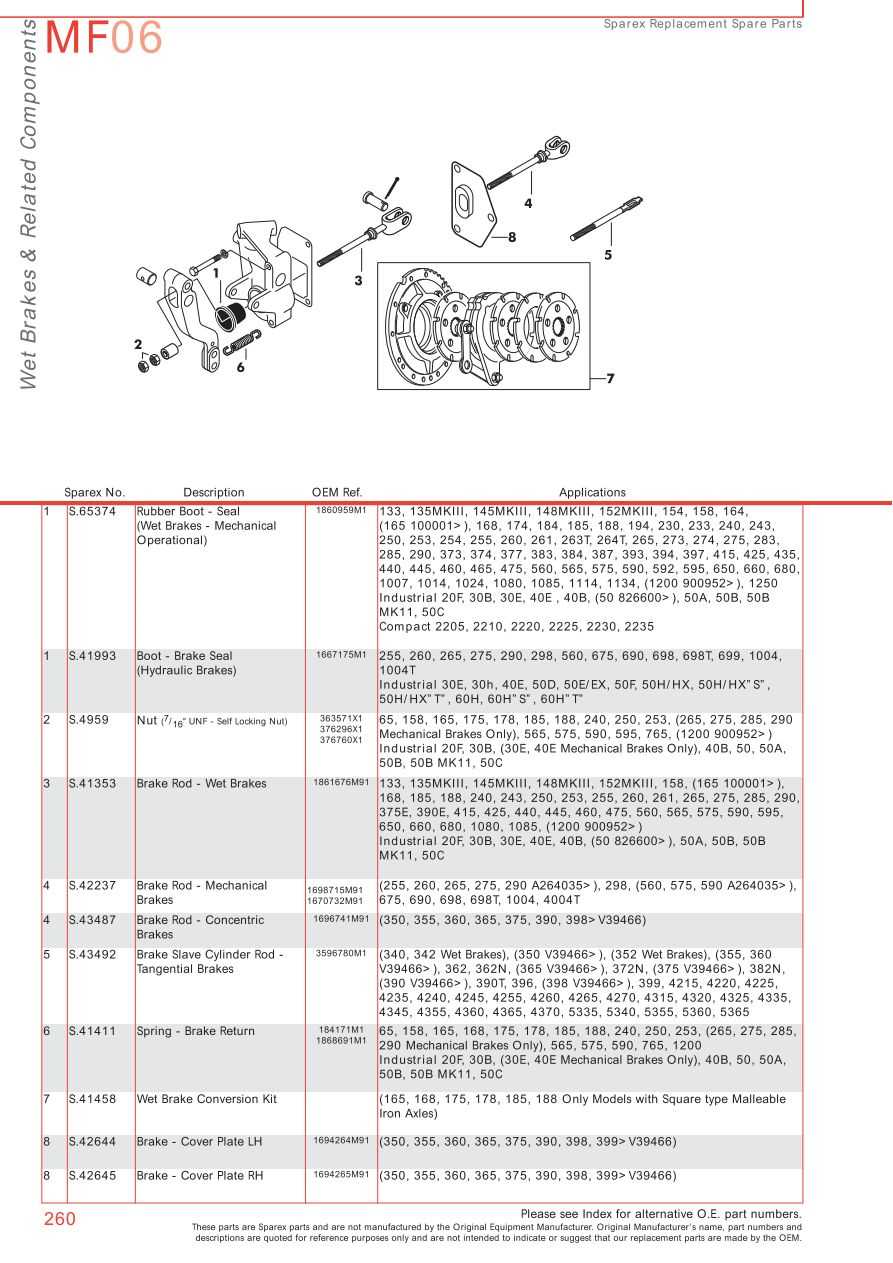

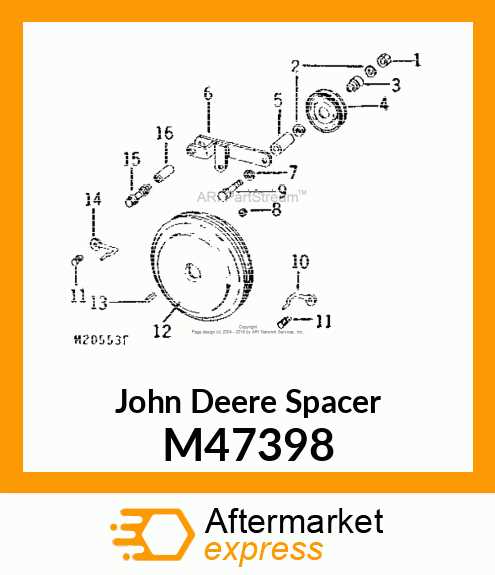

Identifying Key Components in Diagrams

Understanding the essential elements depicted in technical illustrations is crucial for effective maintenance and repair. Each symbol and line represents specific machinery components, and recognizing these parts aids in troubleshooting and assembly. A clear grasp of these visuals can enhance efficiency and reduce the likelihood of errors during operations.

Common Symbols and Their Meanings

Diagrams often employ standardized symbols to convey information succinctly. For instance, circles may indicate rotating parts, while rectangles often represent stationary elements. Familiarizing oneself with these common icons can streamline the identification process and facilitate a quicker comprehension of the overall system.

Relationships Between Components

It’s not enough to recognize individual symbols; understanding how these elements interact is equally important. Arrows typically illustrate the flow of energy or material, highlighting connections between parts. Analyzing these relationships provides insight into the machinery’s functionality and assists in pinpointing areas that may require attention.

Common Issues and Replacement Parts

In the world of agricultural equipment, understanding frequent challenges and the necessary components for replacement is essential for maintaining optimal performance. This knowledge aids operators in troubleshooting and ensuring that machinery runs efficiently throughout the season.

Frequent Challenges

Operators may encounter a variety of issues with their equipment, which can affect productivity and efficiency. Common problems include wear and tear of moving components, misalignment, and inadequate performance in various field conditions. Identifying these issues early can prevent more significant breakdowns and costly repairs.

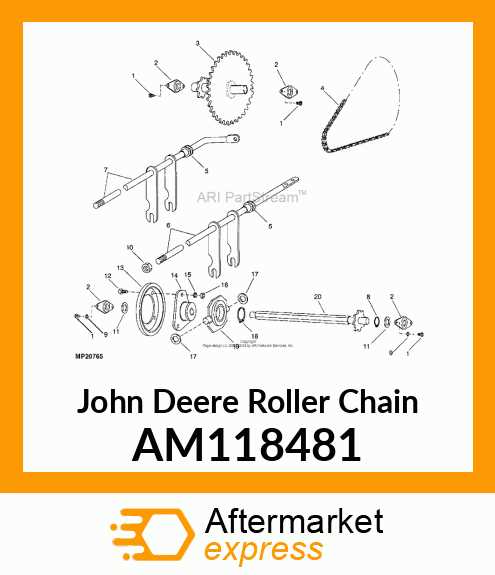

Essential Components for Replacement

To address the identified challenges, having a list of essential components ready for replacement can save time and enhance operational continuity. Below is a table of commonly replaced items and their functions:

| Component | Function |

|---|---|

| Drive Belt | Transmits power from the engine to the operational mechanisms |

| Wheels | Ensure mobility and stability during operation |

| Teeth | Engage with the crop material for effective handling |

| Bearings | Support moving parts and reduce friction |

Having a reliable supply of these components can greatly reduce downtime and enhance the overall efficiency of the machinery in use.

How to Read Parts Diagrams Effectively

Understanding technical illustrations can significantly enhance your ability to identify components and their functions within machinery. These visual representations provide a structured overview, making it easier to locate and comprehend various elements. By mastering the art of interpreting these visuals, you can streamline maintenance and repair tasks, ensuring a more efficient workflow.

Familiarize Yourself with Symbols and Notations

Each illustration utilizes specific symbols and notations to convey information about individual components. Taking time to learn these symbols is crucial for effective navigation. Look for legends or keys that explain the markings, as they often clarify the roles of various parts. This foundational knowledge will aid you in quickly recognizing what each component represents and how it fits into the overall assembly.

Follow the Flow of Assembly

These visuals typically show the arrangement and connection of components in a logical sequence. Pay attention to the flow indicated by lines and arrows, which illustrate how parts interrelate. This not only helps in identifying where each piece belongs but also aids in understanding the assembly process, making repairs and replacements much simpler. Remember to take notes or highlight areas of interest as you go through the illustration.

By honing these skills, you’ll find yourself more confident in tackling any tasks involving mechanical assemblies, ultimately saving time and resources.

Step-by-Step Repair Guide for Owners

This guide aims to provide a comprehensive approach for enthusiasts looking to maintain and repair their machinery effectively. Understanding each step involved will enhance the ownership experience and ensure optimal performance.

| Step | Description |

|---|---|

| 1 | Gather necessary tools and materials before beginning the repair process. |

| 2 | Carefully inspect the equipment for any visible damage or wear. |

| 3 | Refer to the manual to identify specific components that need attention. |

| 4 | Disassemble relevant parts as instructed, taking care to note their arrangement. |

| 5 | Replace worn or damaged components with suitable replacements. |

| 6 | Reassemble the equipment, ensuring all parts are securely fastened. |

| 7 | Test the machinery to confirm everything operates smoothly. |

Upgrading Parts for Improved Performance

Enhancing equipment performance often involves replacing certain components with upgraded versions. By selecting superior materials or more efficient designs, operators can achieve greater efficiency and reliability. This approach not only boosts productivity but also extends the lifespan of machinery.

Here are some key benefits of upgrading components:

- Increased Efficiency: Newer designs often provide improved functionality, leading to faster operation.

- Durability: Upgraded materials can withstand wear and tear better, reducing the need for frequent replacements.

- Cost-Effectiveness: While initial investment might be higher, long-term savings on maintenance and downtime are significant.

- Enhanced Performance: Better components can lead to superior handling and output, making tasks easier and more effective.

When considering enhancements, it is essential to assess compatibility with existing machinery. Consulting manuals or experts can provide valuable insights into which upgrades will yield the best results.

- Identify components that are underperforming.

- Research available upgrade options, focusing on reviews and performance ratings.

- Consult with professionals or trusted suppliers for advice on installation and integration.

- Evaluate the impact of upgrades on overall operational efficiency.

Investing in upgraded components can significantly transform operational capabilities, making it a worthwhile consideration for any operator looking to maximize their equipment’s potential.

Where to Find Quality Replacement Parts

When maintaining agricultural equipment, sourcing high-quality components is crucial for optimal performance and longevity. Understanding the best avenues for acquiring these essentials can significantly enhance the efficiency of your machinery.

Online Retailers

Numerous online platforms specialize in providing a wide selection of components. It’s advisable to explore websites dedicated to agricultural supplies for a comprehensive inventory.

Local Dealers

Visiting local dealerships can also yield beneficial results. Establishing relationships with nearby suppliers often leads to personalized assistance and access to expert advice.

| Source | Advantages |

|---|---|

| Online Retailers | Convenience, variety, competitive pricing |

| Local Dealers | Personalized service, expert knowledge, immediate availability |

Comparing Models: John Deere 660 vs. Others

When evaluating various agricultural implements, it’s essential to analyze the distinctions among different models. Each piece of equipment has unique features, specifications, and efficiencies that cater to specific farming needs. This section aims to explore how one model stacks up against its competitors, focusing on functionality, durability, and user experience.

Performance is a critical aspect when comparing machinery. The discussed model is known for its efficient operation, enabling users to manage large fields effectively. Competitors may offer similar capabilities but often differ in power requirements and overall output. Understanding these differences can significantly influence productivity.

Another vital factor is maintenance. Some models require more frequent upkeep, which can lead to increased operational costs over time. In contrast, the discussed implement boasts a reputation for lower maintenance demands, making it a preferred choice for many farmers who prioritize ease of use.

Additionally, accessories and compatibility play a significant role in the decision-making process. While the featured implement may come with various compatible attachments, others in the market may have limited options. This can affect versatility on the farm, as the ability to customize equipment is often crucial for addressing diverse tasks.

In conclusion, while the highlighted model presents numerous advantages, it is essential to consider the broader landscape of available machinery. Each option has its merits, and careful evaluation can lead to the best choice for specific agricultural needs.